Patents

Literature

45results about How to "Guaranteed steering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

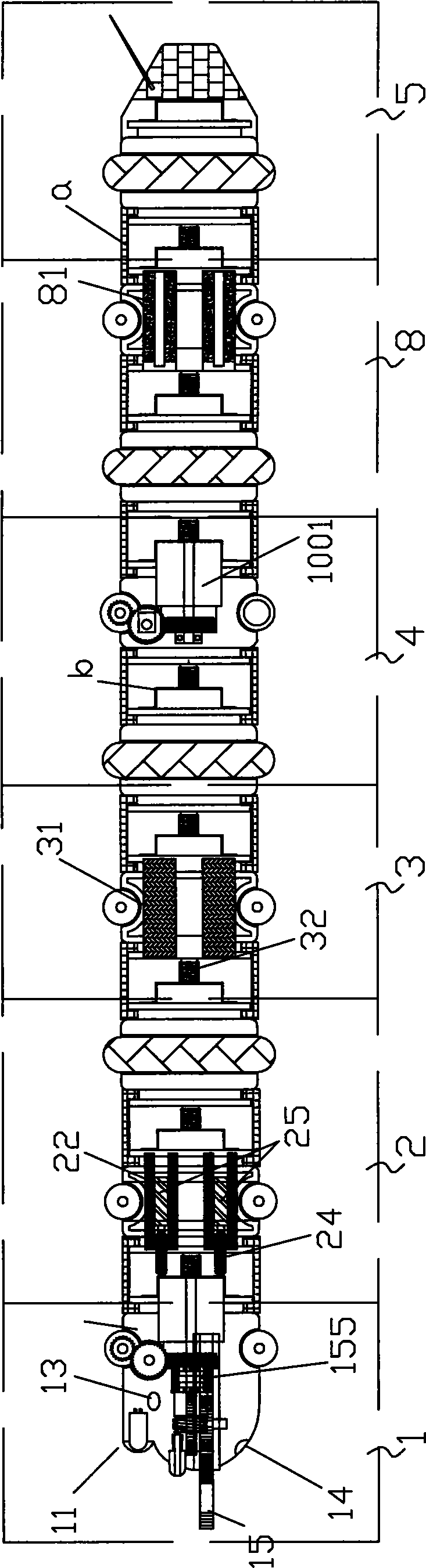

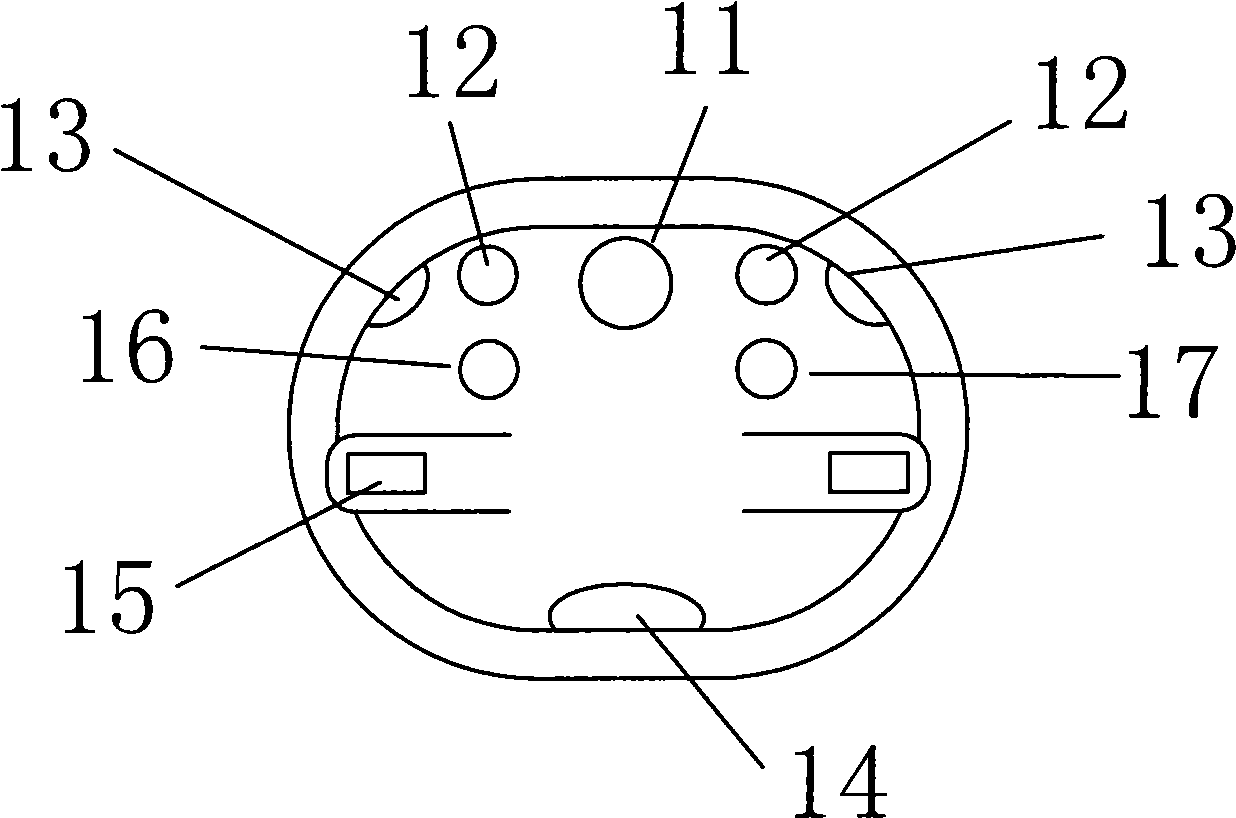

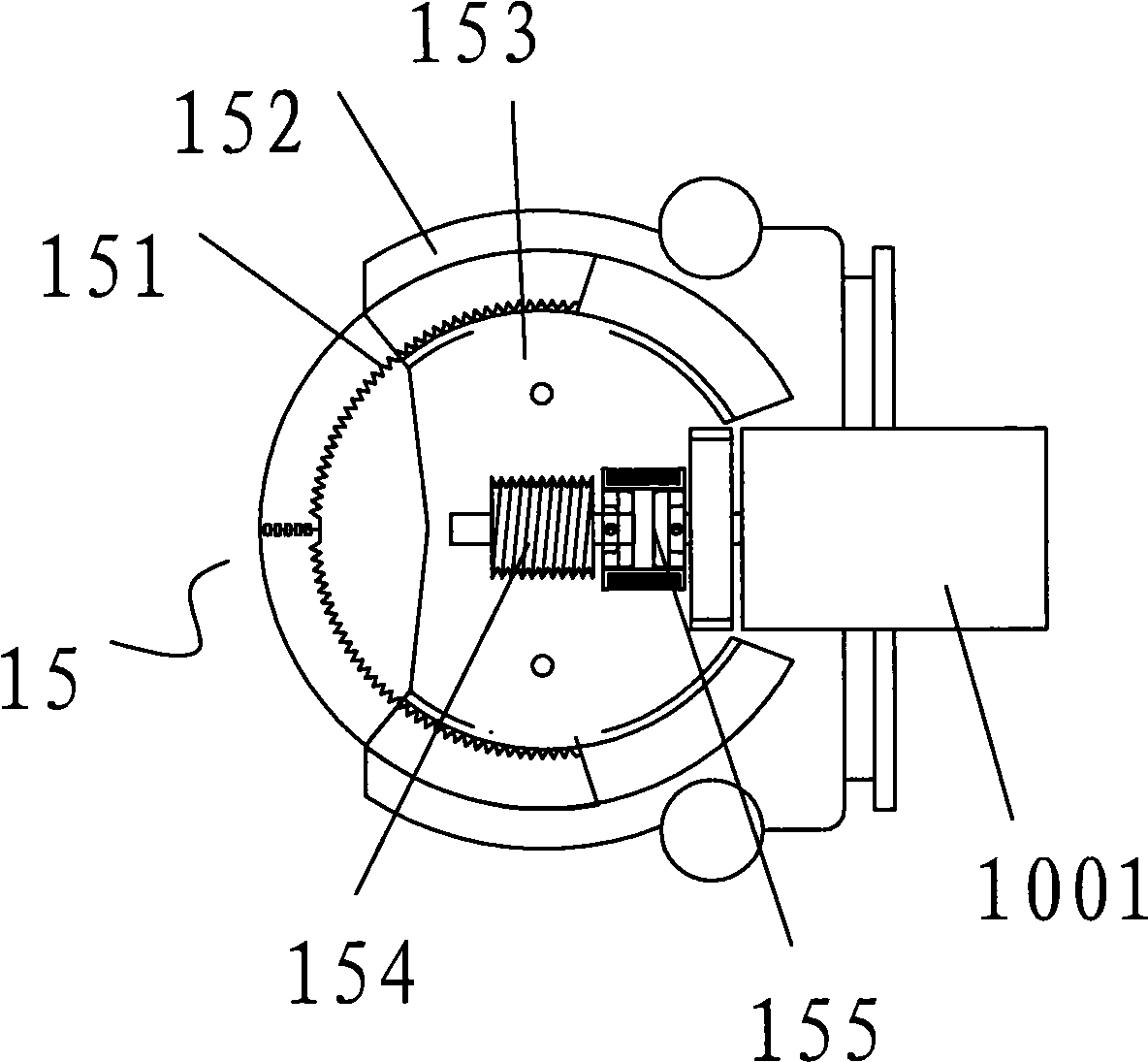

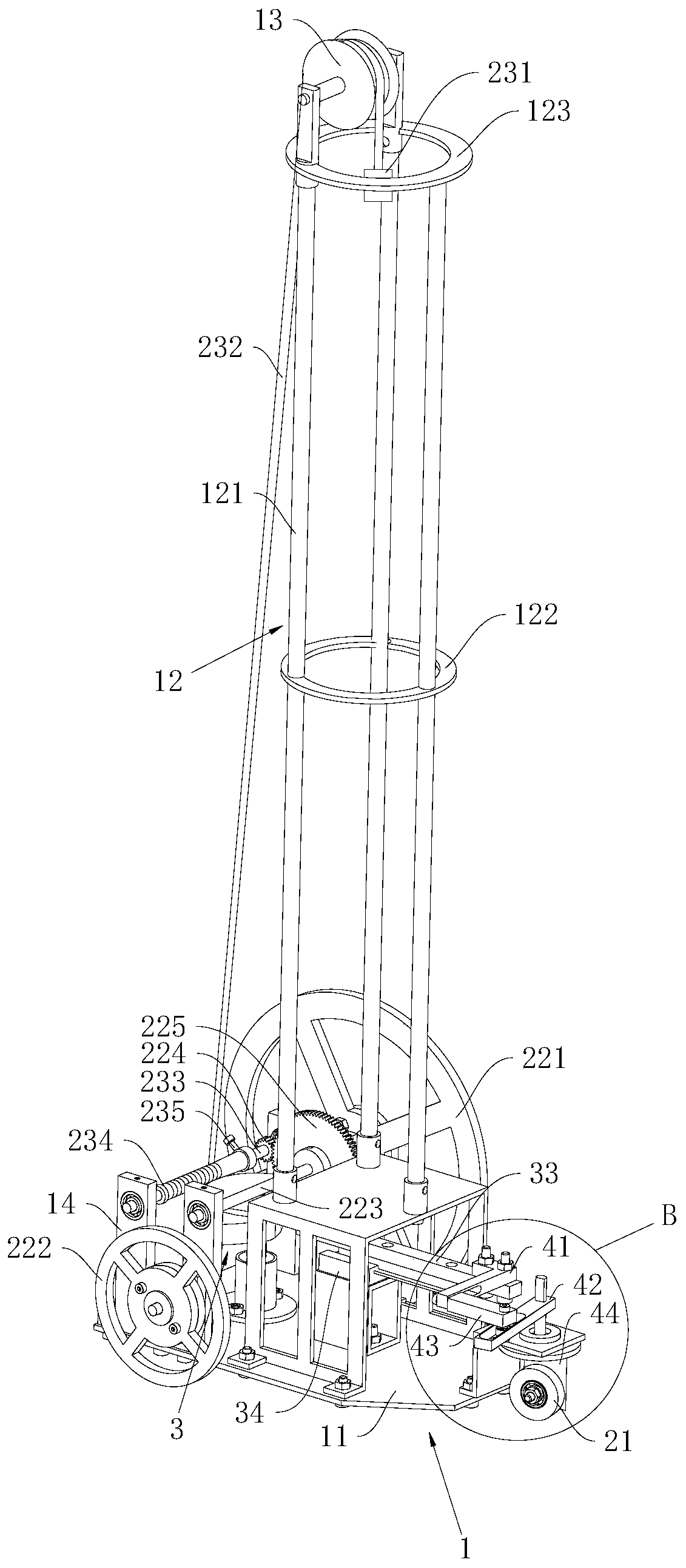

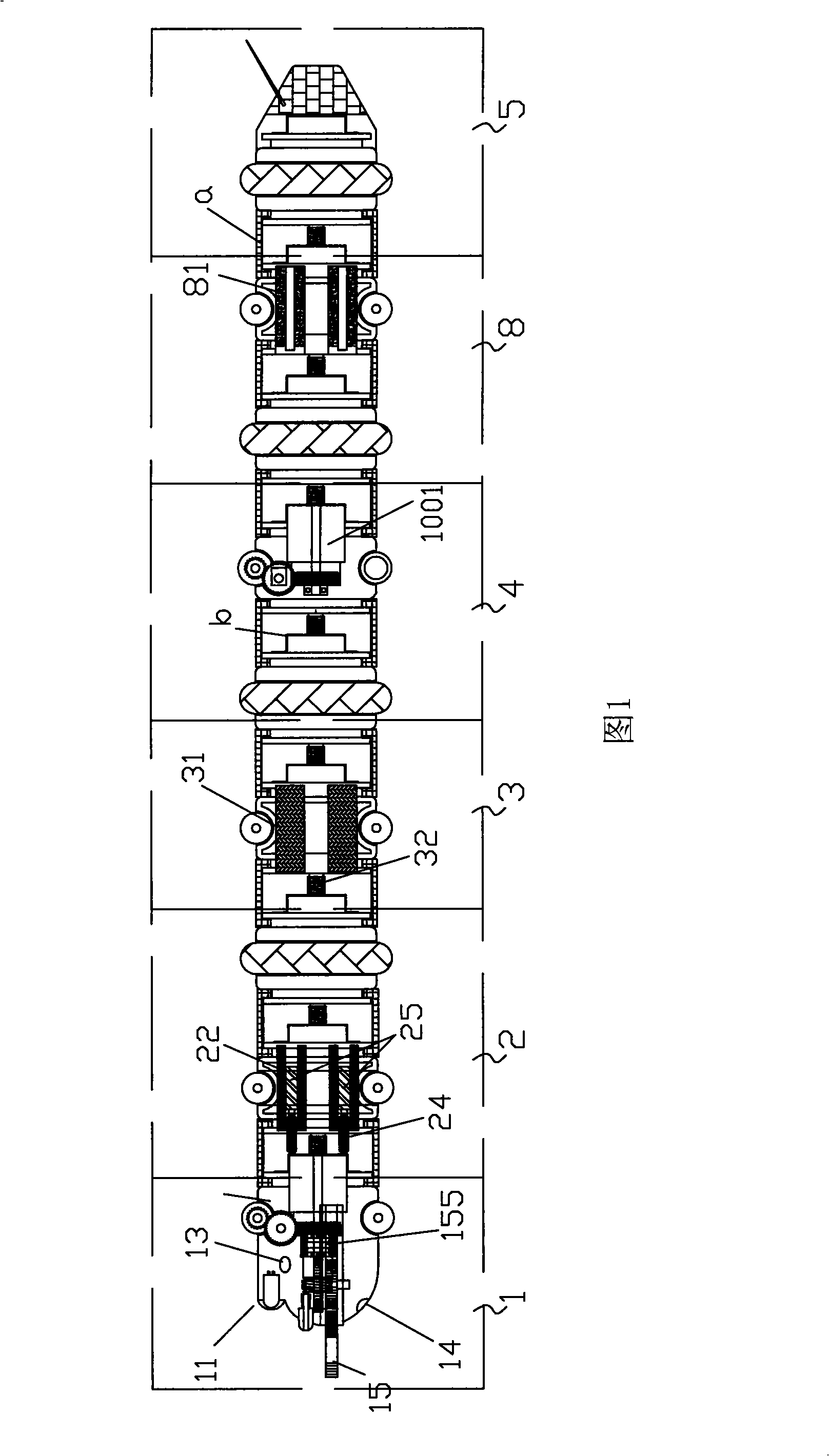

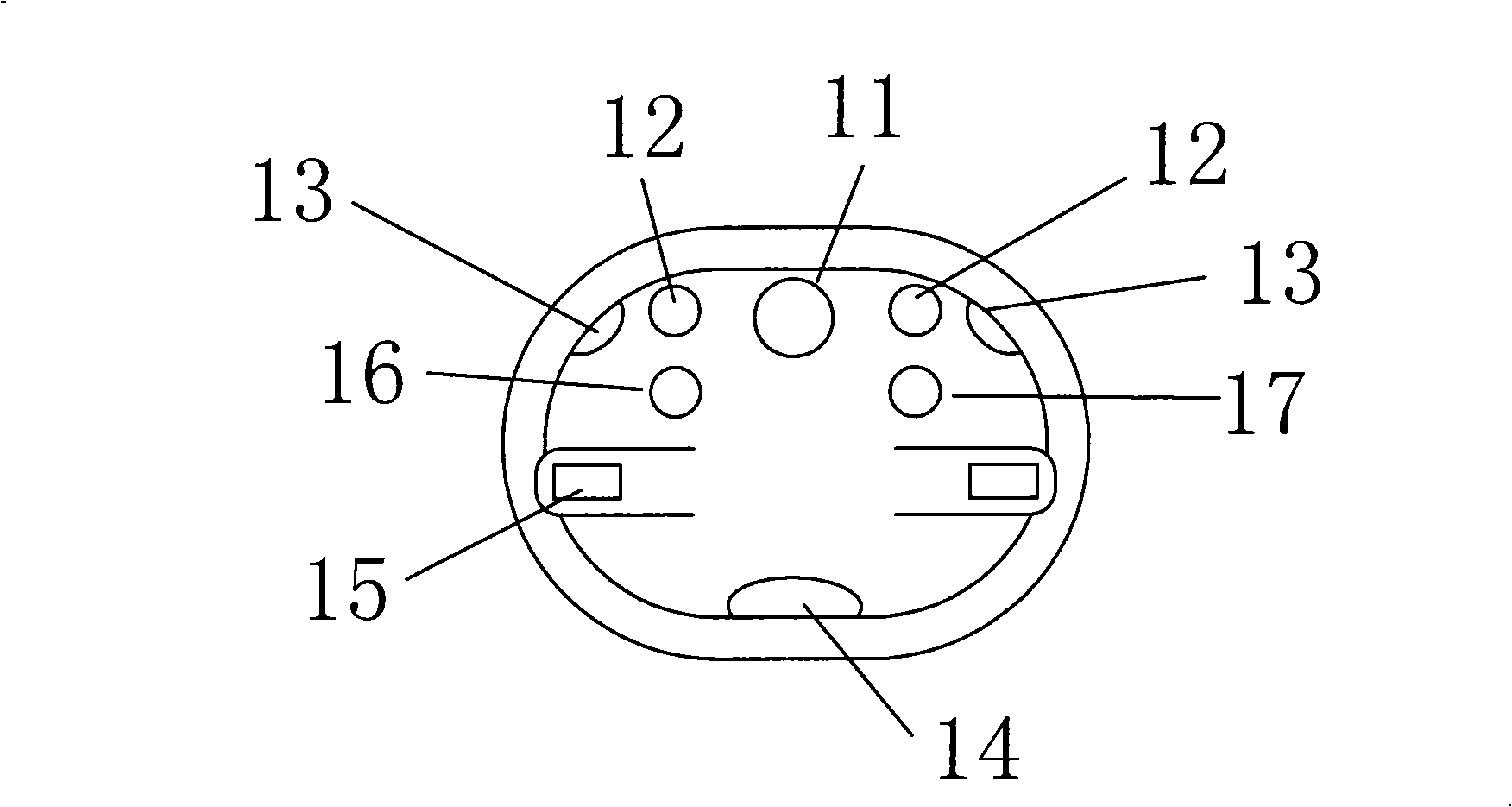

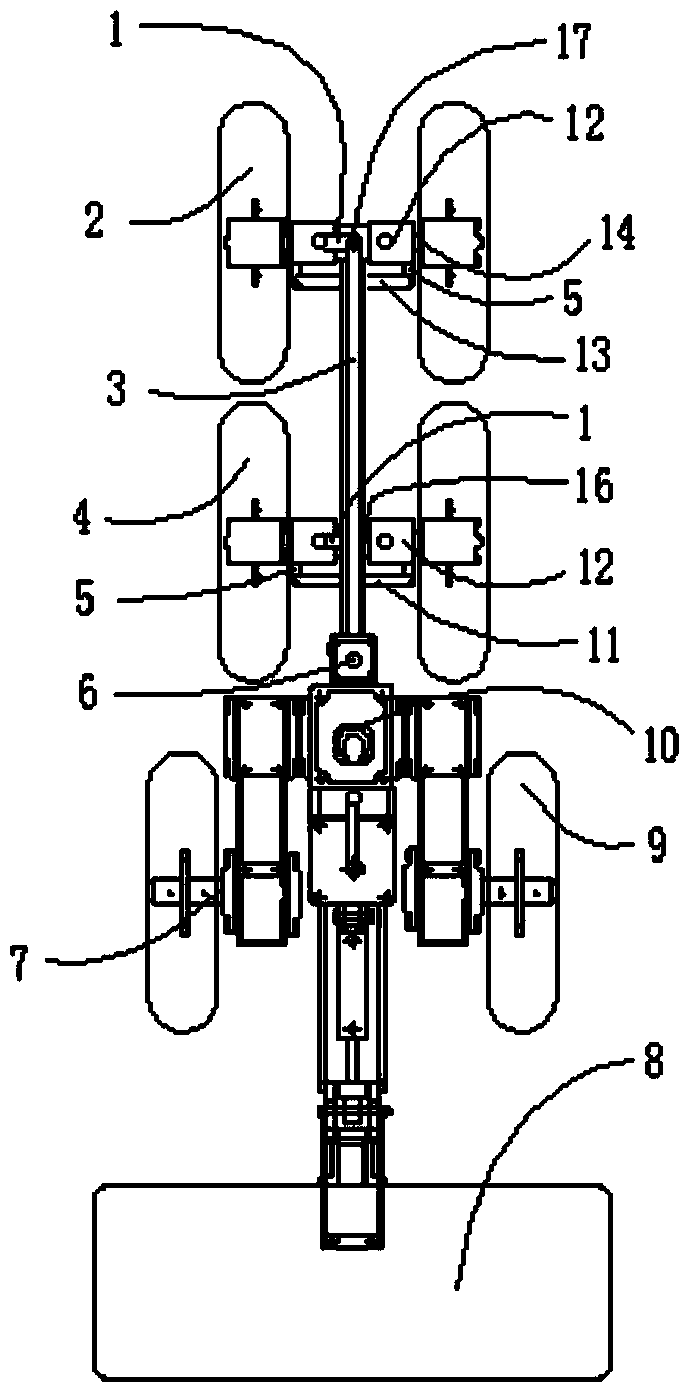

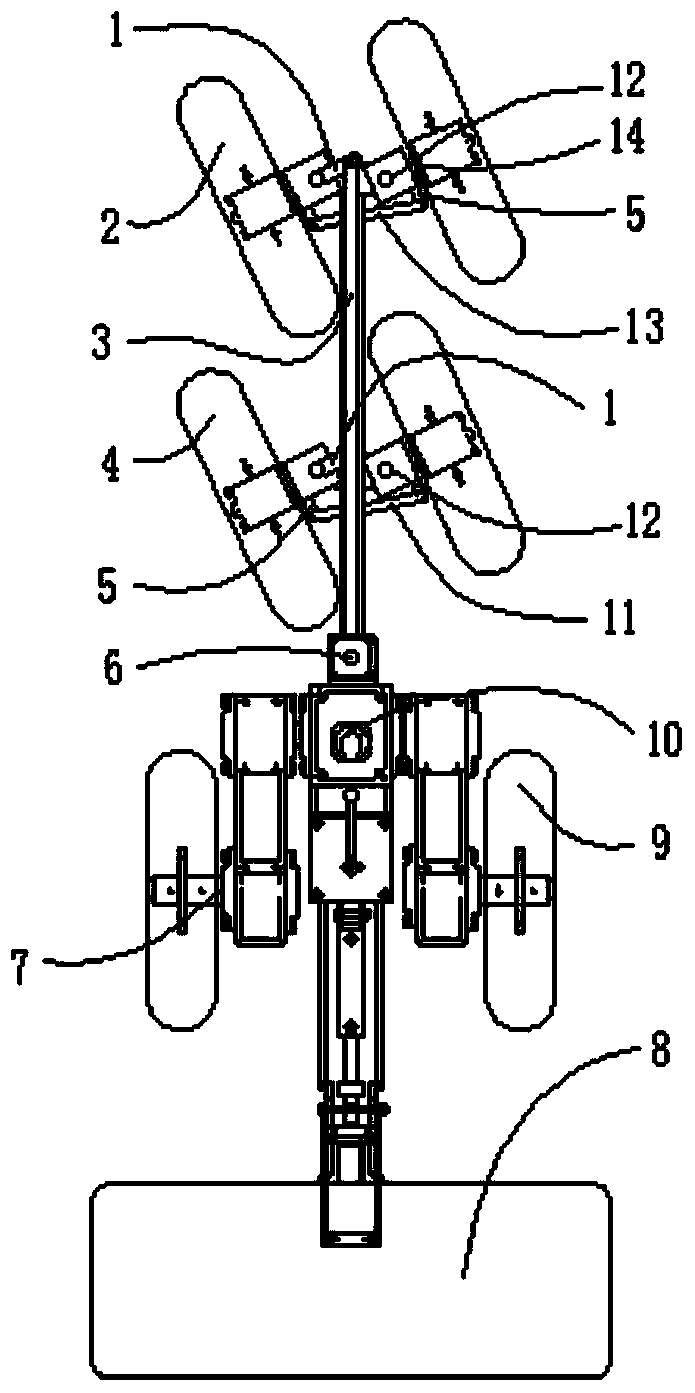

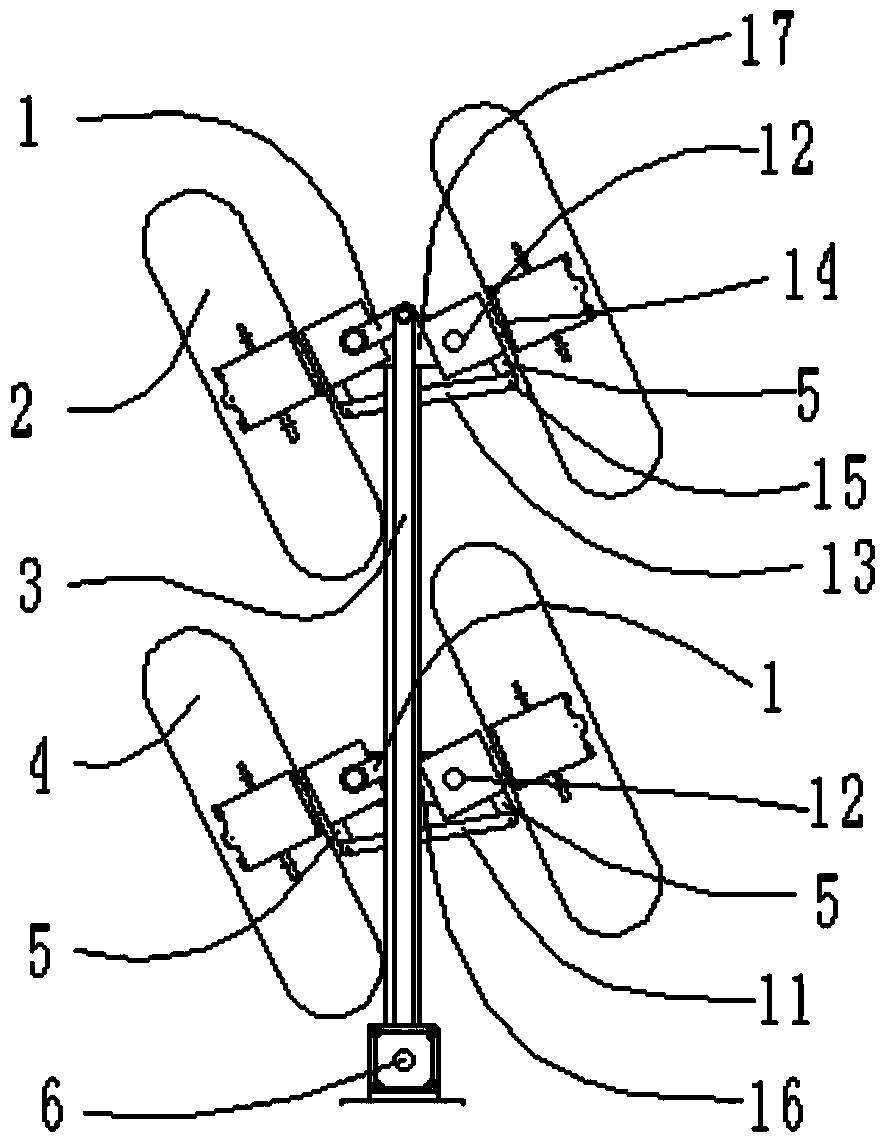

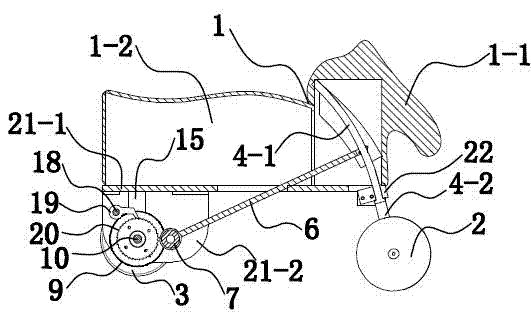

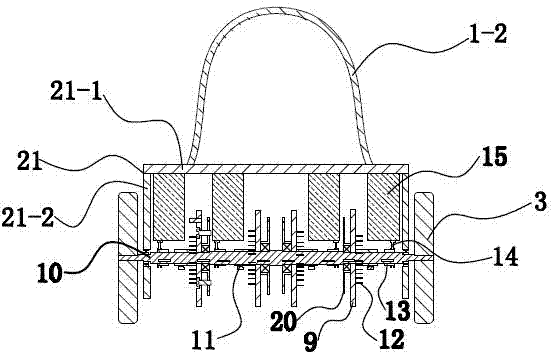

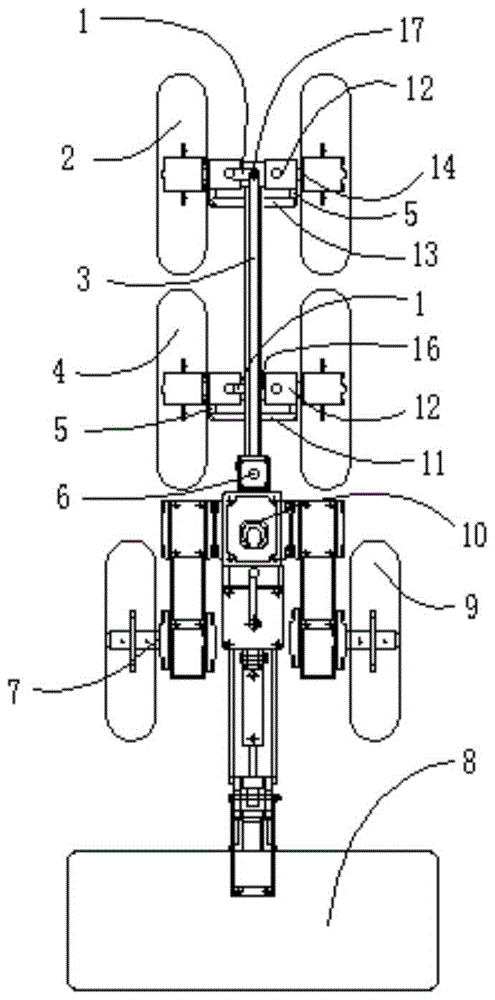

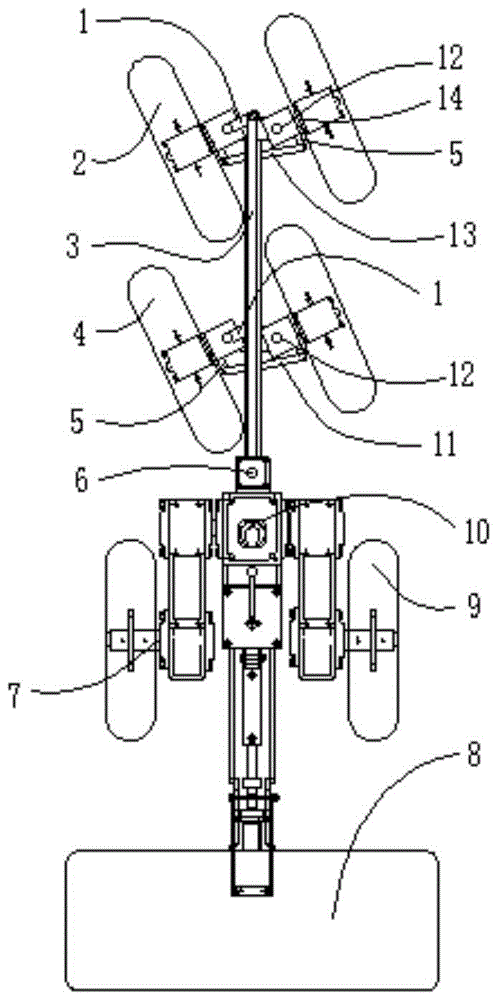

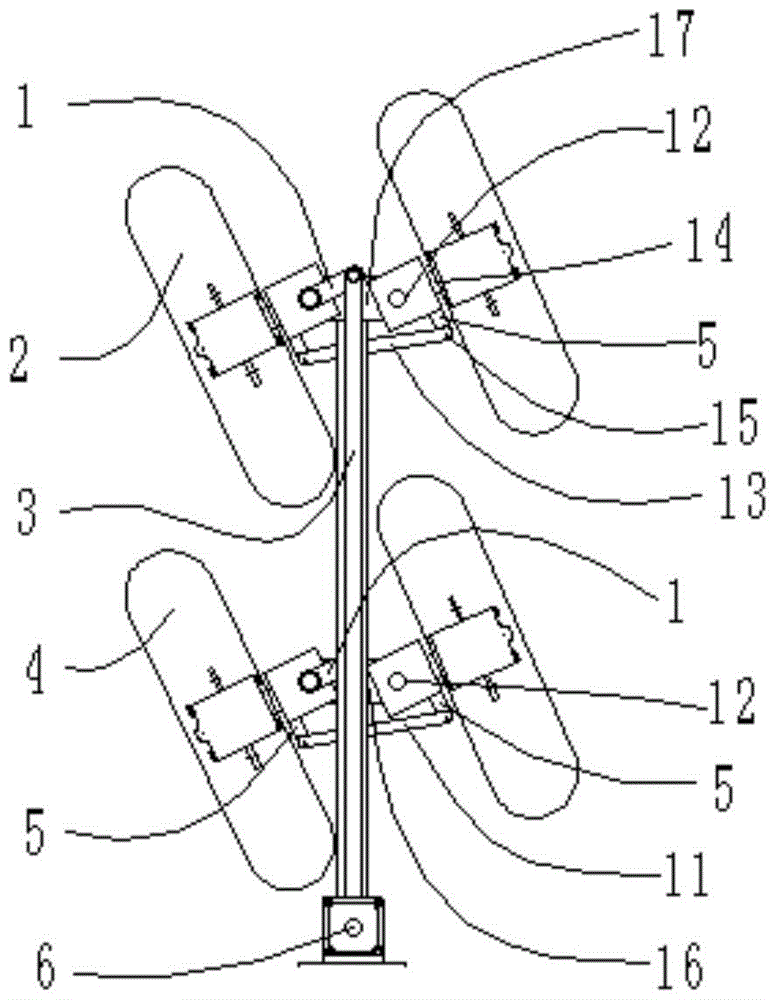

Bionic detection and rescue system

InactiveCN101543666AGuaranteed to move forwardGuaranteed to go backwardsBreathing protectionElectrical steeringControl powerEngineering

The present invention discloses a bionic detection and rescue system, which comprises a detection and rescue head, a turning power unit, a control power unit, an transmitting / receiving power unit, and several segments of moving units connected serially by springs; wherein, the front-end of the turning power unit is connected with the tail end of the detection and rescue head, the tail end of the turning power unit is connected with the front-end of the control power unit, and the tail end of the control power unit is connected with the front-end of the first moving unit, so that a main body is formed; the transmitting / receiving power unit is mounted on the tail end of the main body. The present invention has high accessibility, can move flexibly, and is easy to operate.

