A sawing host of a pipe multi-head sawing machine

A sawing machine and sawing technology, applied in metal sawing equipment, sawing machine devices, metal processing equipment and other directions, can solve the problems of low sawing efficiency, high equipment investment cost and high cost, so as to improve the sawing efficiency and shorten the The effect of sawing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments.

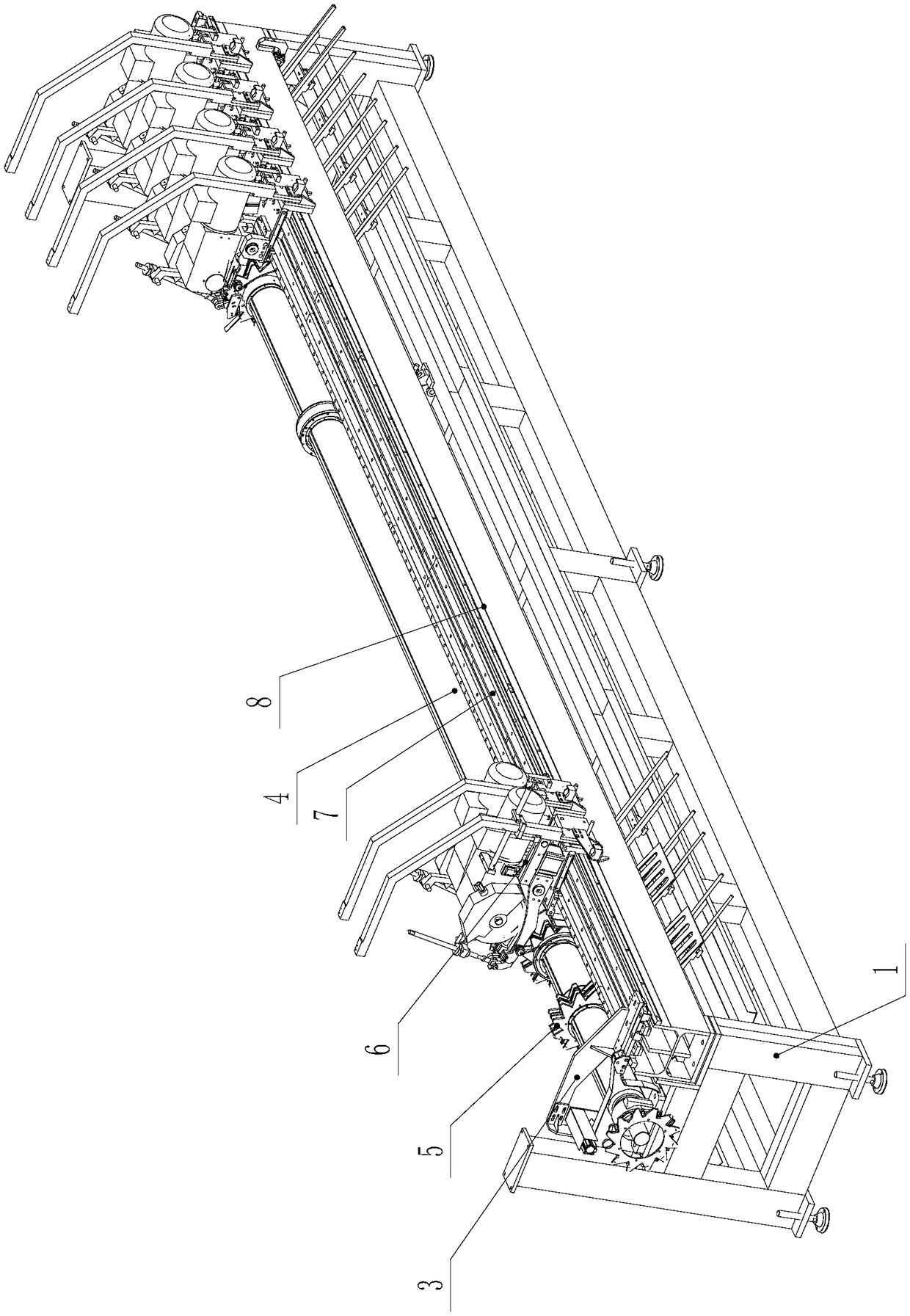

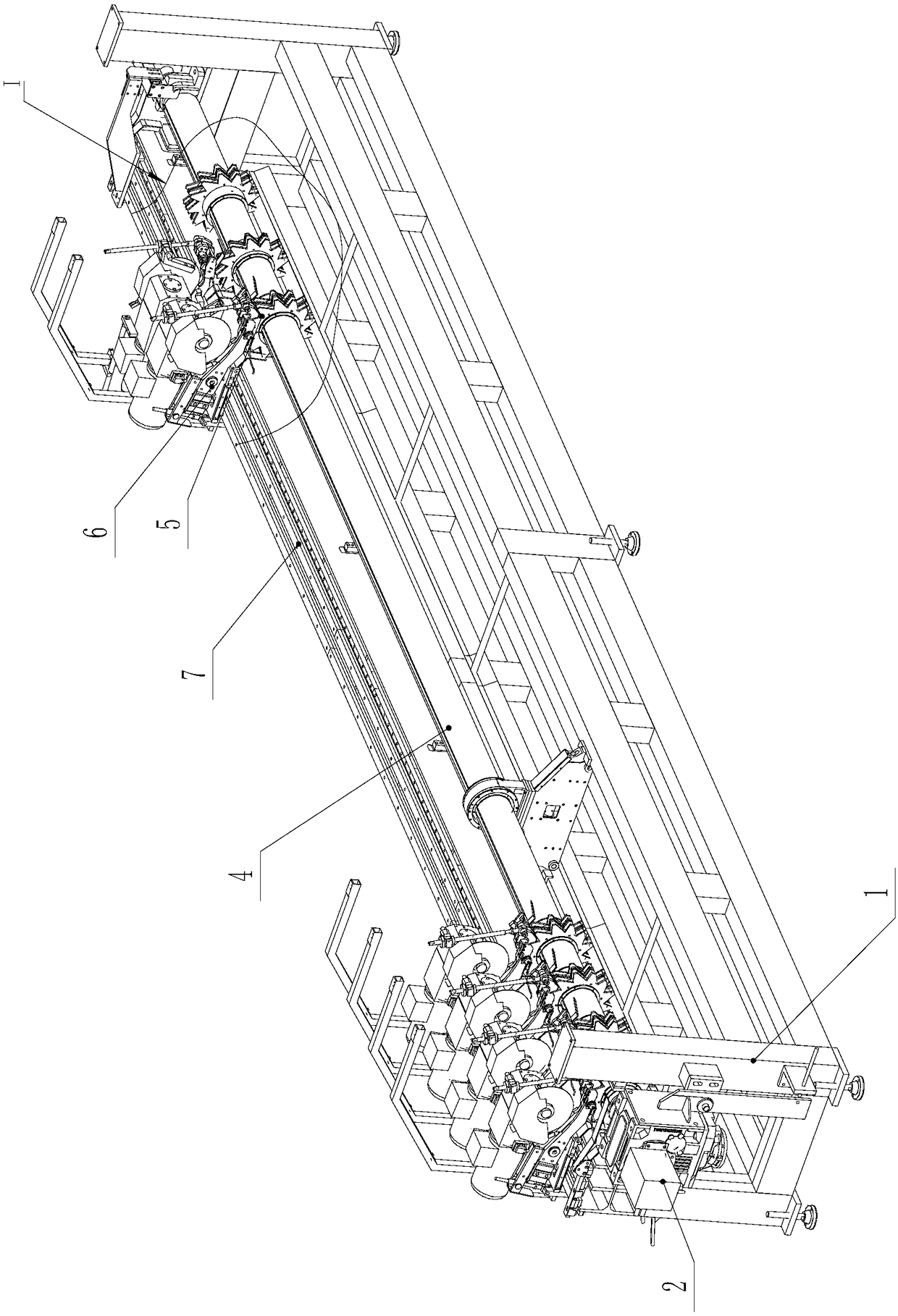

