Semiconductor package and method for manufacturing the same

a technology of semiconductors and packaging, applied in the field of semiconductor packaging, can solve the problems of thin-type substrate warping and serious warping of bga packages having thin-type substrates during subsequent thermal processes, and achieve the effect of decreasing the processing step of semiconductor packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

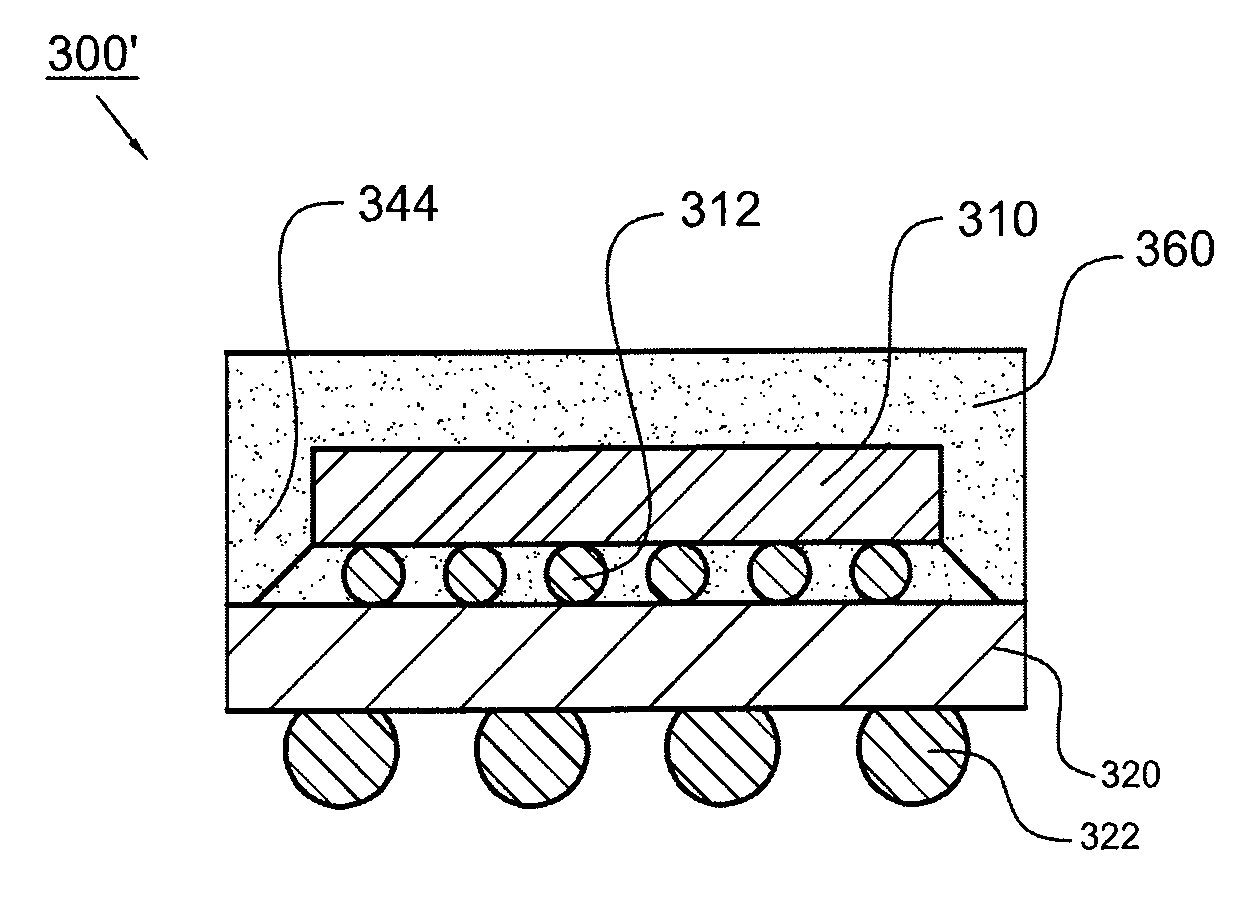

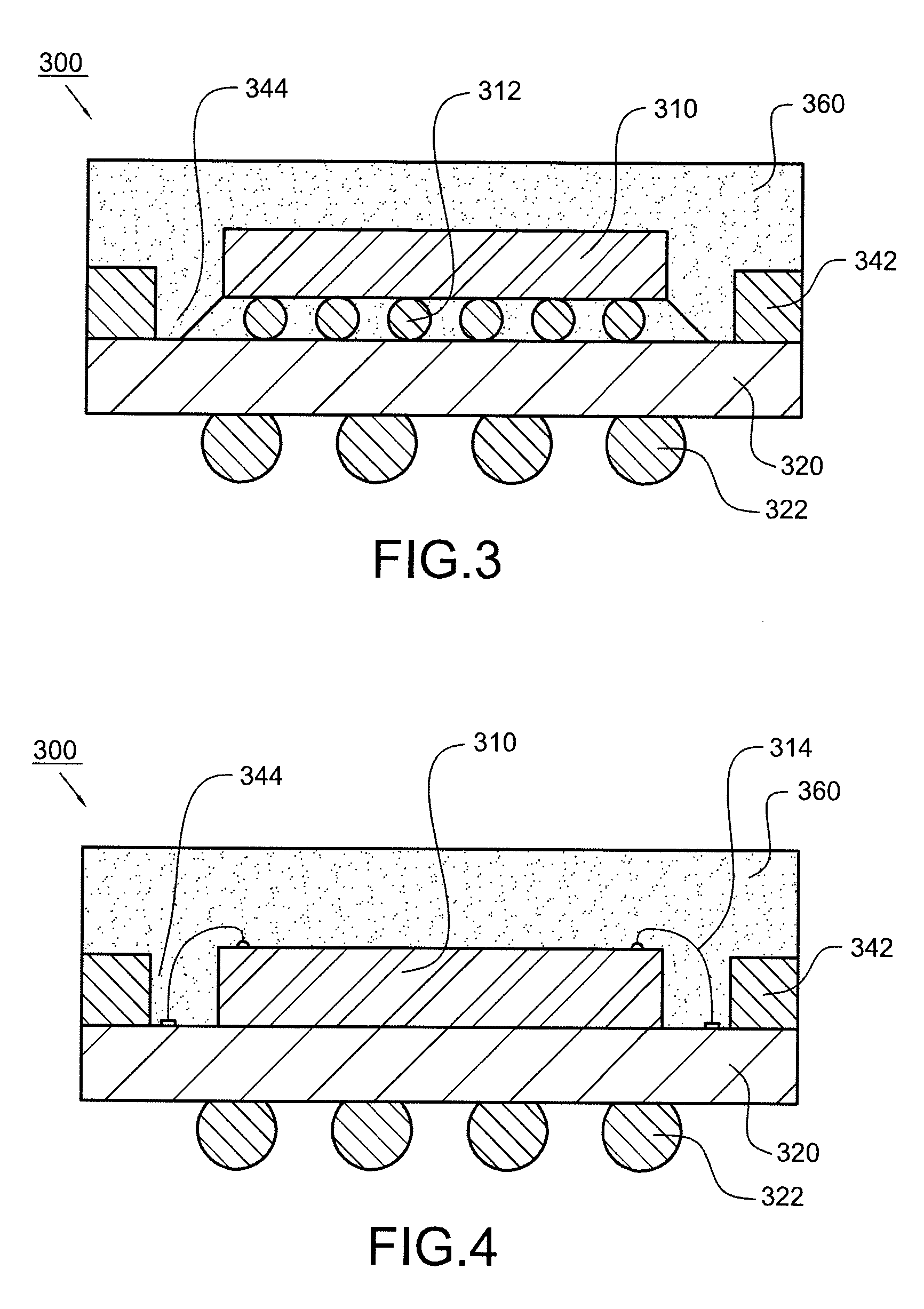

[0024]Referring to FIG. 3, it depicts a semiconductor package 100 according to an embodiment of the present invention. The semiconductor package 300 includes a carrier (e.g. thin type circuit board or substrate 320), a chip 310, a stiffener 342 and an encapsulant 360. The chip 310 is disposed on the substrate 320. The encapsulant is adapted to seal the chip 310 and cover the stiffener 342. A plurality of solder balls 322 are disposed on the substrate 320 for electrically connecting to an external circuit board (not shown) or an electronic device (not shown). In this embodiment, a plurality of bumps 312 are disposed between the chip 310 and the substrate 320 for electrically connecting the chip 310 to the substrate 320. Referring to FIG. 4, in another embodiment, a plurality of bonding wires 314 are adapted for electrically connecting the chip 310 to the substrate 320.

[0025]The stiffener 342 directly contacts the substrate 320, and is mounted on the substrate 320 by an attaching forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com