Owner:王彦明

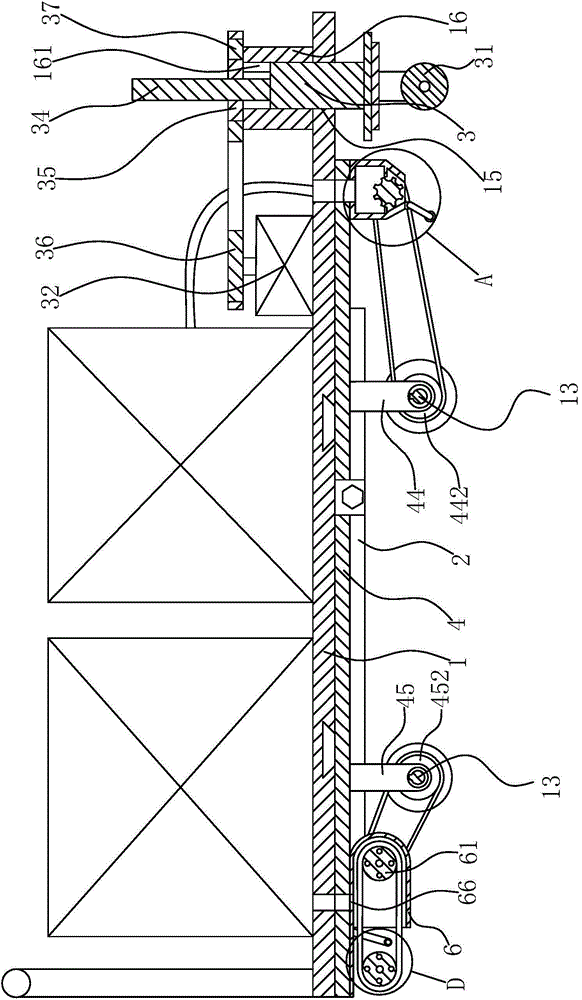

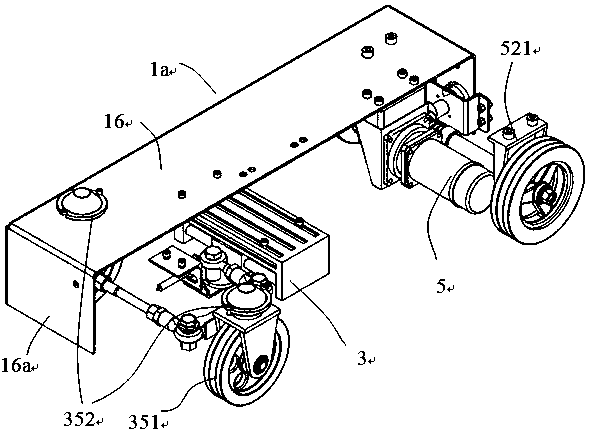

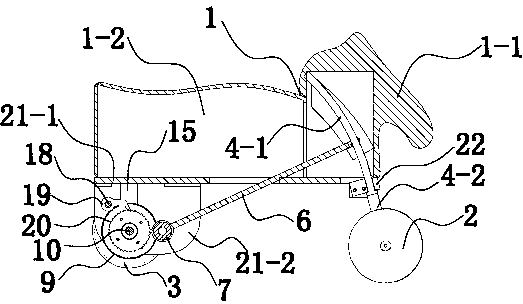

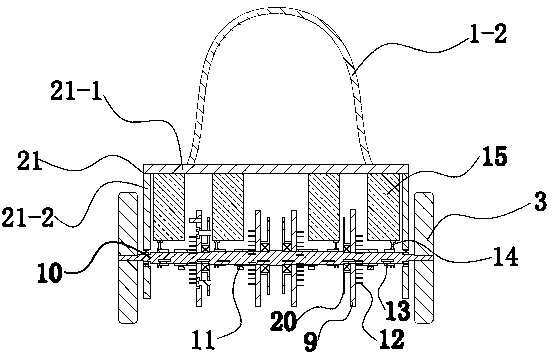

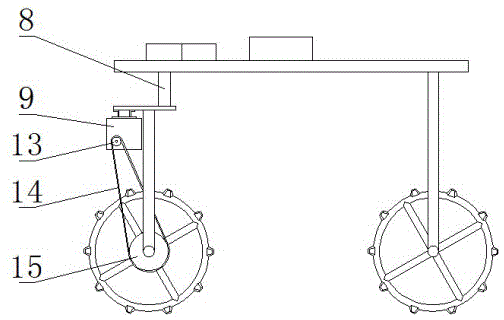

Road line-marking vehicle

InactiveCN104818664AImprove applicabilityGuaranteed to move normallyRoads maintainenceRaw materialAutomotive engineering

The invention provides a road line-marking vehicle, belongs to the technical field of road operation equipment and solves a problem of a poor adaptability of a road marking vehicle in the prior art. The road line-marking vehicle includes a pedestal. A heating barrel and a raw material barrel are fixedly connected to an upper side surface of the pedestal. Two main shafts are rotationally connected to a lower side surface of the pedestal. Two moving rods are slidingly connected to the lower side surface of the pedestal. Each moving rod is hinged to two moving wheels. A moving plate is slidingly connected to the lower side surface of the pedestal. A line-marking box is fixedly connected to a front end of the moving plate. A material discharge outlet is formed in the lower part of the line-marking box. A metering member is arranged in the line-marking box. A bottom shell is fixedly connected to the lower side surface of a back end of the moving plate and is rotatably connected to a front transmission wheel and a back transmission wheel, a transmission net is arranged therebetween in a sleeving manner. A gas spraying tube is fixedly connected to the bottom shell. The road line-marking vehicle is simple in structure, is convenient to use and is strong in adaptability.

