Patents

Literature

45results about How to "Guaranteed to move forward" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

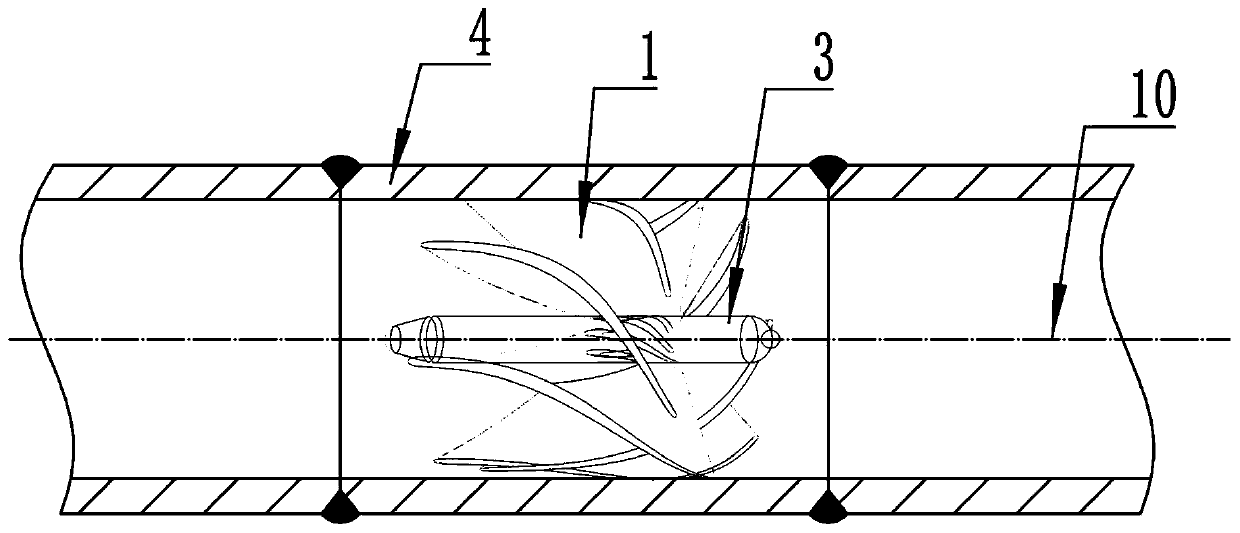

Bionic detection and rescue system

InactiveCN101543666AGuaranteed to move forwardGuaranteed to go backwardsBreathing protectionElectrical steeringControl powerEngineering

The present invention discloses a bionic detection and rescue system, which comprises a detection and rescue head, a turning power unit, a control power unit, an transmitting / receiving power unit, and several segments of moving units connected serially by springs; wherein, the front-end of the turning power unit is connected with the tail end of the detection and rescue head, the tail end of the turning power unit is connected with the front-end of the control power unit, and the tail end of the control power unit is connected with the front-end of the first moving unit, so that a main body is formed; the transmitting / receiving power unit is mounted on the tail end of the main body. The present invention has high accessibility, can move flexibly, and is easy to operate.

Owner:王彦明

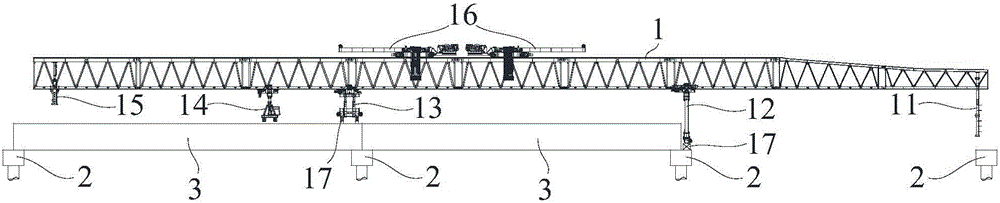

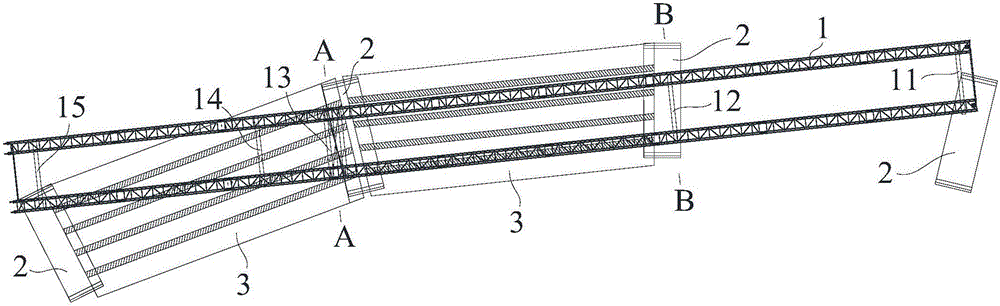

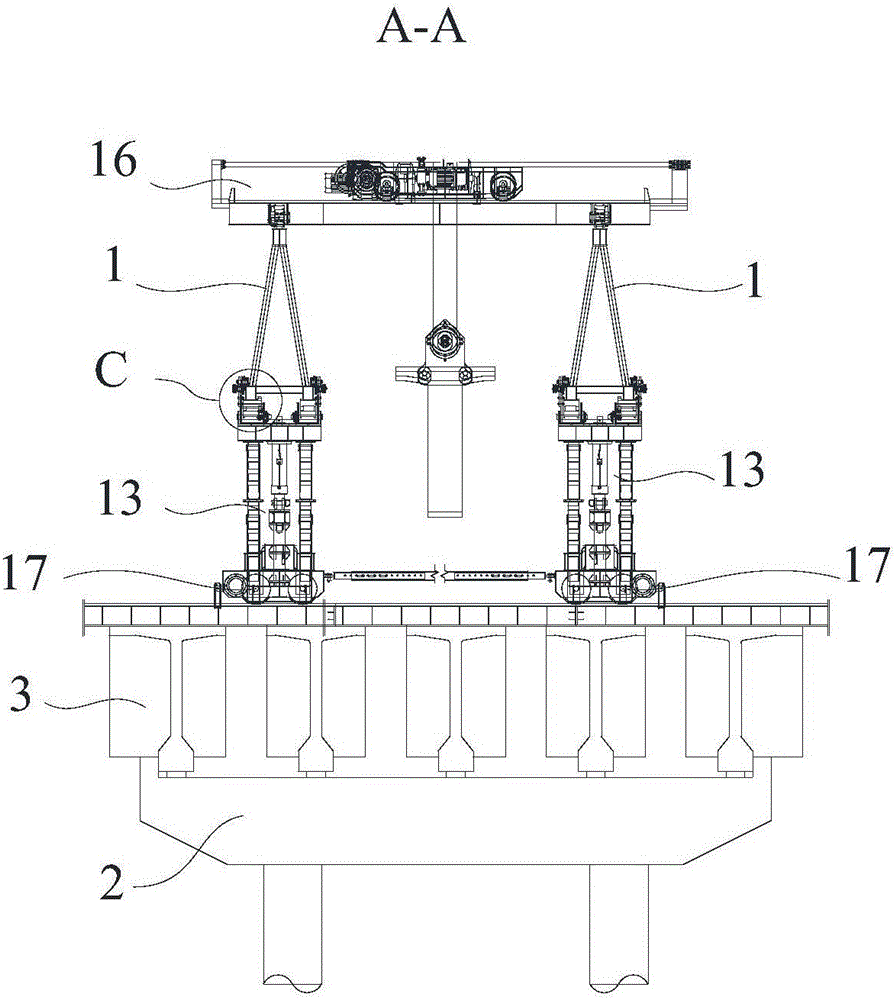

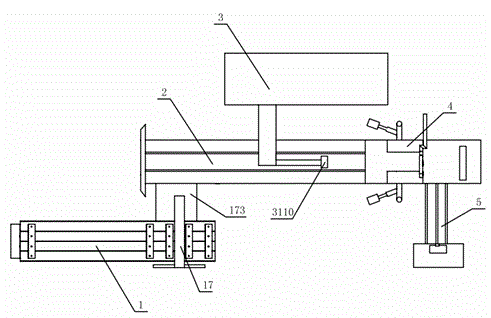

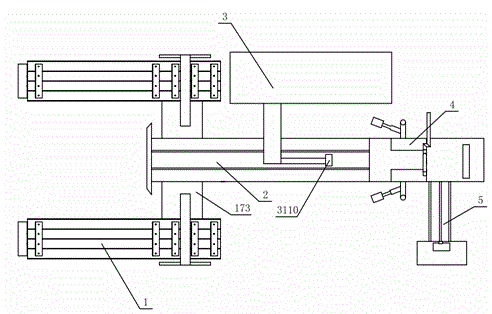

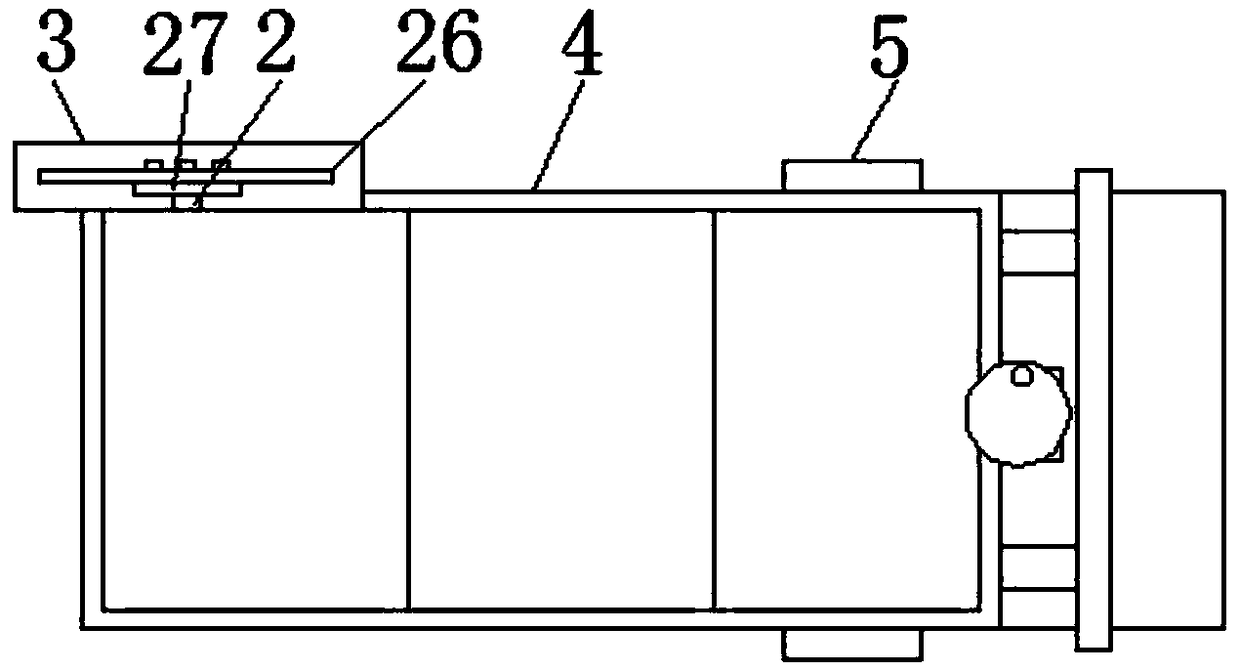

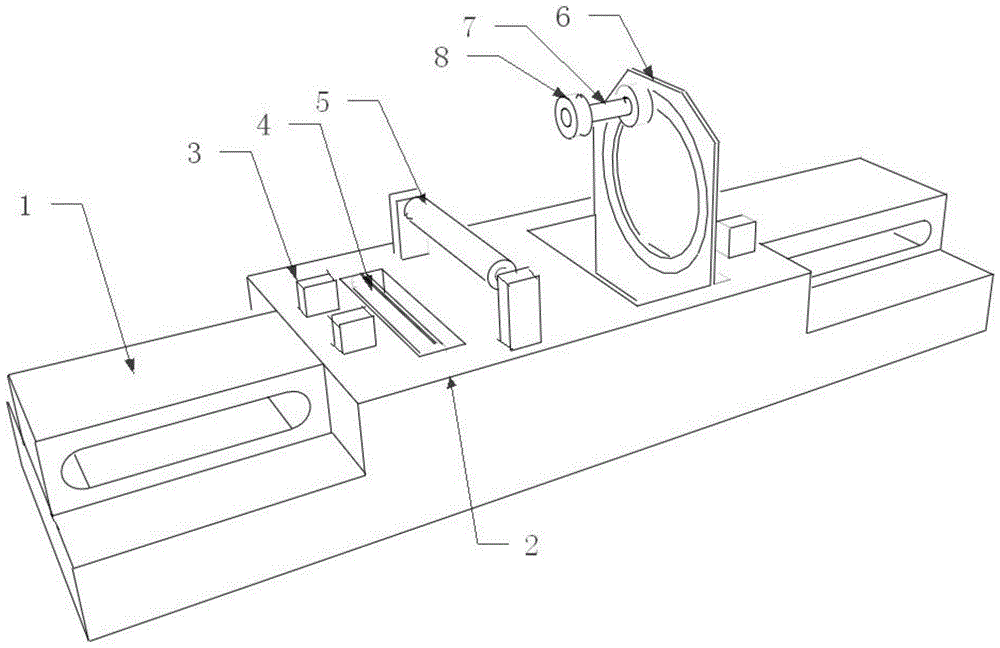

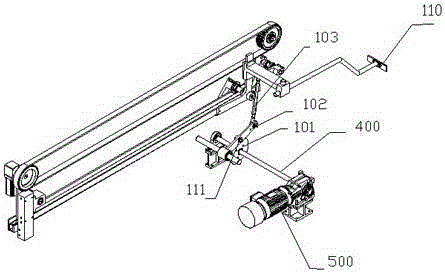

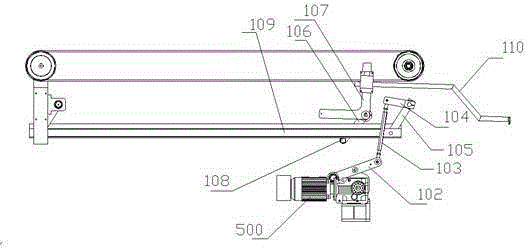

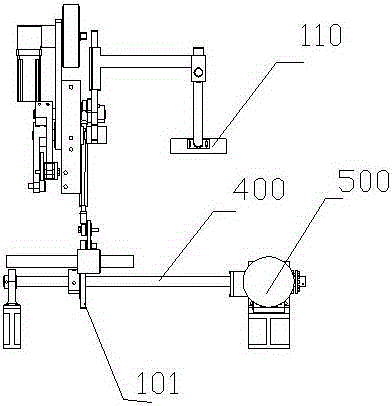

Adjustable small-radius bridge girder erection machine and bridge girder erection method

ActiveCN105839547ASimple structureGuaranteed to move forwardBridge erection/assemblyStructural engineeringBox girder

The invention discloses an adjustable small-radius bridge girder erection machine, which comprises girders and supporting legs, wherein transverse moving mechanisms are arranged at the bottom parts of the supporting legs, and roller wheels are arranged at the top parts of the supporting legs; the transverse moving mechanisms are used for transversally moving on piers or box girders in a contact way, and the two ends of the roller wheels are respectively provided with limiting plates; the distance between the two limiting plates is adjustable, and the girders are slidably connected with the roller wheels and arranged between the two limiting plates; lifting mechanisms for adjusting height are arranged on the supporting legs. By using the bridge girder erection machine, the roller wheels with adjustable limiting plate distances are arranged, and the gaps between the limiting plates and the girders are adjusted to be small, so that the girders normally move forward relative to the supporting legs when the girder erection work is conducted by the bridge girder erection machine; when steering is needed, the gaps between the limiting plates and the girders are adjusted to be maximum, and the transverse moving mechanism of one supporting leg is driven to transversally move, so that the girder makes a circular motion by taking the other supporting leg as a fulcrum to achieve that the girder attitude of the bridge girder erection machine is adjusted to be in parallel with the tangent line of the erected bridge curve and achieve the erection purpose of a small-radius horizontal curve bridge. The bridge girder erection machine has the advantages of simple structure, cost saving and shortening of construction schedule of the small-radius horizontal curve bridge.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

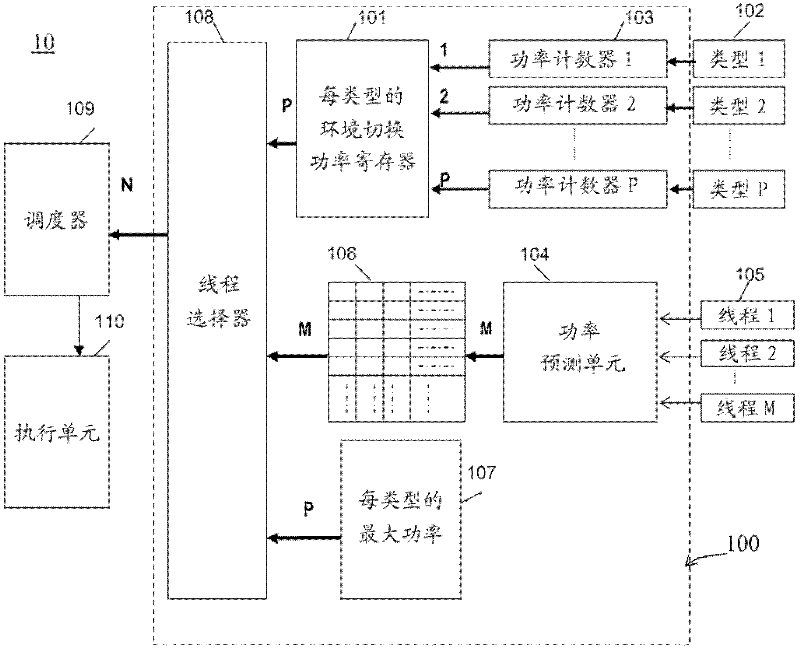

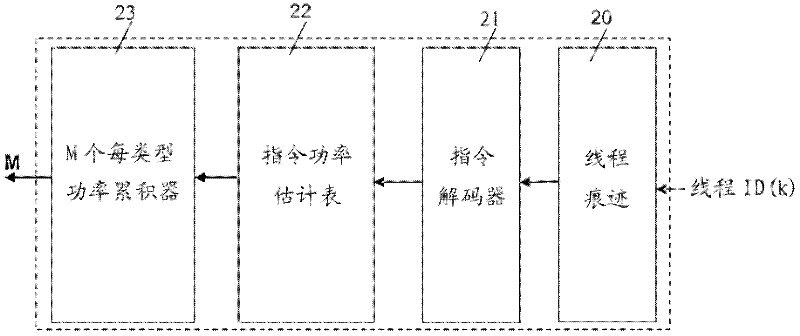

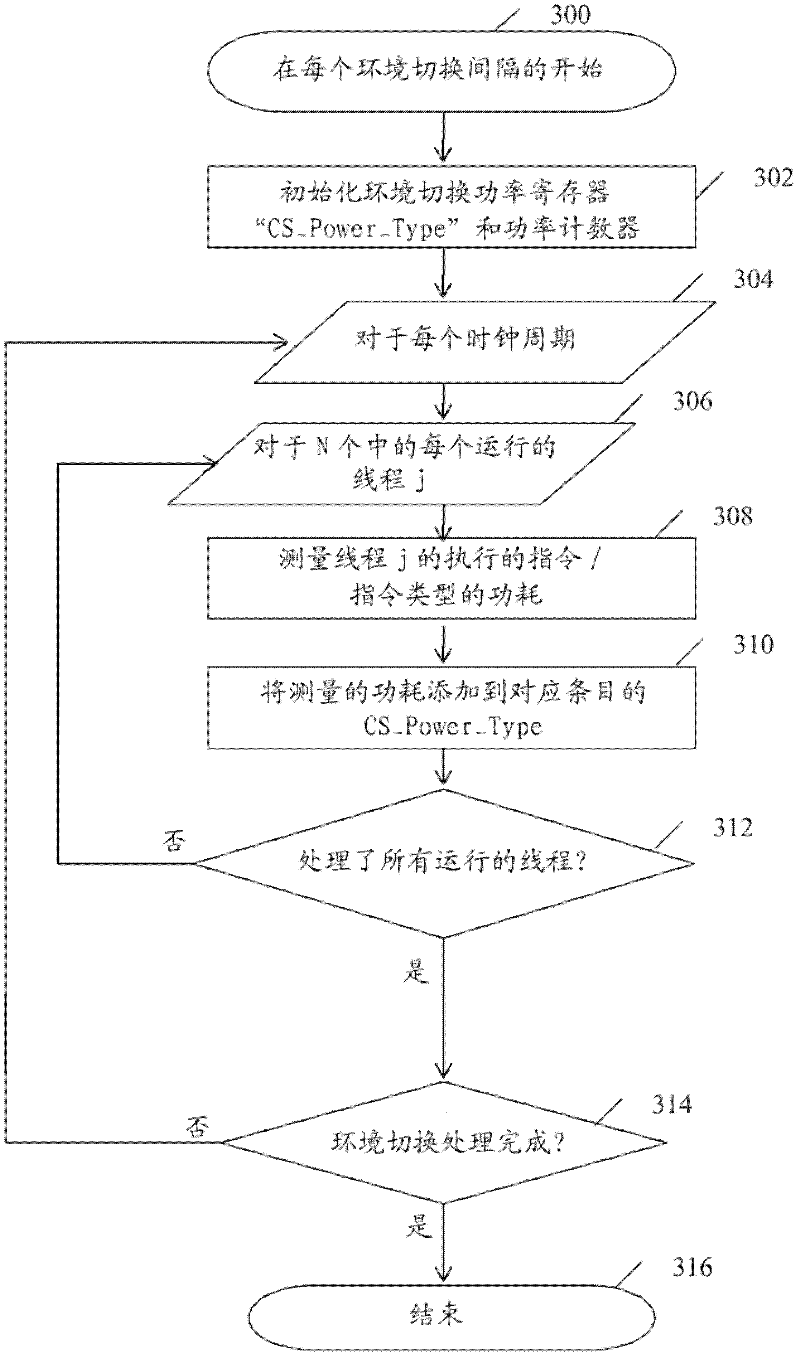

Method and system for scheduling threads in a processor

ActiveCN102567117AGuaranteed to move forwardOvercome deficienciesEnergy efficient ICTResource allocationThread schedulingOperating system

The invention provides a method for guiding OS thread scheduling in multi-core and / or multi-threaded microprocessors. The method includes: determining, for each thread among the active threads, the power consumed by each instruction type associated with an instruction executed by the thread during the last context switch interval; determining for each thread among the active threads, the power consumption expected for each instruction type associated with an instruction scheduled by said thread during the next context switch interval; generating at least one combination of N threads among the active threads (M), and for each generated combination determining if the combination of N threads satisfies a main condition related to the power consumption per instruction type expected for each thread of the thread combination during the next context switch interval and to the thread power consumption per instruction type determined for each thread of the thread combination during said given context switch interval; and selecting a combination of N threads to be scheduled from combinations that satisfy a main condition.