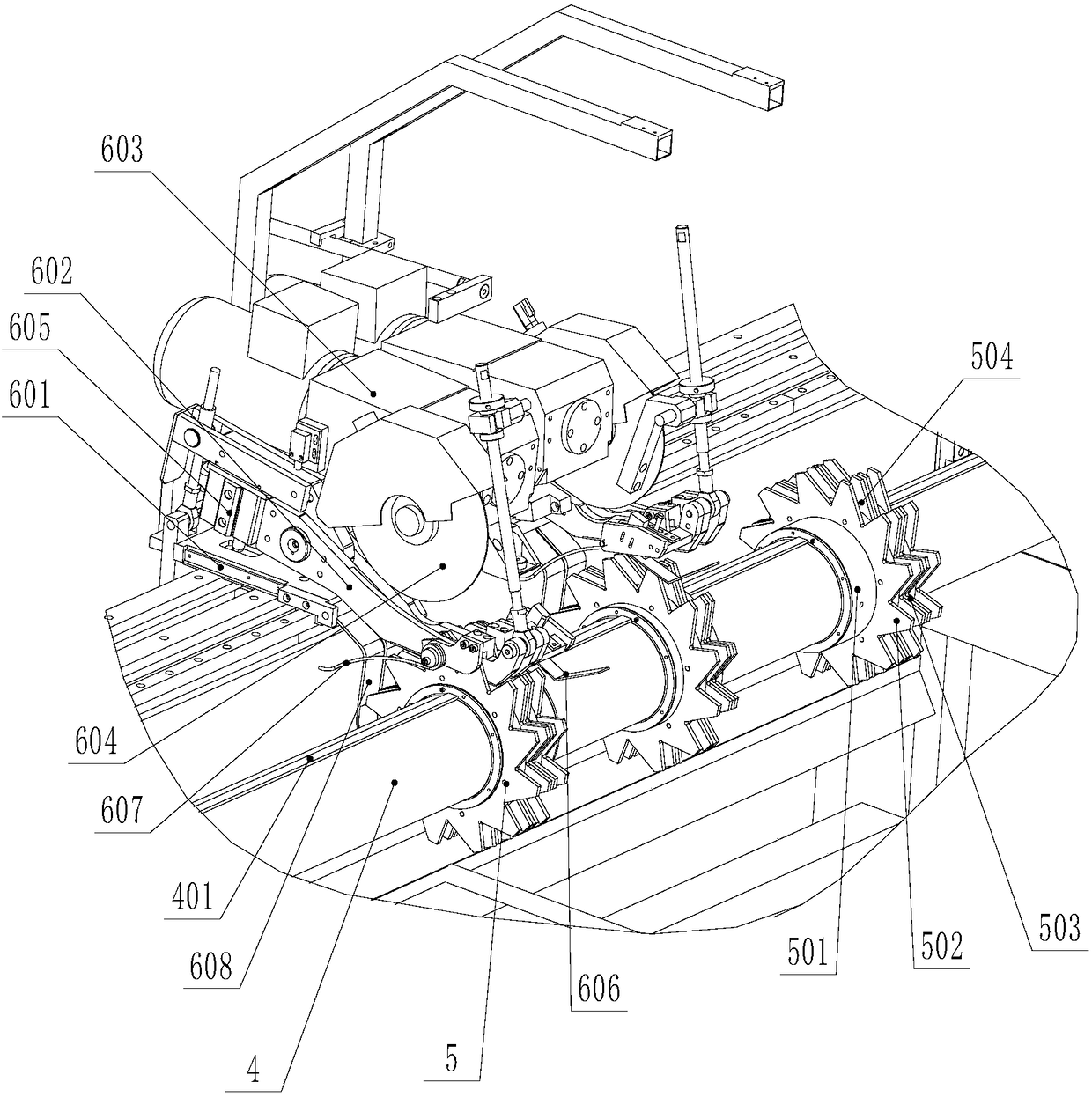

[0030] Such as Figure 1 to Figure 5 As shown, a sawing host of a pipe multi-head sawing machine includes a frame 1 on which a plurality of sawing heads 6 are installed, and the sawing head 6 includes a base installed on the frame 1 601. A bracket 602 is installed on the base 601, a power box 603 is installed on the bracket 602, and the saw blade 604 is installed on the output shaft of the power box 603. The position of the shifting gear set 5 on the feed spindle 4 corresponds to the position of the shifting gear set 5, which is provided with a feed gap 504 that is convenient for the saw blade 604 to enter, and the depth of the feed gap 504 is greater than the pipe diameter of the pipe; The length of the saw blade 604 extending into the knife feed gap 504 is greater than the pipe diameter of the pipe, and the base 601 is provided with a pressing device for pressing the pipe dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com