Owner:ZHEJIANG OCEAN UNIV

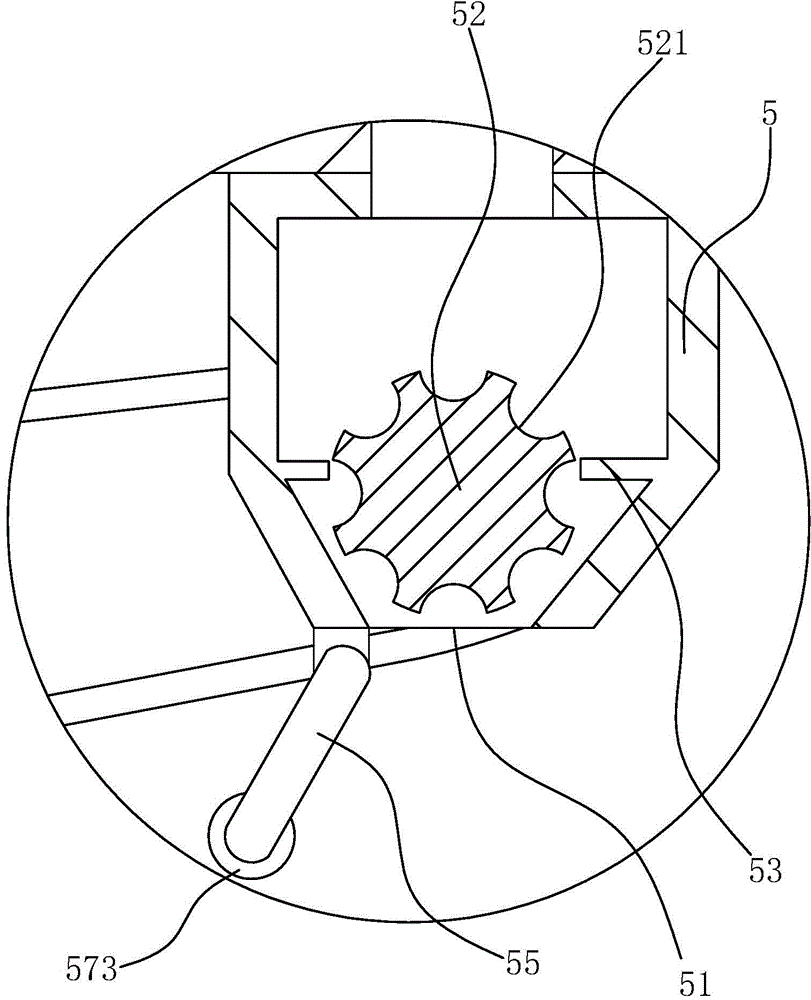

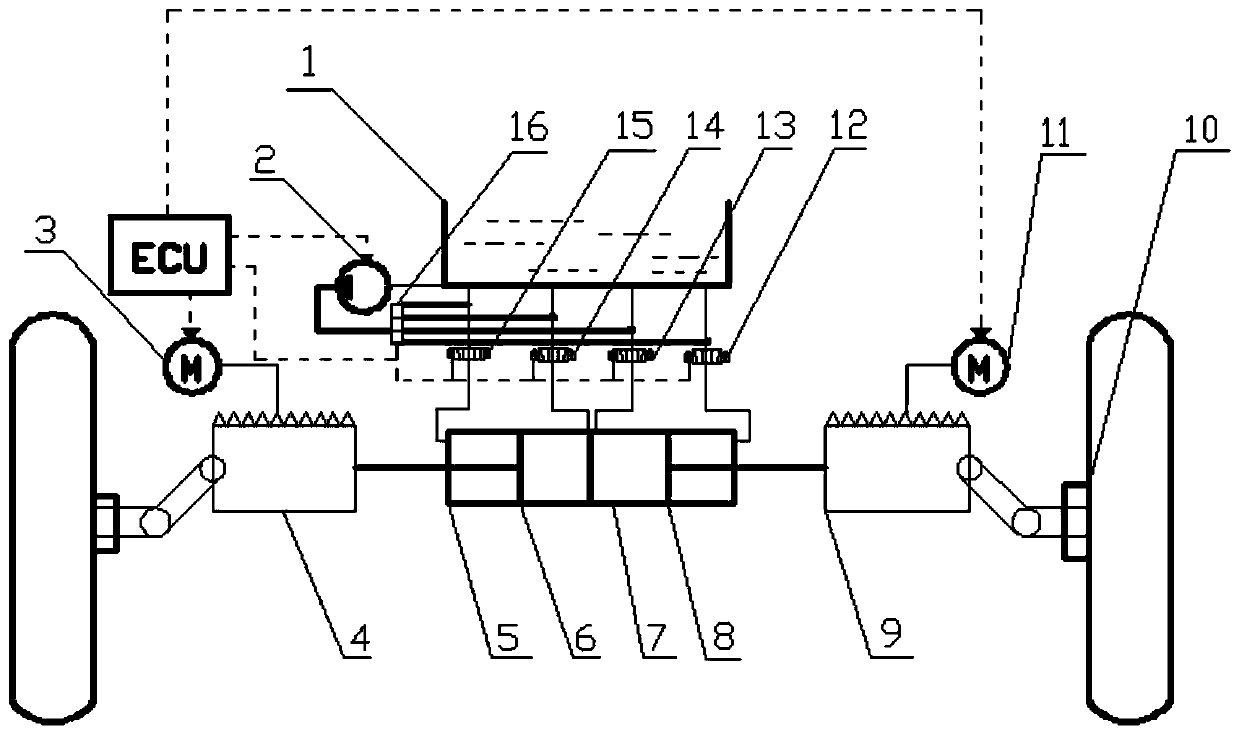

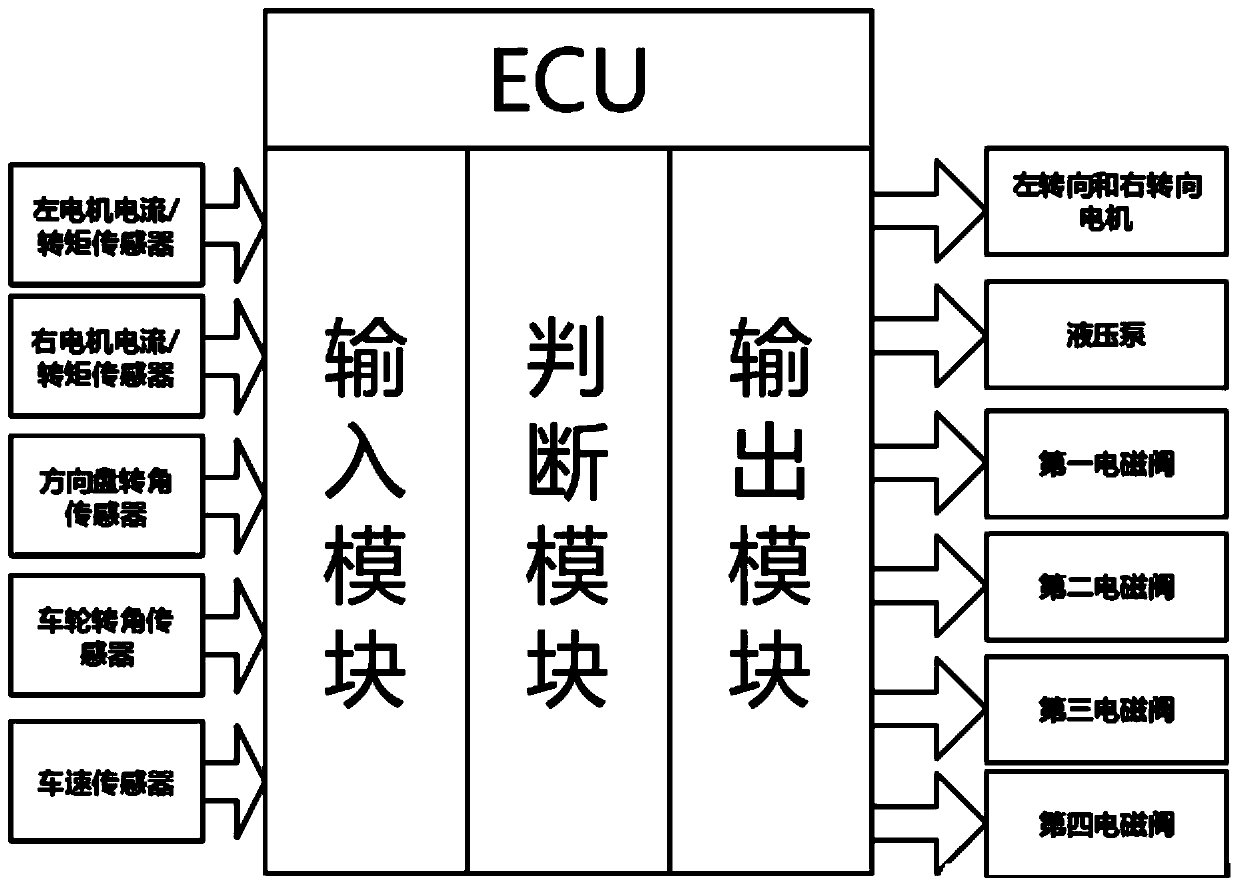

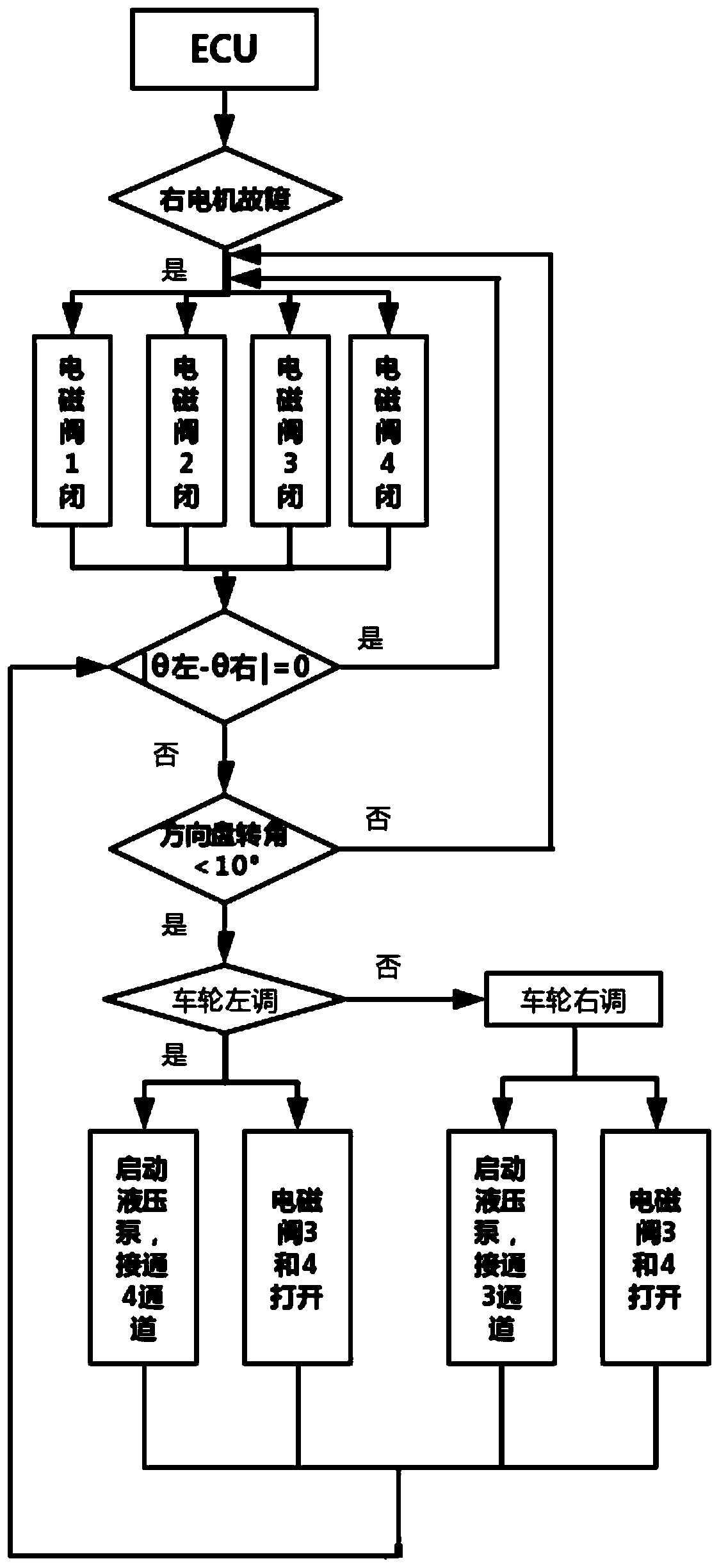

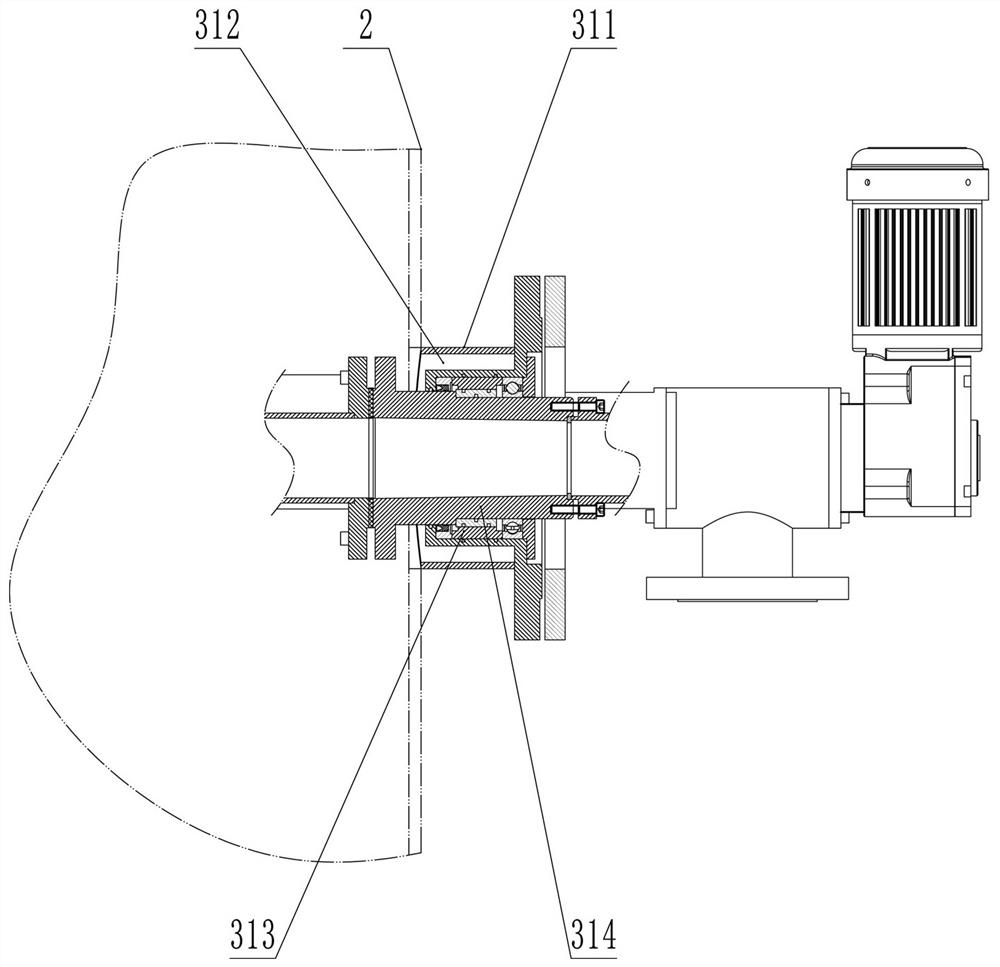

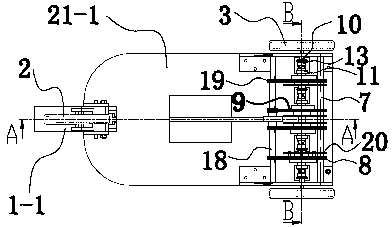

Drive-by-wire independent steering system and method thereof

ActiveCN109850010AGuaranteed steeringGuaranteed to drive in a straight lineFluid steeringCoordinate controlSteering system

The invention provides a drive-by-wire independent steering system and a method thereof. The drive-by-wire independent steering system comprises a detecting mechanism, an execution mechanism and a control unit; the execution mechanism comprises steering motors, a vehicle wheel steering mechanism, an oil supplying system and hydraulic cylinders; under the condition that a vehicle runs normal, the left steering motor and the right steering motor are used for driving a left rack and a right rack correspondingly to perform independent steering coordination control; and when a fault occurs to one of the left steering motor and the right steering motor, the left rack and the right rack are combined into one through closing of magnetic valves, the other one motor is used for driving gears and theracks to ensure normal steering of the vehicle, and when the vehicle approaches steering ending, a redundant backup hydraulic system is used for performing micro-adjustment of fault steering vehiclewheels to ensure normal linear running and steering running of the vehicle. According to the drive-by-wire independent steering system and the method thereof, flexible coordination control over independent steering of a left vehicle wheel and a right vehicle wheel during normal drive-by-wire steering can be realized to improve the operation and control stability of the vehicle, and the condition that the vehicle can perform normal linear running and steering running when the fault occurs to the steering system can be ensured as well.

Owner:湖北凯圣汽车转向系统有限公司

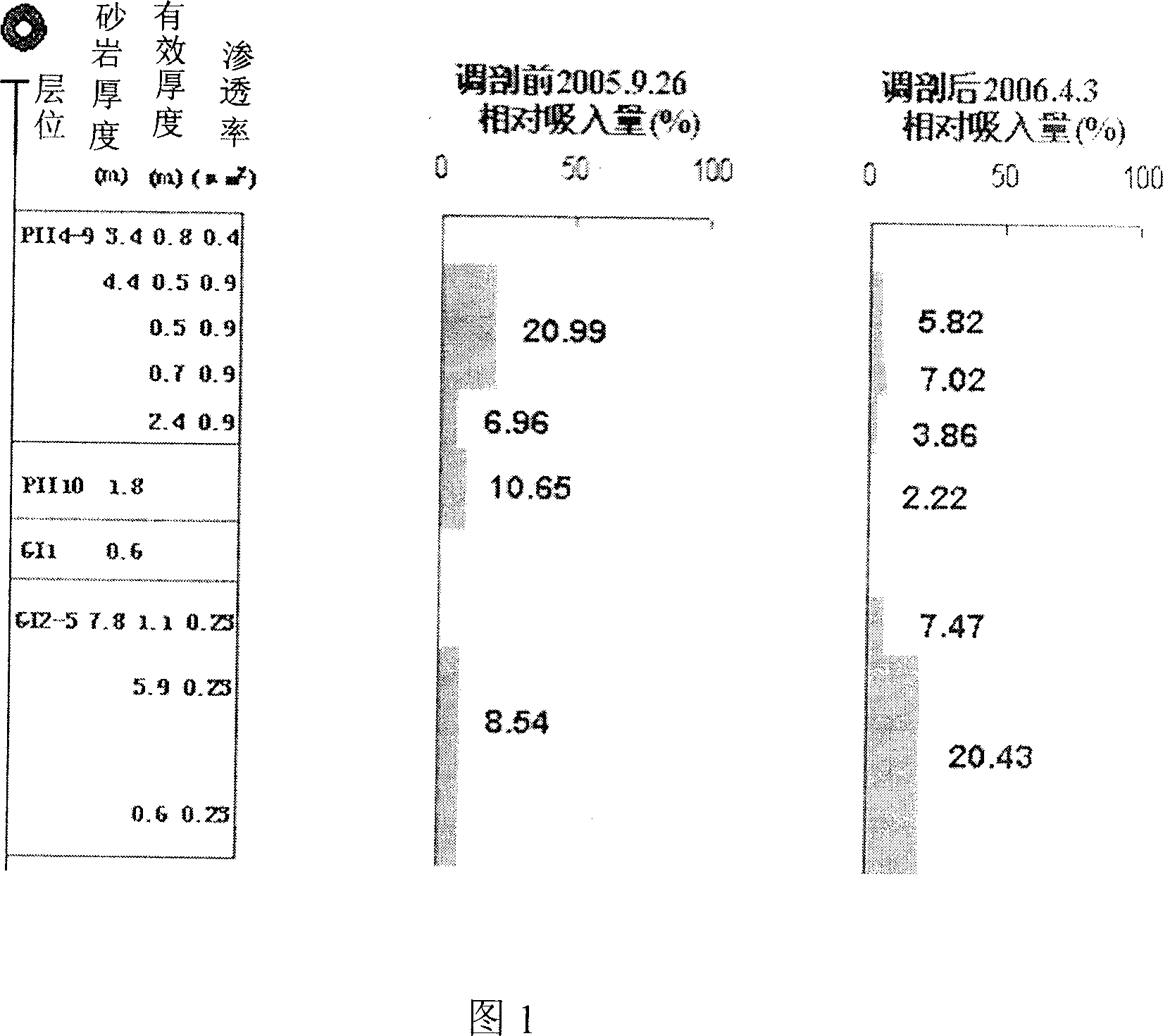

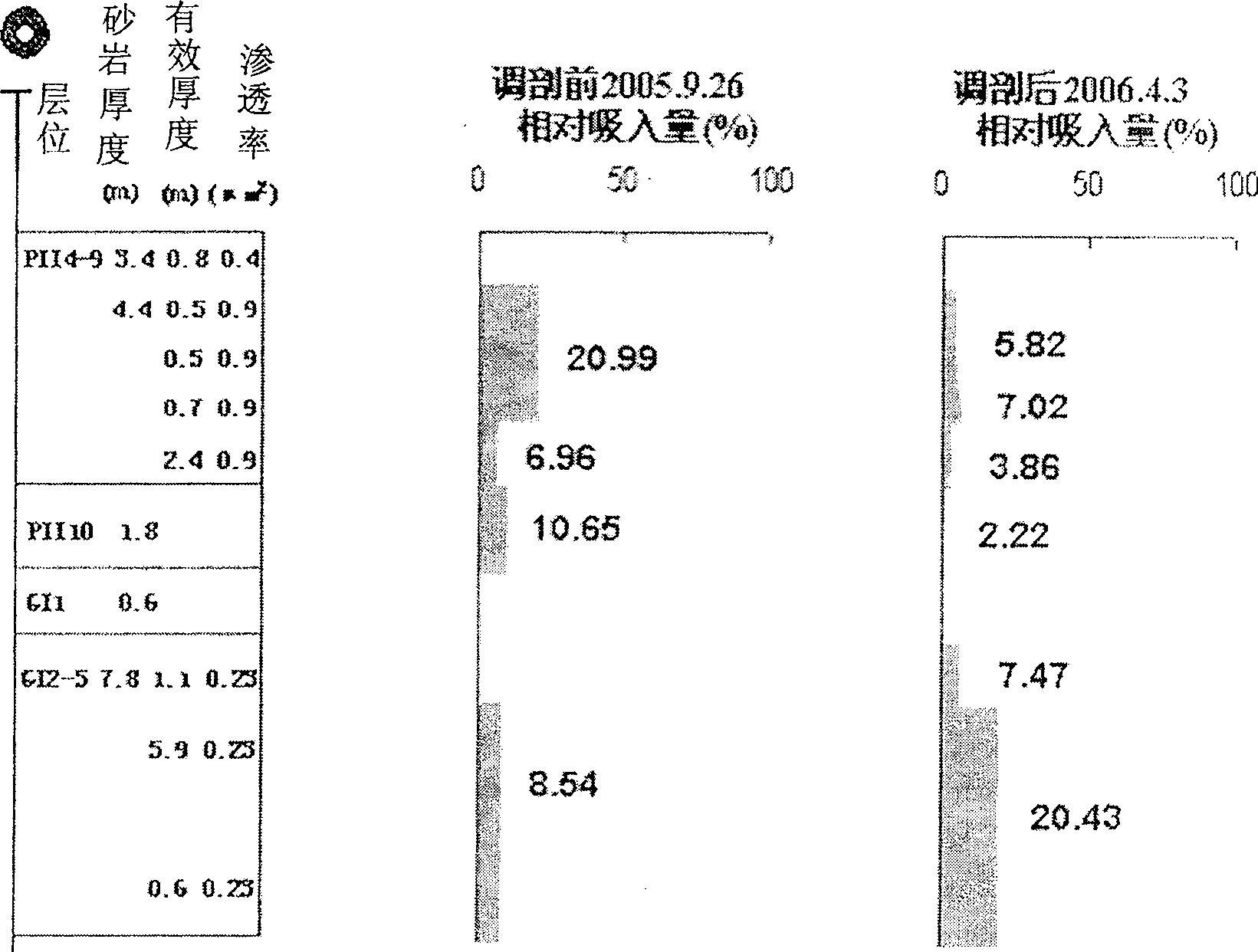

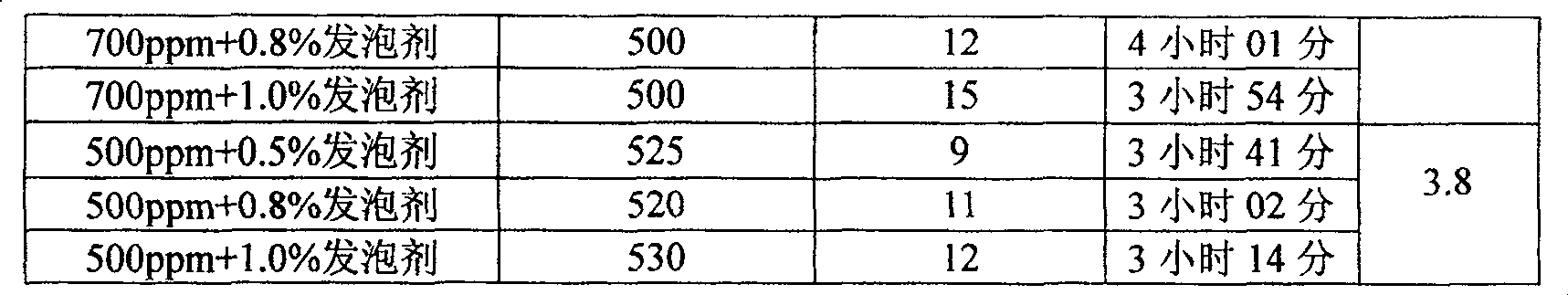

Acid resistant foamed plugging agent

InactiveCN101089117AImprove stabilityEffective blockingDrilling compositionSODIUM DODECYL BENZENE SULFONATECarbon dioxide

The acid resistant foamed plugging agent is mixture comprising CO2 and foamed solution in the underground volume ratio of 2.5 to 1. The foamed solution consists of sodium dodecyl benzene sulfonate in 0.3 wt%, modified guanidine glue in 0.1 wt% and water for the rest. The present invention is applied in regulating the air intake profile of CO2 injecting gas well, and can plug the blow-by layer in gas injecting well and raise the economic value of gas injecting oil field.