Owner:INT BUSINESS MASCH CORP

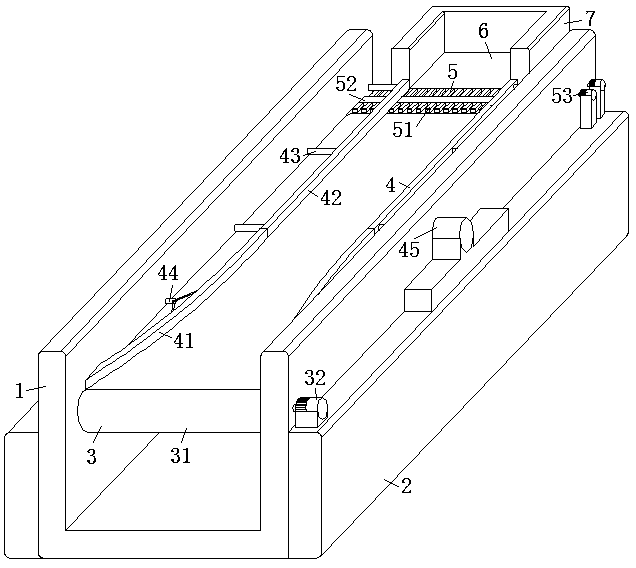

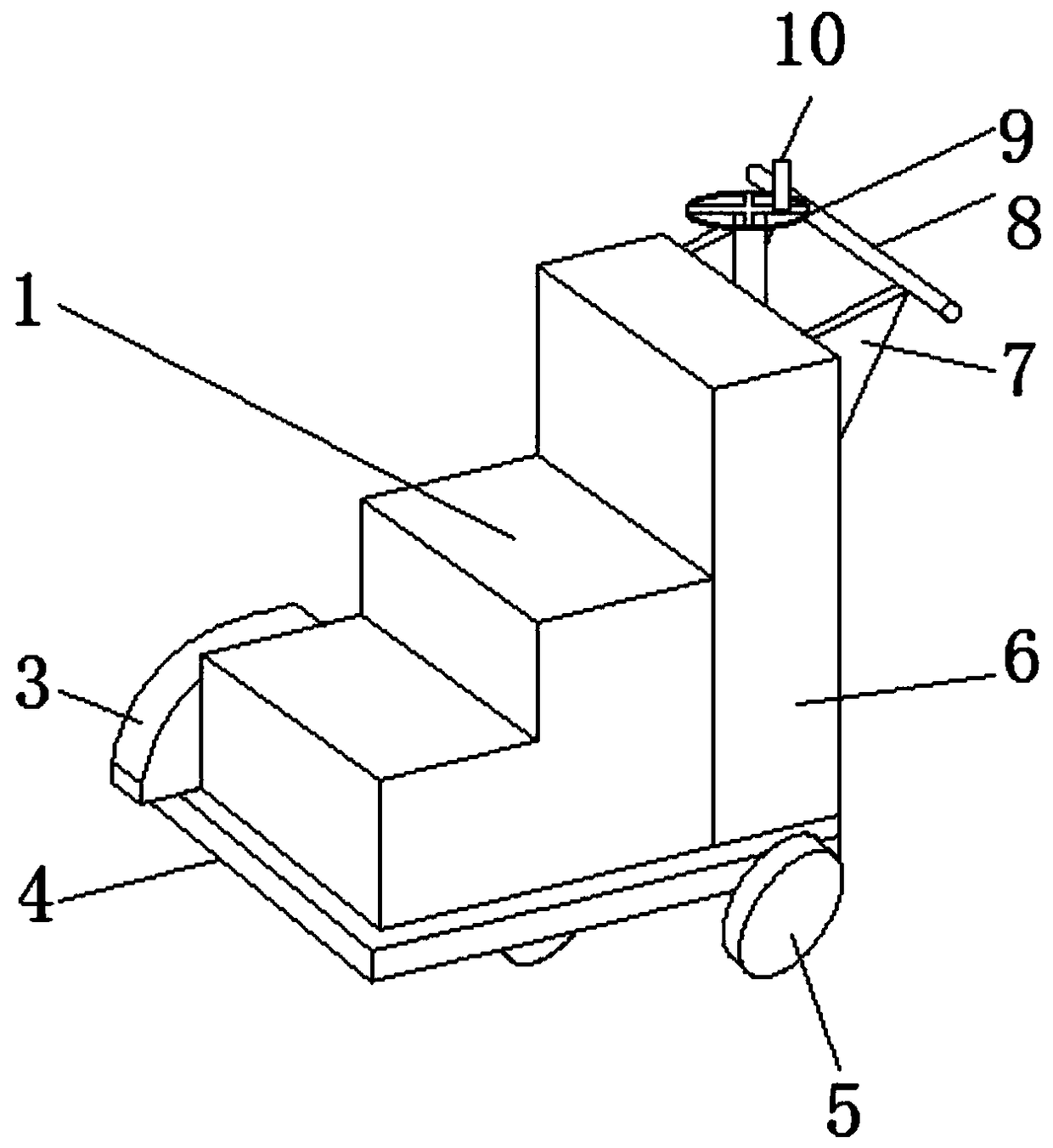

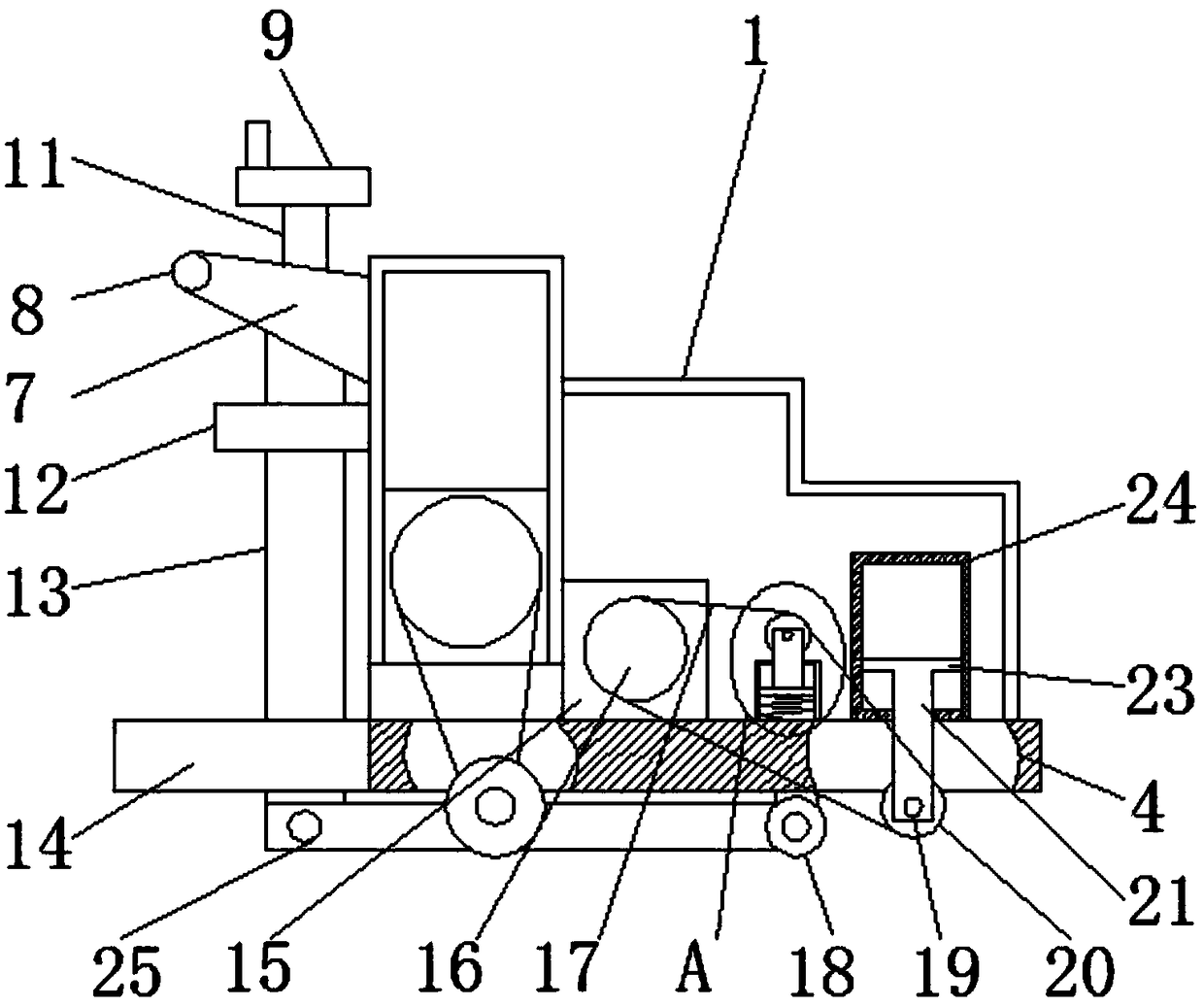

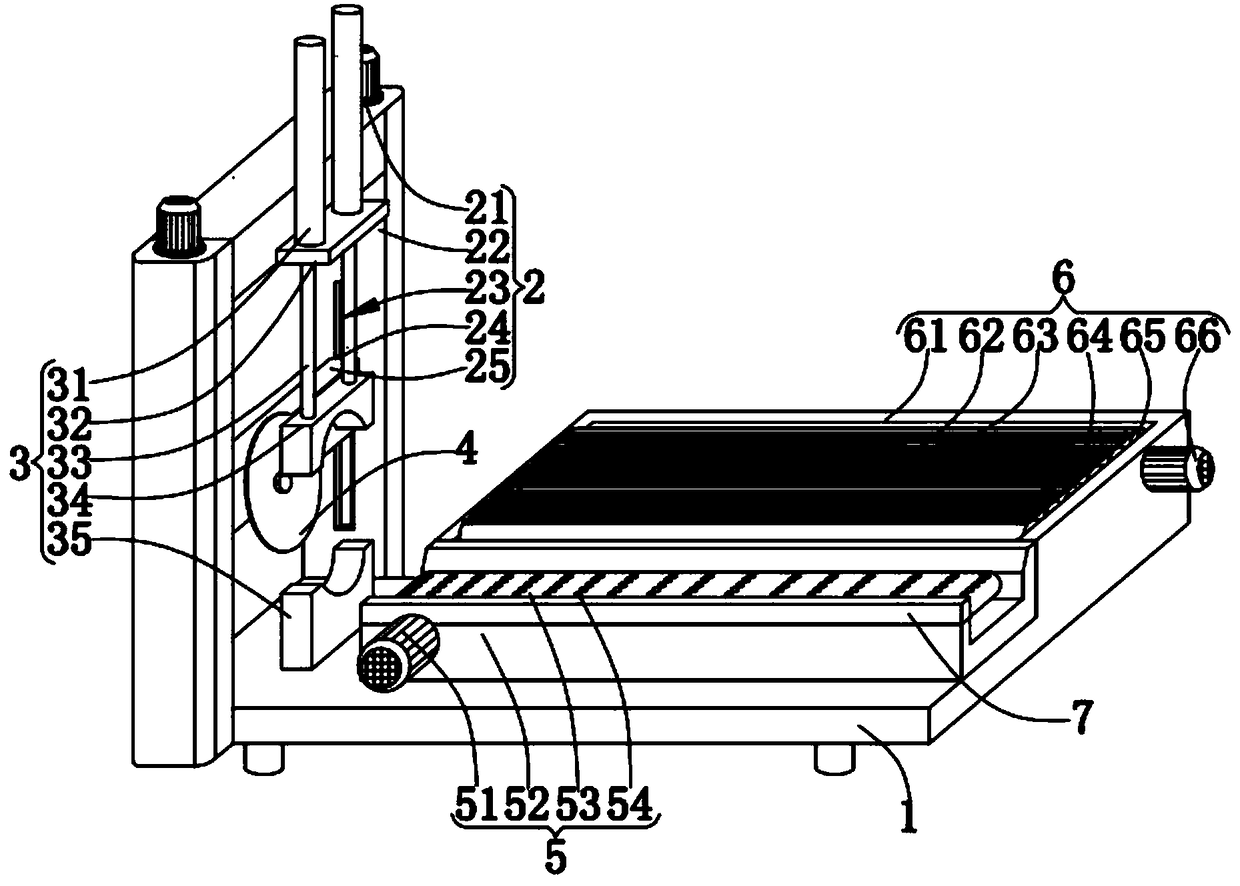

Plate cutting stacking robot

InactiveCN110844611AEasy to palletizeEasy to navigateStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention relates to the field of stacking robots, in particular to a plate cutting stacking robot. The plate cutting stacking robot comprises a fixed seat, a supporting seat, a conveying mechanism, a guiding mechanism, a cleaning mechanism, a stacking mechanism, a small trolley and a clamping mechanism, wherein the guiding mechanism is mounted on the fixed seat, and plates are guided throughthe guiding mechanism, so that the plates can conveniently parallel to the side wall of the fixed seat, guide of the plates is facilitated, and the guiding mechanism can be adjusted to facilitate transmission and guide of the plates with different widths; the cleaning mechanism is installed on the fixed base, and debris on the bottom end of a conveying belt and the plates is cleaned through the cleaning mechanism, so that the cleanliness of the conveying belt is facilitated, the bottom surfaces of the plates conveniently make contact with the conveying belt, and the stability of the plates inthe conveying process is kept; the clamping mechanism is installed on the small trolley, the clamping mechanism is clamped to the fixed seat, the small trolley and the fixed seat are fixed through theclamping mechanism, and the position of the small trolley is shifted due to the impulsive force of the plates when the plates enter the small trolley.

Owner:江西清研扬天科技有限公司

Packaging machine

ActiveCN104129527ASolve highOvercome inspectionConveyorsPackaging machinesPotential riskPackaging machine

The invention discloses a packaging machine. The packaging machine comprises a material arranging device, a packet pushing conveyer belt, a packet pushing device, a bag sucking and opening device and a bag conveying device. The material arranging device is connected with the packet pushing conveyer belt, the packet pushing conveyer belt is connected with the packet pushing device, and the packet pushing conveyer belt is connected with the bag sucking and opening device. The bag sucking and opening device is connected with the bag conveying device. The packet pushing device is arranged on one side of the packet pushing conveyer belt. By means of the packaging machine, the technical problems that the packet pushing device is too high, checking and maintaining are inconvenient, and potential risks exist in the prior art are solved, a machine frame is arranged on one side of the conveying belt, so that checking and maintaining are convenient, and meanwhile potential risks are lowered.

Owner:上海松川峰冠包装自动化有限公司

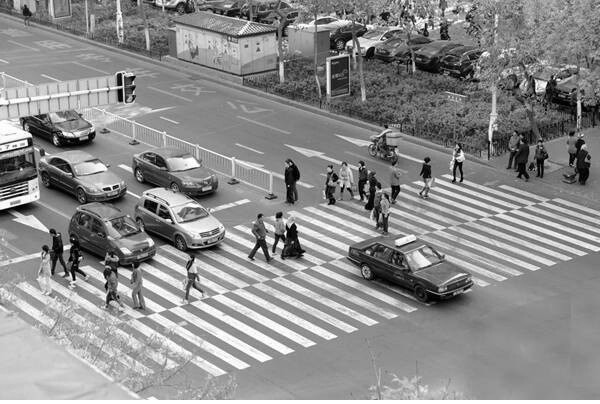

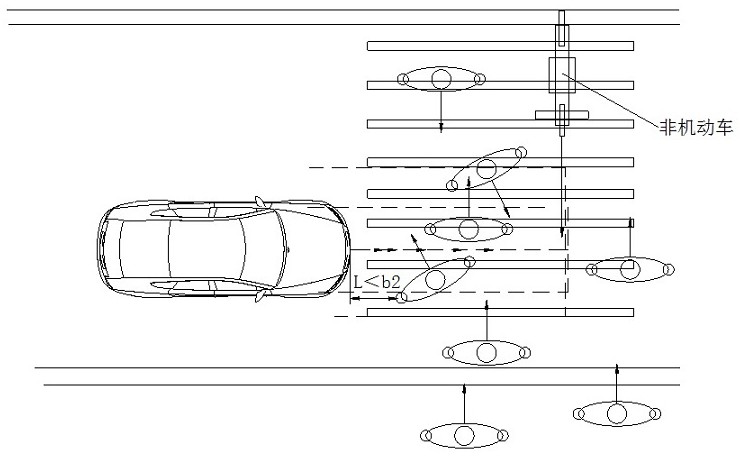

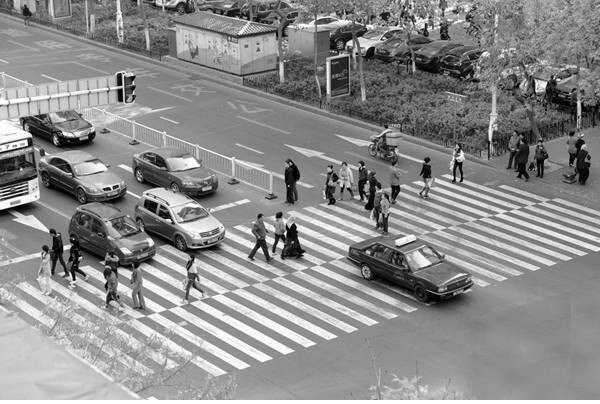

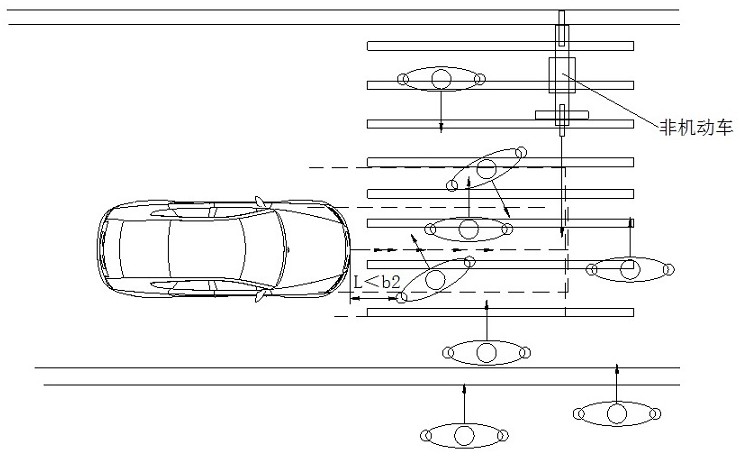

Ultra-low-speed crawling method for pilotless automobile in mixed road congestion state

ActiveCN113306552AEnsure safe passageGuaranteed to move forwardExternal condition input parametersPedestrian flowReal-time computing

The invention belongs to the technical field of pilotless automobiles, and particularly relates to an ultra-low-speed crawling method for a pilotless automobile in a mixed road congestion state. The method comprises the following specific steps: analyzing the moving tracks of pedestrians and non-motor vehicles in a range M around a vehicle pre-enveloping area; and according to the distance between the front end of the vehicle and the pedestrians and the non-motor vehicles, whether the pre-moving tracks of the pedestrians and the non-motor vehicles deviate from a vehicle pre-driving track or not and whether the pedestrians see the vehicle or not, instructing a vehicle to stop for waiting, decelerate or drive at an original speed. According to the method, multiple factors are comprehensively considered, so that pedestrians and non-motor vehicles can safely pass through, the vehicles can be ensured to keep moving forwards, the situation that the vehicles cannot continue to run due to the pedestrian safety principle is avoided, and the traffic jam situation caused when the pedestrian flow is large in the mixed road is greatly relieved.

