High-speed numerical-control circular sawing machine

A technology of circular sawing machine and sawing machine, which is applied in the direction of sawing machine, cutting tool of sawing machine, metal sawing equipment, etc., which can solve the service life of the saw blade, the surface quality of the sawing surface and the damage of the equipment itself, and reduce the feed and cutting speed of the saw blade , The saw edge is not straight, etc., to improve the running accuracy and service life, eliminate the beating of the saw blade, and achieve the effect of uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

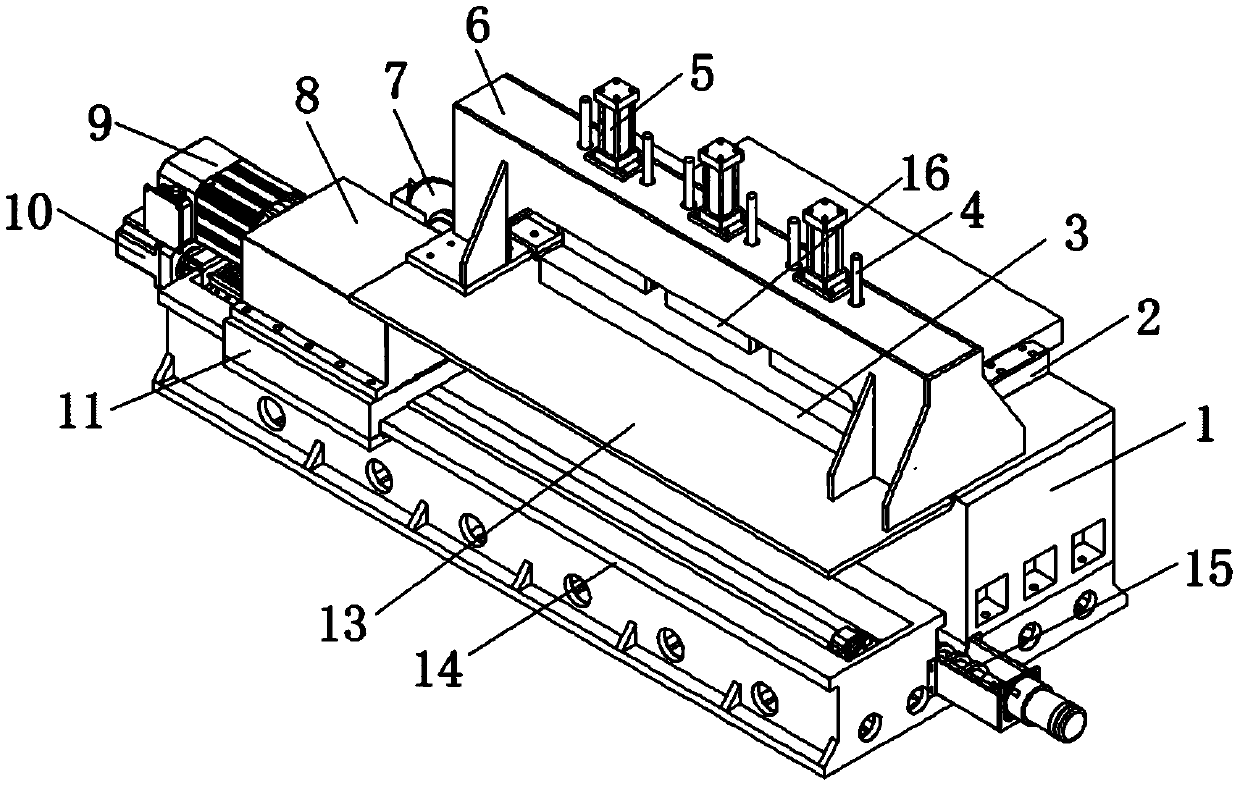

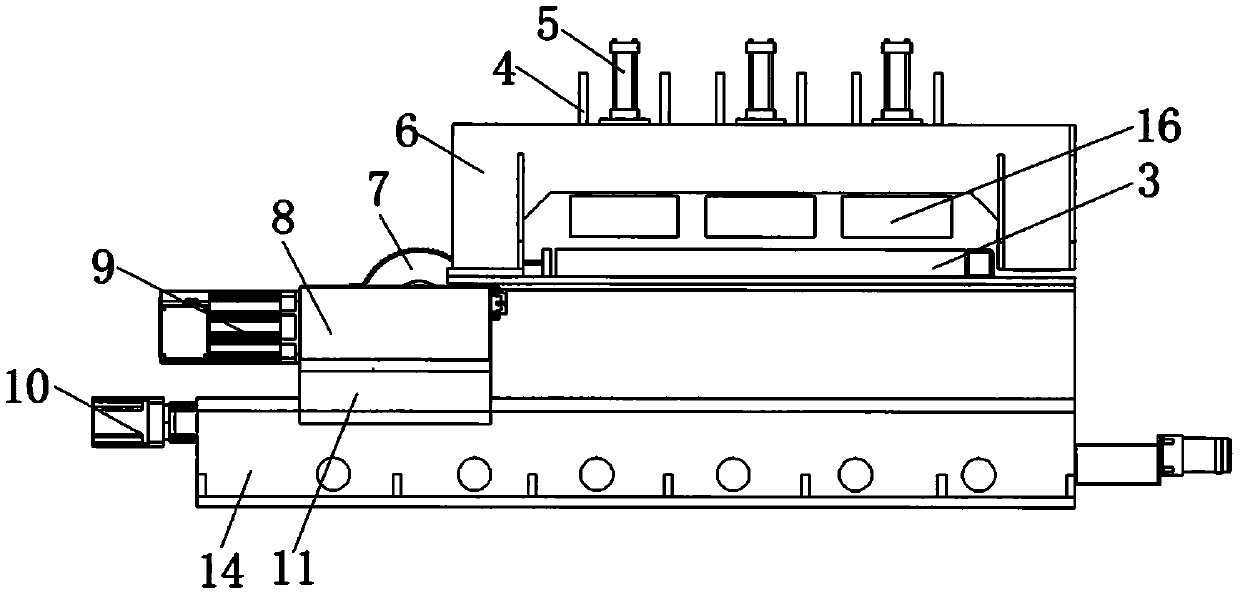

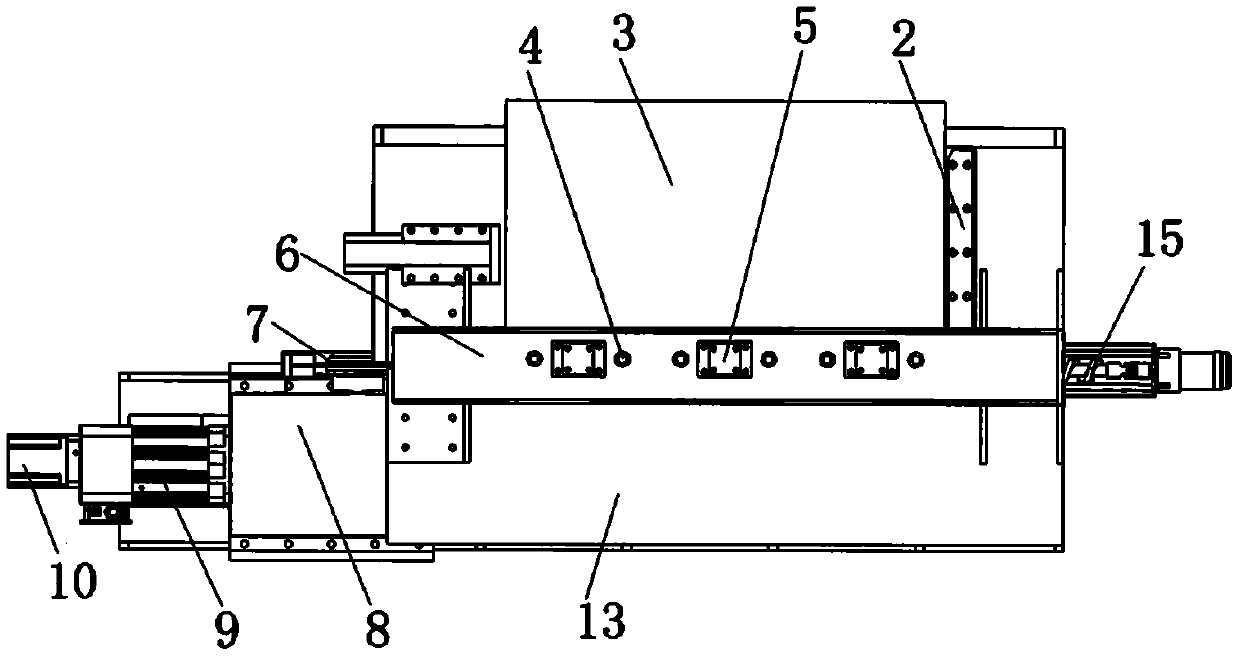

[0028] Embodiment 1: refer to Figure 1-4 , a high-speed numerical control circular sawing machine, comprising a sawing machine frame 1, a sawing machine holder 14, a workpiece clamping mechanism and a spindle feed mechanism, the workpiece clamping mechanism is arranged on the top of the sawing machine frame 1, and the spindle feed mechanism is arranged on The top of the sawing machine holder 14;

[0029] The workpiece clamping mechanism includes an oil cylinder 5, a pressure plate 16, a discharge plate 3 and a positioning reference block 2, and the workpiece clamping mechanism is installed on the steel gantry 6, and the steel gantry 6 is bolted to the sawing machine frame 1 , and the bottom of the steel gantry 6 is also bolted with a workbench plate 13;

[0030] The steel gantry 6 is provided with three oil cylinders 5 arranged in a row, and the bottom of the oil cylinders 5 is connected on the pressure plate 16, the bottom side of the pressure plate 16 is correspondingly pr...

Embodiment 2

[0037] Embodiment 2: refer to Figure 1-4 , a high-speed numerical control circular sawing machine, comprising a sawing machine frame 1, a sawing machine holder 14, a workpiece clamping mechanism and a spindle feed mechanism, the workpiece clamping mechanism is arranged on the top of the sawing machine frame 1, and the spindle feed mechanism is arranged on The top of the sawing machine holder 14;

[0038] The workpiece clamping mechanism includes an oil cylinder 5, a pressure plate 16, a discharge plate 3 and a positioning reference block 2, and the workpiece clamping mechanism is installed on the steel gantry 6, and the steel gantry 6 is bolted to the sawing machine frame 1 , and the bottom of the steel gantry 6 is also bolted with a workbench plate 13;

[0039] The spindle feed mechanism includes a reducer 9, a gearbox 8, a saw blade 7, a saw head sliding seat 11 and an output spindle, and the saw head sliding seat 11 is slidably fitted on the sawing machine fixing seat 14;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com