Owner:DAQING OILFIELD CO LTD

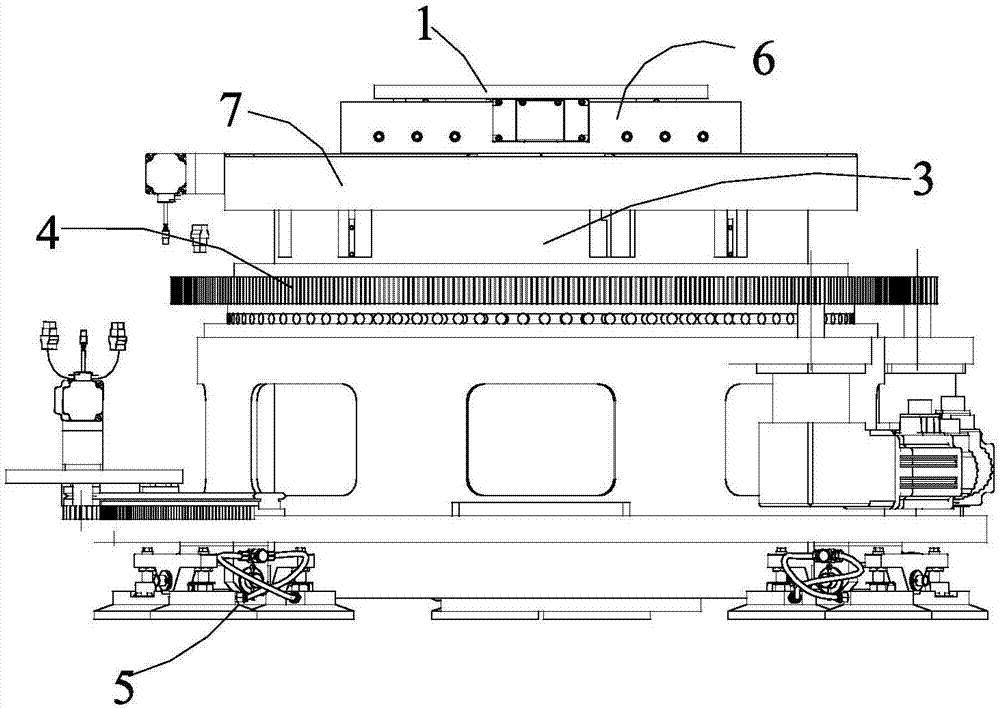

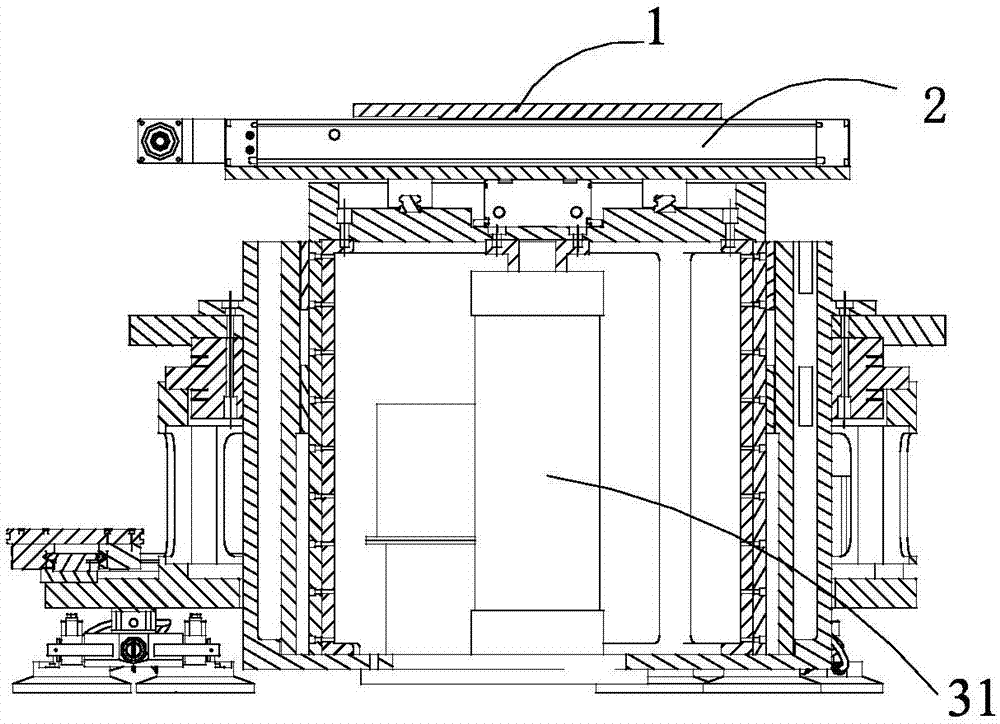

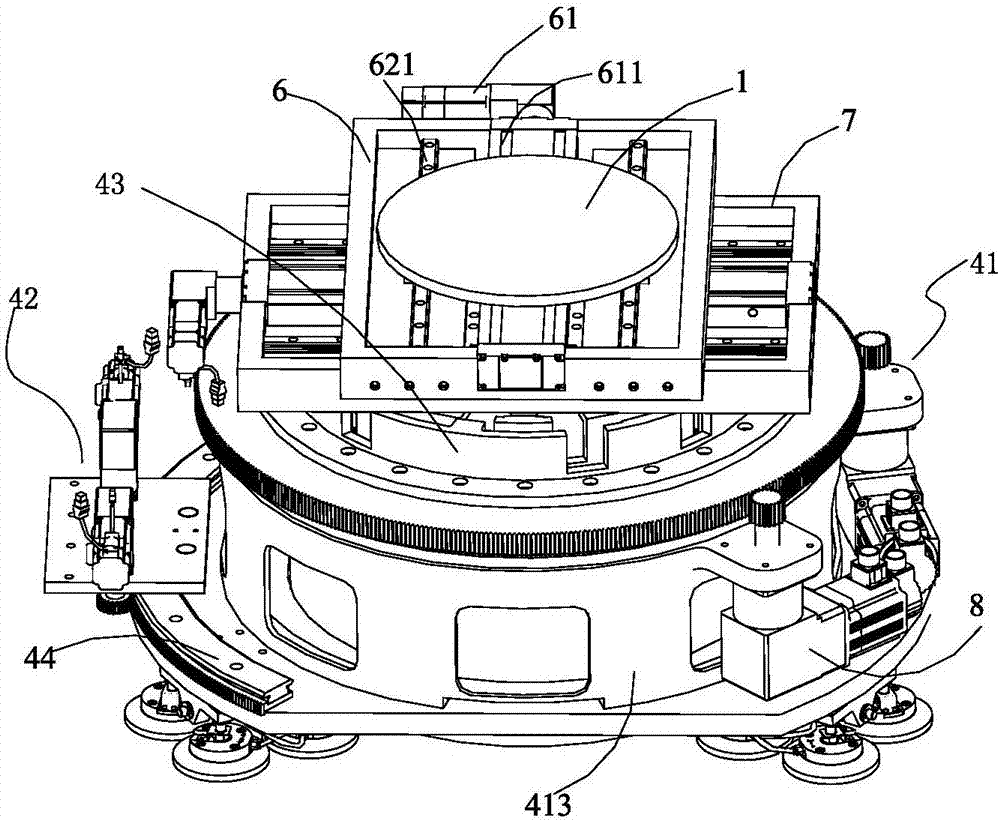

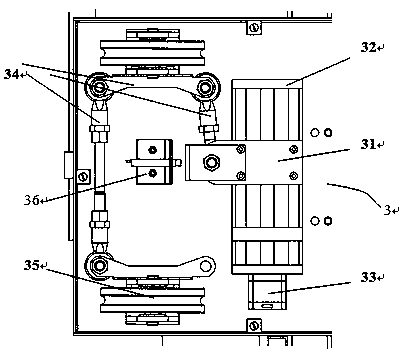

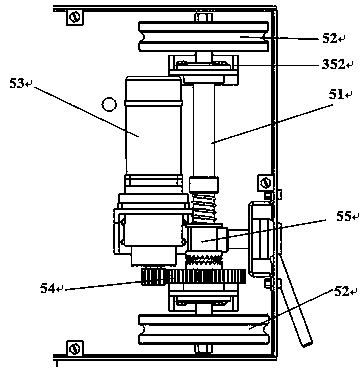

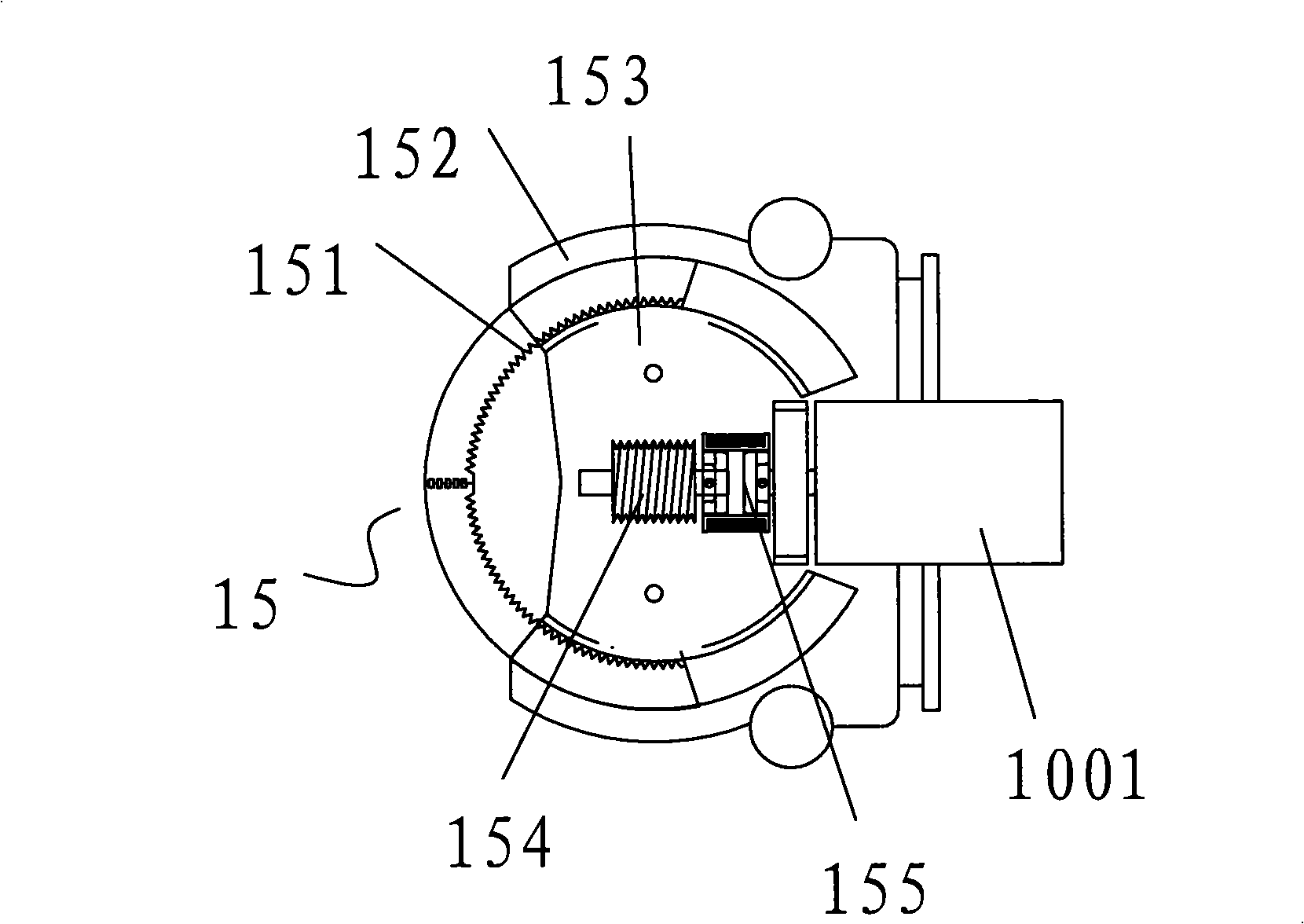

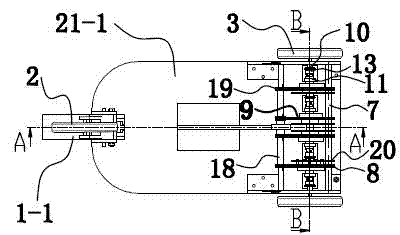

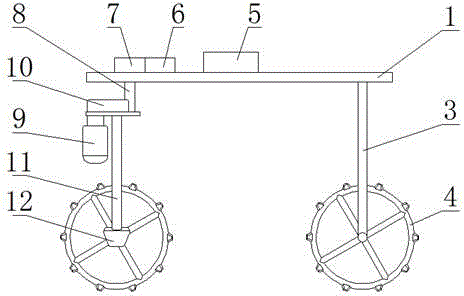

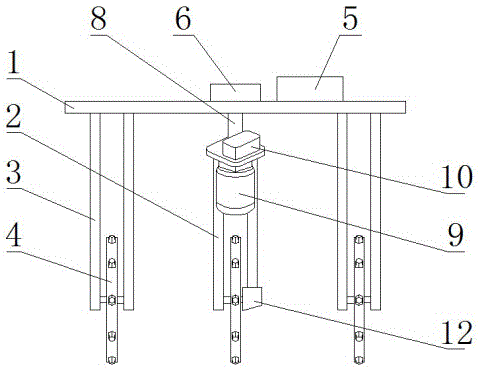

A sample table of a neutron diffraction stress spectrometer

InactiveCN107490590AGuaranteed uptimeReduce the number of clampingMaterial analysis using radiation diffractionSupporting systemMovement system

A sample table of a neutron diffraction stress spectrometer is provided. The sample table includes a sample mounting plate, a horizontal movement system controlling horizontal movement of the sample mounting plate, a vertical lifting and descending system controlling vertical movement of the sample mounting plate, and a rotation movement system controlling rotation of the sample mounting plate, a neutron diffraction stress spectrometer detector and a capturer. The sample mounting plate is disposed on the horizontal movement system. The lower part of the horizontal movement system is connected to the vertical lifting and descending system. The vertical lifting and descending system is connected to the rotation movement system. The bottom of the rotation movement system is connected to a floating supporting system. The rotation movement system includes a sample table autorotation part, a sample table supporting mechanism and a swing and connecting part. The sample table autorotation part is used for controlling the sample mounting plate to rotate around the center axis. The swing and connecting part is mounted to the sample table supporting mechanism through a circular-arc guide rail, and is used for connecting the detector and the capturer, and moves along the circular-arc guide rail.

Owner:CENT SOUTH UNIV

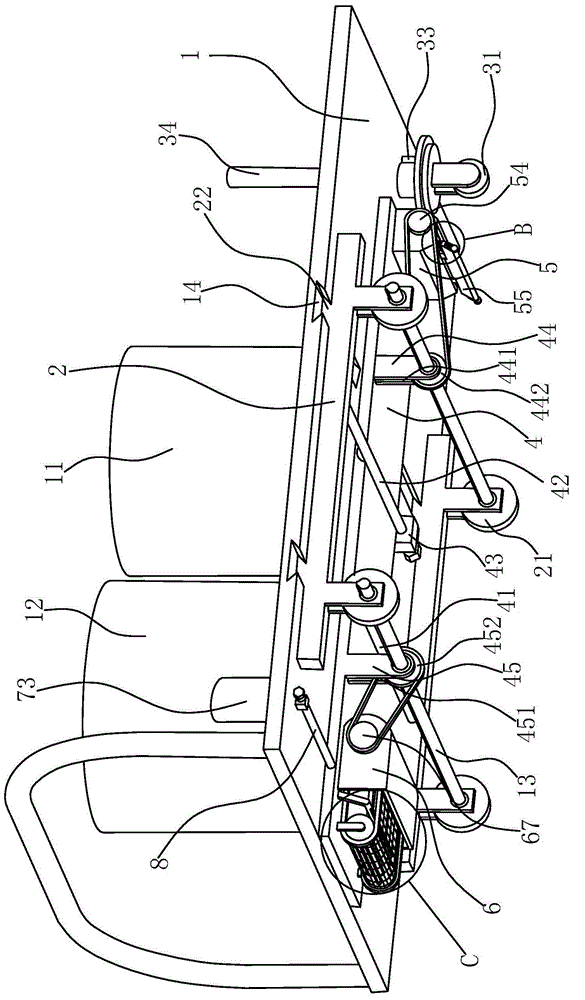

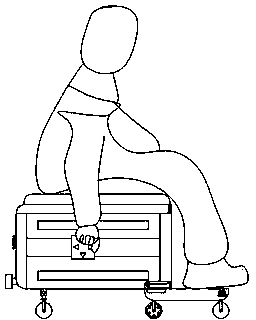

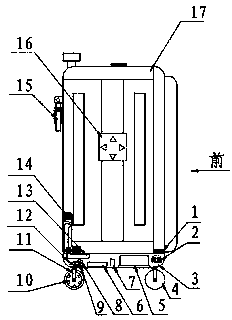

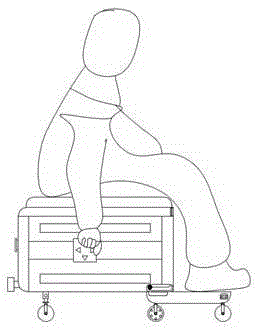

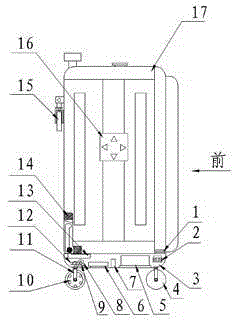

Electric manned luggage box

The invention provides an electric manned luggage box utilizing an advanced technique that a steering motor is matched with a turbine worm to achieve electronic steering. The electric manned luggage box is characterized in that a base is arranged on a conventional luggage box, an electric walking mechanism and an electric steering mechanism are arranged in the base, and direct-current motor wheels serve as driving wheels of the luggage box; when the electric manned luggage box serves as the conventional luggage box, a pull rod is dragged to start an electric device to electrically move forwards, and when the electric manned luggage box is used normally, a passenger can sit on the surface of the luggage box and operates the luggage box to move forwards or steer by touching keys through fingers; the passenger can change the state of the electric manned luggage box at any time to carry the electric manned luggage box or sit on the electric manned luggage box to move forwards, so that a big problem that the passenger cannot timely sit to take a rest when tired during walking is overcome, and the passenger can carry the electric manned luggage box and sit on the electric manned luggage box to move forwards during shopping, touring and vehicle waiting at security halls of airports, superstores, tour and sightseeing places and busy streets such as commercial pedestrian streets. The electric manned luggage box is reasonable in overall layout structure, is convenient to carry and comfort, safe and reliable to sit and has a wide market application prospect.

Owner:WUXI TONGCHUN NEW ENERGY TECH

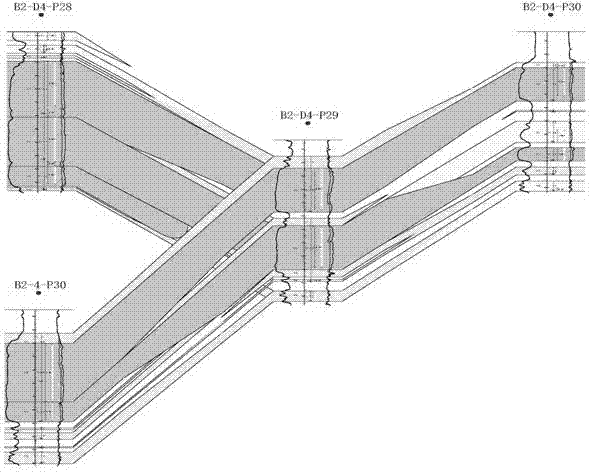

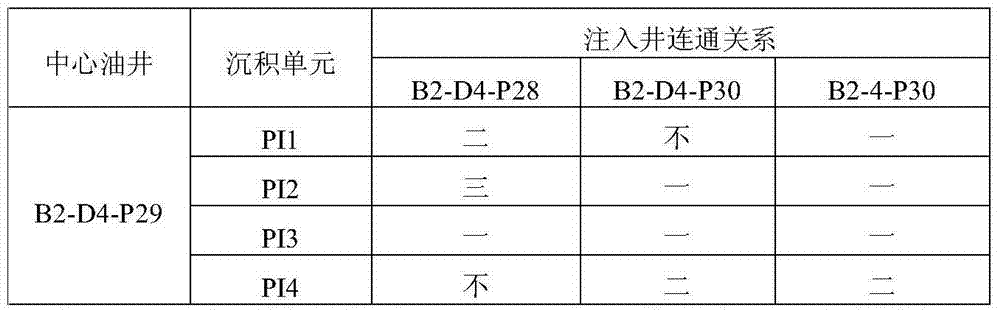

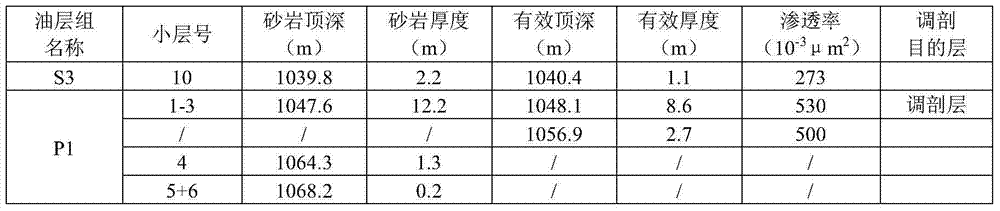

Macropore plugging gelatin

The invention discloses a gel to block large-hole channel, which comprises the following parts: nitrogen and liquid with bulk rate at 2: 1, wherein the liquid is composed of 0.8% sodium dodecylbenzene sulfonate, 0.15% polyacrylamide, 0.3% thiourea, 2% calcium chloride, 1% chromic acetate, 0.1% bactericide and water.