Owner:成都格林希尔德交通科技有限公司

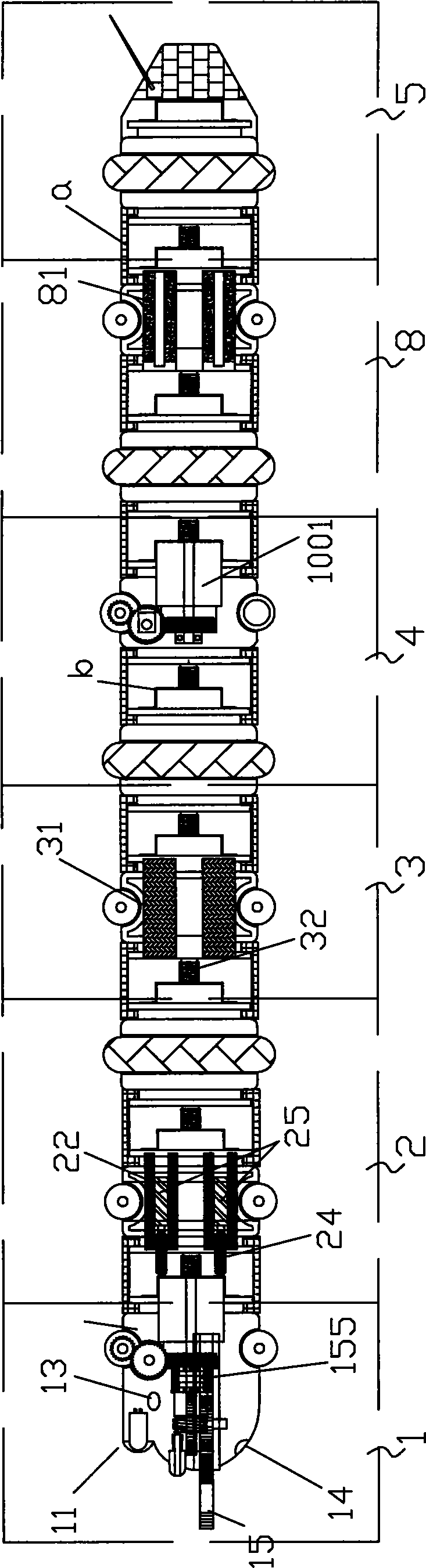

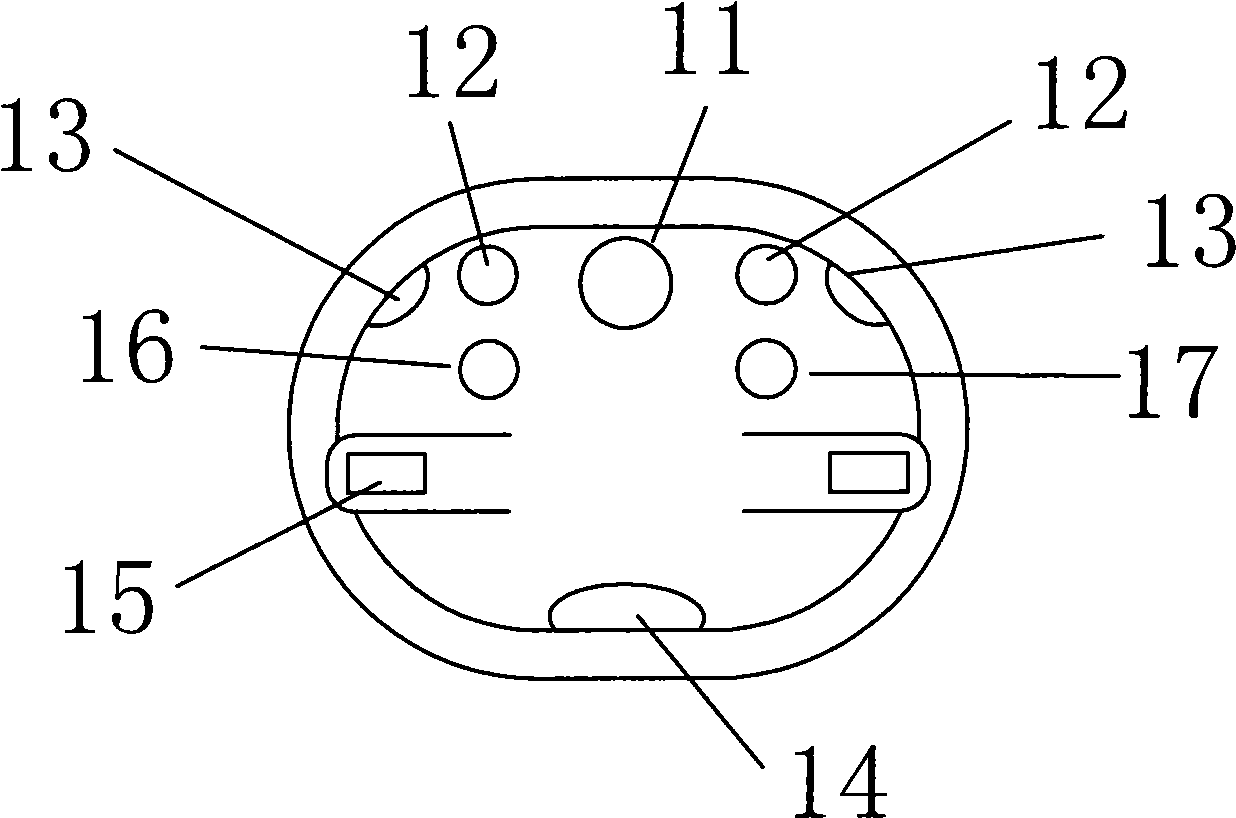

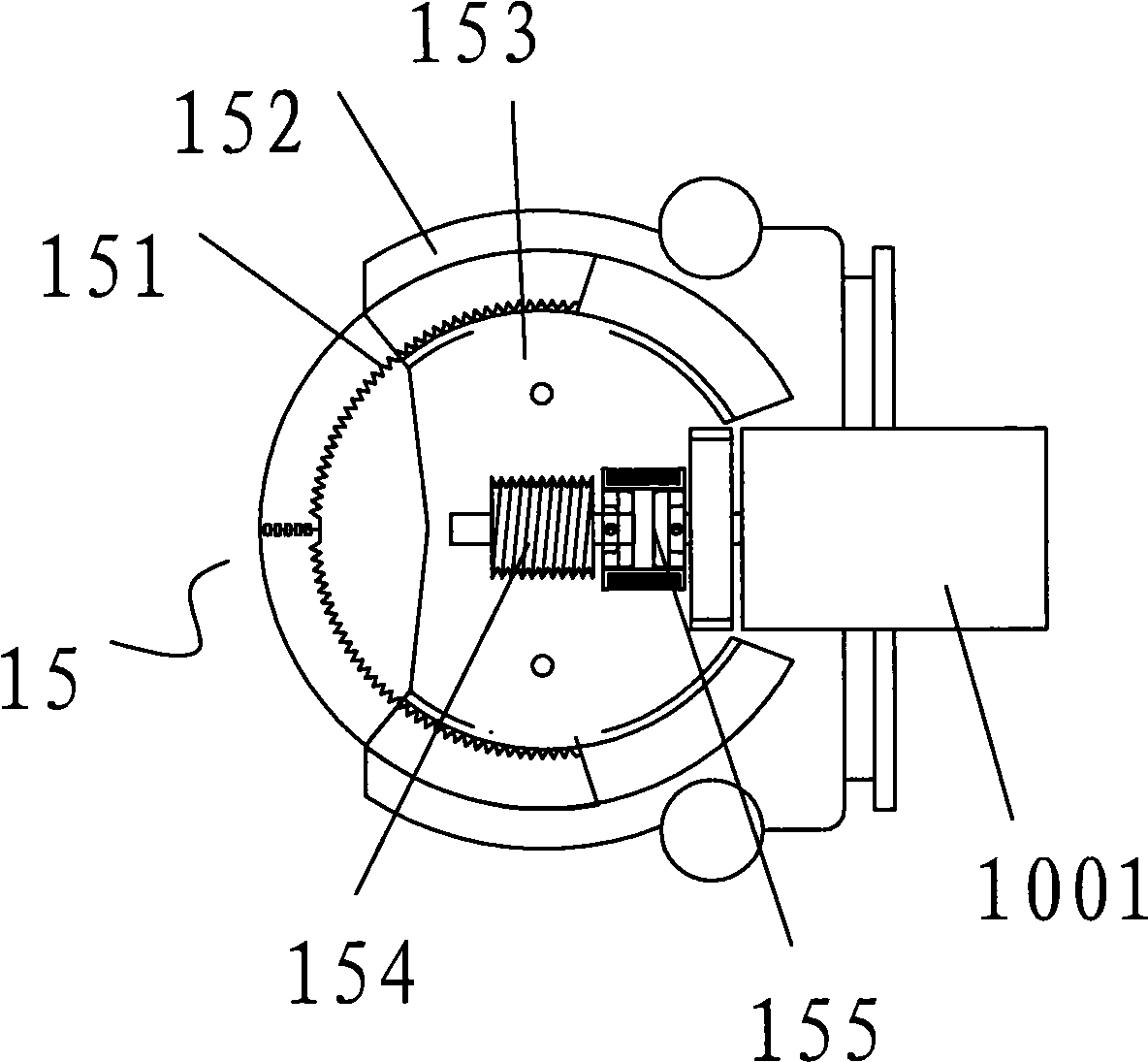

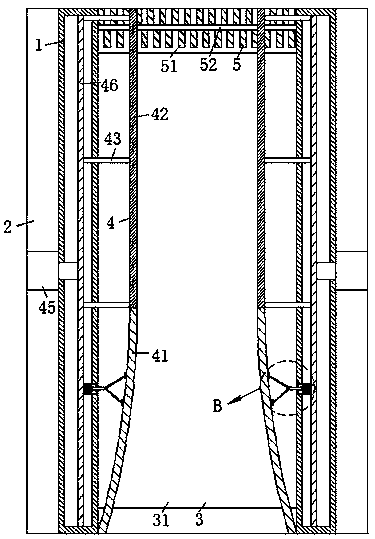

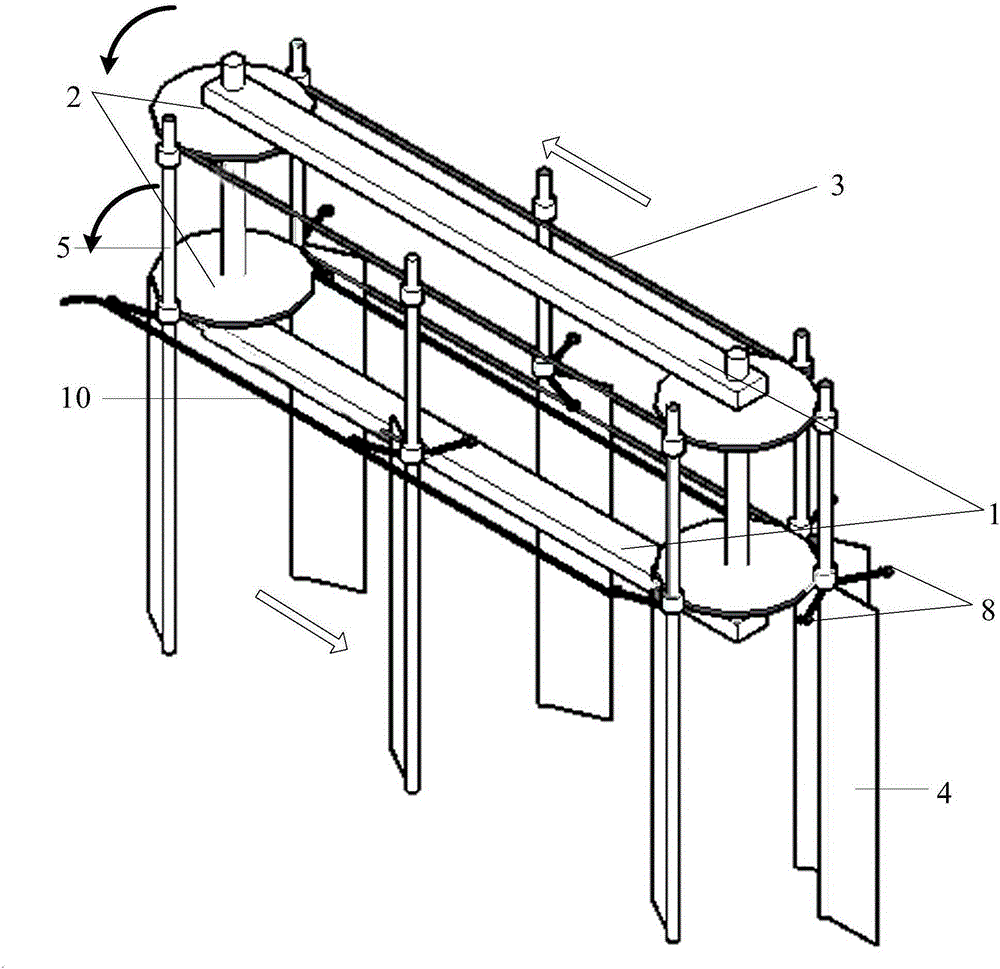

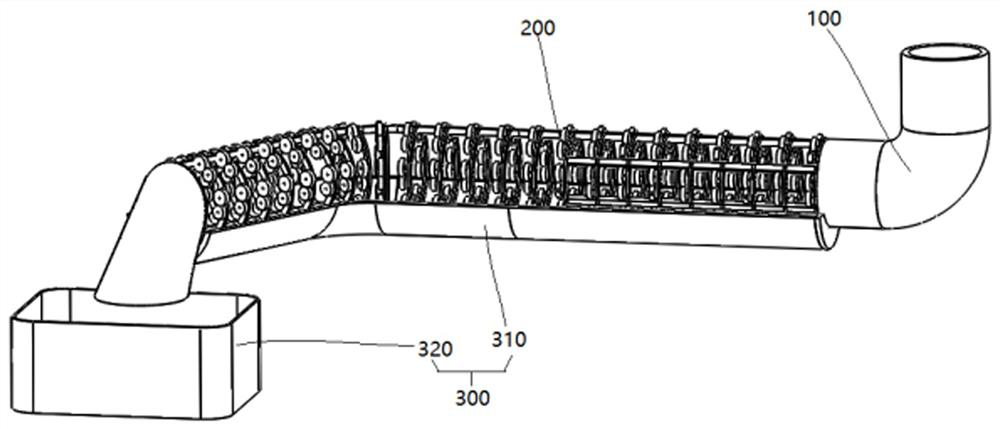

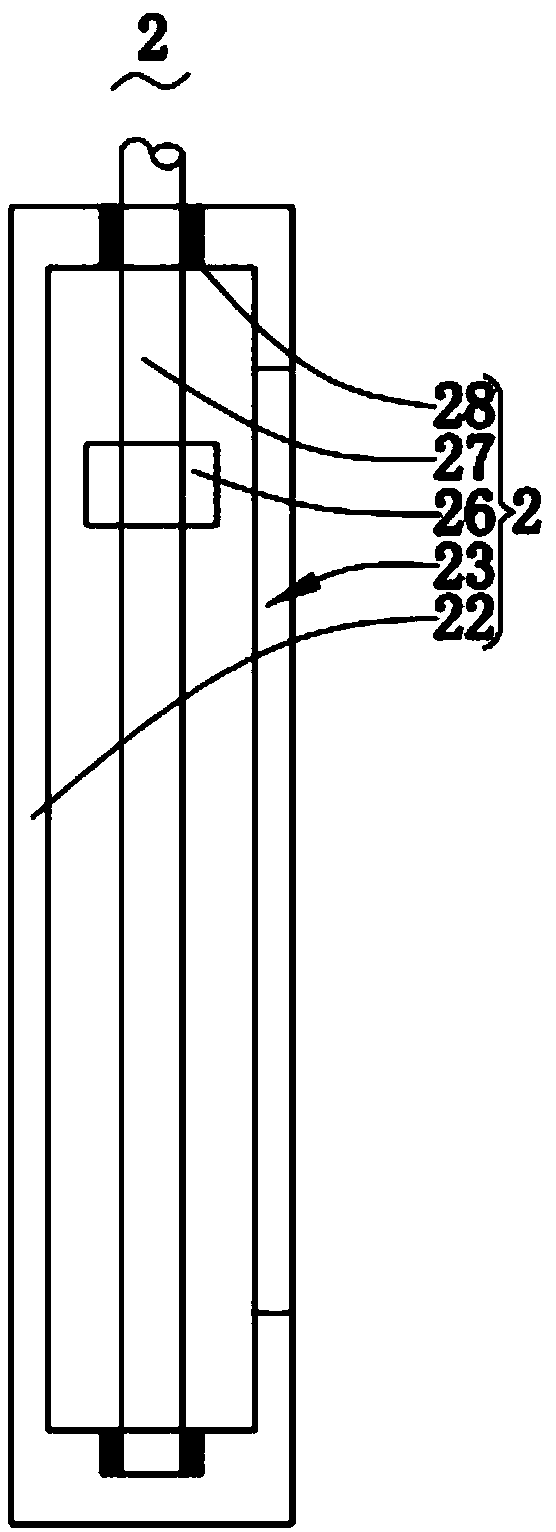

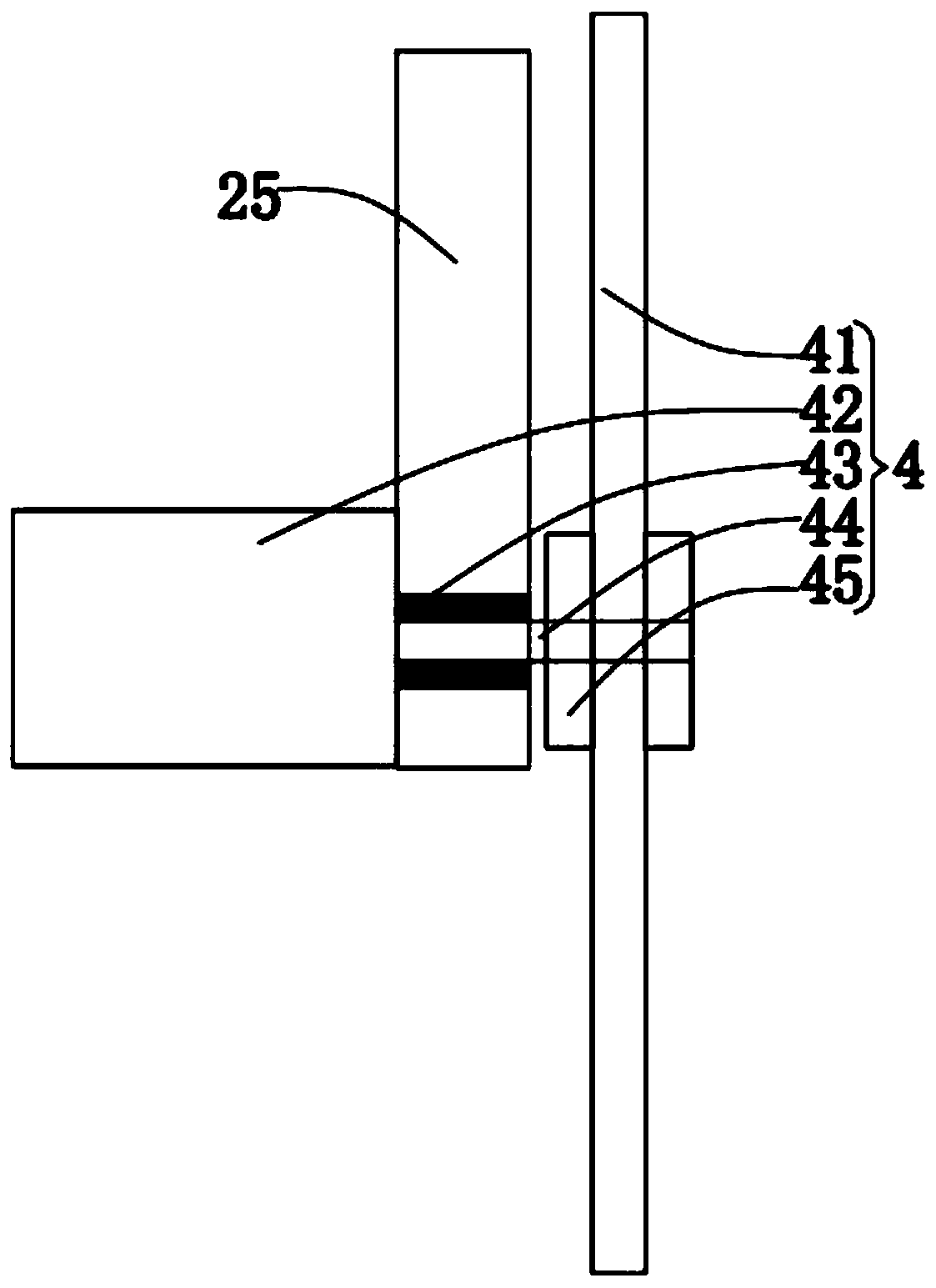

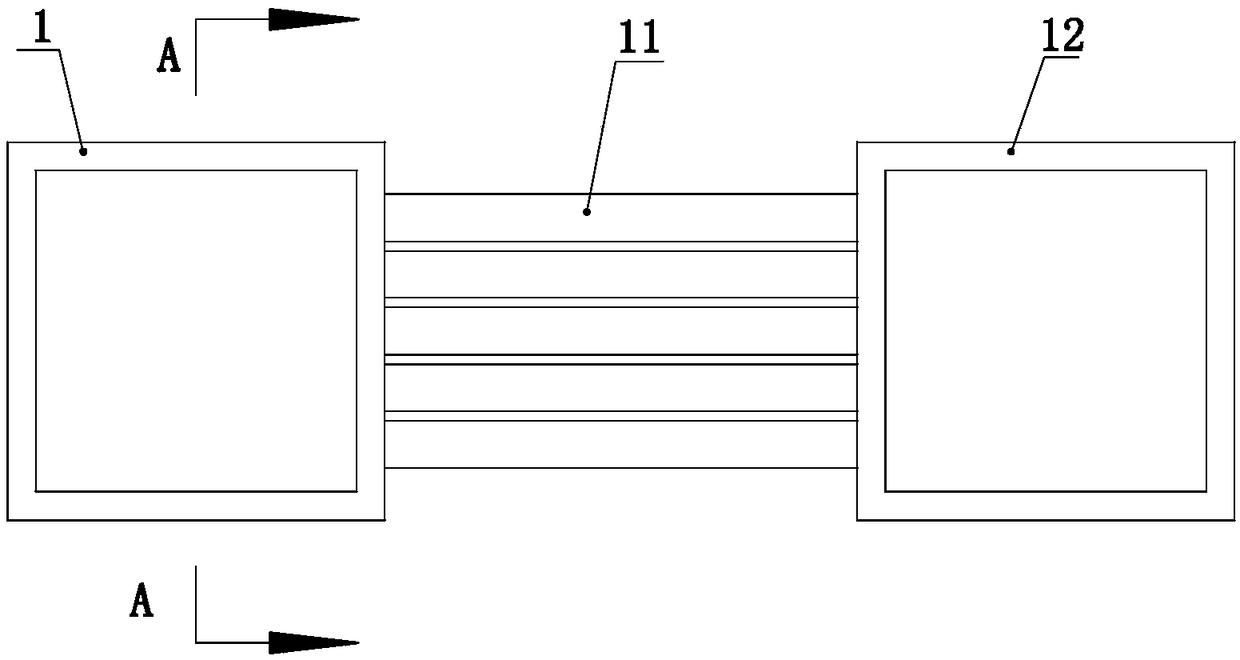

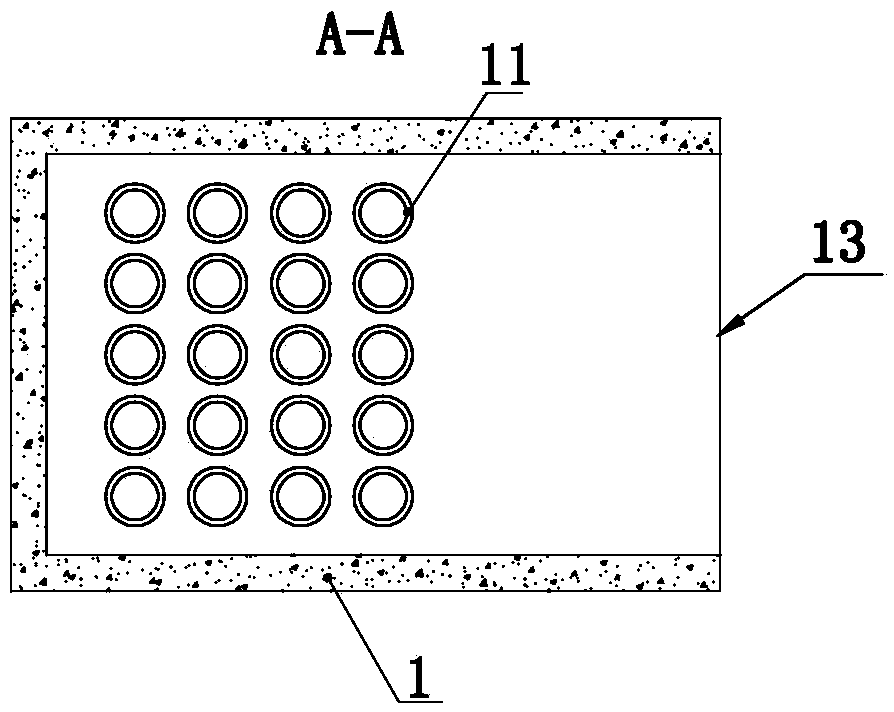

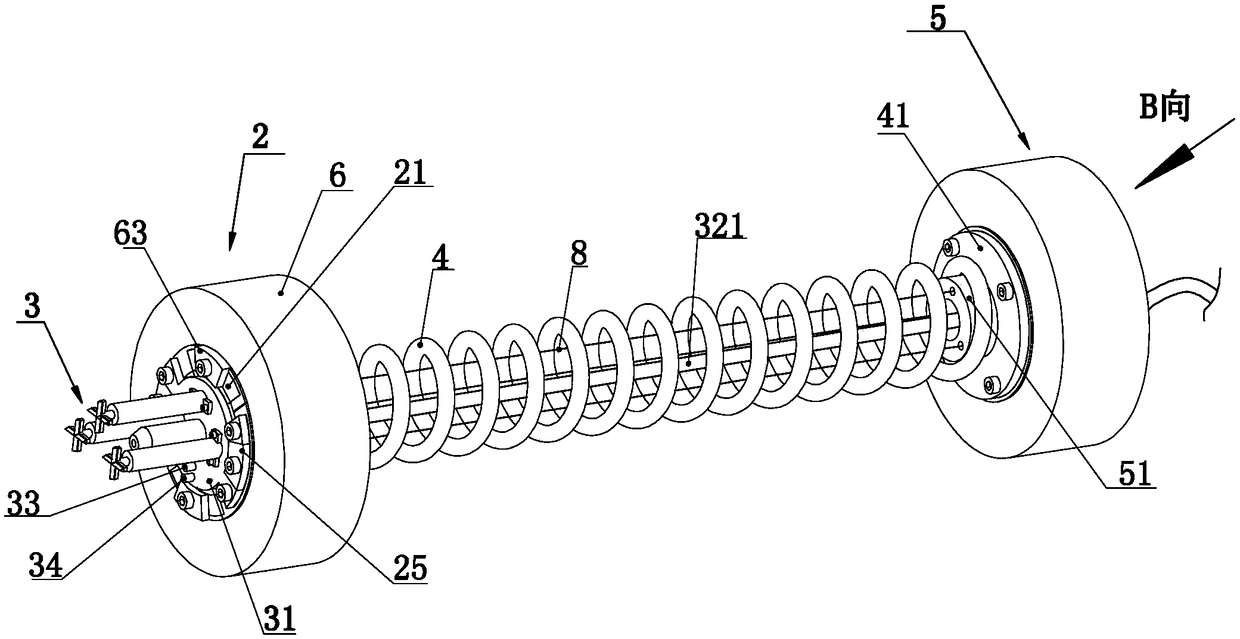

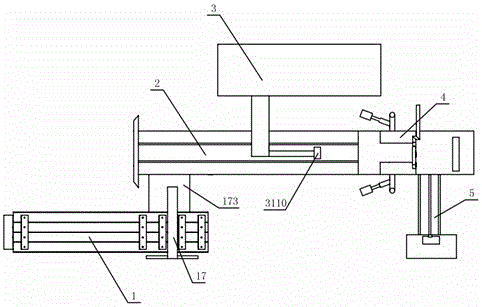

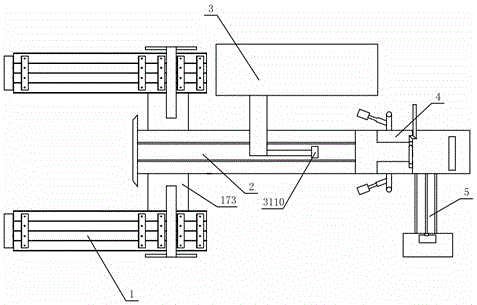

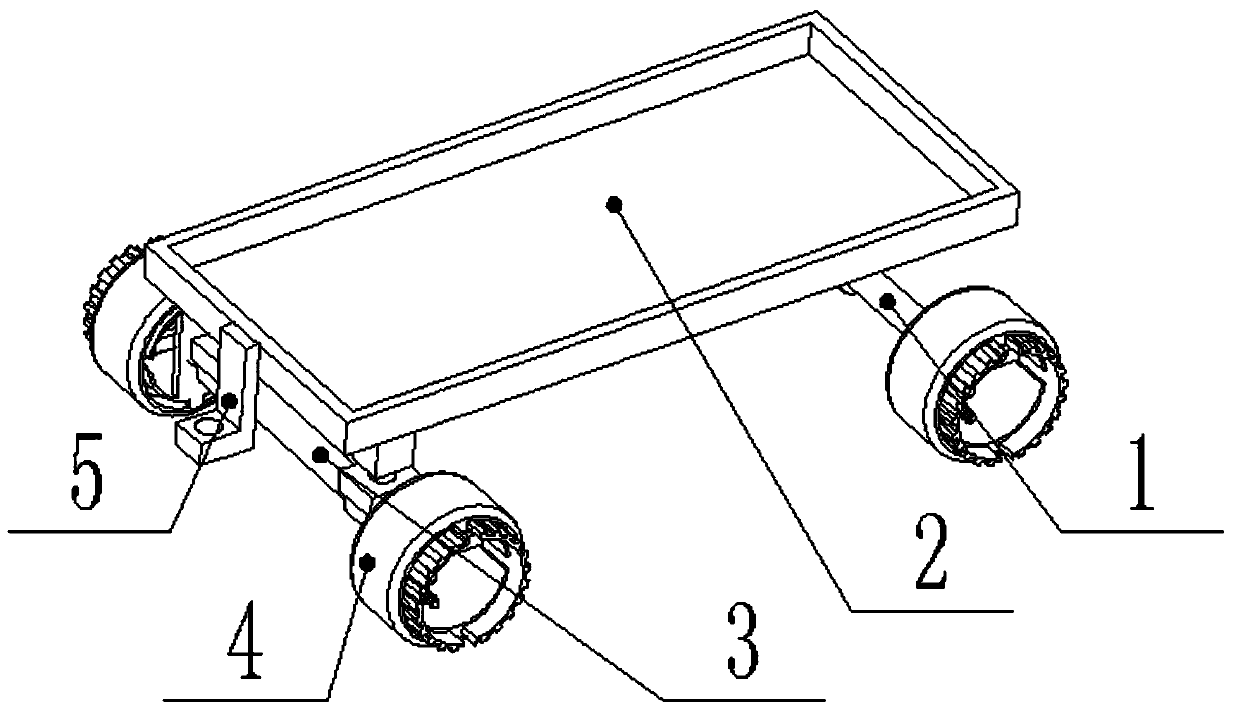

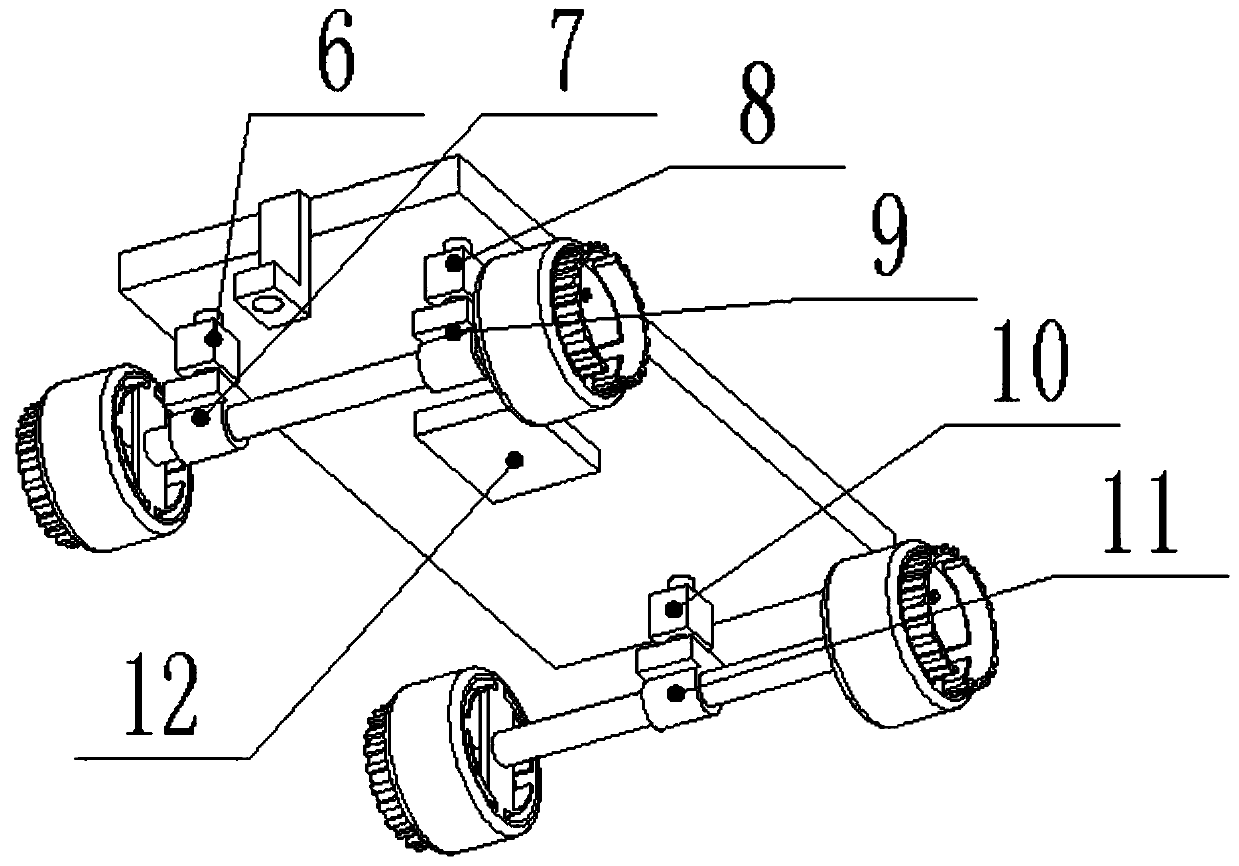

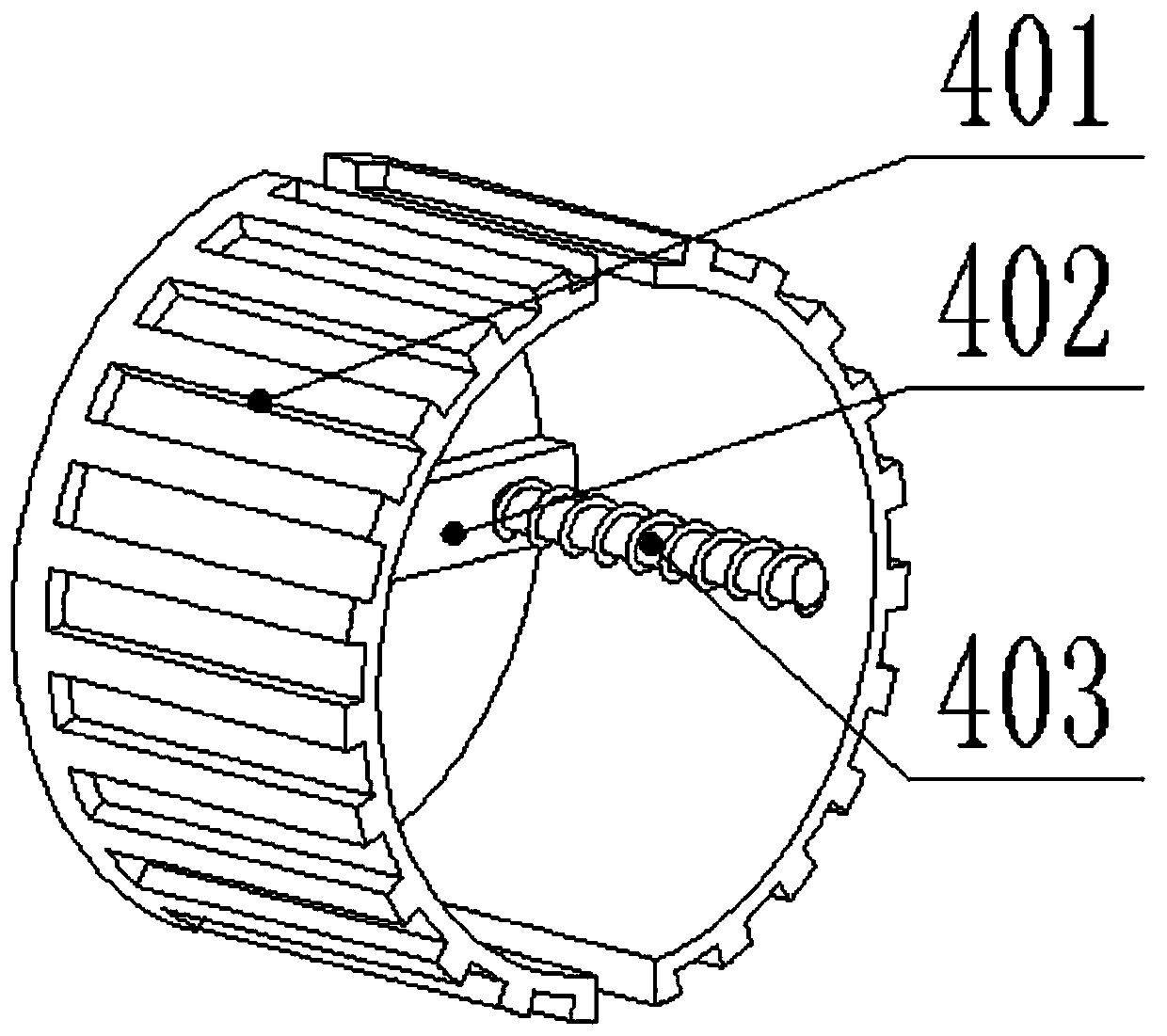

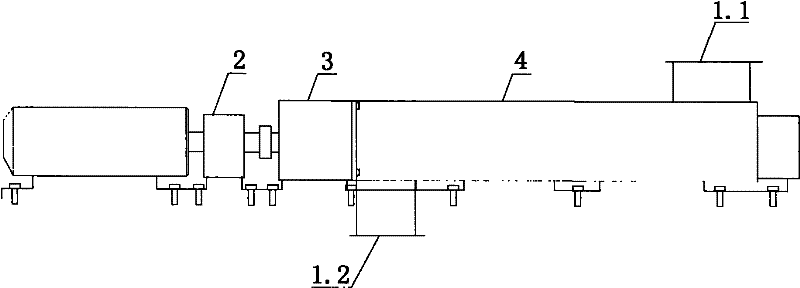

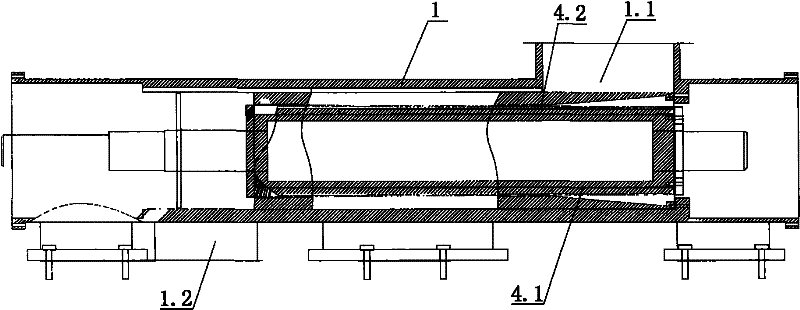

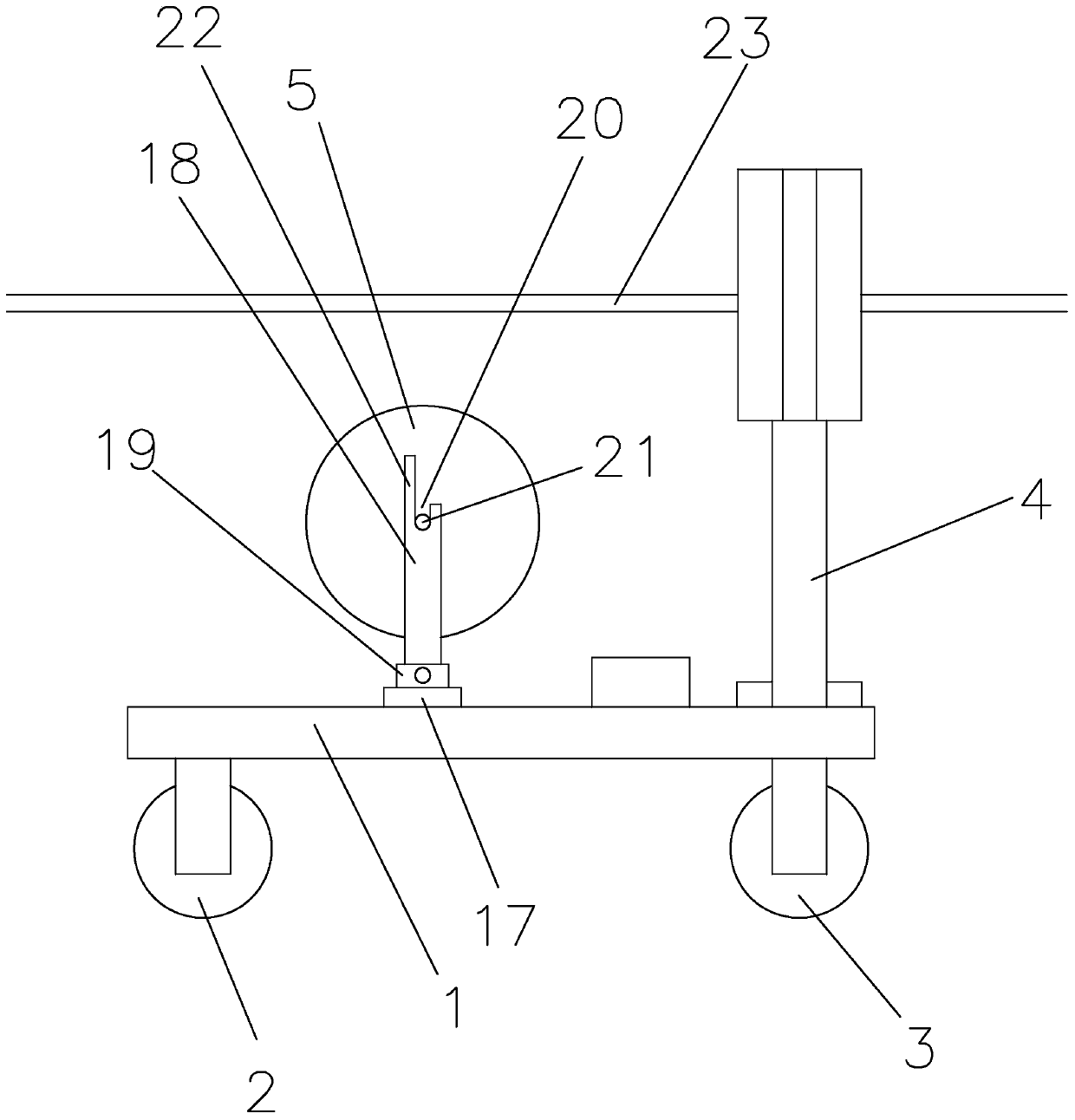

Tunnel cable automatic laying robot and application method thereof

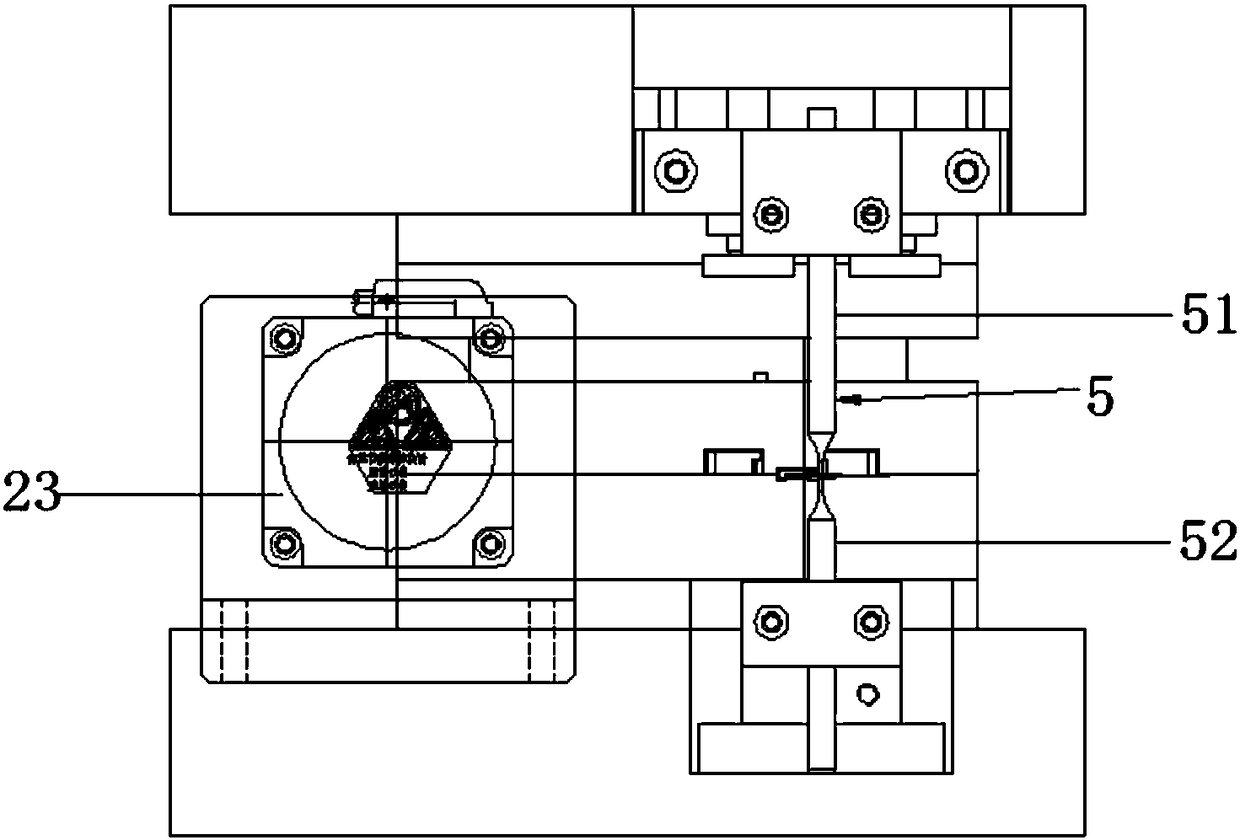

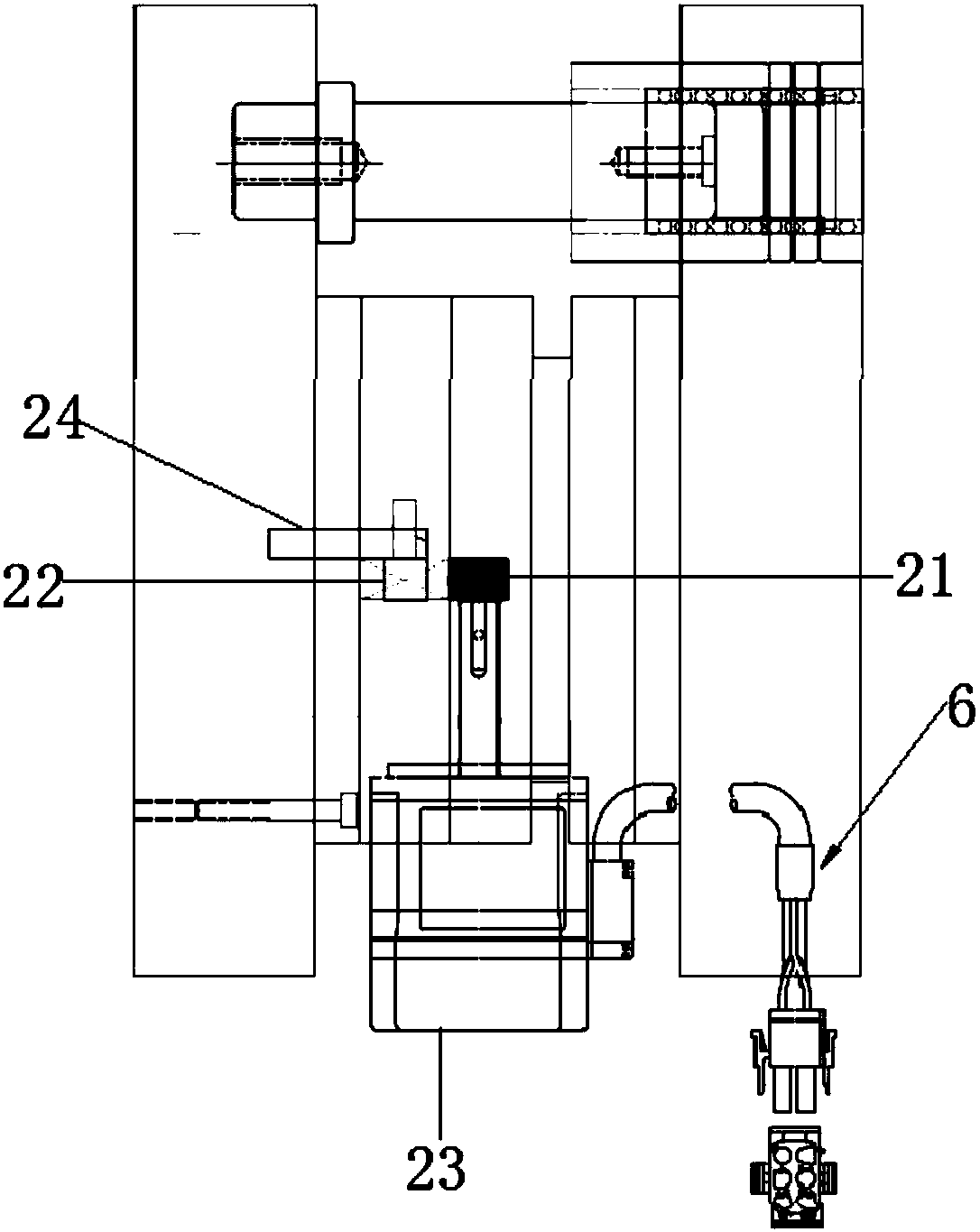

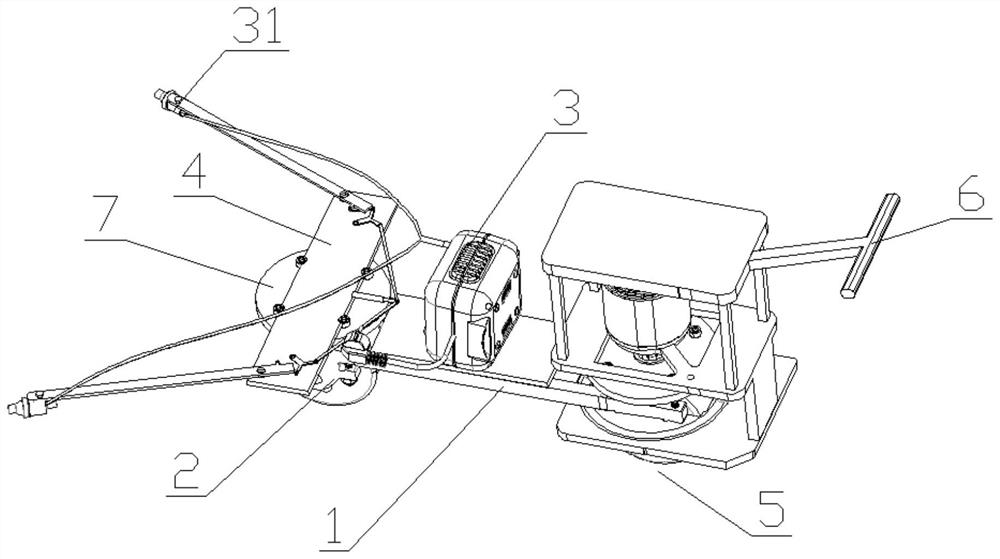

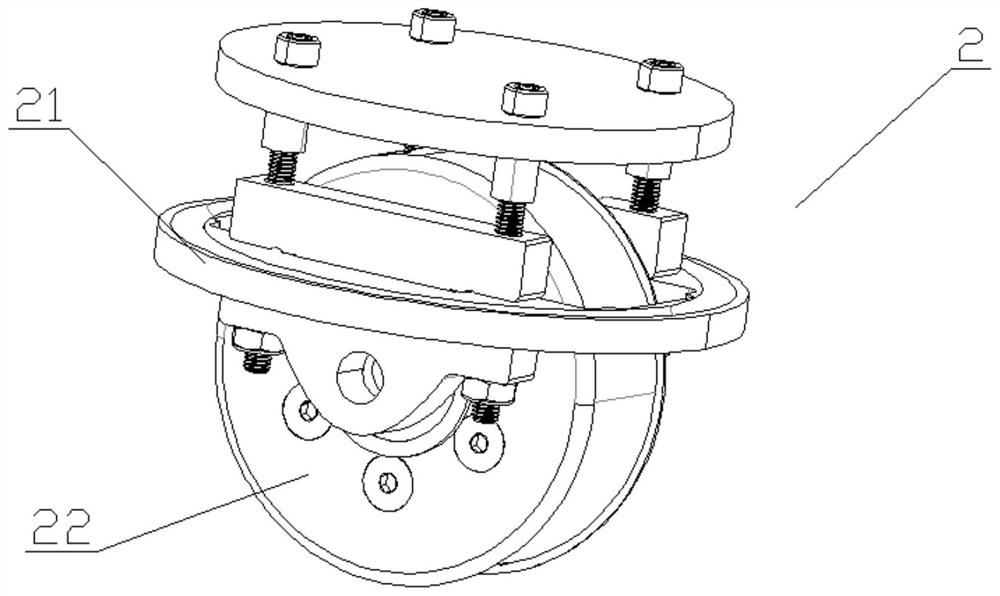

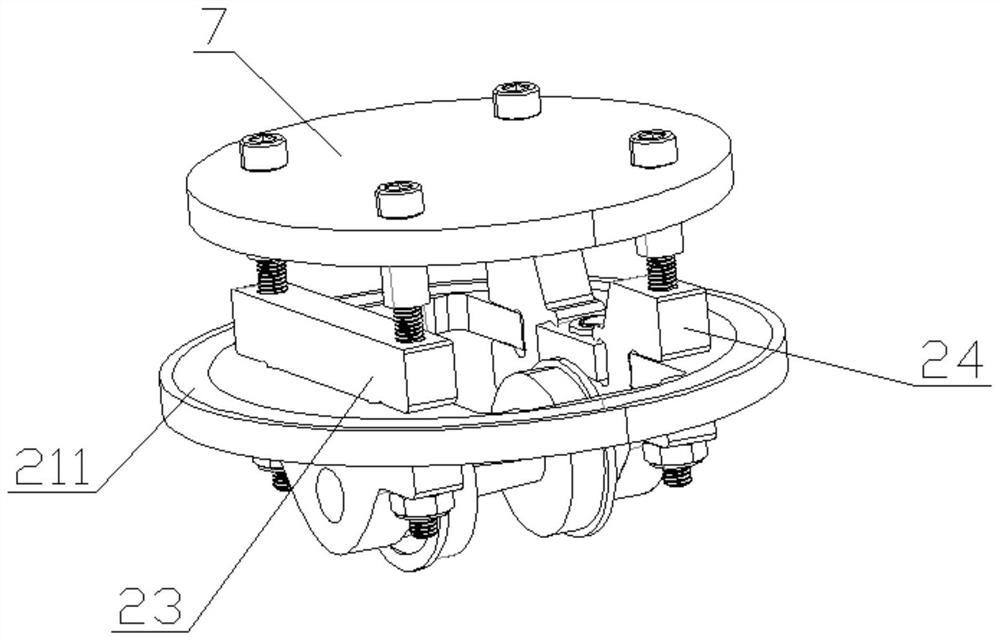

ActiveCN107171254AGuaranteed to move forwardSolve construction problemsCable installations in tunnelsApparatus for laying cablesWireless transmissionElectric power system

The invention relates to a tunnel cable automatic laying robot and an application method thereof, which belong to the technical field of power system infrastructure equipment. The tunnel cable automatic laying robot is characterized by comprising a control unit, a motion unit (2), a wireless transmission unit, a visual unit, a traction unit (5) and a power supply (6), wherein the visual unit, the wireless transmission unit and the control unit are connected in sequence to form a robot head portion ( 134), the robot head portion (134), the motion unit (2), the power supply (6) and the traction unit (5) are sequentially arranged in serpentine shape, the control unit and the motion unit (2) are interconnected by means of a CAN bus, and the control unit, the motion unit (2) and the traction unit (5) are each connected with the power supply (6). The tunnel cable automatic laying robot and the application method thereof have the beneficial effects that: the passing ability of the robot in laying the cable is greatly improved by utilizing the serpentine robot, the robot can even climb through some narrow slots, the robot is safe and reliable, the cost is saved and the efficiency is improved.

