Soaking compression restructuring artificial board and method for producing same

A manufacturing method and technology of wood-based panels, which are applied in the direction of impregnating wood, manufacturing tools, and wood impregnation, etc., can solve the problems of application limitations, low degree of resin polycondensation, and difficulty in ensuring that the formaldehyde emission of the board is at a safe level, and achieve raw material utilization. High, the effect of abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

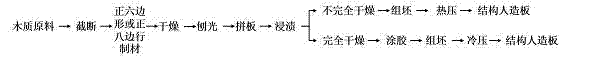

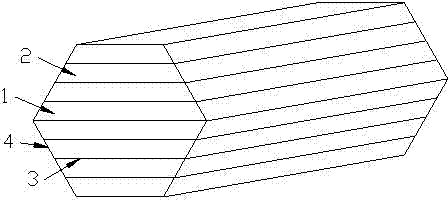

[0052] Take small-diameter fast-growing Chinese fir with a diameter of 9-20 cm, cut it to the corresponding length according to the bending state of the wood, and use the regular hexagonal sawing method to saw it into a board with a thickness of 10.5 cm (the yield can reach more than 65%), see Figure 12 , image 3 , dried to a moisture content of about 12%, planed to a thickness of 10cm, take the same cross-sectional size and shape of the board longitudinally finger-jointed into a 3m-long board (the length of the finger-joint can be determined according to the needs of the user, the same below), and the length of the tenon is 20mm , the finger joint adhesive is resorcinol formaldehyde resin, and the glue amount is 150g / m 2 ;The same size and shape of the end face have beveled boards to be combined in width, which is basically a combination of string-sawn boards and string-sawn boards, and quarter-sawn boards and quarter-sawn boards. The width of the boards is 1m (the width o...

Embodiment 2

[0060] Take the fast-growing poplar wood with a diameter of 20cm or more, cut it to the corresponding length according to the bending state of the wood, and use the regular octagonal sawing method to saw it into a board with a thickness of 6.5cm (the yield rate can reach more than 70%), see Figure 4 , dried to a moisture content of about 8%, planed to a thickness of 6cm, take the same cross-sectional size and shape of the board longitudinally finger-joined into a 3m-long board, the length of the finger tenon is 20mm, and the finger-joint adhesive is phenol-modified resorcinol formaldehyde Resin, glue amount is 150g / m 2 ; The boards with beveled edges on the end face and the plates without beveled edges are assembled in width respectively, the width of the panels is 1m, the adhesive is phenol-modified resorcinol formaldehyde resin, and the amount of glue applied is 150g / m 2 , the length and width are assembled in the jigsaw machine, the cold pressing time is 60 minutes, and i...

Embodiment 3

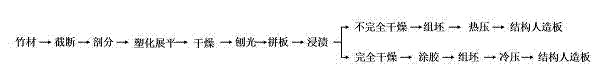

[0069] Take moso bamboo with a diameter of 12-18cm, cut it to the corresponding length according to the diameter change, divide it into 5.5cm wide, plasticize, flatten, dry to about 10% moisture content, planed to set the width to 5cm, and set the thickness to 1cm sheet. Finger-join the plates of different lengths longitudinally into 3m-long plates, the length of the finger tenon is 20mm, the finger joint adhesive is resorcinol formaldehyde resin, and the glue amount is 160g / m 2 ;The width of the horizontal panel is 1.2m, the adhesive is resorcinol formaldehyde resin, and the amount of glue is 150g / m 2 , the length and width are assembled in the jigsaw machine, the cold pressing time is 60 minutes, and it can be used in the next process after 24 hours. spelling method see Figure 8 (There are vertical teeth 17 on the end face of the plate) or Figure 9 (There are horizontal teeth 18 on the end face of the plate), see Figure 7 (Straight edge fight).

[0070] Put the forma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com