Owner:DAQING OILFIELD CO LTD

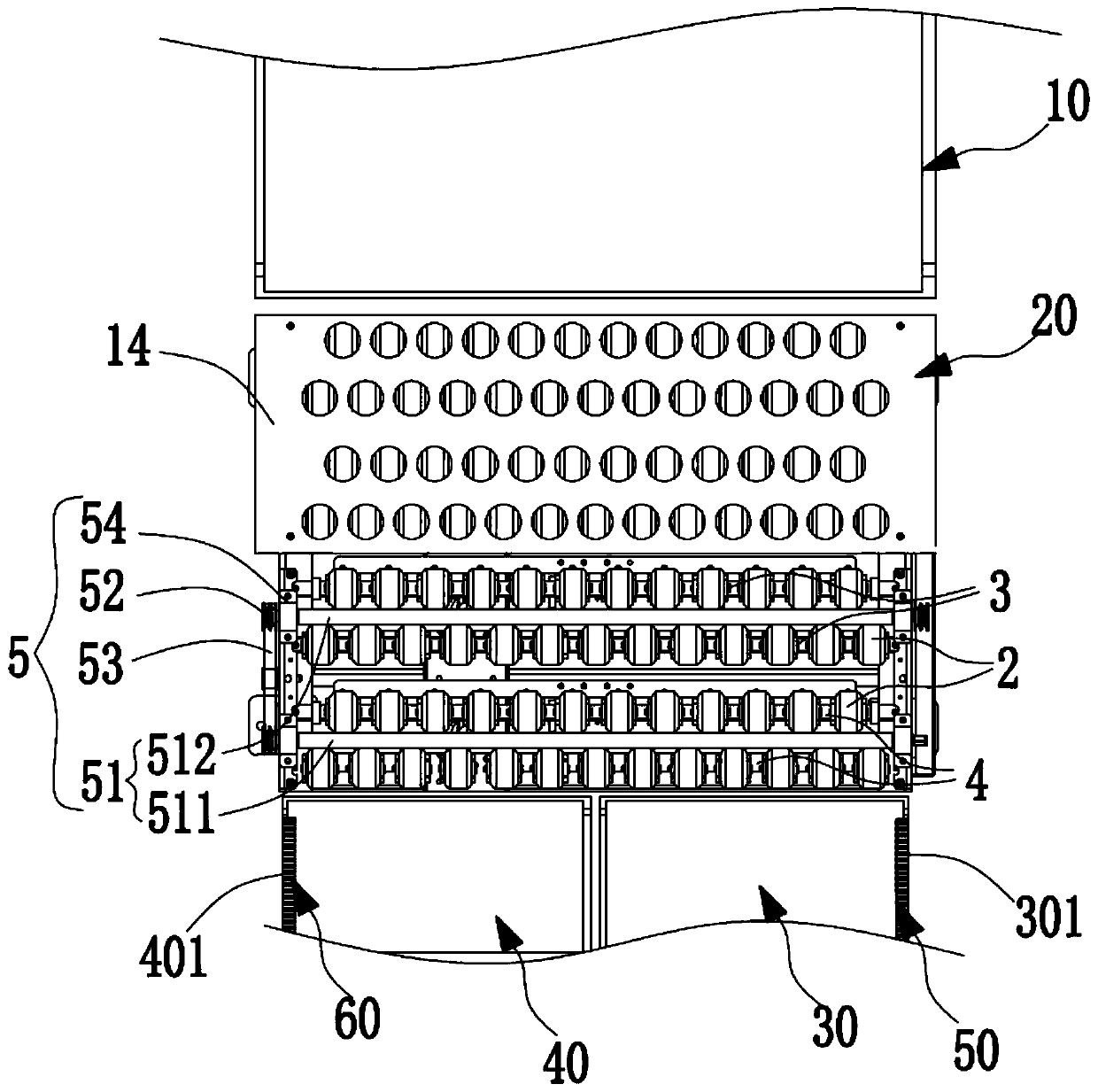

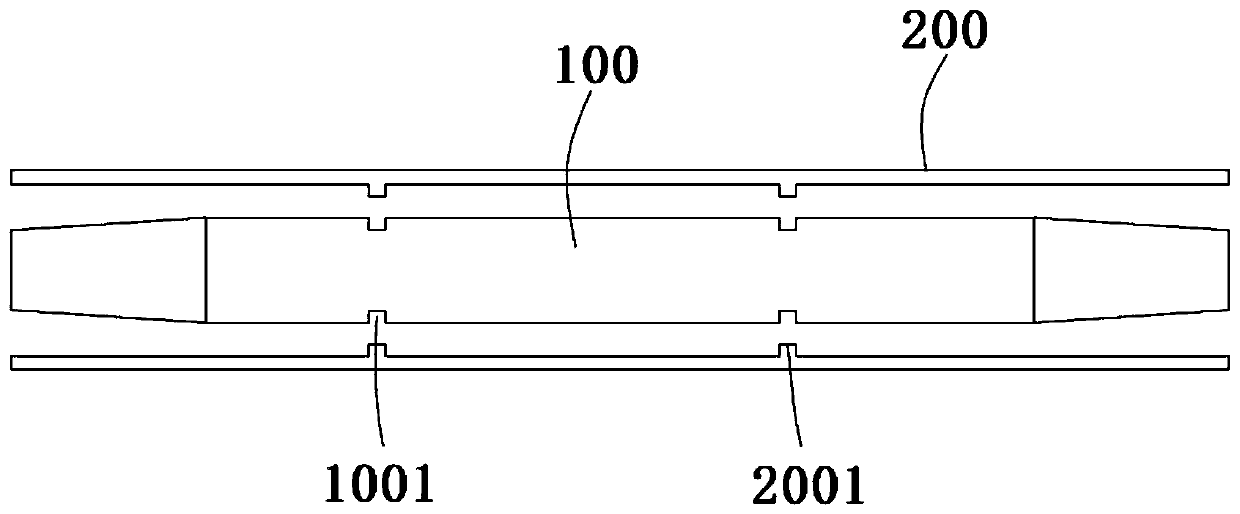

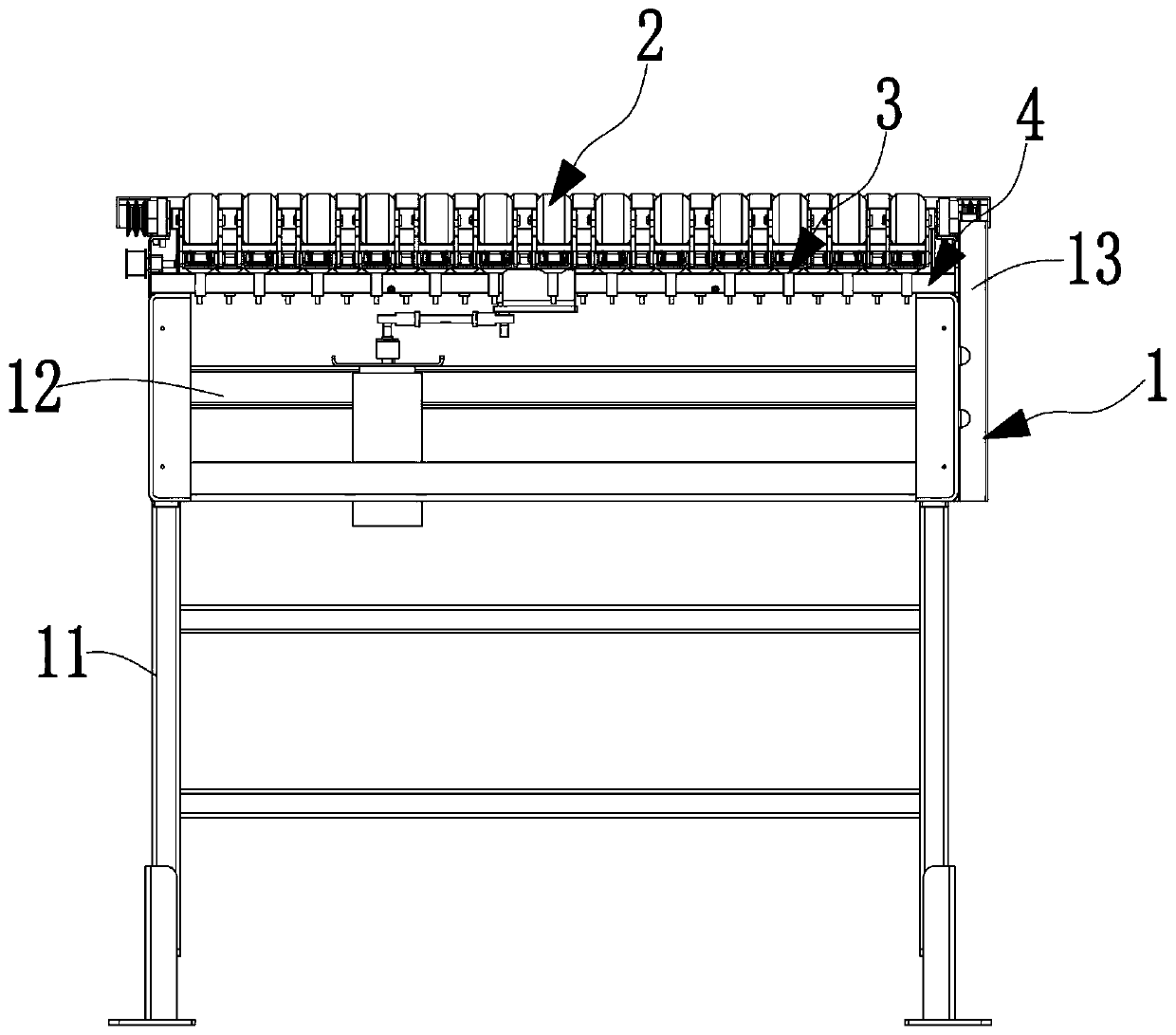

Diverting and converging system based on multi-directional sorting wheels

The invention discloses a diverting and converging system based on multi-directional sorting wheels. The diverting and converging system comprises a main conveying line, wherein the main conveying line is connected with a friction driving type sorting wheel conveying line in a matched mode, the output end of the sorting wheel conveying line is connected with a first branch conveying line and a second branch conveying line which are parallel, and in a converging state, axes of the sorting wheels in the sorting wheel conveying line are parallel to driving rollers in the sorting wheel conveying line, wherein the driving rollers drive the sorting wheels to rotate through friction; and in a diverting state, the axes of the sorting wheels in the sorting wheel conveying line keep included angleswith the driving rollers, and the conveying direction of the sorting wheel conveying line can be switched between facing the first branch conveying line and facing the second branch conveying line. According to the scheme, the characteristic that the sorting wheels of the sorting wheel conveying line can freely turn is fully utilized, so that diverting or converging operation is realized, objectsare not damaged in the diverting process, the movement of the objects is not hindered in the converging process, and the combination of the high safety and the high efficiency are effectively realized.

Owner:SUZHOU GP LOGISTICS SYST

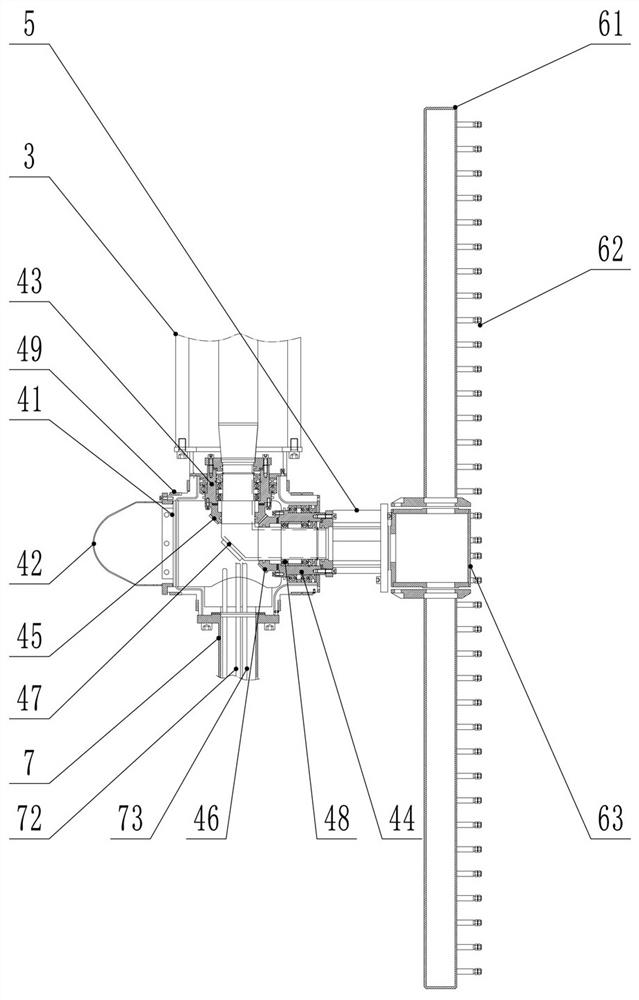

Rotary online flushing device and process system for tubular heat exchanger

ActiveCN112432547APull away in timeEasy to fixGeothermal energy generationFlush cleaningProcess systemsGear wheel

The invention provides a rotary online flushing device for a tubular heat exchanger, which comprises a liquid inlet tube assembly, a hydraulic steering mechanism, a liquid outlet tube assembly and a heat exchange tube flushing nozzle, wherein the hydraulic steering mechanism comprises a shell, a right-angle insertion tube, a drive bevel gear and a driven bevel gear; two ports of the right-angle insertion tube communicate with a liquid outlet of the liquid inlet tube assembly and a liquid inlet of the liquid outlet tube assembly respectively, the drive bevel gear and the driven bevel gear are arranged on the outer sides of two right-angle side pipelines of the right-angle insertion tube in a sleeving mode respectively, the liquid inlet tube assembly drives the drive bevel gear to rotate, and the driven bevel gear drives the liquid outlet tube assembly to rotate; The invention further provides a process system with the rotary online flushing device for the tubular heat exchanger. The rotary online flushing device and process system for the tubular heat exchanger have the advantages of being scientific in design, not easy to damage, smooth in transmission, reliable in use and capableof integrating the functions of high-pressure water flushing, dosing and cleaning.

Owner:郑州赛为机电设备有限公司

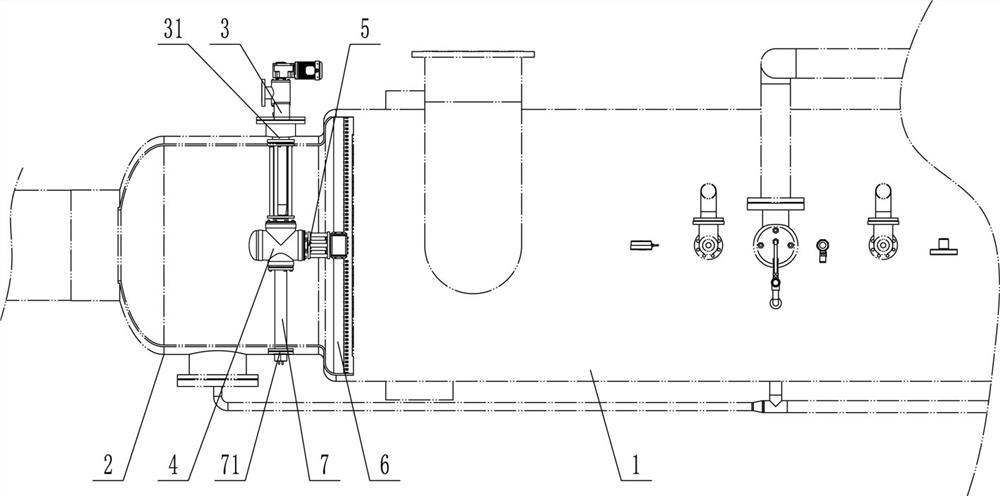

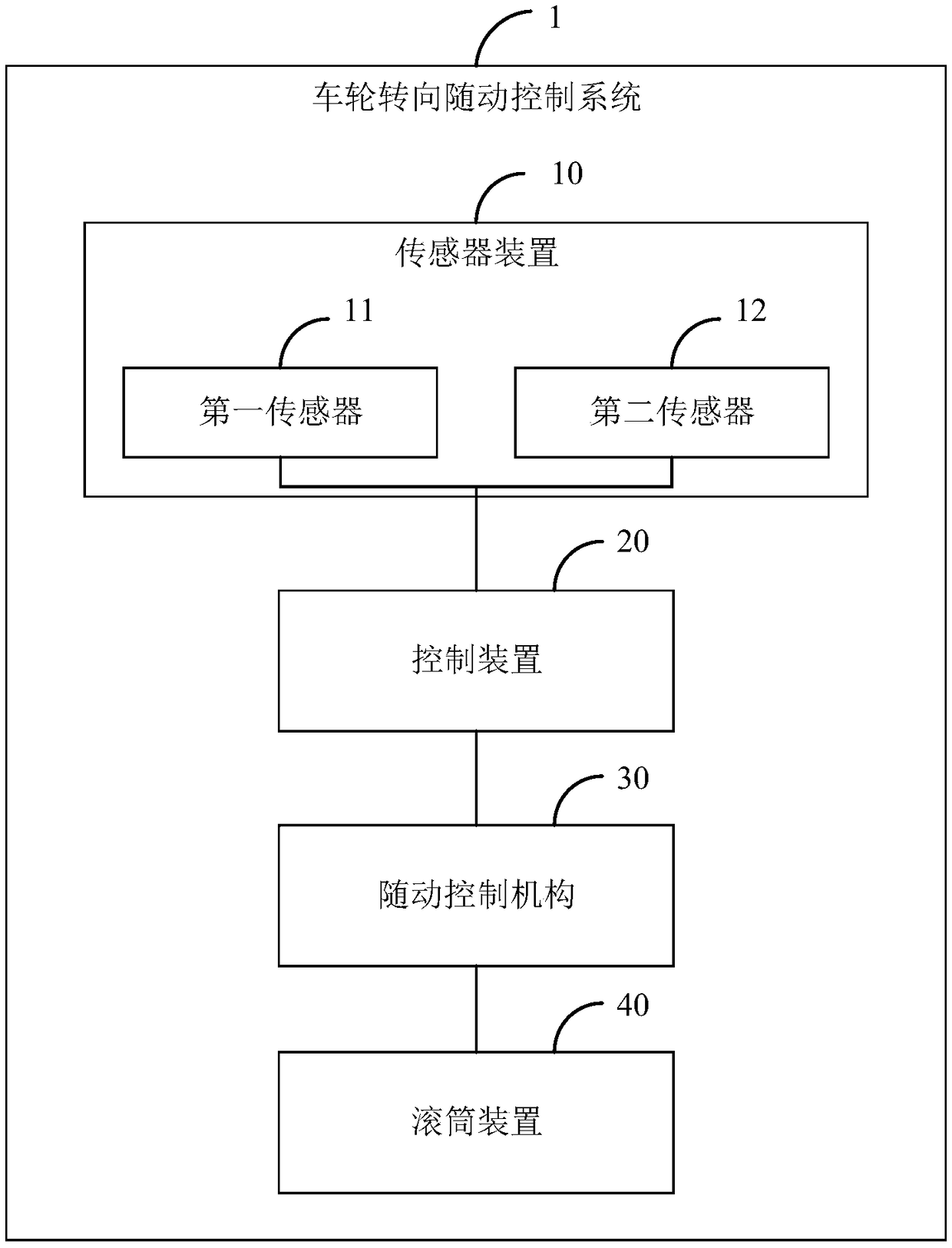

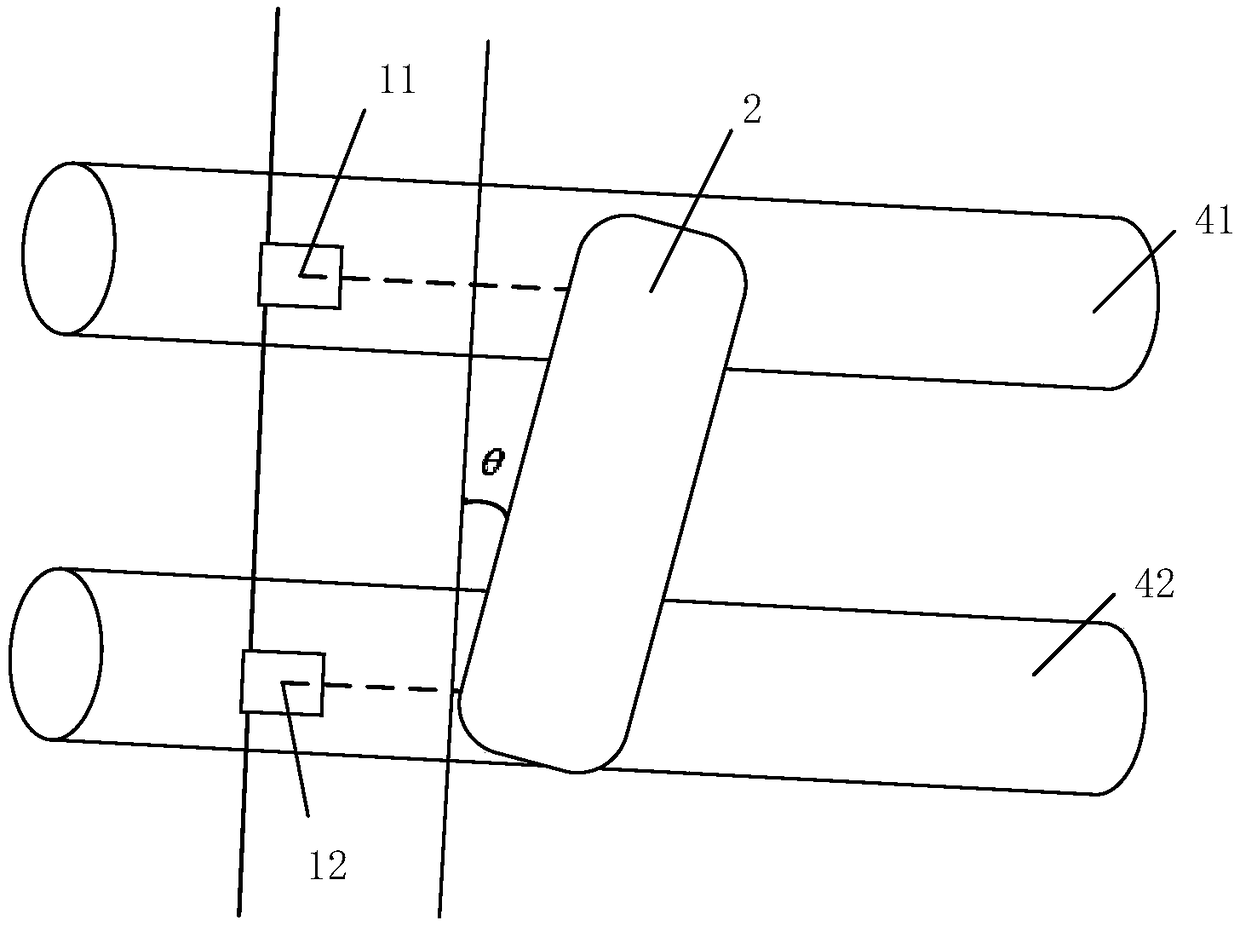

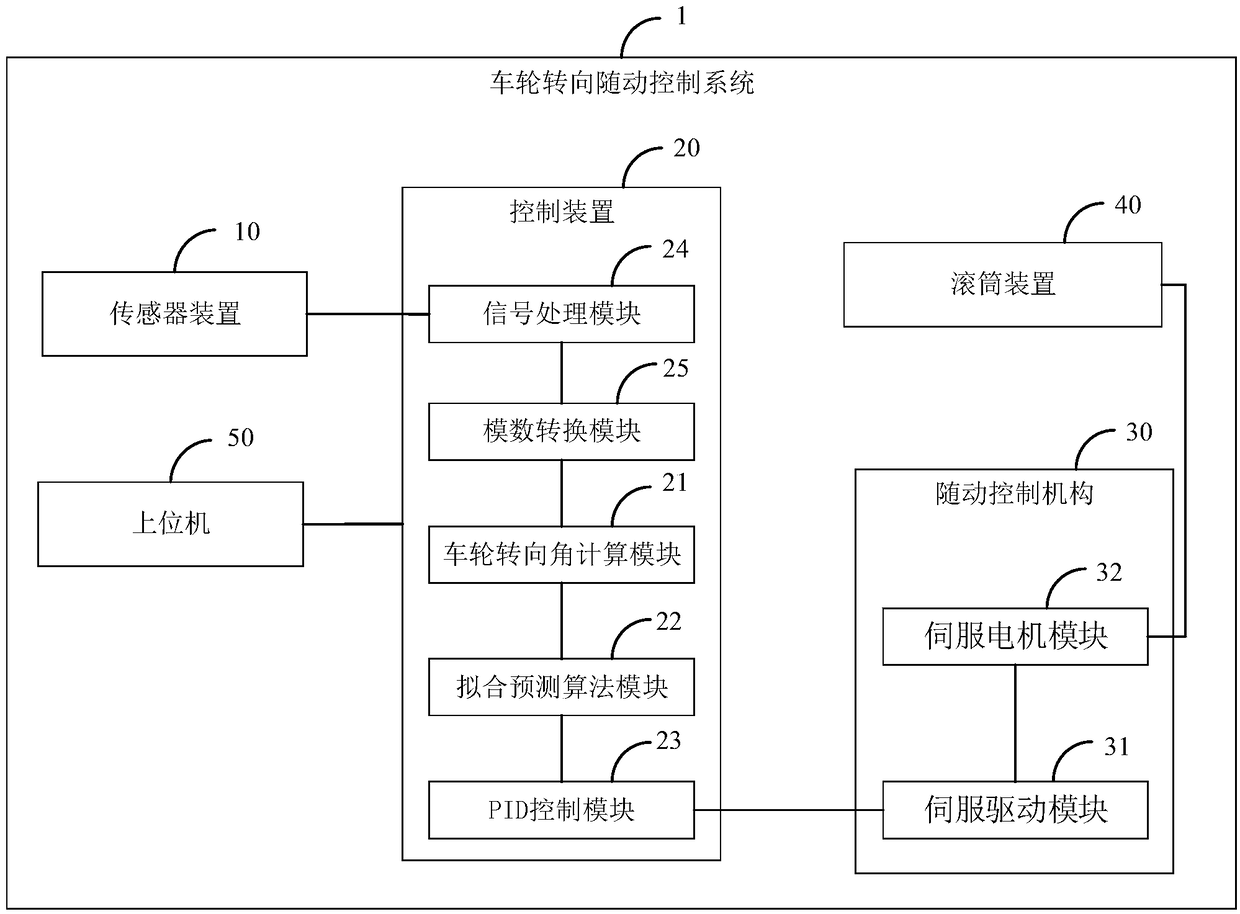

Wheel steering following control system

ActiveCN109238743AReduce lateral forceGuaranteed steeringVehicle testingSteering angleControl system

The invention is applicable to the technical field of vehicle bench testing and provides a wheel steering following control system, which comprises a sensor device, a control device, a following actuator and a roller device. The sensor device comprises a first sensor and a second sensor, wherein a first distance to the wheel is detected through the first sensor, and a second distance to the wheelis detected through the second sensor; the control device obtains roller controlled quantity according to the first distance, the second distance and current roller steering angle; the following control mechanism drives the roller device to steer according to the roller controlled quantity so that the difference between the roller steering angle and the wheel steering angle of the wheel meets a preset angular difference condition. The wheel steering following control system in the invention controls a drive mechanism to change the roller steering angle according to the wheel steering angle andthe current roller steering angle so that the roller device follows the wheel to rotate in real time so as to reduce yawing force received by the wheel in the steering process; the position between the wheel and the roller is kept to be relatively stable; and the vehicle is ensured to normally steer during driving on a rack.