Owner:STATE GRID JIBEI ELECTRIC POWER CO LTD TANGSHAN POWER SUPPLY CO +1

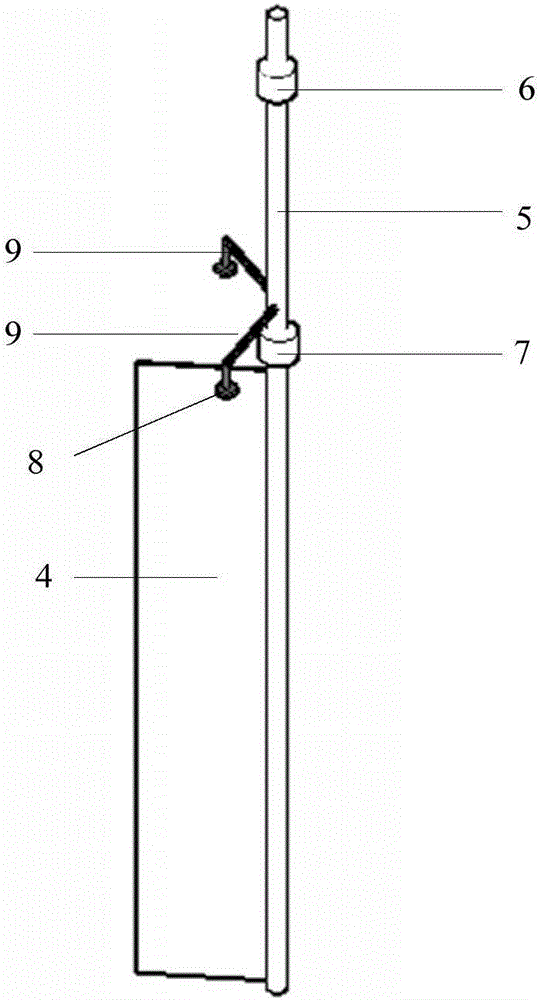

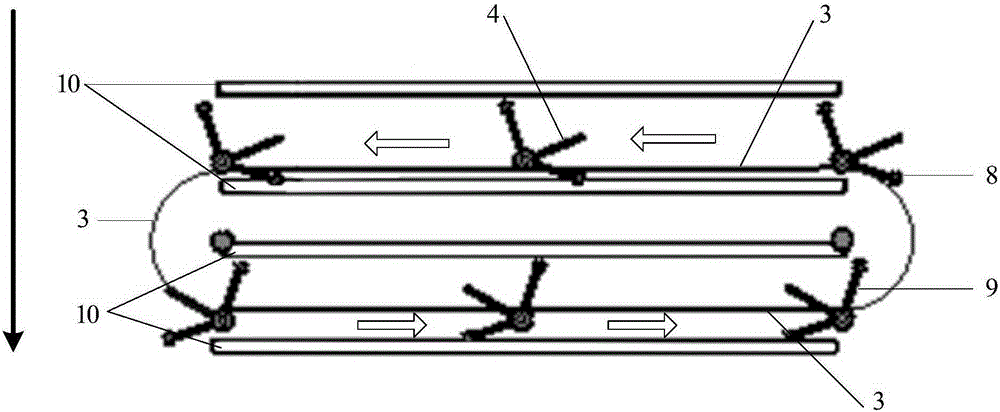

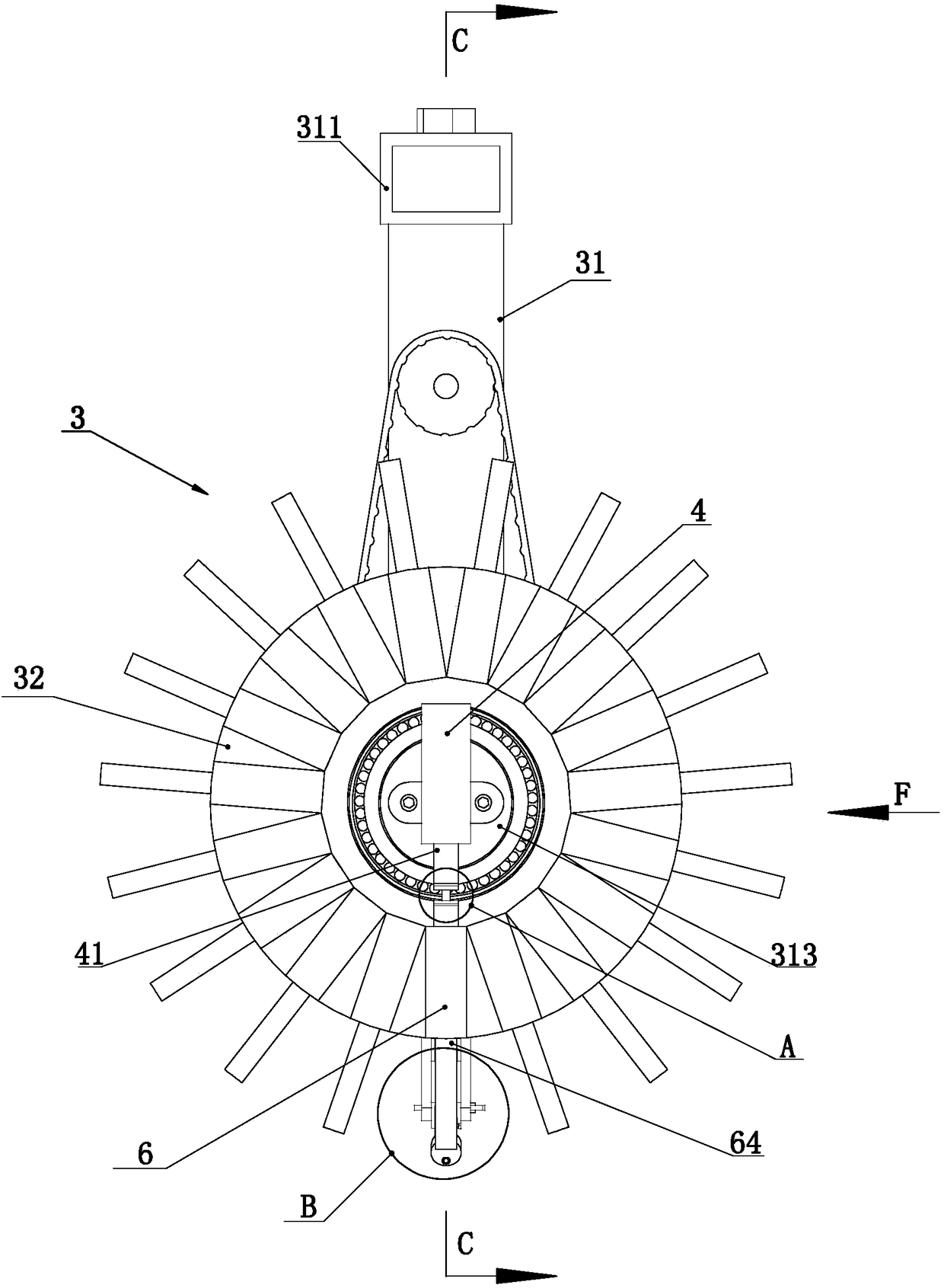

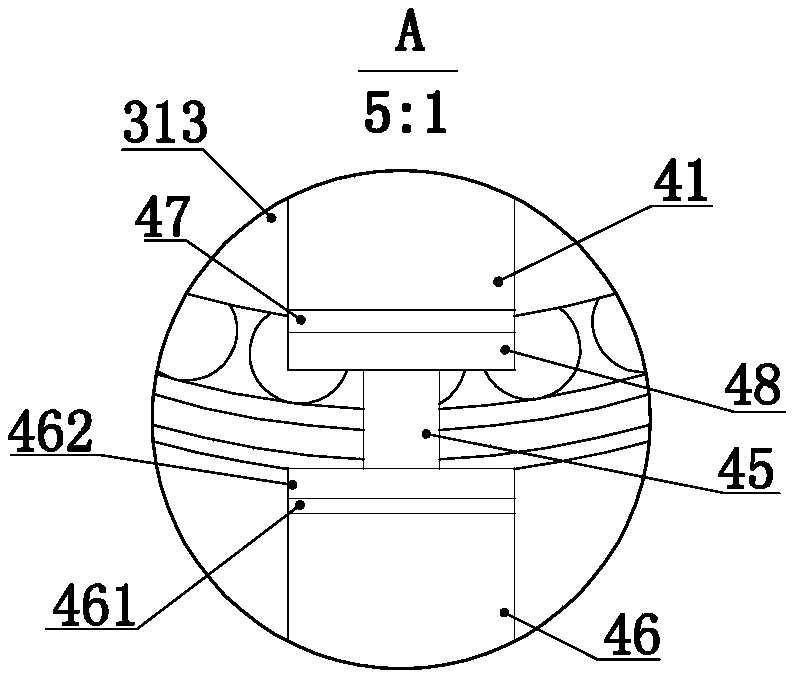

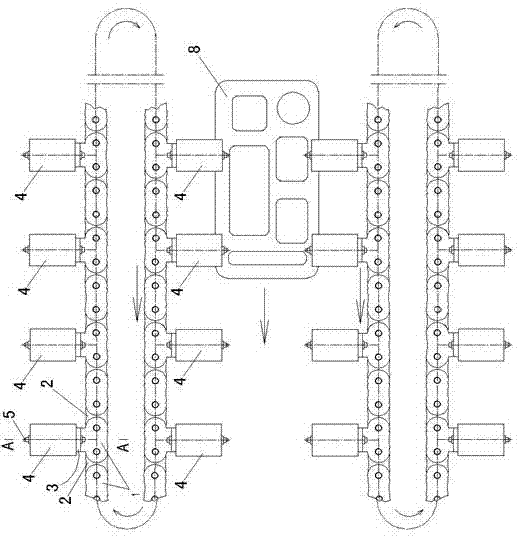

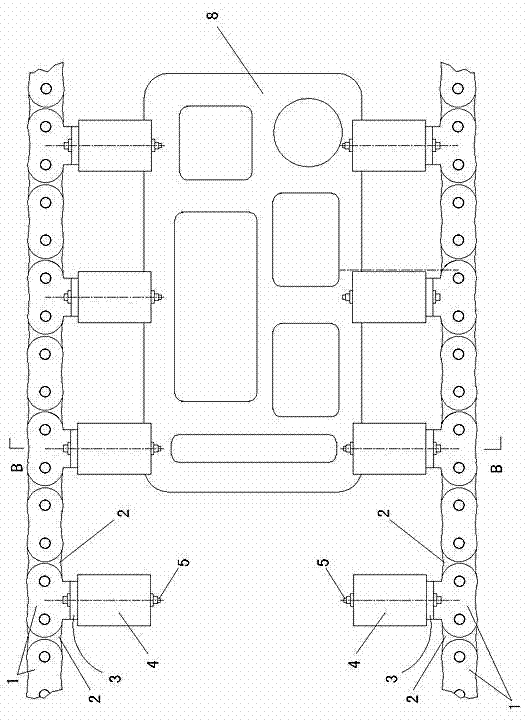

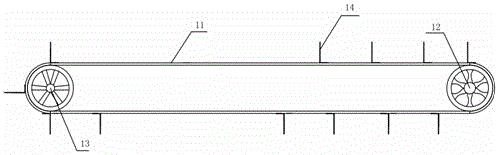

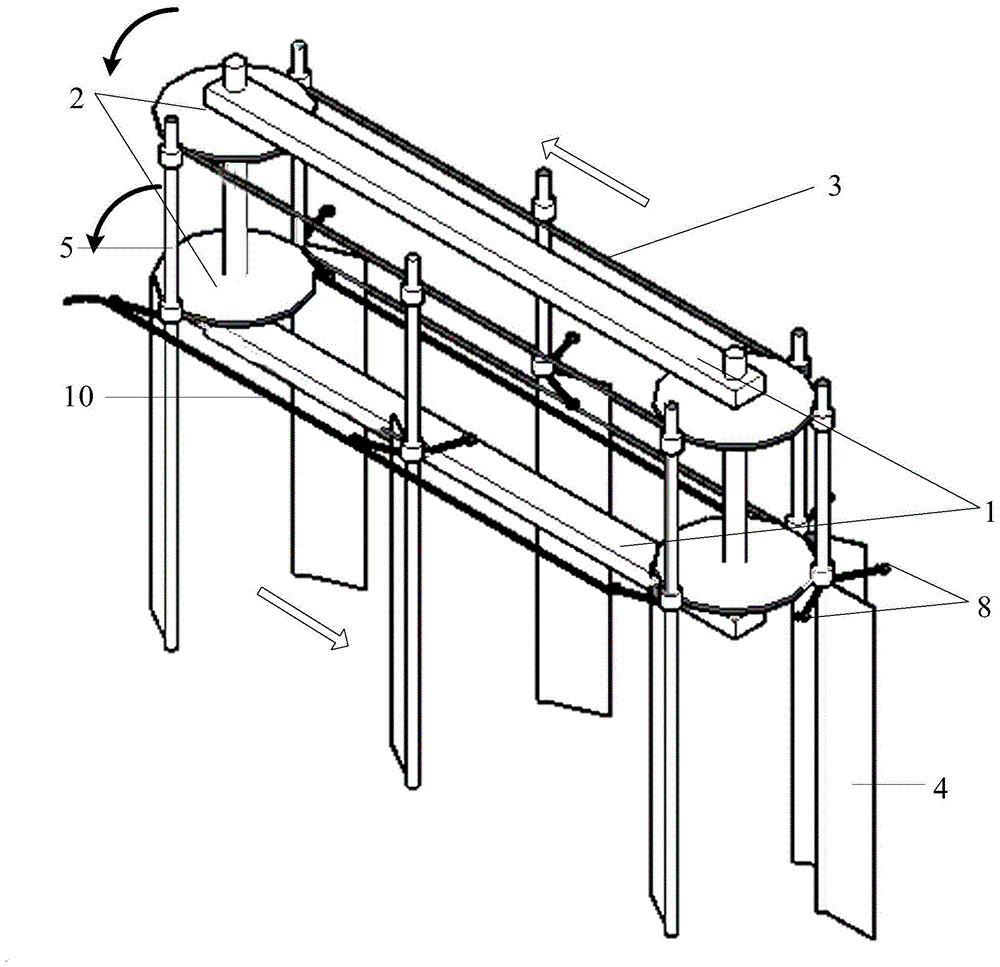

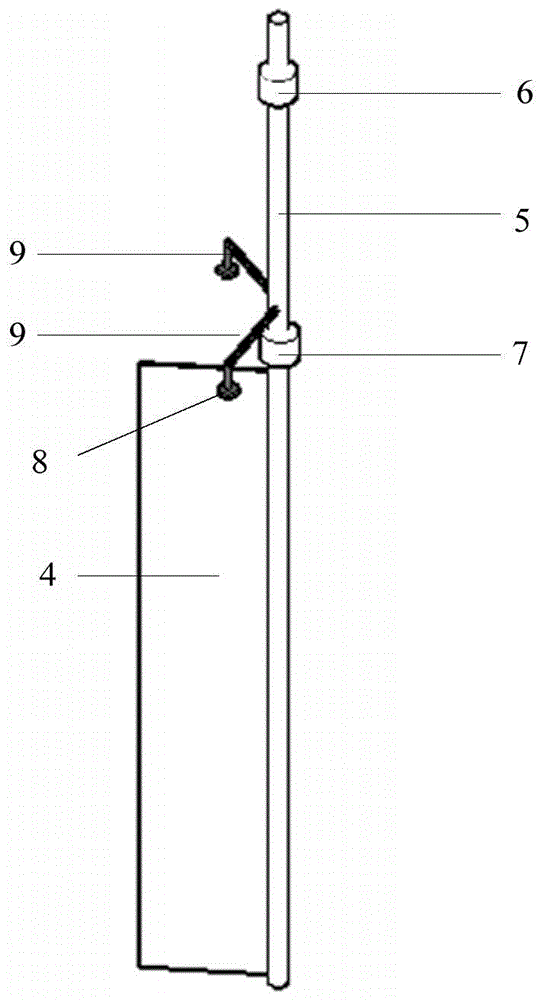

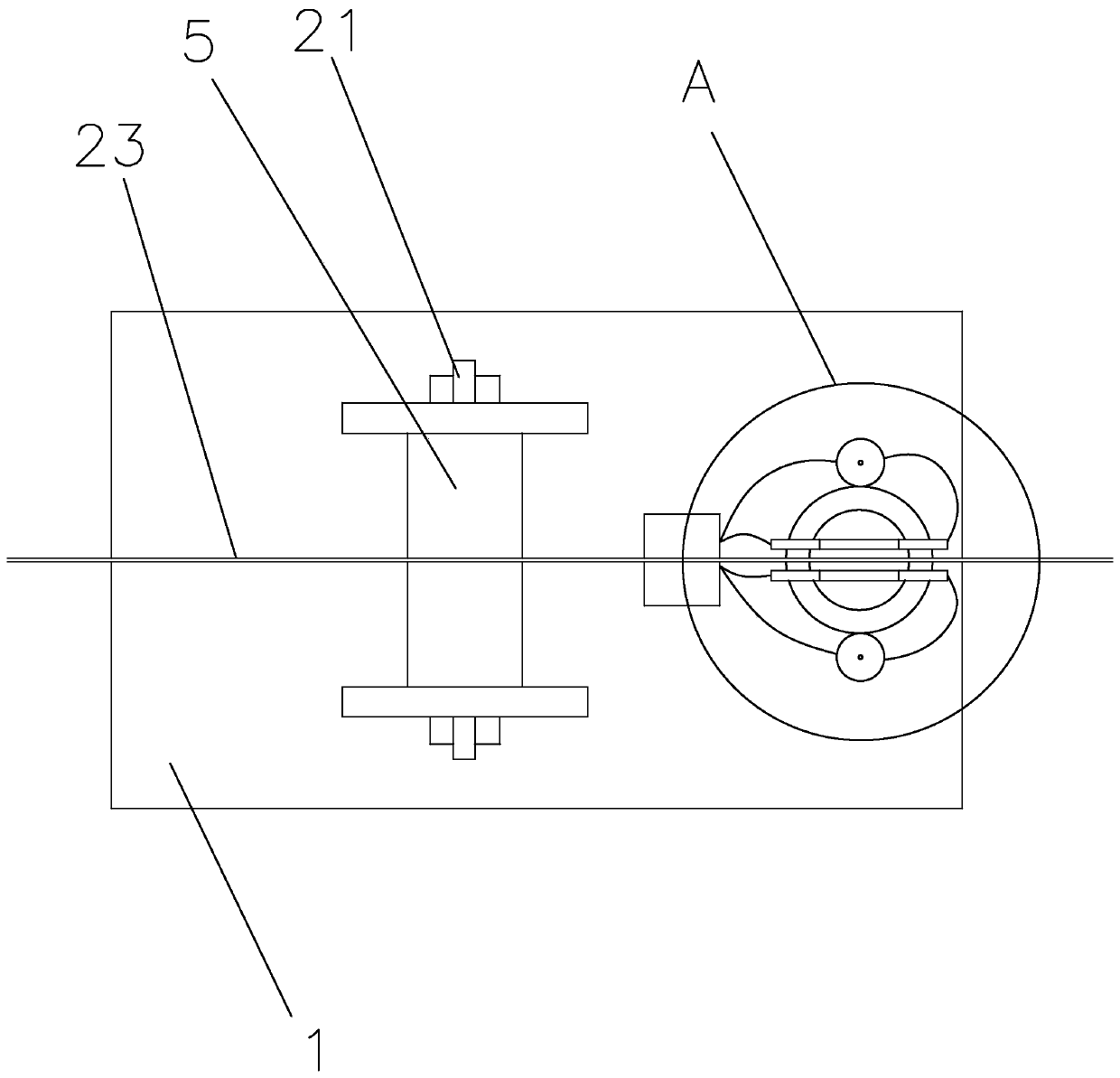

Marine paddle type propeller device

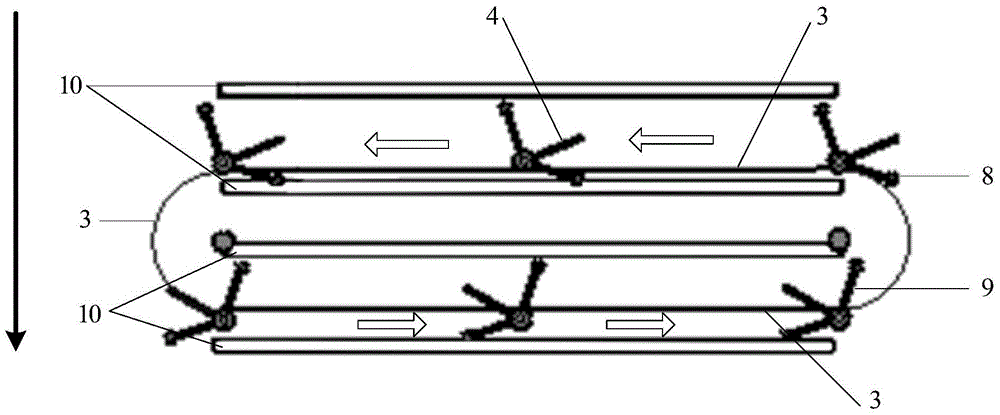

ActiveCN105216997AGuaranteed to move forwardIncrease working areaPropulsive elements of rotary typeEngineeringMotion direction

The invention discloses a marine paddle type propeller device. The marine paddle type propeller device comprises two layers of parallel supports, chain wheels, chains, a power device and a propelling force control mechanism (further comprises a plurality of propelling mechanisms and two propelling direction control devices). Each propelling mechanism comprises a blade, a blade rotating shaft, two bearings and a set of blade limiting wheels, wherein the two bearings are fixed to all the layers of chains respectively, the blade is fixed to the blade rotating shaft, the blade limiting wheels are fixed to the blade rotating shaft through connecting rods, and the blade limiting wheels are located on the two sides of the blade respectively. The propelling direction control device comprises two parallel linear limiting chutes, and the blade limiting wheels slide in the motion direction of the chains with one linear limiting chute serving as a rail. The problems that an existing marine propeller is low in paddling efficiency and high in energy consumption cost can be solved through the marine paddle type propeller device.

Owner:倪忠

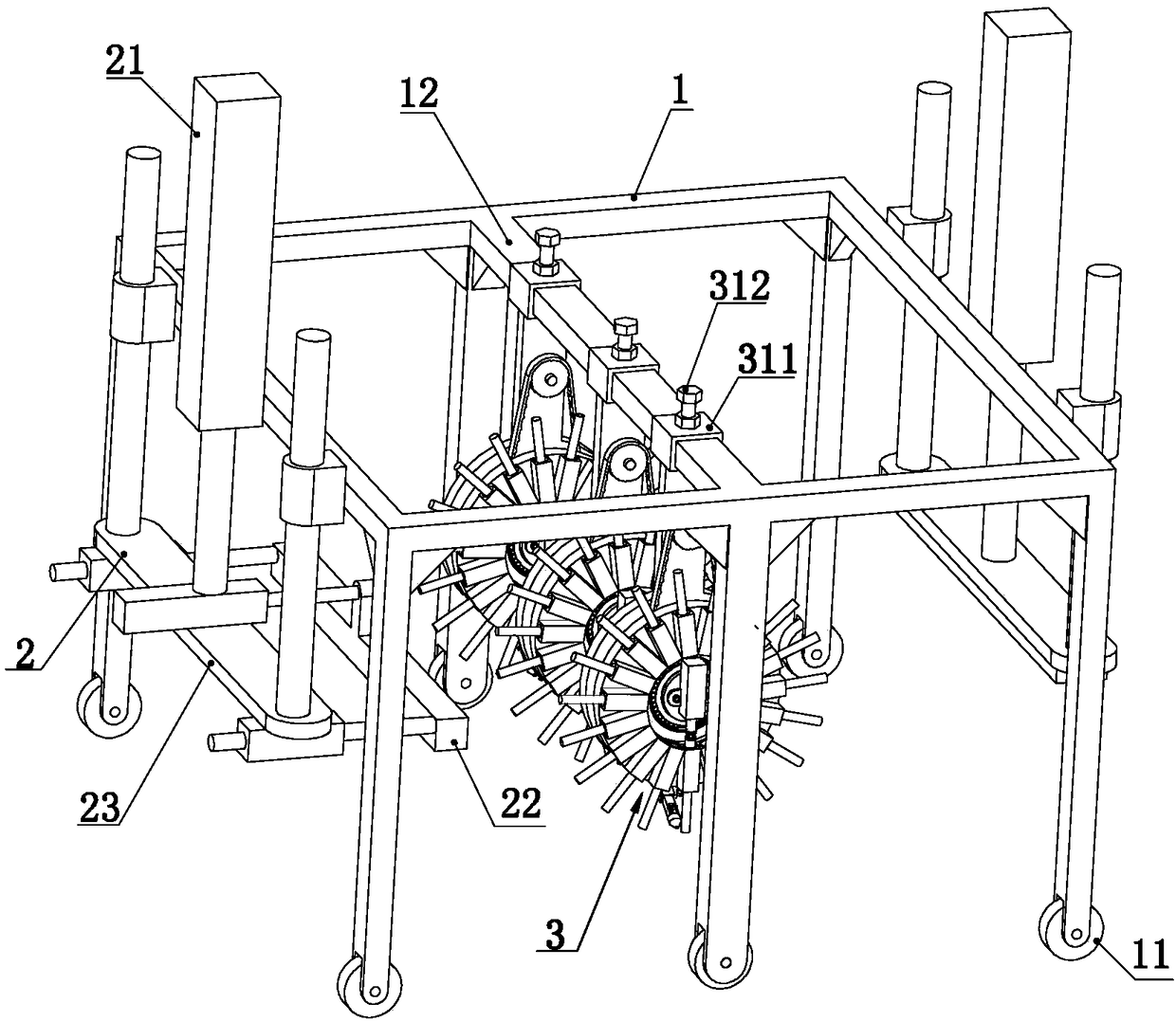

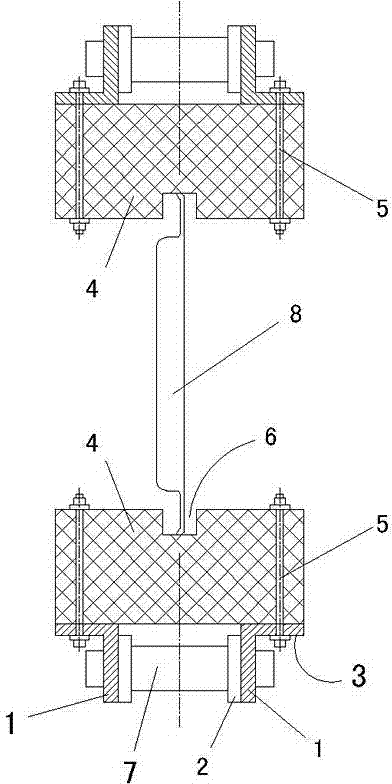

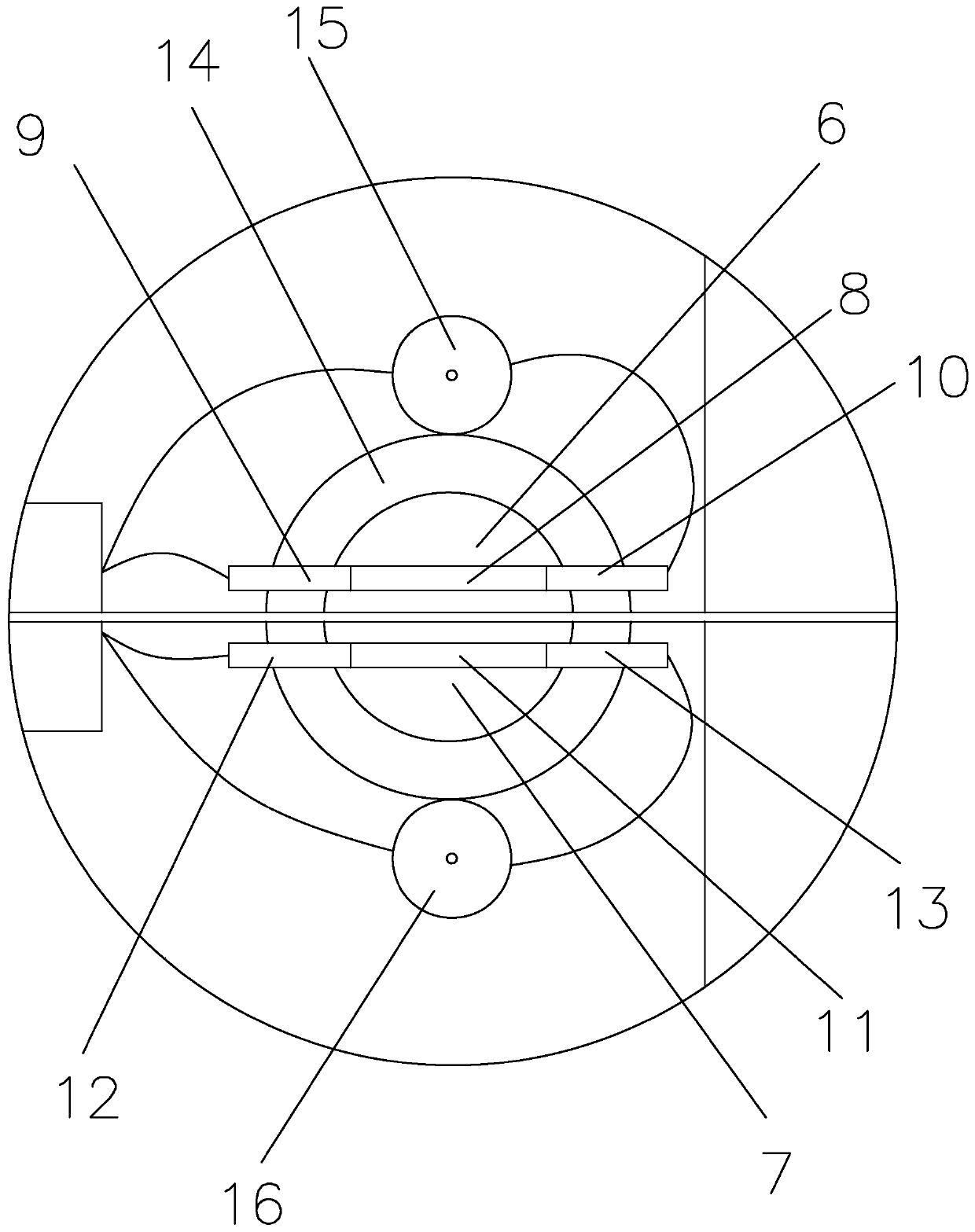

Device for welding screw rod sets in ship manufacturing process

ActiveCN108381062AGuaranteed to push toGuaranteed to move forwardWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a device for welding screw rod sets in a ship manufacturing process, relates to the technical field of welding machinery, and solves the problems of low working efficiency andhigh working intensity during setting of screw rod sets in the prior art. The device for welding the screw rod sets in the ship manufacturing process comprises a crane frame, two sets of connecting frames and multiple welding machines; the crane frame is provided with wheels facilitating walk; each connecting frame is slidingly connected to the crane frame; the connecting frames can slide on the crane frame in the up-down direction; the connecting frames are distributed front and back; lifting drivers for driving the corresponding connecting frames to slide up and down are arranged between theconnecting frames and the crane frame; the connecting frames are connected with electromagnets; and welding heads are used for welding screw rods on workpieces. The device has the beneficial effect of capability of improving the welding efficiency of the screw rod sets.

Owner:WEIHAI VOCATIONAL COLLEGE

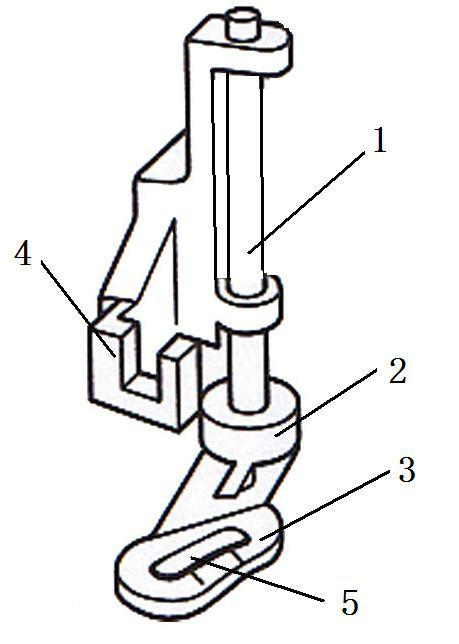

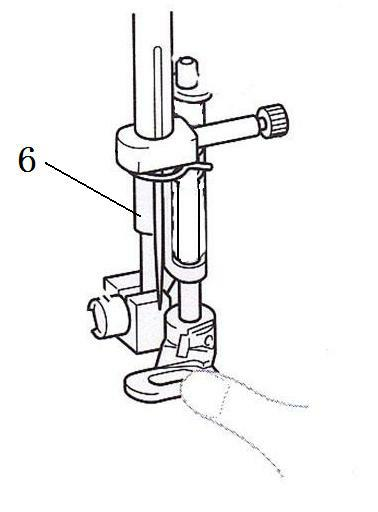

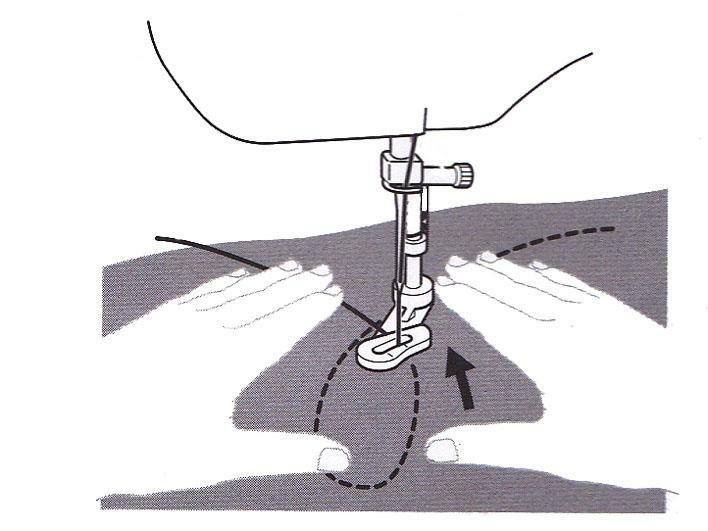

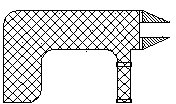

Quilting seam pressing foot and method of using quilting seam pressing foot

