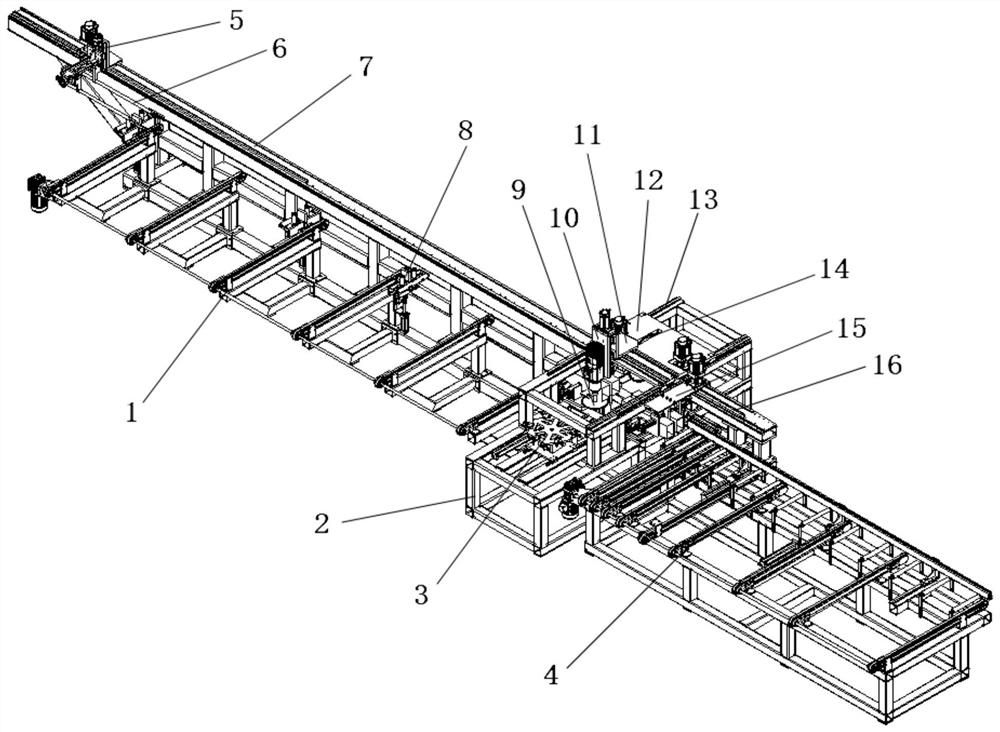

Sawing and milling system and method

A milling and end milling technology, which is applied in the field of sawing and milling processing systems, can solve problems such as complex control programs, troublesome tool changes, and low cutting and milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0043]BRIEF DESCRIPTION OF THE INVENTION A saw-making method is provided on the basis of the first embodiment, including the following steps:

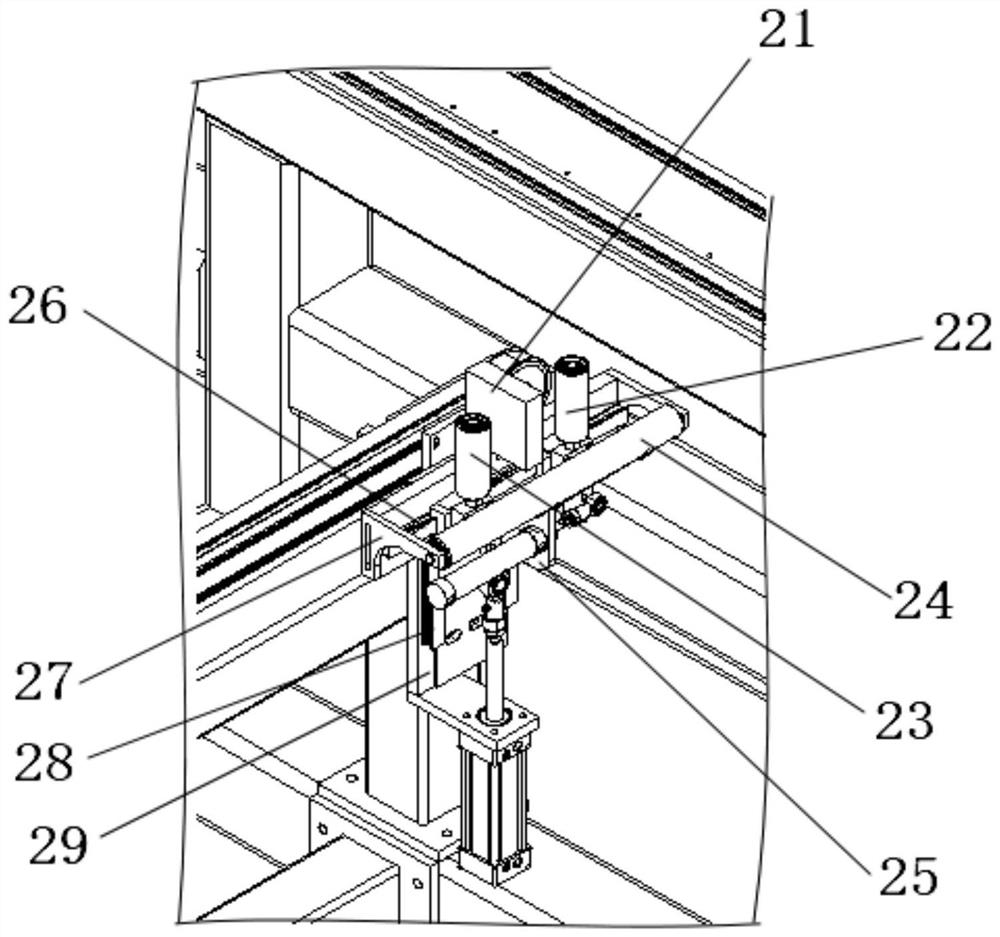

[0044]A1: The profile is delivered to the clamping guide 8 position by the belt conveying mechanism, and the two profiles are located on both sides of the intermediate reference plate 21;

[0045]A2: The plurality of support rollers 24 simultaneously rises, so that the two profiles are supported on the plurality of support rollers 24, and the left clamping roller 22 and the right side clamping roller 23 pushes two profiles to the intermediate reference plate 21. The profile is clamped at the intermediate reference plate 21, and the plurality of support rollers 24 rises after the upper portion of the horizontal base, the two sides of the intermediate reference plate 21 are vertical base, and the support and intermediate reference panels 21 of the support roller 24. Top relying on two profiles;

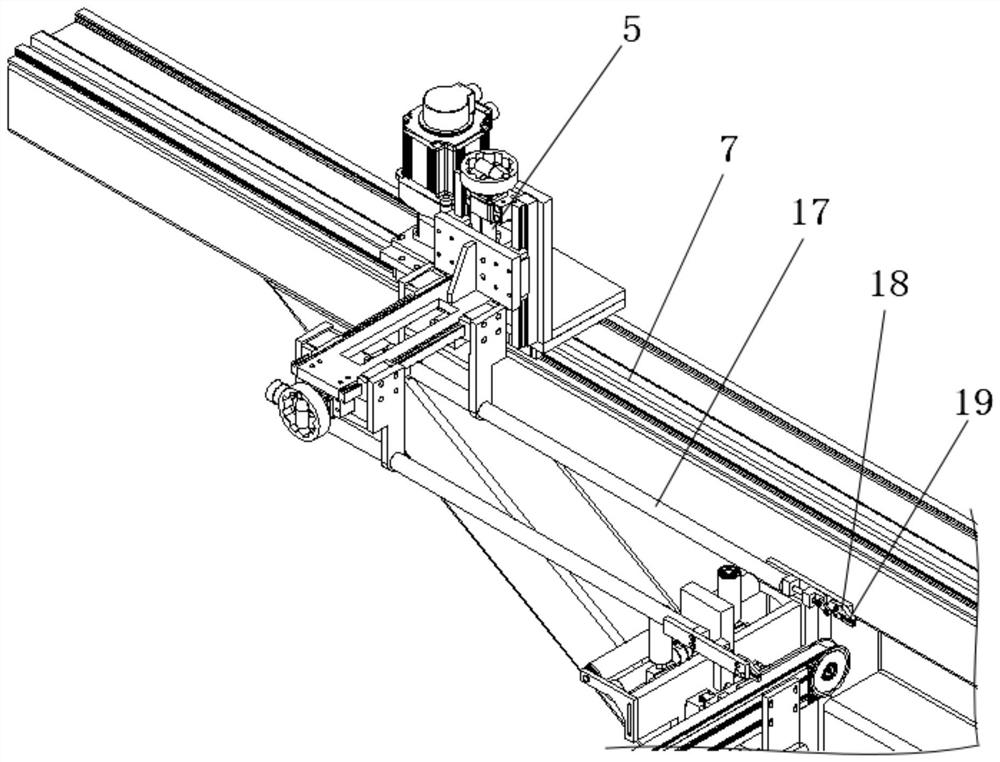

[0046]A3: The two pusher stem 17 is positioned by the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com