Owner:石家庄华燕交通科技有限公司 +1

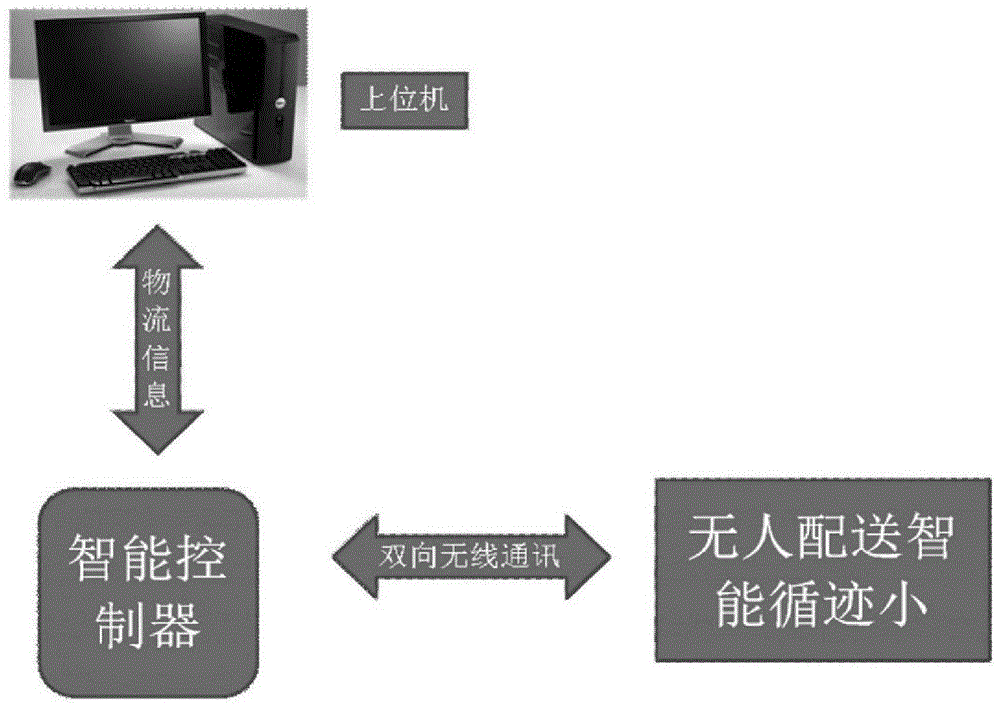

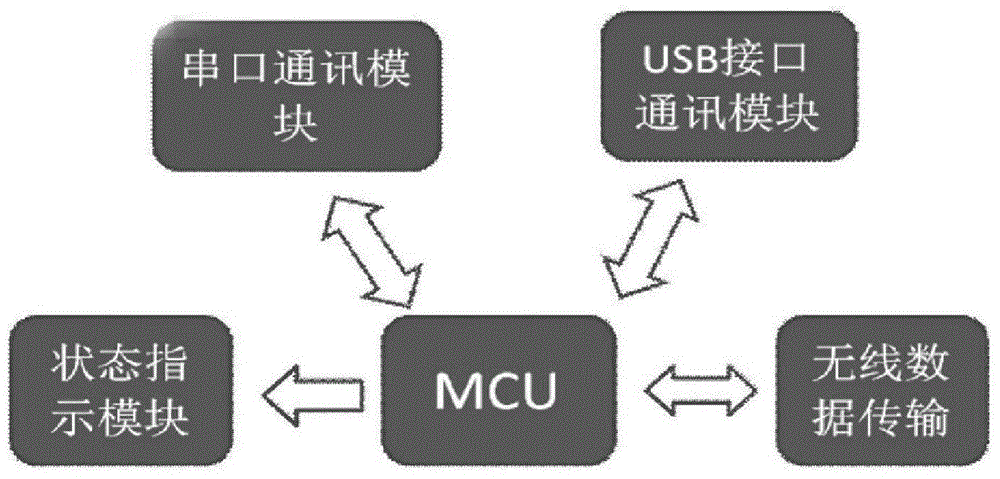

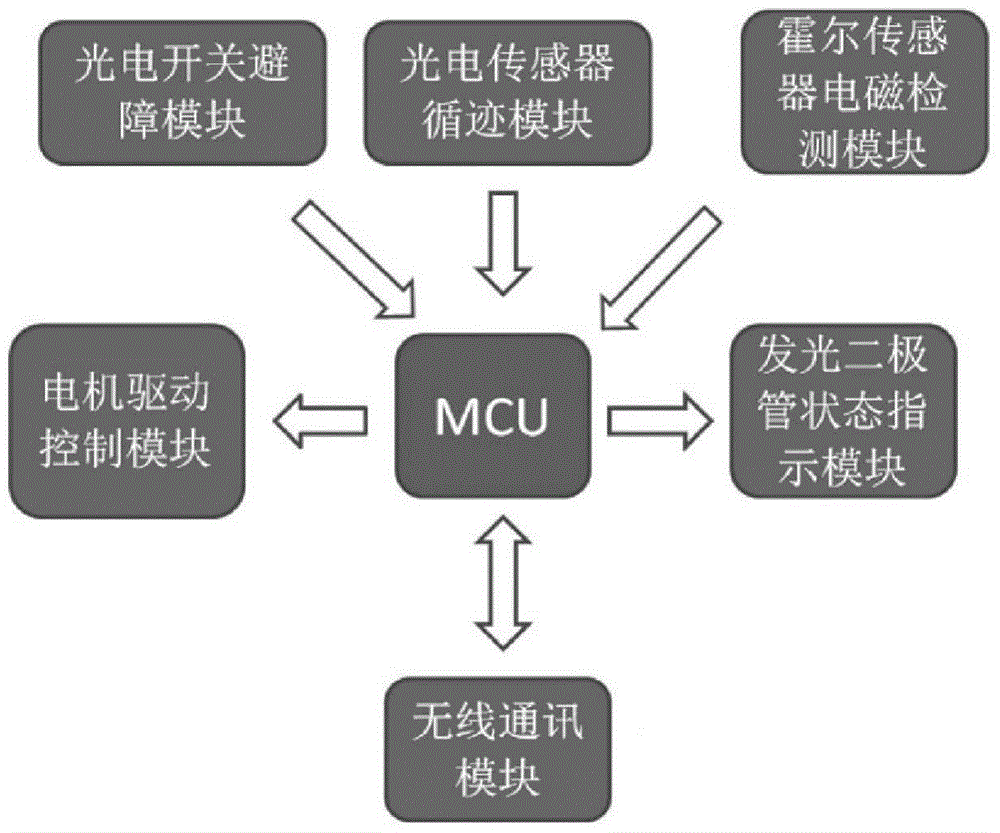

Intelligent logistics tracking trolley and control system thereof

InactiveCN103558855AGuaranteed accuracyNo errorsPosition/course control in two dimensionsControl systemSmart control

The invention discloses an intelligent logistics tracking trolley and a control system thereof. The intelligent tracking trolley and an upper computer used for controlling the intelligent tracking trolley are included, and the upper computer comprises an operating system. The intelligent logistics tracking trolley and the control system thereof are characterized in that the intelligent tracking trolley is provided with the intelligent tracking trolley control system used for controlling the intelligent tracking trolley to move, an intelligent controller is further included, the upper computer transmits signals to the intelligent controller, and after the signals are analyzed by the intelligent controller, the signals are transmitted to the intelligent tracking trolley control system so that the intelligent tracking trolley can be controlled to move. According to the intelligent logistics tracking trolley and the control system thereof, adoptive materials are simple, implementation can be achieved in a programming or designing mode according to the content of the intelligent logistics tracking trolley and the control system thereof, and popularization and application are convenient.

Owner:广西柳工路创制造科技有限公司

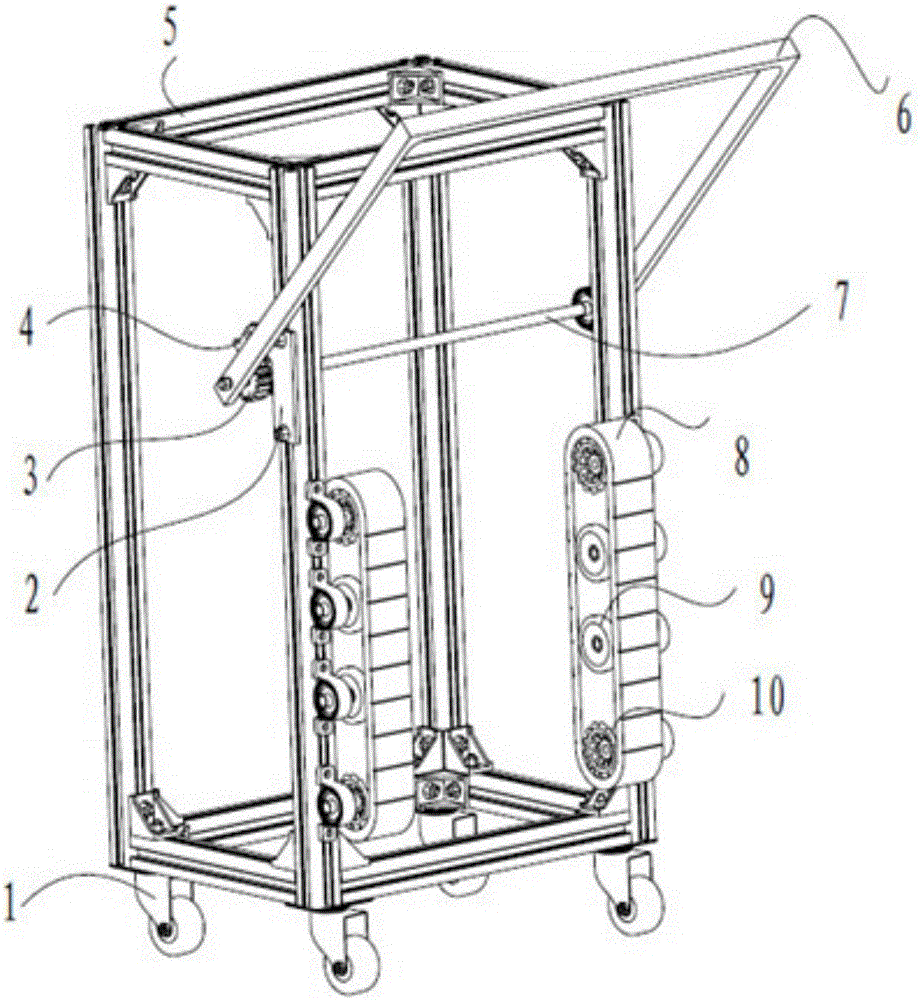

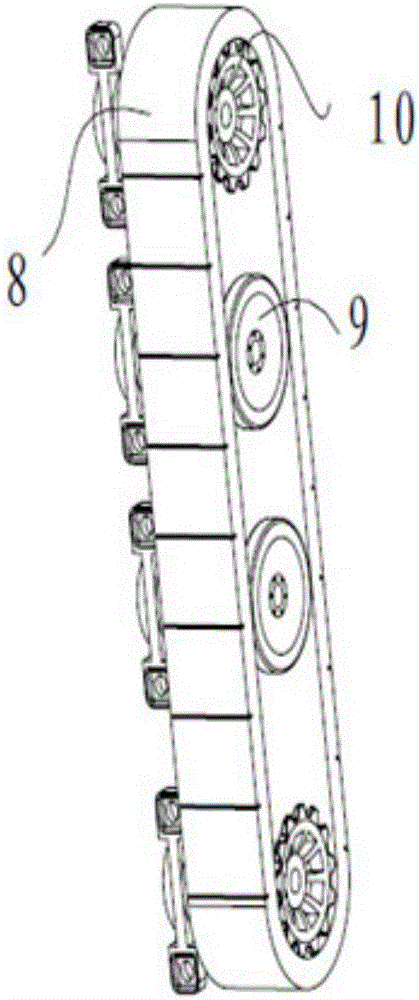

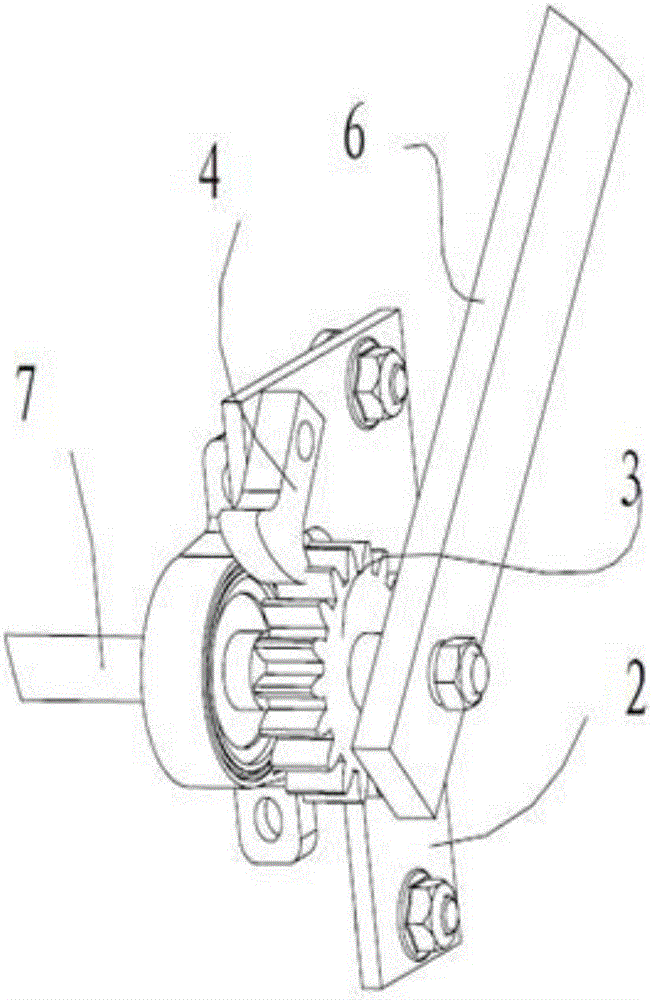

Luggage case

The invention discloses a luggage case. The luggage case comprises a case body, and except for normal luggage case wheels, a moving structure is added on the side surface of the case body to help the luggage case to achieve the vertical or horizontal motional functions, such as climbing stairs, so that manpower can be saved and the efficiency can be improved. The luggage case has the advantages of reasonable design, simpliness, easy implementation, high implementability, high efficiency, labor economization and the like.

Owner:广州市谷希欧皮具有限公司

Automatic welding trolley, automatic welding device and control method of automatic welding device

PendingCN111531303AEnsure weldingTroubleshoot travel-restricted issuesWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses the technical field of automatic welding equipment, and particularly discloses an automatic welding trolley, automatic welding device and a control method of the automatic welding device. The automatic welding trolley comprises a travelling component and a steering component; the steering component comprises a linear module provided with a movable sliding block and a powersource for driving the movable sliding block; the movable sliding block is connected with an in-situ steering mechanism through a connecting rod mechanism, the automatic welding device comprises the automatic welding trolley, the trolley is provided with a weld joint detection component and a welding component, the welding component comprises a welding controller, the welding controller is in communication connection with the weld joint detection component, the steering component and the travelling component are controlled through received weld joint information, so that the automatic weldingtrolley walks and tracks along a weld joint, and the automatic welding is completed. According to the scheme, the welding device can conduct long-distance welding on the weld joint, is not affected bythe stroke of a tracking device, and has the advantages of flexibility, convenience, high adaptability and high control precision.

Owner:CHENGDU ALANGTECH

Hand-rocking type mechanical energy storage bionic toy car

The invention discloses a hand-rocking type mechanical energy storage bionic toy car which comprises a car body, front wheels, rear wheels and a driving mechanism for driving the rear wheels to operate. The hand-rocking type mechanical energy storage bionic toy car is characterized in that the driving mechanism comprises a power input mechanism, at least one group of mechanical energy storage assembly, a power releasing assembly matched with the mechanical energy storage assembly and a power output shaft. The rear wheels are sleeved on two ends of the power output shaft in empty mode. During driving of the toy car, the power input mechanism is started manually, power is delivered to the mechanical energy storage assembly to be stored through the power input mechanism, then the power in the mechanical energy storage assembly is released through the releasing assembly and delivered to the power output shaft so as to drive the toy car to operate. Compared with the prior art, the hand-rocking type mechanical energy storage bionic toy car has the advantages of improving playing enjoyment of children and having a practicing effect. The toy car is of a pure mechanical mechanism and is not driven electrically.

Owner:CHONGQING UNIV OF TECH

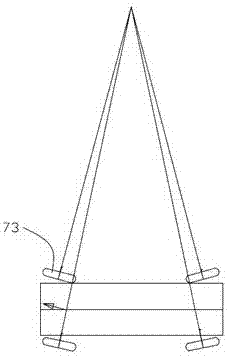

Carbon-free trolley

The invention provides a carbon-free trolley. The problem of difficult adjusting of the deflecting direction of an existing trolley is solved. The carbon-free trolley comprises a trolley frame, a traveling mechanism, a transmission mechanism and a steering mechanism, wherein the traveling mechanism, the transmission mechanism and the steering mechanism are arranged on the trolley frame; the traveling mechanism comprises a front wheel rotatably connected with the trolley frame, rear wheels arranged on the two sides of the trolley frame, and a driving assembly used for driving the rear wheels torotate; and the transmission mechanism comprises a cycle adjusting assembly used for adjusting the transmission cycle, the transmission mechanism is connected with the rear wheels and the steering mechanism, one end of the steering mechanism is connected with the transmission mechanism, the other end of the steering mechanism is connected with the front wheel, the driving assembly drives the rearwheels to rotate so as to drive the transmission mechanism to adjust the deflecting direction of the front wheel connected with the transmission mechanism, and the cycle adjusting assembly changes the transmission cycle to change the steering cycle that the steering mechanism drives the front wheel to deflect. Through cooperation of the traveling mechanism, the transmission mechanism and the steering mechanism, the trolley operates circularly according to a double-8-shaped trajectory and according to the preset requirements, and the trajectory size of the trolley can be adjusted through the cycle adjusting assembly.

Owner:GUANGDONG UNIV OF TECH

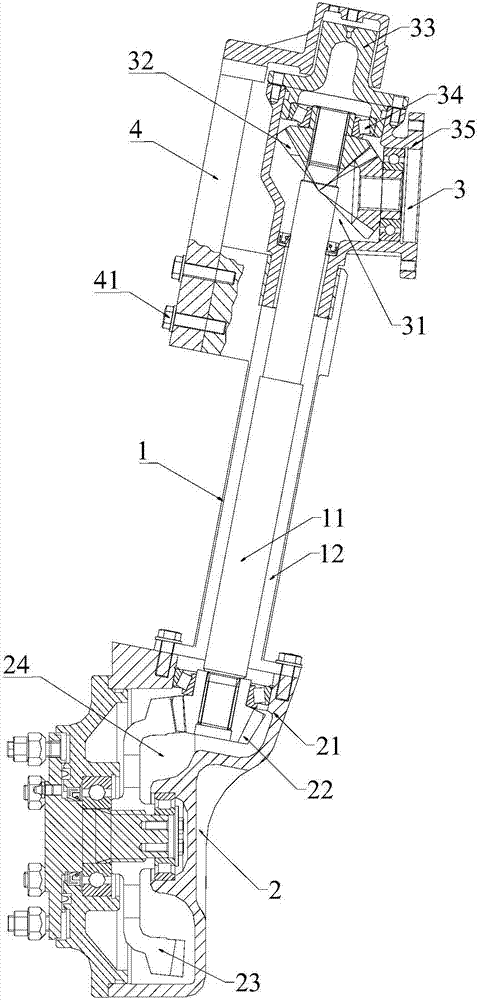

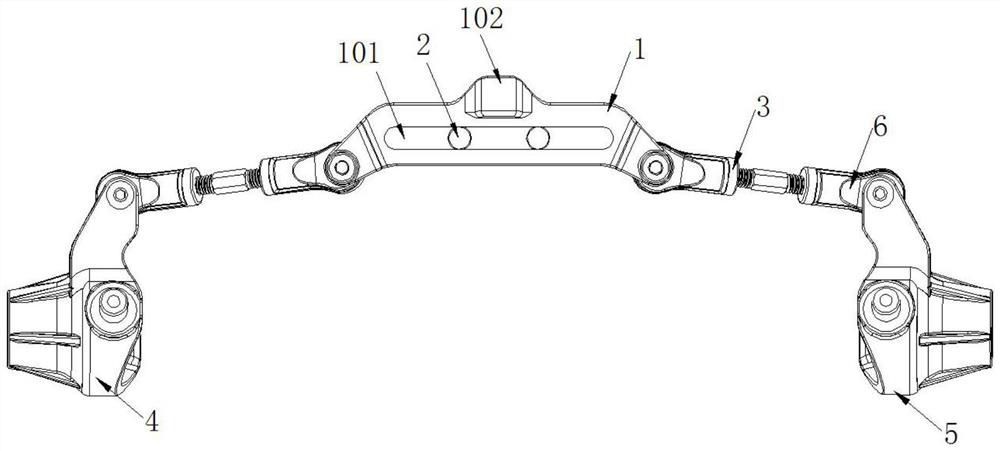

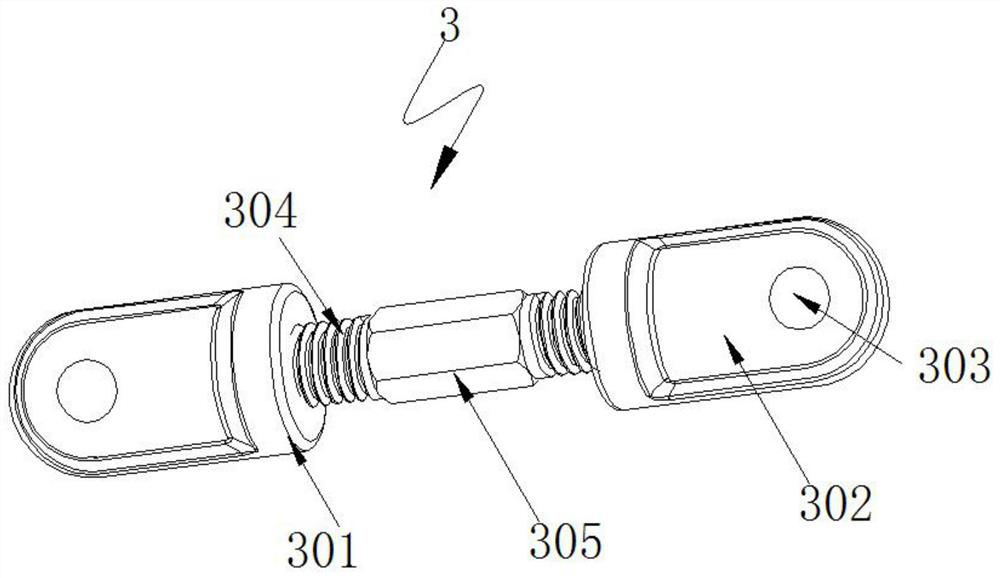

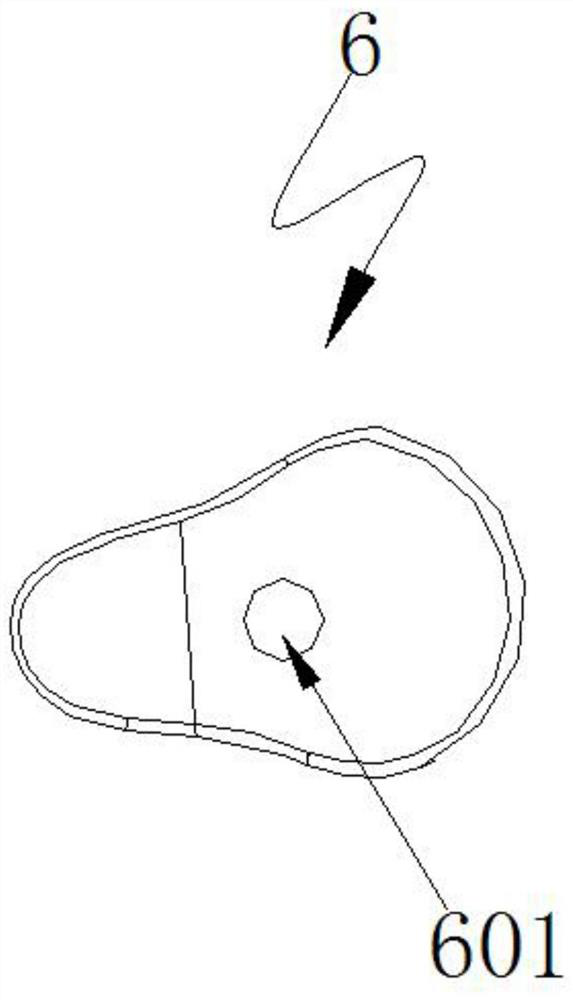

Steering arm for front axle of medicine spraying machine

PendingCN107020884AGuaranteed steeringNormal steering effectSteering linkagesAxle unitsGear wheelControl theory

The invention discloses a steering arm for a front axle of a medicine spraying machine, which is arranged at each of two ends of the front axle and comprises a steering part, an edge reduction device and a transfer part, wherein the steering part comprises a steering shaft and a vertical shaft sleeve, the vertical shaft sleeve is sleeved on the outer ring of the steering shaft, the top end of the vertical shaft sleeve is fixedly connected with the outer wall of the transfer part, the bottom end of the vertical shaft sleeve is fixedly connected with the edge reduction device, the transfer part is connected with the end part of the front axle, and the steering part is connected with the end part of the front axle through the transfer part. The steering arm for the front axle of the medicine spraying machine, disclosed by the invention, effectively isolates muddy water and dust, effectively prevents the steering shaft and the reduction device from being polluted by external pollutants, ensures the normal steering function of the steering arm, and prolongs the service life of an oil seal and a gear. The steering arm disclosed by the invention has the characteristics of good practicability, good stability, good sealing property, high reliability, long service life, and the like.