The invention discloses a quilting seam pressing foot. The quilting seam pressing foot comprises a supporting seat, a connecting seat, a base and a connecting part for connecting pressing foot brackets of a sewing machine, wherein the connecting seat is cylindrical in shape and is used for connecting the supporting seat with the base; the base is arc-shaped; and a needle groove is arranged in the base. According to the quilting seam pressing foot, the arc-shaped base can flatten four sides of a sandwich fabric to be quilted, so that regular quilted trace is guaranteed, missed stitches and skipping stitches are avoided, and the quality of the quilting seam is guaranteed. The invention also discloses a method of using the quilting seam pressing foot. The method is simple and convenient to use.

Owner:SUZHOU JINGCUN GARMENT CO LTD

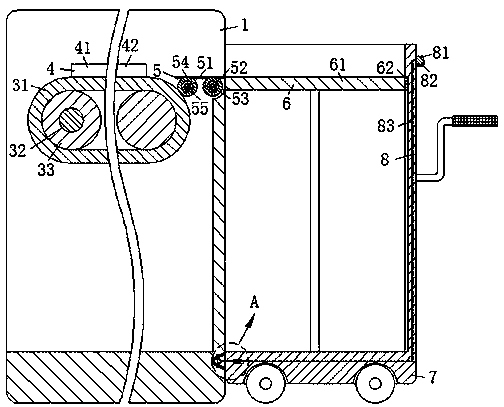

Grooving device for cement concrete road pavement for highway engineering

InactiveCN108867268ARealize notching workQuality assuranceRoads maintainenceHydraulic cylinderSteering wheel

The invention discloses a grooving device for a cement concrete road pavement for highway engineering. The grooving device comprises an outer casing, a drive shaft, a dustproof cover, a bottom plate,a back wheel, a drive box, a connecting plate, a push rod, a rotary disc, a rocking handle, a steering shaft, a fixed plate, a fixed rod, a pedal plate, a first motor, a drive gear, a chain, a steering wheel, a first rotary shaft, a drive gear, a lifting plate, a drive belt wheel, a piston, a hydraulic cylinder, a steering joint, a saw disc, a fixed disc, a transition gear, a support rod, a rectangular box, a blocking plate, a compression spring, a second motor and a drive belt wheel, wherein the outer casing is arranged at the left side of the top part of the bottom plate; the drive box is arranged at the right side of the outer casing; a hydraulic cylinder is fixedly arranged at the left side of the bottom surface of the interior of the outer casing; the piston is arranged in the hydraulic cylinder; the lifting plate is fixedly welded under the piston; the first rotary shaft is arranged at the bottom part of the lifting plate. The grooving device has the advantages that the groovingdepth can be adjusted, and the straightness of the grooving line is guaranteed.

Owner:HEFEI JINGMEI GRAPHIC TECH CO LTD

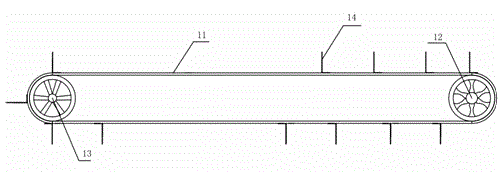

Chain clamping mechanism for dish washing machine

InactiveCN103919516AGuaranteed uptimeGuaranteed to move forwardTableware washing/rinsing machine detailsEngineeringSprocket

The invention discloses a chain clamping mechanism for a dish washing machine. The chain clamping mechanism comprises chain transmission mechanisms which are in up-down symmetry and connected with a drive device. The chain transmission mechanisms are formed by chains and sprockets. Elastic clamping blocks are connected to outer chain pieces of each chain at intervals. A groove is formed in the outer middle portion of each elastic clamping block. During operation, the chain clamping mechanism is coordinated with the washing machine to sequentially convey dishes into the washing machine, the upper chain and the lower chain operate at the same time, the dishes are inserted in the grooves the elastic clamping blocks on by one, the dishes are conveyed continuously by the operation of the chains, when the dishes are inserted, and the elastic clamping blocks have a certain amount of deformation to form certain clamping force so as to guarantee that the dishes can bear the acting force of brushes and spraying water during washing. The chain clamping mechanism is simple in overall structure, the dishes can move stably along with the chains, the dishes can move forwardly one by one, and thorough washing is achieved.

