Rotary online flushing device and process system for tubular heat exchanger

A tubular heat exchanger and flushing device technology, which is applied in the direction of cleaning heat transfer devices, flushing, geothermal power generation, etc., can solve the problems of easy shaking, damage to the seal of the inlet pipe and the installation hole, and liquid leakage, etc., to achieve fixed and stable, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

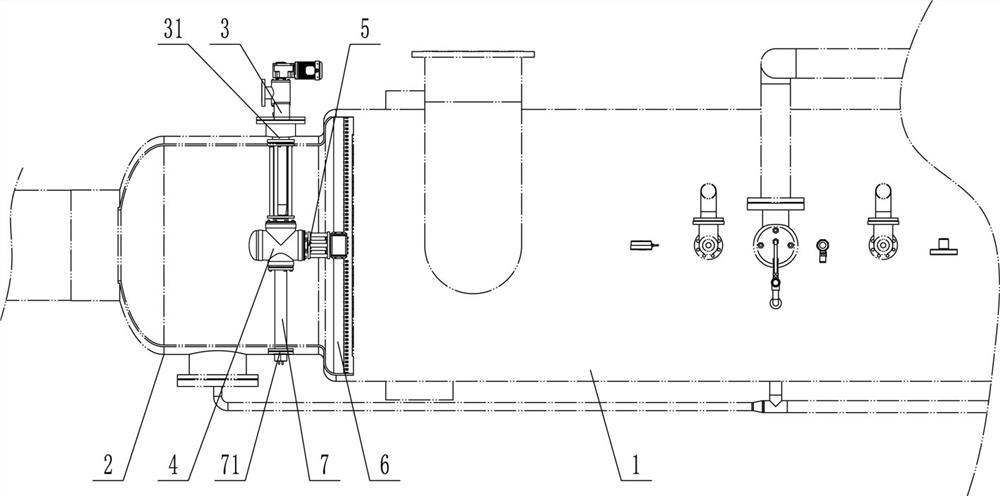

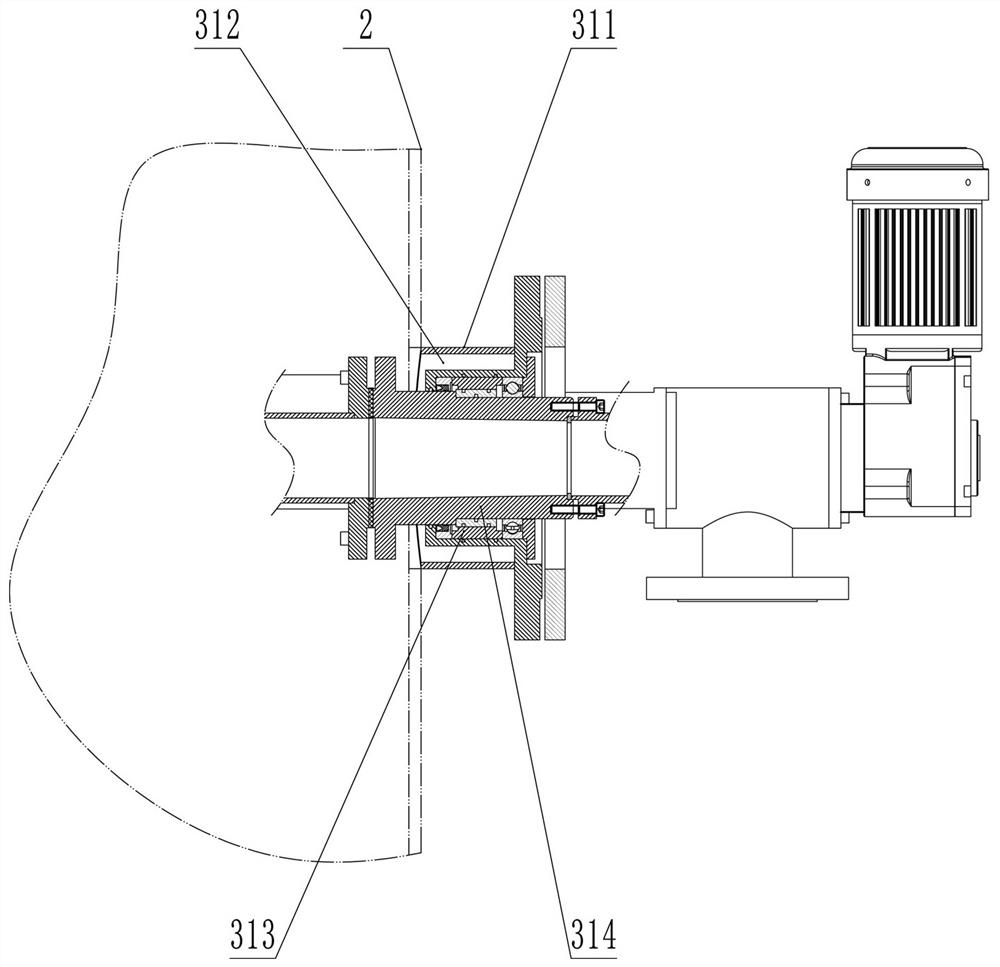

[0034] Such as Figure 1-4 As shown, a rotary online flushing device for a tubular heat exchanger includes a liquid inlet pipe assembly 3, a hydraulic steering mechanism 4, a liquid outlet pipe assembly 5 and a liquid outlet connected to the liquid outlet pipe assembly 5 The heat exchange tube flushing nozzle 6.

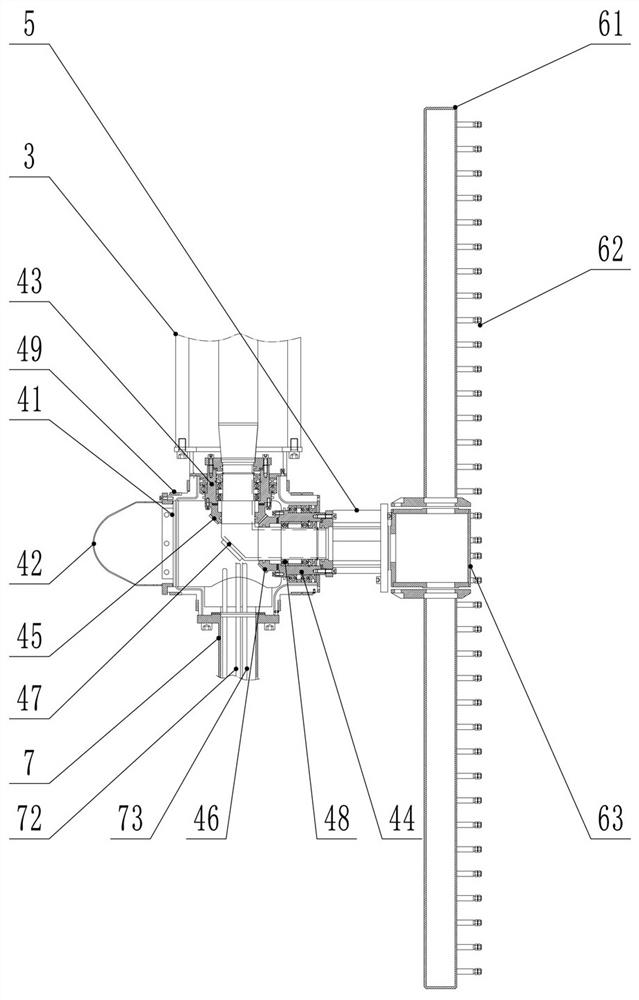

[0035] The hydraulic steering mechanism 4 specifically includes a housing 41, a liquid inlet bushing 43, a fluid outlet bushing 44, a right-angle insertion tube 47 arranged in the housing 41, and a driving bevel gear 45 meshed together with a slave A movable bevel gear 46; an input port and an output port are provided on the housing 41, the liquid inlet shaft sleeve 43 is rotatably installed in the input port, and the liquid outlet shaft sleeve 44 is rotatably installed in the In the output port, the liquid outlet of the liquid inlet sleeve 43 and the liquid inlet of the liquid outlet sleeve 44 are respectively sleeved outside the two ports of the right-angled cannu...

Embodiment 2

[0045] Such as Figure 5 As shown, a tubular heat exchanger rotary on-line flushing process system includes a high-pressure water pump 11, a liquid supply main pipe 12 installed at the outlet of the high-pressure water pump 11, a dosing mixer 13 and a plurality of embodiments 1 Rotary online flushing device, the outlet of the dosing agitator 13 is connected to the liquid supply main pipe 12, and the liquid supply main pipe 12 is connected to each of the rotary online flushing devices through a plurality of liquid supply branch pipes 14. Cleaning fluid inlet. Each of the liquid supply branch pipes 14 is provided with an electric valve, and the electric valve is opened and closed by a PLC controller. There are filters 16 .

[0046] When in use, the high-pressure water pump 11 can take water from the water inlet pipeline of the heat exchanger, and can also take water from the public system. The high-pressure water pump 11 can simultaneously supply liquid to multiple online flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com