Owner:YANCHENG RONGNAN MACHINERY MFG

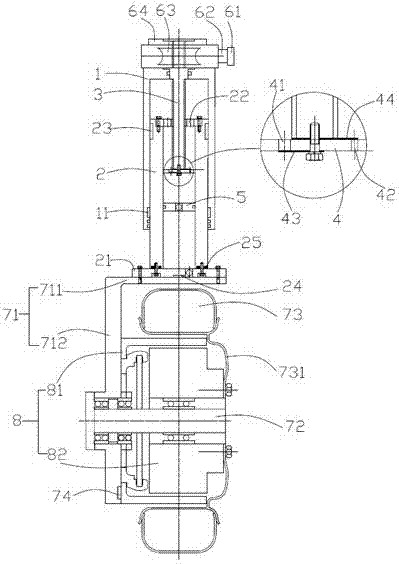

Hydro-pneumatic spring, wheel steering mechanism, wheel and electromobile

PendingCN107989946AImprove handlingGood elastic damping effectSpringsElectrical steeringDamping functionEngineering

The invention provides a hydro-pneumatic spring, a wheel steering mechanism provided with the hydro-pneumatic spring, a wheel provided with the wheel steering mechanism and an electromobile adopting the wheel. The hydro-pneumatic spring comprises an oil cylinder, a guide shaft, a damping plate and a floating piston. The oil cylinder comprises a cylinder barrel and a hollow piston rod communicatingwith an oil cavity of the cylinder barrel. The guide shaft is coaxially fixed to the top of the cylinder barrel, and the bottom end of the guide shaft stretches into an inner cavity of the piston rod. The damping plate is arranged in the inner cavity of the piston rod in a sliding manner and is fixedly connected with the bottom end of the guide shaft. A damping oil passing channel is arranged onthe damping plate. The floating piston is arranged in the inner cavity of the piston rod in a sliding manner and located below the damping plate, and the inner cavity of the piston rod is divided intoan upper oil chamber and a lower gas chamber. Through the division function of the floating piston and the damping function of the damping plate, based on the compression or expansion effect of relation motion between the piston rod and the cylinder barrel on the gas chamber, it can be guaranteed that a good elastic damping effect can be achieved in the automobile running process, and the automobile operation stability can be improved.

Owner:武汉梦马易腾智能汽车科技有限公司

Rocket power composite heat carrier throughput fluid diversion technique

InactiveCN103924954AExpand the affected volumeThe slug combination method is economical and feasibleFluid removalHeat carrierEngineering

The invention relates to a rocket power composite heat carrier throughput fluid diversion technique. The technique includes the steps: (1) determining a fluid channeling direction and fluid channeling layer thickness; (2) optimizing total dosage of a fluid diversion agent by means of numerical simulation; (3) injecting 10% of high-temperature-resistant particle slugs, injecting 20% of high-temperature-resistant particle and gel mixed slugs, injecting 20% of high-temperature-resistant gel slugs, injecting 20% of high-temperature-resistant gel and foam fixed slugs, injecting 20% of high-temperature-resistant foam slugs, and injecting 10% of high-temperature-resistant particle slugs in sequence according to the dosage, optimized in the second step, of the fluid diversion agent. By the rocket power composite heat carrier throughput fluid diversion technique, the fluid flow direction can be changed effectively for a long time at the temperature of 350 DEG C, swept volume is enlarged, and a slug combination mode is economical and feasible.

Owner:PETROCHINA CO LTD +1

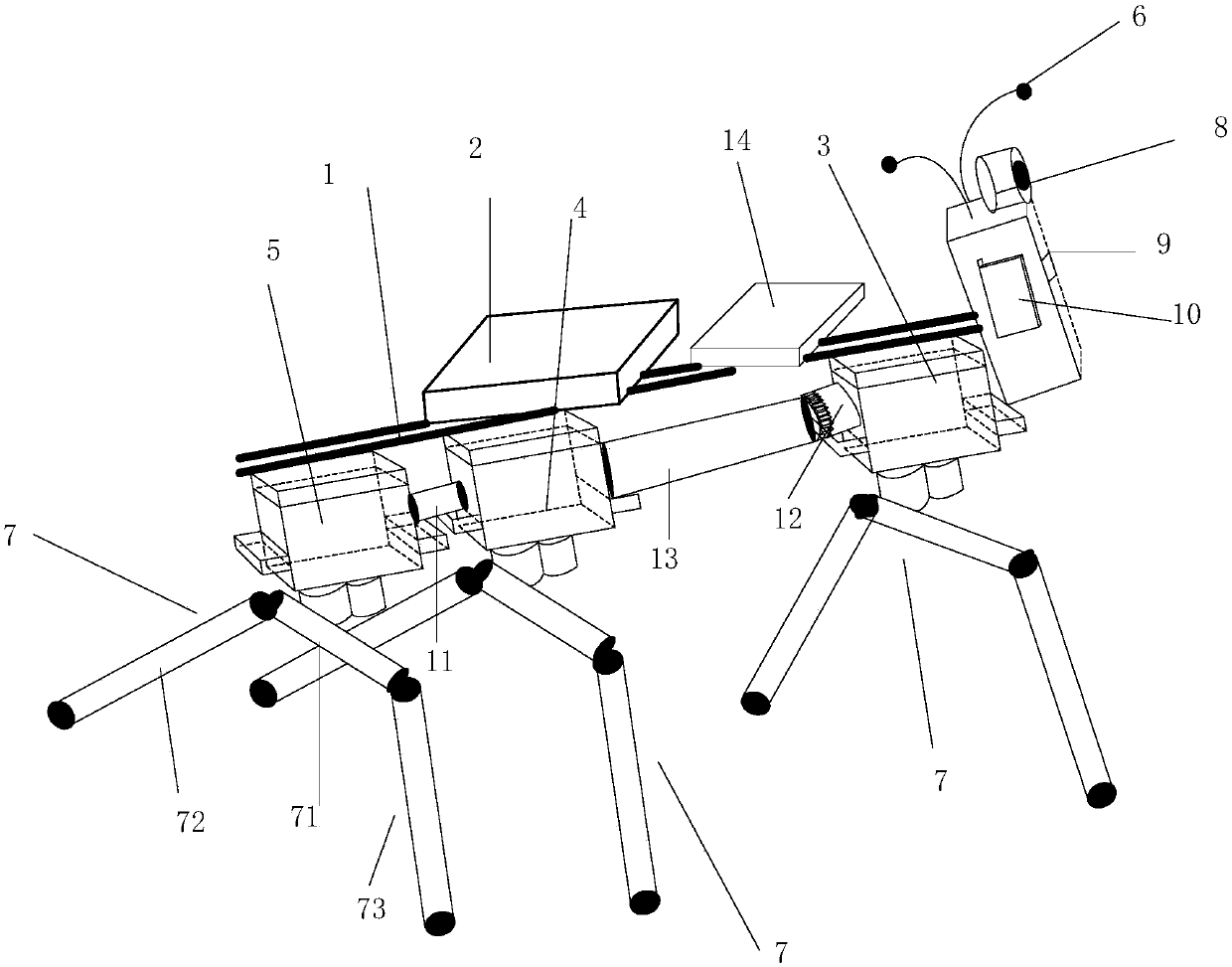

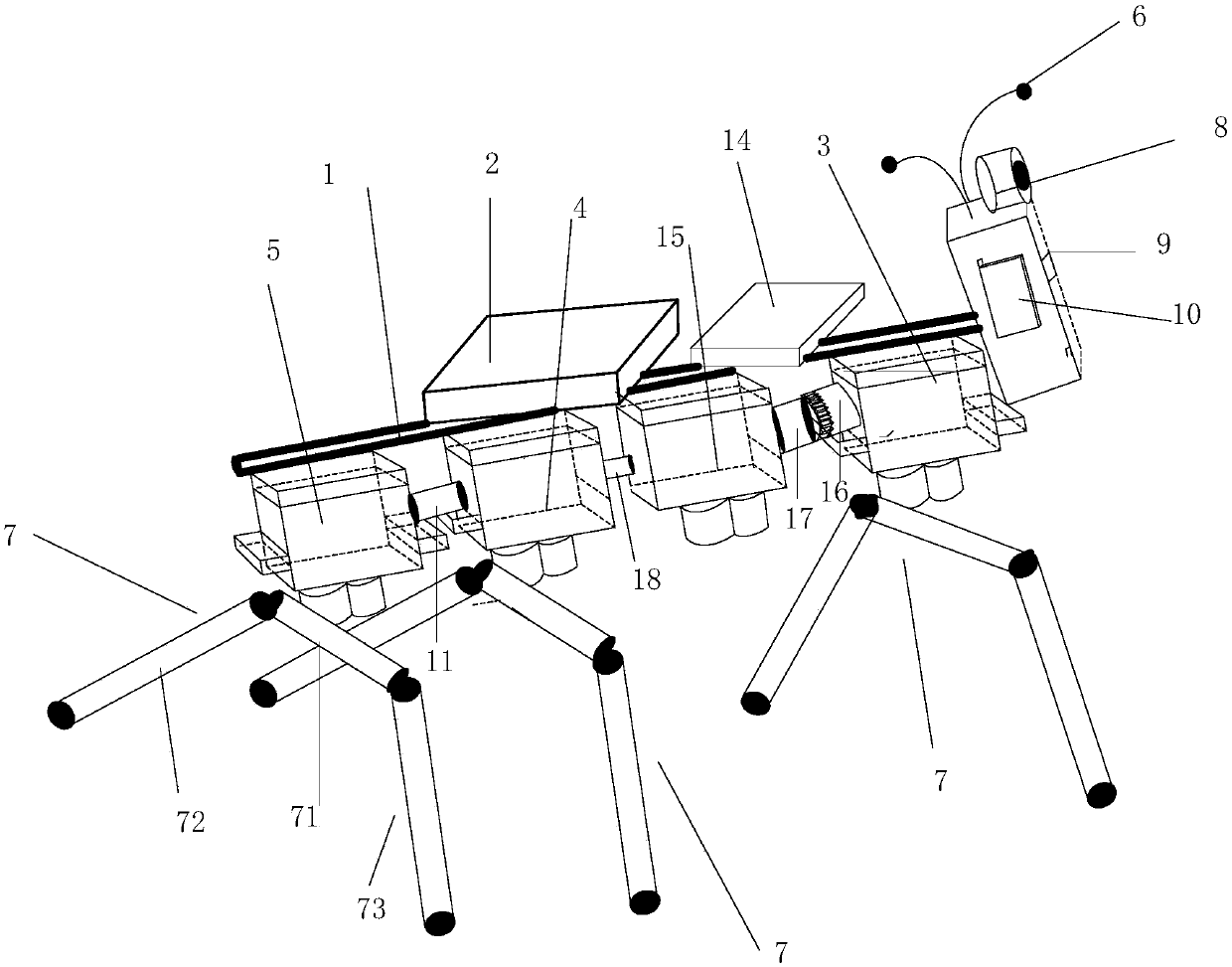

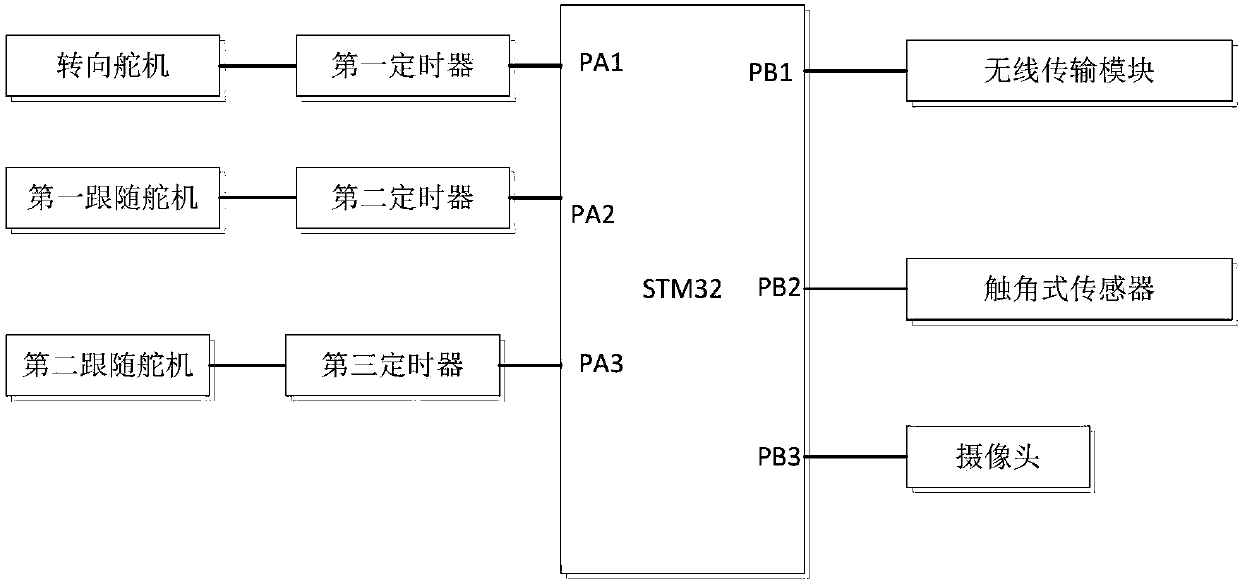

Bionic ant robot

PendingCN107813323AThe overall structure is simpleSimple functionProgramme-controlled manipulatorVehiclesElectricityAnt robotics

The invention discloses a bionic ant robot. The ant robot comprises a trunk frame, wherein a power supply module is arranged above the trunk frame; a walking mechanism is arranged below the trunk frame; a detecting mechanism and a control mechanism for controlling the walking mechanism are arranged at the front end of the trunk frame; the walking mechanism comprises a steering actuator, a first following actuator and a second following actuator; mechanical legs are connected on output shafts of the steering actuator, the first following actuator and the second following actuator; the detectingmechanism comprises an antenna type sensor and a camera; the camera is electrically connected with a wireless transmission module; the control mechanism comprises the wireless transmission module andan MCU (master control unit); an input end of the MCU is electrically connected with the wireless transmission module and the antenna type sensor; and an output end of the MCU is respectively electrically connected with control signal input ends of the steering actuator, the first following actuator and the second following actuator. The bionic ant robot disclosed by the invention is simple in integral structure and more easily enters complex geological environments to inspect by adopting the way of crawling by the mechanical legs.

Owner:CHENGDU UNIV

Bionic detection and rescue system

InactiveCN101543666BGuaranteed steeringImprove accessibilityBreathing protectionElectrical steeringControl powerPower unit

The present invention discloses a bionic detection and rescue system, which comprises a detection and rescue head, a turning power unit, a control power unit, an transmitting / receiving power unit, and several segments of moving units connected serially by springs; wherein, the front-end of the turning power unit is connected with the tail end of the detection and rescue head, the tail end of the turning power unit is connected with the front-end of the control power unit, and the tail end of the control power unit is connected with the front-end of the first moving unit, so that a main body is formed; the transmitting / receiving power unit is mounted on the tail end of the main body. The present invention has high accessibility, can move flexibly, and is easy to operate.

Owner:王彦明

Macropore plugging gelatin

The invention discloses a gel to block large-hole channel, which comprises the following parts: nitrogen and liquid with bulk rate at 2: 1, wherein the liquid is composed of 0.8% sodium dodecylbenzene sulfonate, 0.15% polyacrylamide, 0.3% thiourea, 2% calcium chloride, 1% chromic acetate, 0.1% bactericide and water.

Owner:DAQING OILFIELD CO LTD

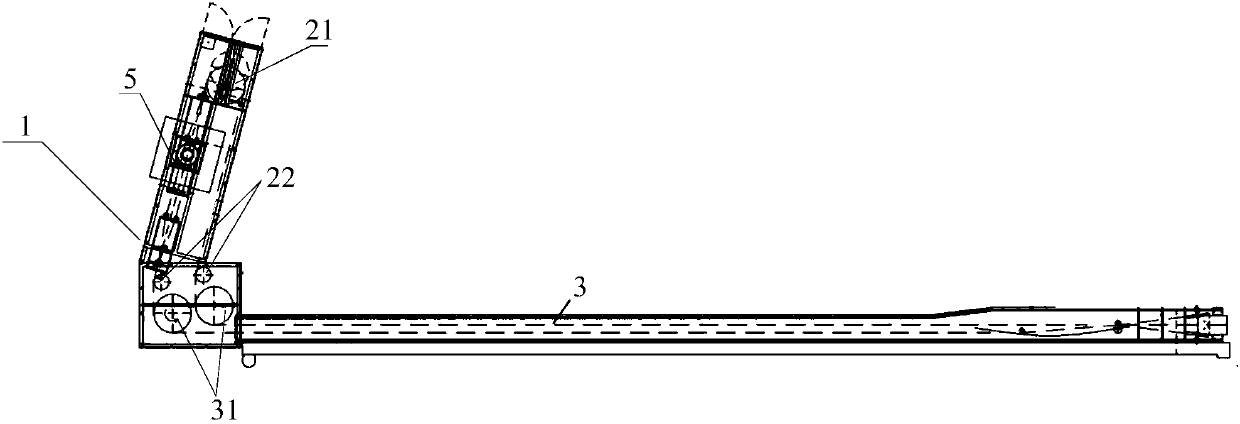

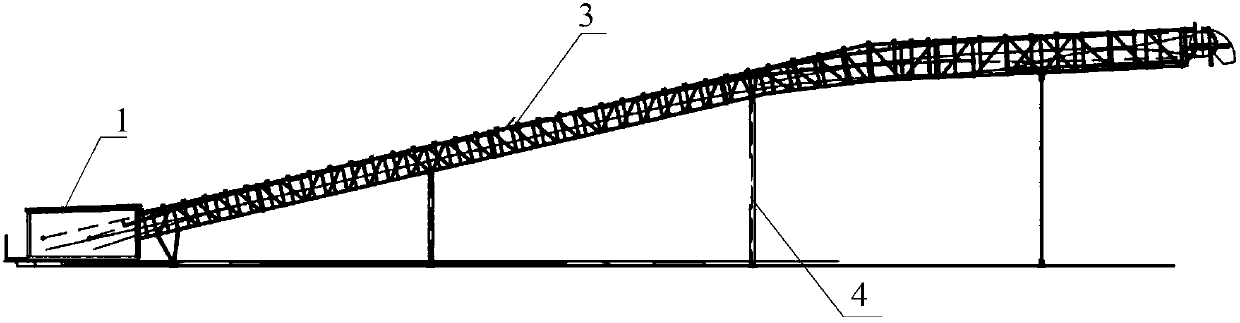

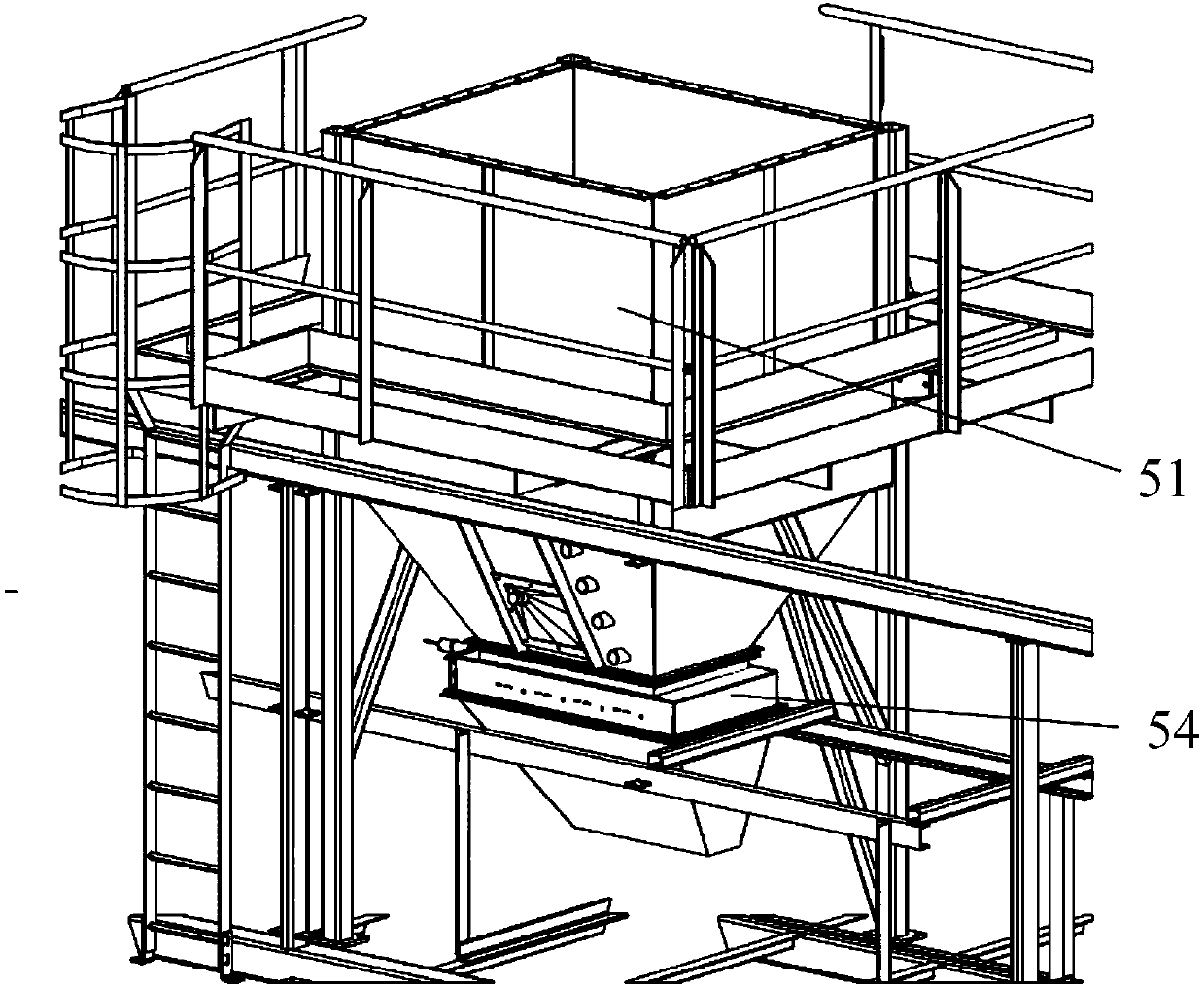

Bulk particle conveying device

ActiveCN107934466AGuaranteed steeringConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:HUBEI OCEAN ENG EQUIP RES INST CO LTD

Six-wheel double-drive mini-tiller

ActiveCN103879447AGuaranteed steeringDoes not affect steering angleSteering linkagesSteering angleTiller

The invention discloses a six-wheel double-drive mini-tiller which comprises a vehicle, front wheels, middle wheels, rear wheels and a rotary tiller. The front wheels, the middle wheels, the rear wheels and the rotary tiller are arranged on the vehicle, the front wheels and the middle wheels are arranged on the vehicle via a steering device, and the steering device comprises a steering gear, a front beam, a middle beam, a steering tie rod I, a steering tie rod II and a steering drag link; the steering gear is arranged at the bottom of the middle end of the vehicle; the front beam is arranged at the bottom of the front side of the vehicle; the middle beam is arranged at the bottom of the middle end of the vehicle and is positioned between the steering gear and the front beam; four steering knuckles are respectively arranged at two ends of the front beam and two ends of the middle beam; two ends of the steering tie rod I are respectively hinged to hinge lugs of the steering knuckles at the two ends of the front beam via tie rod arms; two ends of the steering tie rod II are respectively hinged to hinge lugs of the steering knuckles at the two ends of the middle beam via tie rod arms; one end of the steering drag link is connected with the steering gear, and the other end of the steering drag link is connected with two steering knuckle arms respectively. The six-wheel double-drive mini-tiller has the advantages that a four-wheel same-direction steering effect can be realized, and a preset steering angle of the six-wheel double-drive mini-tiller is unaffected when one or two of the four wheels slips.