Owner:于潇潜

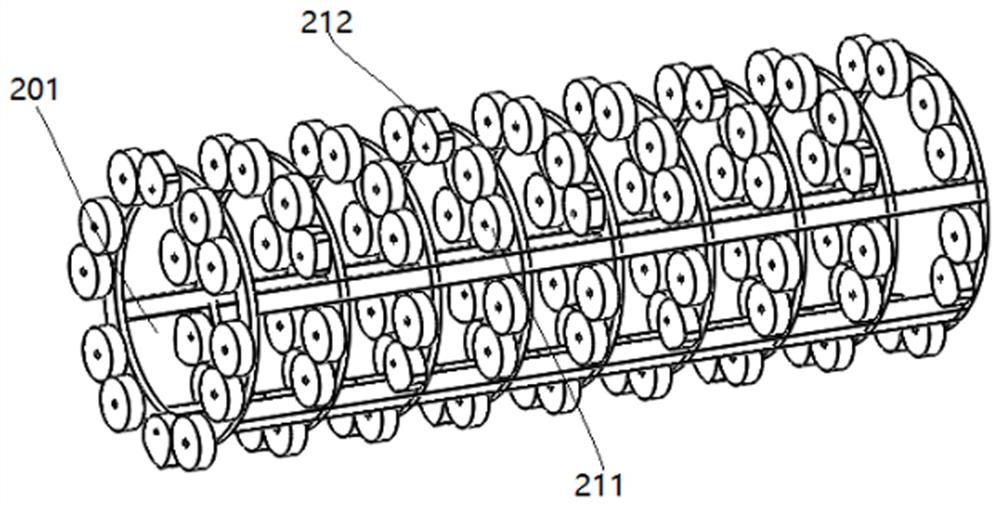

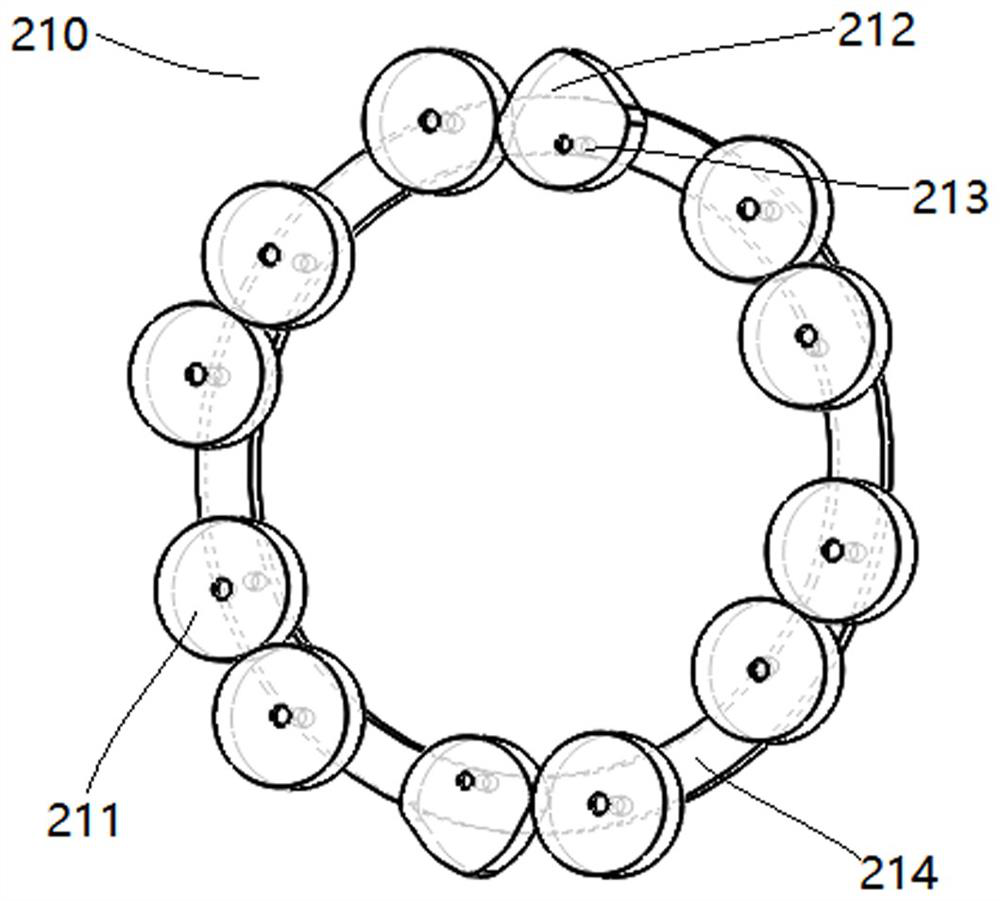

Combined egg processing equipment and processing technology thereof

InactiveCN112335849AImprove space utilizationHigh peeling rateFood scienceStructural engineeringMachining process

The invention discloses combined egg processing equipment which comprises a discharging device, a shelling device, a collecting device and a cleaning device. The discharging device is communicated with the shelling device. The shelling device is a turning channel, which is formed by connecting a plurality of extrusion sub-channels and shelling sub-channels, each extrusion sub-channel is formed bysurrounding a plurality of rotating roller sets and a plurality of eccentric roller sets in an equal-angle circumferential mode, and each shelling sub-channel is formed by surrounding a plurality of separating roller sets in an equal-angle circumferential mode. The rotating roller sets and the separating roller sets are two rollers with different sizes, different roughness, opposite rotating directions and different rotating speeds, the eccentric roller sets are combinations of eccentric rollers and rotating rollers with opposite rotating directions and different rotating speeds, differentialspeeds exist between the adjacent separating roller sets, rotating roller sets and eccentric roller sets, and the size of the turning channel can be adjusted in a self-adaptive mode. The equipment adopts a combined shelling device with turning, has the advantages of high shelling rate, low breakage rate and the like, improves the space utilization rate, and is suitable for eggs of different sizes.

Owner:苏州昆卓精密制造有限公司

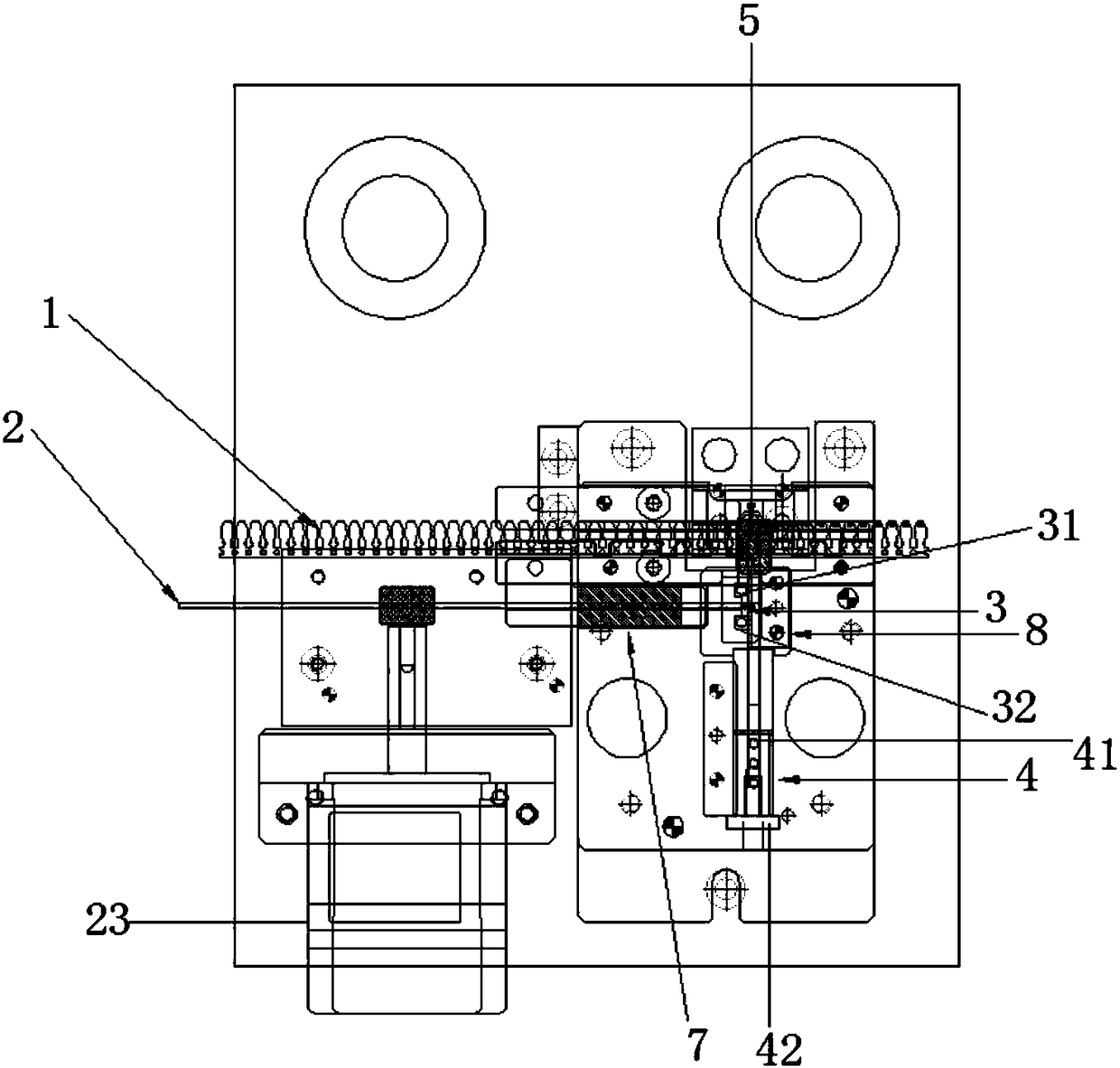

Automatic silver point welding equipment for bimetal sheet of thermal protector

PendingCN108067718ARunning speed is stableThere will be no material jamsWelding/soldering/cutting articlesMetal working apparatusFailure rateDrive wheel

The invention discloses automatic silver point welding equipment for a bimetal sheet of a thermal protector. The automatic silver point welding equipment comprises a bimetal sheet feeding mechanism, asilver belt feeding mechanism, a material cutting mechanism, a material pushing mechanism and a welding mechanism. The bimetal sheet feeding mechanism, the silver belt feeding mechanism, the materialcutting mechanism, the material pushing mechanism and the welding mechanism are respectively fixed on a worktable. The silver belt feeding mechanism includes a conveyor belt, a driving wheel, a driven wheel and a first motor for driving the driving wheel to rotate. The material cutting mechanism includes an upper blade and a lower blade disposed opposite to the upper blade and arranged in dislocation with upper blade. The material pushing mechanism includes a push rod and a cylinder for driving the push rod to move. The welding mechanism includes a positive electrode welding pin and a negative electrode welding pin which are arranged oppositely. According to the equipment, the silver belt feeding mechanism can smoothly convey silver belts to the material cutting mechanism for cutting intosquare silver points to be welded on bimetal sheets, the overall operation speed of the equipment is stable, the phenomenon of material blocking is reduced, the failure rate of equipment operation isreduced, and production efficiency is improved.

Owner:苏州聚生精密冲件有限公司

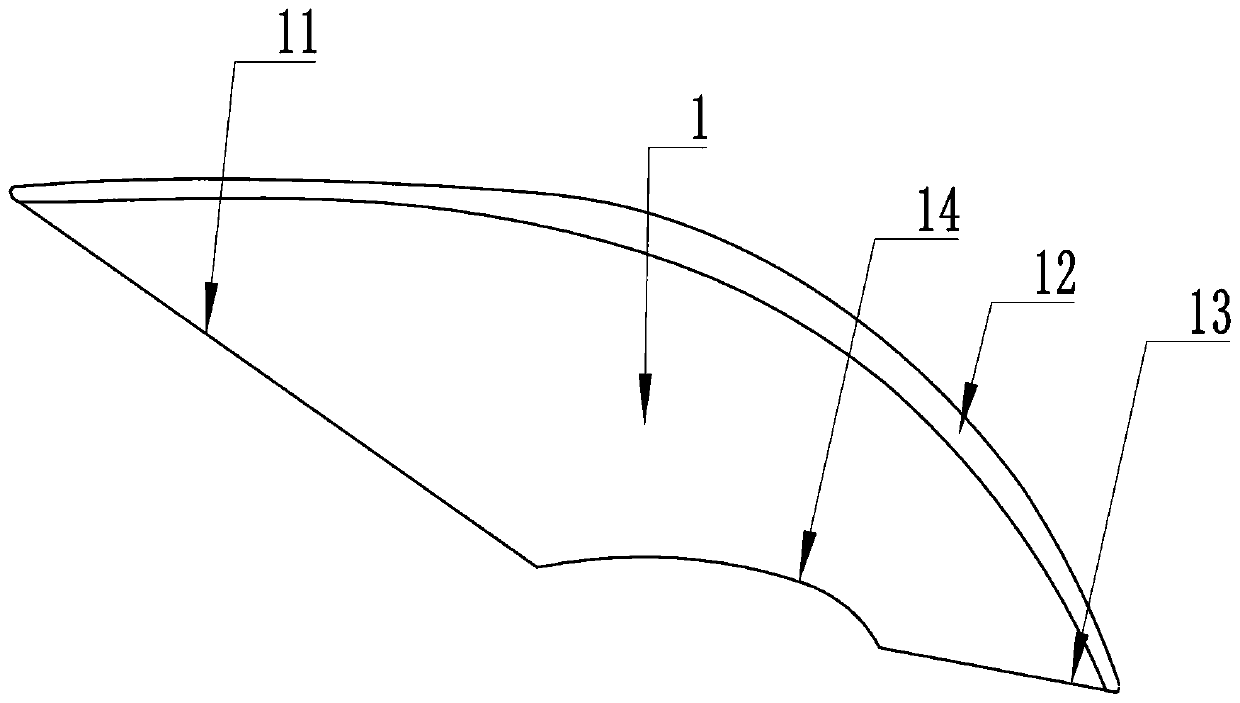

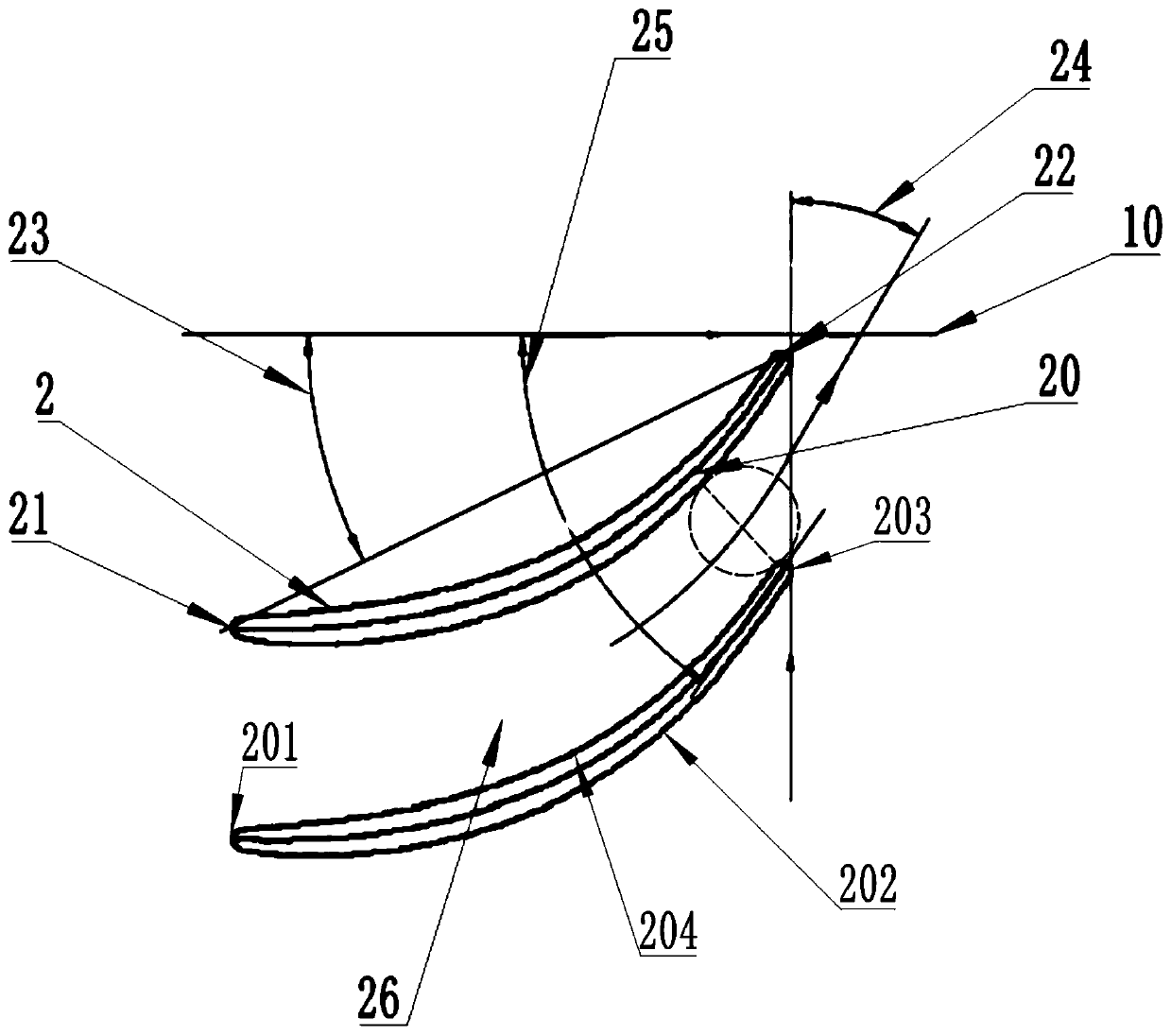

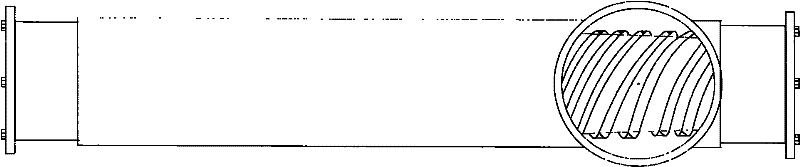

Swirl blade, swirl fan, swirl pipeline and preparing method of swirl pipeline

PendingCN109827459AGuaranteed normal rotationGuaranteed to move forwardHeat transfer modificationFront edgeCurve line

The invention discloses a swirl blade. The swirl blade comprises a front edge, a back arc, a tail edge and an inner arc which are connected end to end in sequence, the swirl blade rotates around the rotating axis, the projection of the swirl blade on the cylinder face coaxial with the rotating axis forms a blade molded line, the blade molded line is a closed curve line, the crossed point of the middle arc line of the blade molded line and the front edge line is the front edge point, the crossed point of the middle arc line of the blade molded line and the tail edge line is the tail edge point,the included angle between the connection line of the front edge point and the tail edge point and the rotating axis is the blade mounting angle, when the radius of the cylinder face is gradually increased, the blade mounting angle is gradually increased, and meanwhile, the outlet airflow angle is gradually reduced; according to the swirl blade, in the radial direction, the blade mounting angle is gradually increased, the outlet airflow angle is gradually reduced, it can be ensured that after fluid flows through the swirl blade, the fluid carries out spiral motion in the circumferential direction at the higher speed, and pressure energy is converted into tangent and axial kinetic energy of fluid to the maximum degree.

Owner:GUANGDONG SUOTE ENERGY TECH CO LTD +1

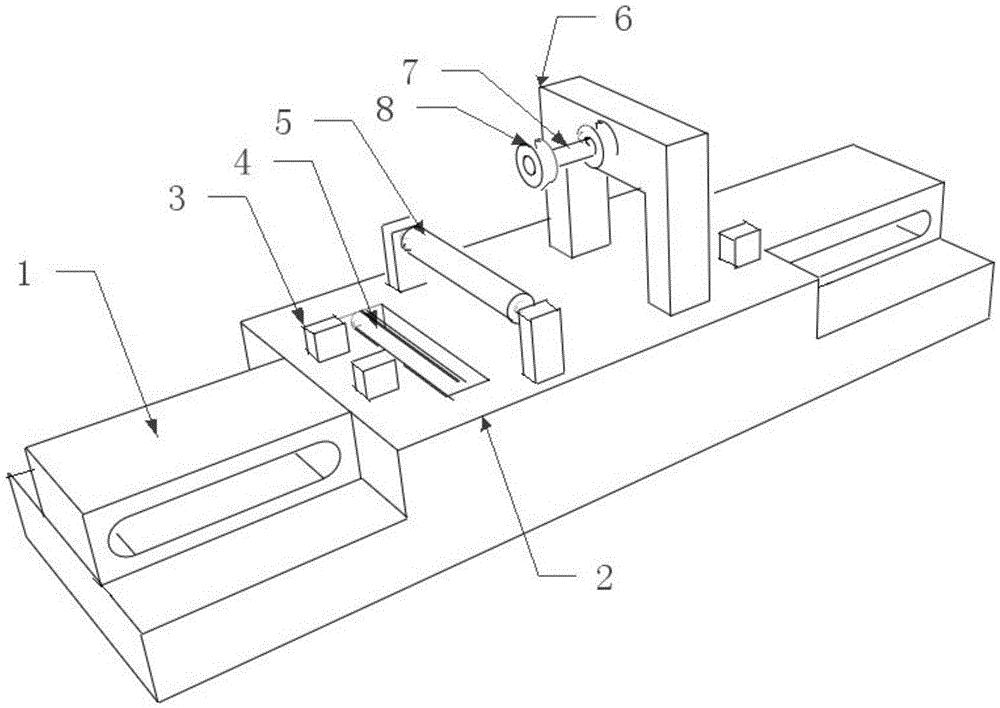

Automobile pipe cutting device

PendingCN109332805AGuaranteed to move forwardShorten the timeMetal sawing devicesEngineeringMachining

The invention relates to the field of automobile pipe machining devices, in particular to an automobile pipe cutting device. The automobile pipe cutting device comprises a base, a lifting structure, afixing structure, a sawing structure, a first feeding structure, a second feeding structure and a guiding structure; and the first feeding structure is arranged at the top end of the base. Through work of the first feeding structure, an automobile pipe rolling into the first feeding structure can be automatically conveyed to the right bottom end of the sawing structure, manual pushing is not needed, the time and labor are saved, continuous sawing can be achieved, and the work efficiency is improved; through the guiding effect of the guiding structure, it can be ensured that the pipe moves forward normally, and the jamming phenomenon can be avoided; and the second feeding structure is arranged at one end of the first feeding structure, through arrangement of the second feeding structure, the pipe can enter the first feeding structure in an automatic rolling-in mode, the time and labor are saved, the work efficiency is improved, and the continuity of sawing work can be achieved.

Owner:邢箫

A cable duct dredging device

ActiveCN107008710BGuaranteed to move forwardSmooth sailingHollow article cleaningEngineeringDrive motor

Owner:JINAN LICHENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Packing machine for machining strip-shaped timbers

InactiveCN106586061AGuaranteed to move forwardEasy to assembleConveyor wrappingPack materialEngineering

The invention discloses a packing machine for machining strip-shaped timbers. The packing machine is characterized by comprising a worktable with a rectangular structure and two conveying devices, wherein the two conveying devices are respectively positioned at a feed end and a discharge end of the worktable; limiting tables for guaranteeing linear movement of the timers are respectively arranged in the connected places of the two conveying devices and the worktable; the worktable is provided with a bracket for mounting a hanging rolling shaft; one end of the hanging rolling shaft is pinned at the top of the bracket; an external thread is arranged at the other end of the hanging rolling shaft, and is connected with a nut for preventing falling of packing materials; the axial direction of the hanging rolling shaft is the same with the feeding direction of the conveying devices; the bracket is provided with a limiting device for preventing the timbers from swinging up and down; and the limiting device includes a lower rolling shaft and an upper rolling shaft. The packing machine has the characteristics of simple structure and low cost.