Owner:WANDONG FENGYUAN MACHINERY

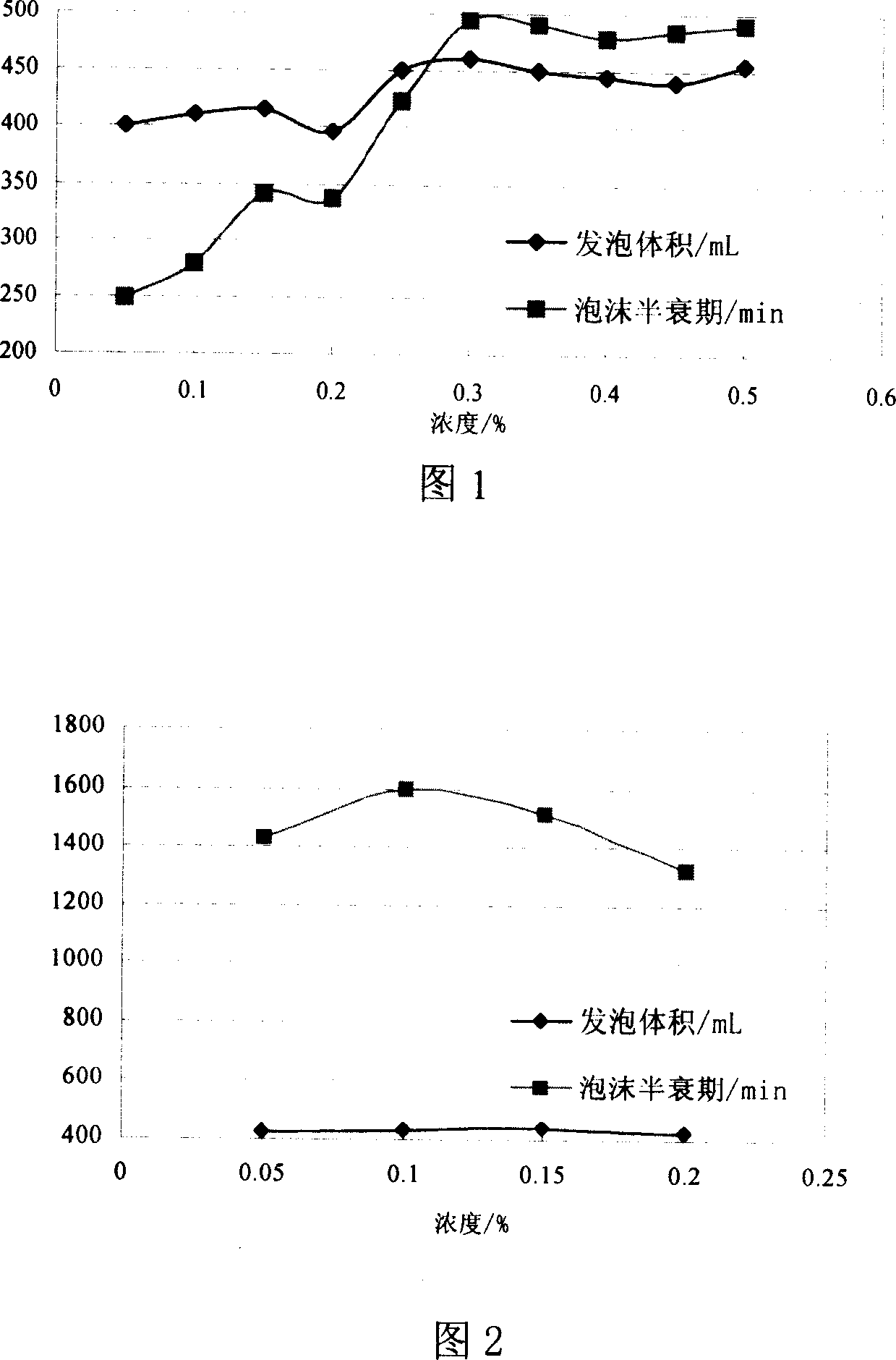

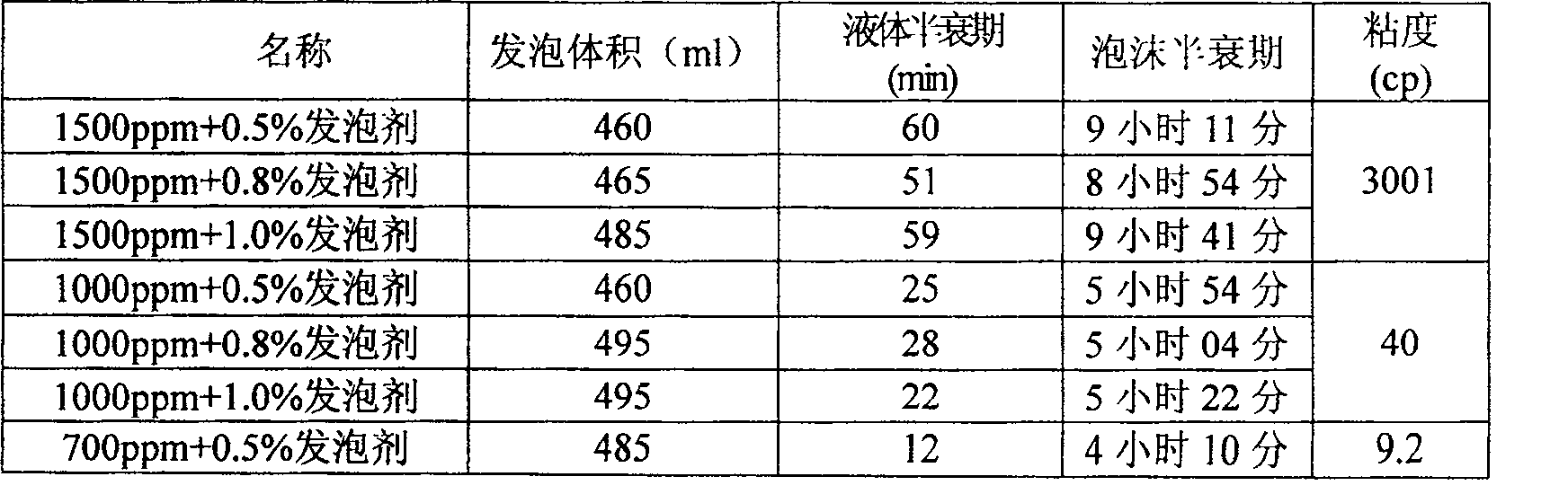

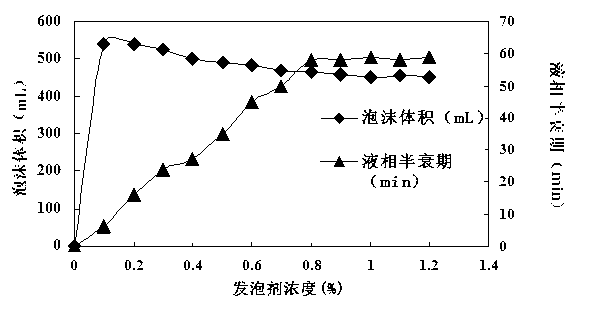

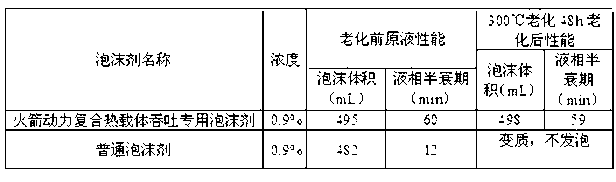

Foaming agent special for huff and puff of rocket power compound heat carrier

InactiveCN102838971AGuaranteed steeringOil displacement effect is goodDrilling compositionSulfonateHeat carrier

The invention discloses a heat-resistant foaming agent special for huff and puff of a rocket power compound heat carrier. The foaming agent resolves the problems that a conventional foaming agent is poor in compatibility with the rocket power compound heat carrier, and temperature resistant performance and stability cannot meet field test requirements. The foaming agent comprises, by weight, 0.5-1.0% of sodium akylbenzene sulfonate, 0.1-0.3% of hydroxypropyl modified cellulose, and the balance water. The stratum temperature to which the foaming agent can adapt can be up to more than 300 DEG C; and foam volume, liquid phase half life and other indicators of the foaming agent are significantly better than those of a common foaming agent.

Owner:PETROCHINA CO LTD +1

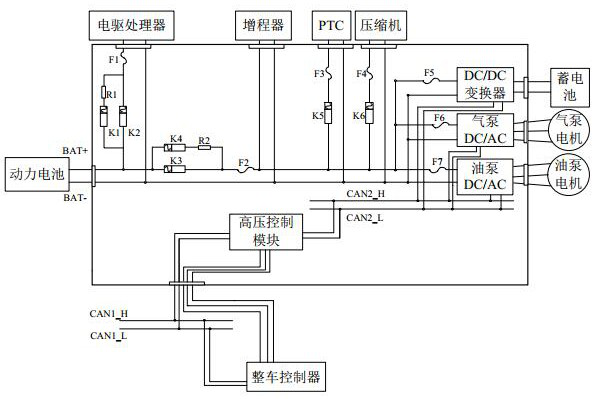

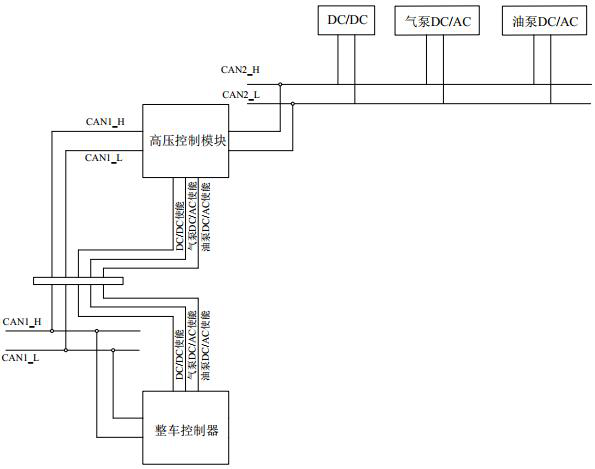

All-in-one high-voltage power supply distribution assembly for non-road wide-body vehicle and working method

ActiveCN113910927AImprove continuous working abilityGuaranteed steeringElectric devicesPropulsion by batteries/cellsSupply & distributionMechanical engineering

The invention particularly relates to an all-in-one high-voltage power supply distribution assembly for a non-road wide-body vehicle and a working method. The all-in-one high-voltage power supply distribution assembly for the non-road wide-body vehicle comprises a high-voltage power supply module, a high-voltage control module and a first low-voltage connector; when a CAN bus between the high-voltage control module and the vehicle control unit fails, enabling control is carried out between the high-voltage control module and the vehicle control unit through a hard wire; the high-voltage control module receives a driving signal of the vehicle control unit and drives the high-voltage power supply module to execute a corresponding instruction; the high-voltage control module collects the working state of the high-voltage power supply module and sends the working state to the vehicle control unit; the CAN bus and the hard wire are arranged between the high-voltage control module and the whole vehicle controller, redundancy control can be conducted on the DC / DC converter, the air pump DC / AC converter and the oil pump DC / AC converter in the high-voltage power module, the continuous working capacity of the high-voltage power module is greatly improved, and the vehicle steering and braking capacity is guaranteed.

Owner:NEW UNITED RAIL TRANSIT TECH

Hand-rocking type mechanical energy storage bionic toy car

The invention discloses a hand-rocking type mechanical energy storage bionic toy car which comprises a car body, front wheels, rear wheels and a driving mechanism for driving the rear wheels to operate. The hand-rocking type mechanical energy storage bionic toy car is characterized in that the driving mechanism comprises a power input mechanism, at least one group of mechanical energy storage assembly, a power releasing assembly matched with the mechanical energy storage assembly and a power output shaft. The rear wheels are sleeved on two ends of the power output shaft in empty mode. During driving of the toy car, the power input mechanism is started manually, power is delivered to the mechanical energy storage assembly to be stored through the power input mechanism, then the power in the mechanical energy storage assembly is released through the releasing assembly and delivered to the power output shaft so as to drive the toy car to operate. Compared with the prior art, the hand-rocking type mechanical energy storage bionic toy car has the advantages of improving playing enjoyment of children and having a practicing effect. The toy car is of a pure mechanical mechanism and is not driven electrically.

Owner:CHONGQING UNIV OF TECH

Remotely-controlled three-wheel agricultural locomotive with high passing ability

InactiveCN104925165ACompact structureSmall driving forceSpeed controllerVehiclesAgricultural engineeringSteering system

Owner:HEFEI DUOJIA AGRI SCI & TECH

Toy car synchronous steering device

InactiveCN111617493AGuaranteed steeringGuaranteed normal drivingToy vehiclesSteering angleMechanical engineering

The invention relates to the technical field of toy car related equipment. The invention discloses a toy car synchronous steering device. The device comprises a transmission cross beam, and a long-strip-shaped transverse sliding rail is arranged in the middle of the transmission cross beam. The transmission cross beam is arranged on two fixed columns in a sliding and sleeving manner through a transverse sliding rail; the upper part of the transmission cross beam is also fixedly connected with a connecting block; two connecting pieces are in threaded connection with the two sides of the transmission cross beam through bolts; the tail ends of the two connecting pieces are further rotationally connected with a first rotating block and a second rotating block through bolts correspondingly. Interms of the toy car synchronous steering device, a transverse sliding rail is additionally arranged on a transmission cross beam; the displacement distances of the two connecting pieces are consistent, the rotating amplitudes of the two rotating blocks are consistent, synchronous steering of wheels on the two sides is guaranteed, meanwhile, difference and deviation of steering angles of the wheels are effectively avoided, and the normal steering and running process of the toy car is guaranteed; the length of each connecting piece can be adjusted by rotating a threaded rod, and then the purpose of adjusting the structure and the steering range of a toy car to a certain extent is achieved.

Owner:BSD RACING TECH

A six-wheel two-drive tiller

ActiveCN103879447BGuaranteed steeringDoes not affect steering angleSteering linkagesSteering angleTwo-wheel drive

Owner:WANDONG FENGYUAN MACHINERY

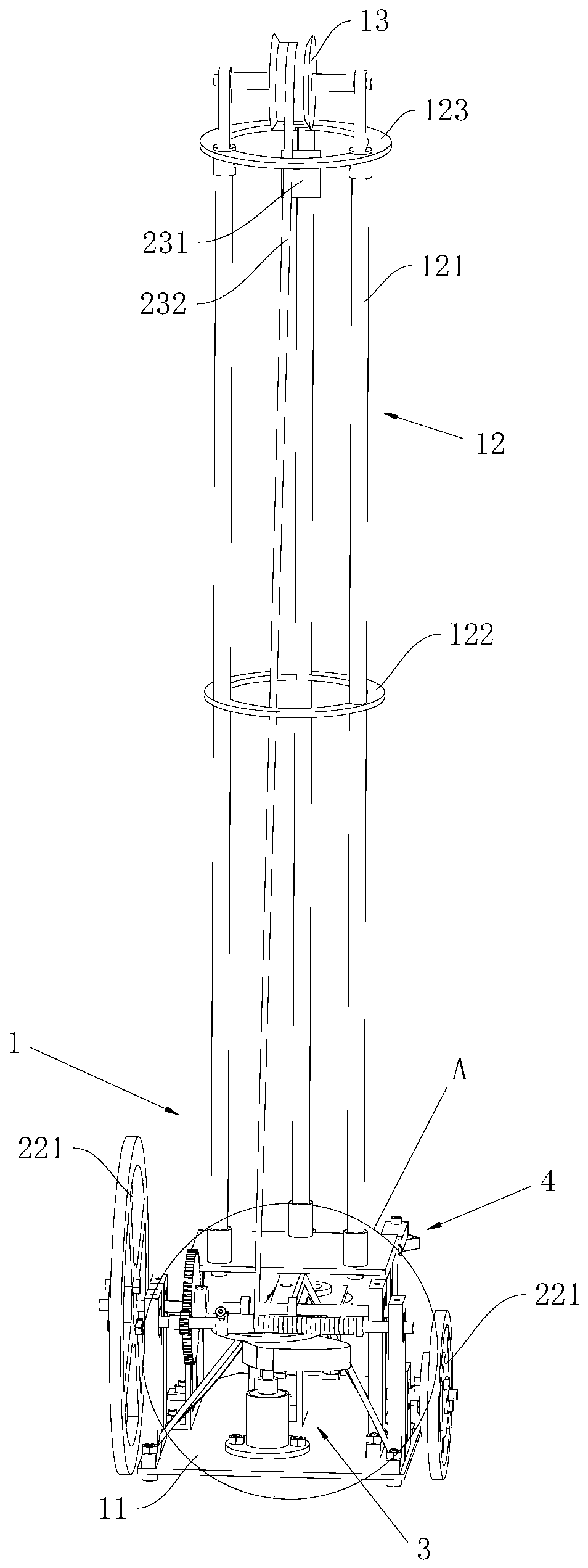

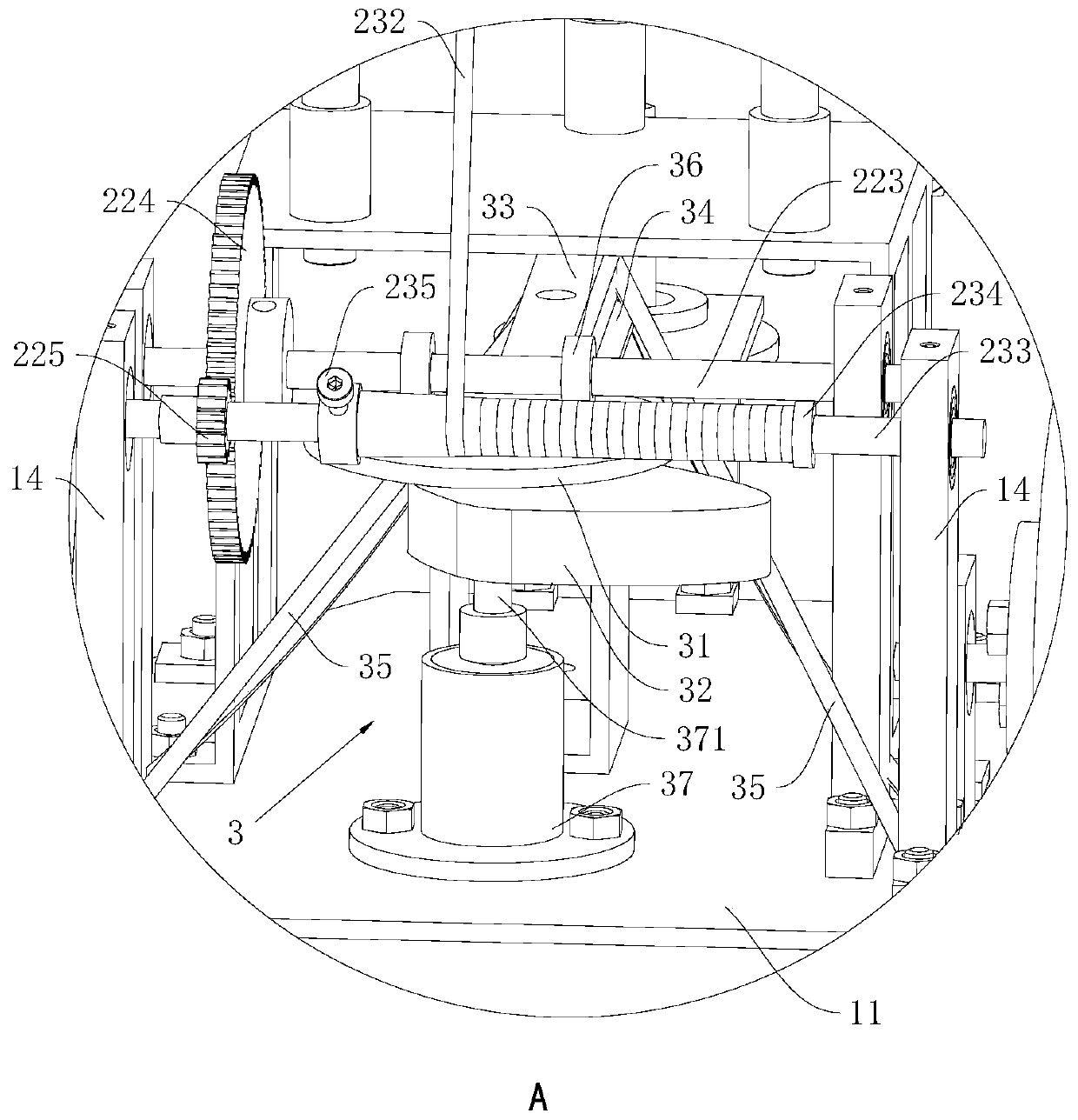

An electric passenger suitcase

ActiveCN104172707BEnsure normal walkingGuaranteed steeringLuggageOther accessoriesDrive wheelMarket place

The invention provides an electric manned luggage box utilizing an advanced technique that a steering motor is matched with a turbine worm to achieve electronic steering. The electric manned luggage box is characterized in that a base is arranged on a conventional luggage box, an electric walking mechanism and an electric steering mechanism are arranged in the base, and direct-current motor wheels serve as driving wheels of the luggage box; when the electric manned luggage box serves as the conventional luggage box, a pull rod is dragged to start an electric device to electrically move forwards, and when the electric manned luggage box is used normally, a passenger can sit on the surface of the luggage box and operates the luggage box to move forwards or steer by touching keys through fingers; the passenger can change the state of the electric manned luggage box at any time to carry the electric manned luggage box or sit on the electric manned luggage box to move forwards, so that a big problem that the passenger cannot timely sit to take a rest when tired during walking is overcome, and the passenger can carry the electric manned luggage box and sit on the electric manned luggage box to move forwards during shopping, touring and vehicle waiting at security halls of airports, superstores, tour and sightseeing places and busy streets such as commercial pedestrian streets. The electric manned luggage box is reasonable in overall layout structure, is convenient to carry and comfort, safe and reliable to sit and has a wide market application prospect.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com