Owner:TIANJIN YONGXIN LEADING TECH

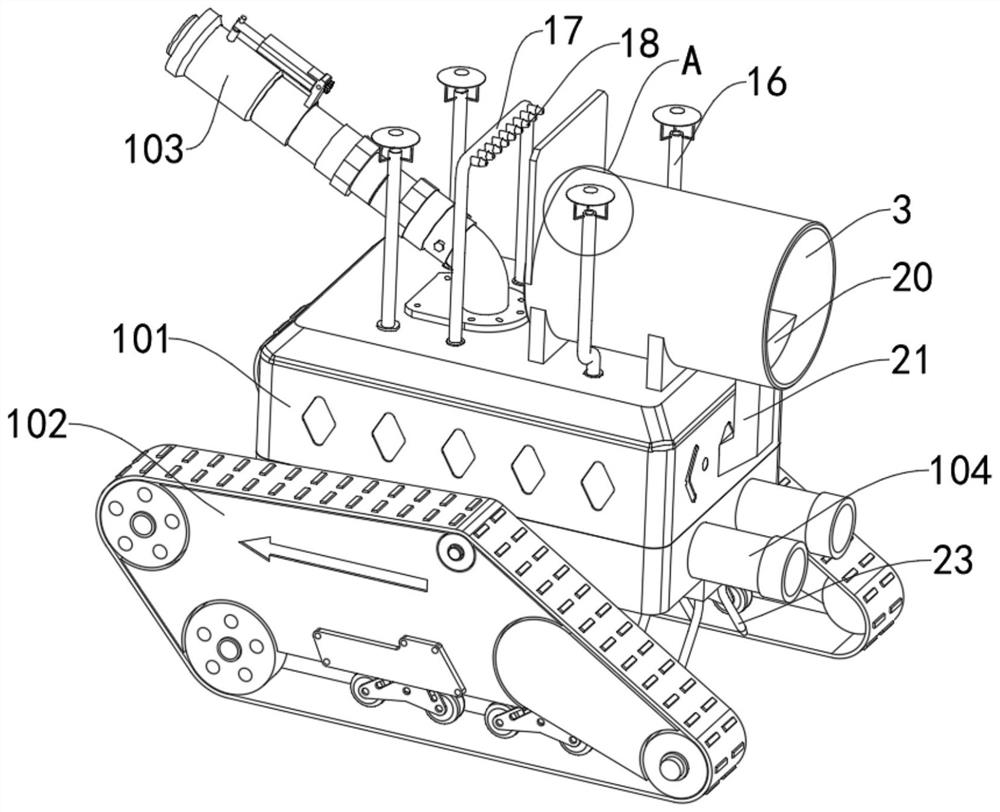

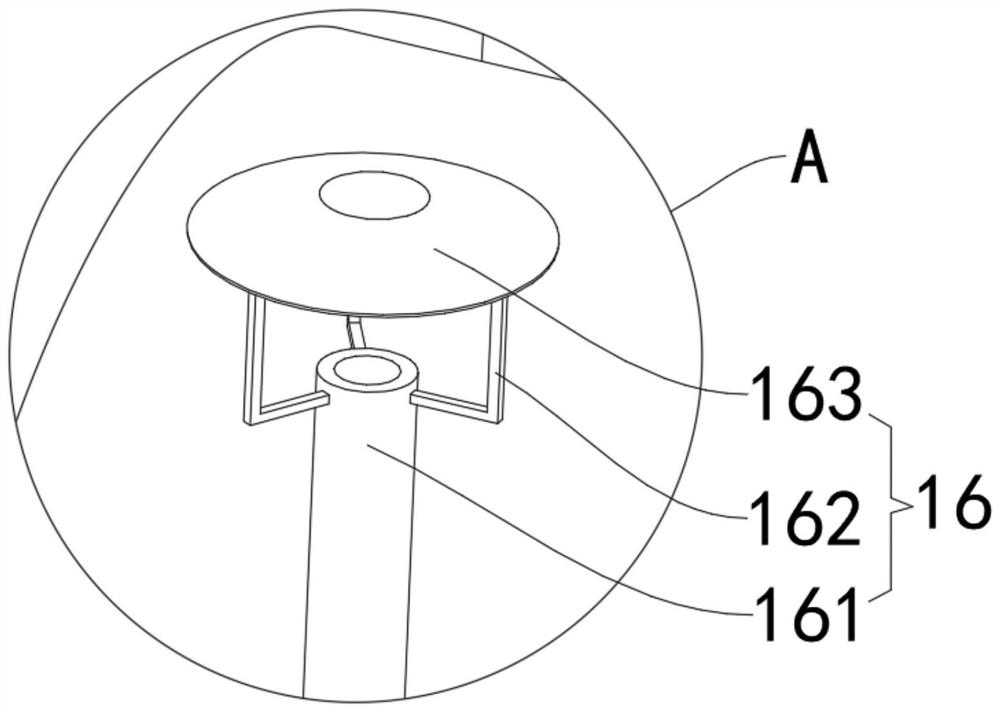

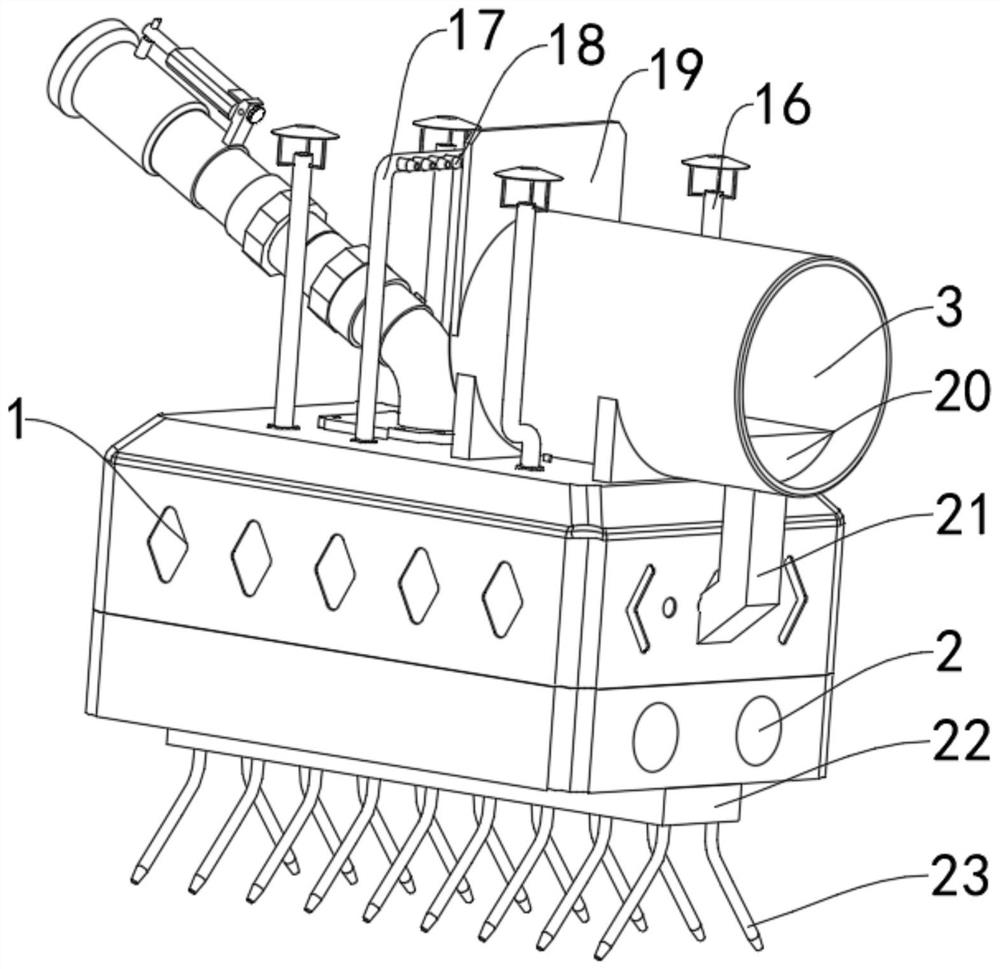

Composite multifunctional intelligent fire-fighting robot

ActiveCN114470580AIncrease the smoke exhaust timeReduce loadDrying gas arrangementsFire rescueElectrical batteryDrive shaft

The composite multifunctional intelligent fire-fighting robot comprises a fire-fighting robot body, a water flowing cavity is formed in the middle of the fire-fighting robot body, an air duct is fixedly installed at the top end of the fire-fighting robot body, and a first fixing frame is fixedly installed in an inner cavity of the air duct; a connecting shaft is movably connected to the middle of the first fixing frame, fan blades are fixedly installed in the middle of the connecting shaft, and a transmission device is arranged at the left end of the connecting shaft. The turbine can be driven to rotate through flowing of water, so that the extending shaft is driven to rotate to output power, the power is transmitted to the transmission shaft through the steering assembly, the connecting shaft is driven to rotate, the fan blades suck external air into the air duct, and in the using process, the air duct does not need to be driven by electric power to conduct smoke exhaust operation; therefore, the load of a battery in the device is reduced, the smoke exhaust time of the air duct is prolonged, and the service life of the device is prolonged.

Owner:广东广新信息产业股份有限公司 +1

Packing machine of novel structure

The invention discloses a packing machine of a novel structure. The packing machine comprises a working table of a rectangular structure and two conveying devices. The two conveying devices are located at the feed end and the discharge end of the working table correspondingly. Limiting platforms for guaranteeing that timbers move along the straight line are arranged at the joints between the two conveying devices and the working table correspondingly. A rollway support for mounting a material hanging rolling shaft is arranged on the working table. A circular through hole for guaranteeing passing of timbers is formed in the rollway support. A track is mounted on the periphery of the circular through hole. One end of the material hanging rolling shaft is in pin connection with a fixed base. A rolling wheel connected with the track is mounted on the fixed base. The other end of the material hanging rolling shaft is provided with an external thread. A nut for preventing a packing material from falling off is connected to the external thread. The axial direction of the material hanging rolling shaft is the same as the feeding direction of the conveying devices. A limiting device for preventing timbers from swinging up and down is arranged on the rollway support. The limiting device comprises an upper rolling shaft and a lower rolling shaft. Through the technical scheme, the packing machine of the novel structure has the characteristics of being simple in structure and low in cost.

Owner:TIANJIN YONGXIN LEADING TECH

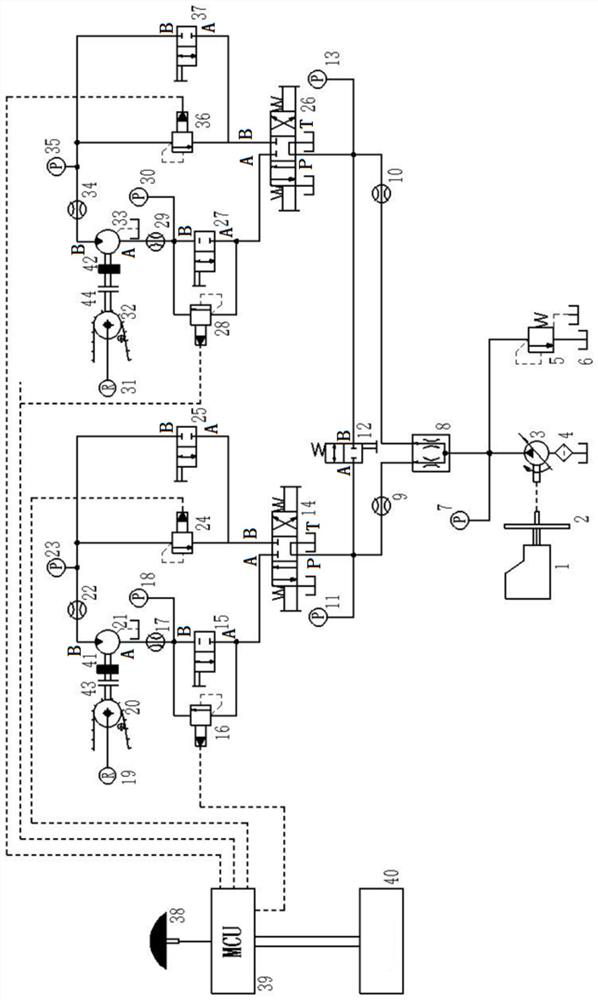

Crawler chassis testing system and testing method

ActiveCN112253577AGuaranteed to move forwardEasy to testFluid-pressure actuator testingFluid-pressure actuator componentsClutchDrive motor

The invention discloses a crawler chassis testing system and a testing method. An engine is connected with a variable pump through a connecting device; an oil outlet of the variable pump is connectedwith an oil tank through an overflow valve and is connected with oil inlets of manual reversing valves A and B through diverter valves; a port A of the manual reversing valve A is connected with a port A of a left side driving motor through a parallel branch path of a manual reversing valve C and a proportional overflow valve A, and a port B of the left side driving motor is connected with a portB of the manual reversing valve A through a parallel branch path of a proportional overflow valve B and a manual reversing valve D; a port A of the manual reversing valve B is connected with a port Aof a right driving motor through a parallel branch path of a manual reversing valve E and a proportional overflow valve C, and a port B of the right driving motor is connected with a port B of the manual reversing valve B through a parallel branch path of a proportional overflow valve D and a manual reversing valve F; and the left driving motor and the right driving motor are in drive connection with a left crawler belt and a right crawler belt through a left clutch and a right clutch correspondingly. According to the system and the method, the performance of the crawler chassis can be reliably tested.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Ultra-low-speed crawling method for driverless cars under mixed road congestion

ActiveCN113306552BEnsure safe passageGuaranteed to move forwardExternal condition input parametersLow speedPedestrian

The invention belongs to the technical field of unmanned vehicles, and in particular relates to an ultra-low-speed crawling method of unmanned vehicles under mixed road congestion conditions. The specific technical scheme is: analyze the action trajectories of pedestrians and non-motorized vehicles within the range M around the vehicle pre-envelopment area, according to the distance between the front end of the vehicle and pedestrians and non-motorized vehicles, whether the pre-action trajectories of pedestrians and non-motorized vehicles deviate from the vehicle pre-envelope The driving trajectory, whether the pedestrian sees the vehicle, instructs the vehicle to stop and wait, slow down or drive at the same speed; this method comprehensively considers a variety of factors, which can not only ensure the safe passage of pedestrians and non-motor vehicles, but also ensure that the vehicle keeps moving forward. It avoids that vehicles are often unable to continue driving due to the principle of pedestrian safety, and greatly alleviates traffic jams when there is a large flow of people on mixed roads.

Owner:成都格林希尔德交通科技有限公司

Medium charter

ActiveCN104129527BAccurate and timely fall resetReduce consumptionConveyorsPackaging machinesEngineeringMaterials processing

The invention discloses a middle bale machine, which comprises a material sorting device, a bag pushing conveyor belt, a bag pushing device, a suction bag opening device and a bag feeding device, the material sorting device is connected with the bag pushing conveyor belt, and the bag pushing conveyor belt is connected with the bag pushing device. The device is connected, the bag pushing conveyor belt is connected with the suction bag opening device, the suction bag opening device is connected with the bag feeding device, and the bag pushing device is arranged on one side of the bag pushing conveyor belt. The invention overcomes the technical problems in the prior art that the height of the bag pushing device is too high, it is inconvenient to inspect and maintain, and there are potential safety hazards. Hidden danger.

Owner:上海松川峰冠包装自动化有限公司

Marine paddle thrusters

ActiveCN105216997BGuaranteed to move forwardIncrease working areaPropulsive elements of rotary typeMarine propulsionEngineering

The invention discloses a marine paddle type propeller device. The marine paddle type propeller device comprises two layers of parallel supports, chain wheels, chains, a power device and a propelling force control mechanism (further comprises a plurality of propelling mechanisms and two propelling direction control devices). Each propelling mechanism comprises a blade, a blade rotating shaft, two bearings and a set of blade limiting wheels, wherein the two bearings are fixed to all the layers of chains respectively, the blade is fixed to the blade rotating shaft, the blade limiting wheels are fixed to the blade rotating shaft through connecting rods, and the blade limiting wheels are located on the two sides of the blade respectively. The propelling direction control device comprises two parallel linear limiting chutes, and the blade limiting wheels slide in the motion direction of the chains with one linear limiting chute serving as a rail. The problems that an existing marine propeller is low in paddling efficiency and high in energy consumption cost can be solved through the marine paddle type propeller device.

Owner:倪忠

A kind of off-road pallet truck device

ActiveCN108045460BGuaranteed to move forwardAvoid leaningSpecial tyresLoad securingHydraulic cylinderFriction loss

The invention provides an off-road tray vehicle device and belongs to the field of cargos conveying equipment. The two ends of a rear axle of a tray vehicle are fixed to off-road tires, the position under the left end of the front side of a vehicle hopper is connected with a first hydraulic cylinder, and the two ends of a front axle of the tray vehicle are connected with outer tire bodies of the off-road tires. A traction hook is mounted on the middle portion of the front side of the vehicle hopper, the first hydraulic cylinder is mounted under the left end of the front side of the vehicle hopper, and the front axle of the ray vehicle is mounted on a base of the first hydraulic cylinder. First supports are inlaid in inner tire bodies of the off-road tires, and the inner tire bodies of theoff-road tires are mounted in the outer tire bodies of the off-road tires. Through movable connection of fixing screws inlaid in the tires and fixing inserting holes, during travelling on a muddy roadsurface, the inner tire bodies of the off-road tires are taken out from the outer tire bodies of the off-road tires by adjusting the fixing screws so that the off-road tires cannot be sunken under the road surface, and normal advancing of the tray vehicle is ensured; and during travelling on a smooth road surface, the inner tire bodies of the off-road tires are stored in the outer tires of the off-road tires, so that the friction loss of the tires is reduced, the ground friction resistance is reduced, and the conveying efficiency of the device is improved.

Owner:管家依

High concentration paper pulp grinding method and device

ActiveCN101838947BControl coincidenceIncrease bite forcePulp beating/refining methodsHigh concentrationFiber

The invention relates to a high concentration paper pulp grinding method and device. The method symmetrically combines the conical roller with threads with the corresponding grinding sleeve with threads. The interfaces of the conical roller and the grinding sleeve move relatively to transport, extrude, knead, cut and fibrillate high concentration paper pulp and consequently complete the paper pulp fiber pulping. The invention can reduce energy consumption and water consumption and improve fiber fibrillation rate and internal fibrillation furthest without reducing the water filtration performance of the paper pulp. Consequently, the invention has the advantages of strong papermaking strength, high air permeability and light and firm paper characteristic.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

Post-tensioning prestress hole cleaning and reeving device and method

InactiveCN103726664AAvoid damageGuarantee the construction qualityBuilding material handlingPre stressPrism

The invention discloses a post-tensioning prestress hole cleaning and reeving device and method, and belongs to the technical field of engineering construction facilities. The device is characterized in that one end of a connecting rod is in a shape of a four-edge tetragonal prism, and the other end is hollow and cylindrical; the end of tetragonal prism is tightly connected with a power device in an inserted manner, and the hollow and cylindrical end is tightly connected with a cable type drilling rod in an inserted manner; the cable type drilling rod is a low-relaxation unbonded prestressed steel strand with strength and toughness; the drill bit is in a semi-hollow cylindrical structure and is tightly connected with the cable type drilling rod in an inserted manner, the non-hollow end is cylindrical, and outer diameter of the cylindrical end is larger than that of the hollow end. The device has the advantages that destroys on an existing structure are reduced to the utmost extent, and construction quality of post-tensioning prestress can be guaranteed effectively; the reeving method is time saving and force saving; reeving quality can be guaranteed easily; application range is wide, and construction cost is low; structure is simple and operation is facilitated; the device is simple in structure and convenient to operate, and ordinary workers can operate the device to perform construction after simple training.

Owner:CHINA RAILWAY 13TH BUREAU GRP 6TH ENG COMPANY

A cable pulling device

ActiveCN109888675BReduce deflectionGuaranteed to move forwardApparatus for laying cablesSteering wheelGear wheel

The invention discloses a cable traction device, and relates to the field of a cable laying device. The cable traction device comprises a base, wherein a straight wheel and a steering wheel are arranged below the base, a steering shaft is inserted onto the base, a winding roller is rotatably connected with the base, a first positioning sheet and a second positioning sheet are fixedly connected with a top end of the steering shaft, a positioning wire is arranged between the first positioning sheet and the second positioning sheet, the first positioning sheet comprises a first insulation sheet,the first insulation sheet is fixedly connected with a first conductive sheet and is fixedly connected with a second conductive sheet, the second positioning sheet comprises a second insulation sheet,the second insulation sheet is fixedly connected with a third conductive sheet and is fixedly connected with the fourth conductive sheet, a driven gear is fixedly connected with the steering shaft, afirst gear and a second gear are engaged with the driven gear, a power supply is arranged on the base, a sliding block is connected with the base in a sliding way, a support is arranged on the sliding block, a connection sheet is fixedly connected with the sliding block, a groove is formed in a top end of the support, a rotation shaft is arranged on the winding roller in a penetrating way, and aguide rod is fixedly connected with the groove. Linear cable laying is convenient.

Owner:金华八达集团有限公司 +1

Pesticide spraying device

ActiveCN114287413AWide range of sprayingReasonable structure layoutInsect catchers and killersPesticideVehicle frame

The invention discloses a pesticide spraying device which comprises a frame, the frame comprises a front section, a middle section and a rear section, a driven wheel assembly is arranged at the bottom of the front section of the frame, a spraying box is arranged on the middle section of the frame, a spraying mechanism is arranged at the top of the front section of the frame, and a nozzle of the spraying box is arranged on the spraying mechanism. A driving mechanism is arranged at the bottom of the rear section of the frame, and a handrail is arranged on the rear section of the frame and arranged at the rear end of the driving mechanism. The driving mechanism can ensure that the whole spraying device runs uniformly, can ensure that the amount of pesticide sprayed to crops in different areas is consistent, and can ensure that the spraying range is expanded through the spraying mechanism, so that the spraying working efficiency is improved.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

A driving device for a medium-package machine

ActiveCN104071401BAccurate and timely fall resetReduce consumptionPackaging machinesEngineeringDrive motor

The invention discloses a medium package machine driving device which comprises a driving motor and a camshaft. The camshaft is connected to the driving motor. The driving device further comprises package pushing cams, a first package pushing swing arm, a package pushing connecting rod, a second package pushing swing arm, a third package pushing swing arm, a fourth package pushing swing arm, a fifth package pushing swing arm, a roller, a pressing board, a belt absorbing cam, a first bag absorbing swing arm, a bag absorbing connecting rod, a second bag absorbing swing arm, an open claw cam, an open claw swing arm and an open claw connecting rod. Lifting and falling motion of a pushing rod of a medium package machine, forward and backward motion of an open claw component and lifting and falling motion of a bag absorbing rod are all driven through the cams and achieved through one driving motor, a whole driving mechanism is stable and reliable, and debugging is simple and easy.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com