Graphite preheating piece, semiconductor preheating device, silicon core furnace and phosphorus detection furnace

A technology of graphite preheating sheet and preheating device is applied in the fields of graphite preheating sheet, silicon core furnace, phosphorus inspection furnace and semiconductor preheating device, which can solve the problems of easy fusing of molybdenum wire, slow heating speed and reduced reliability. , to achieve the effect of avoiding pollution, avoiding energy waste, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment firstly provides a semiconductor preheating device, which is used for preheating the semiconductor masterbatch during the semiconductor manufacturing process. This embodiment and other embodiments will take silicon as an example to describe the structure and functional characteristics of the semiconductor preheating device of the present invention in detail. It should be noted that this preheating device is also suitable for preheating semiconductor materials such as germanium, and will not be described in detail here.

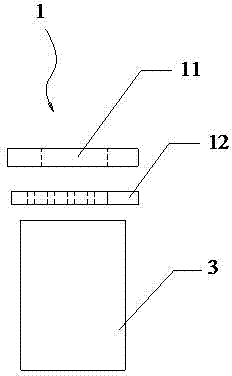

[0034] refer to image 3 As shown, the semiconductor preheating device 1 of this embodiment is arranged inside the silicon core furnace, includes a high frequency coil 11, and also includes a graphite preheater 12 coaxially arranged with the high frequency coil 11, and the graphite preheater 12 is placed The lower edge of the high frequency coil 11, but not in contact with the high frequency coil 11.

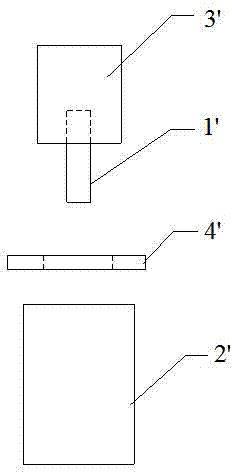

[0035] like Figure 4 As shown, ...

Embodiment 2

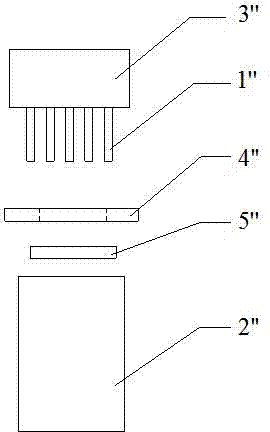

[0038] refer to Figure 5 As shown, this embodiment provides another semiconductor preheating device 10, which differs from the semiconductor preheating device 1 described in Embodiment 1 in that the semiconductor preheating device 10 of this embodiment also includes a preheating Sheet extraction device 20, preheating sheet extraction device 20 includes a control rod 13, one end of the control rod 13 stretches out of the silicon core furnace, and the other end is connected with the handle 123 provided on the graphite preheating 12 sheets, The graphite preheating sheet 12 is drawn out of the silicon core furnace through the control rod 13 .

[0039] In addition, in the semiconductor preheating device 10 of this embodiment, a power monitor 14 is connected to the high-frequency coil 11 for real-time monitoring of the output power of the high-frequency coil 11. When the master material 3 reaches a certain temperature, it becomes a magnetic conductor , and produce an eddy current ...

Embodiment 3

[0042] refer to Image 6 As shown, this embodiment provides a silicon core furnace 2 capable of drawing multiple silicon cores at a time. The silicon core furnace 2 includes the semiconductor preheating device 10 described in Embodiment 2, and also includes a furnace body 21 and a seed Crystal fixtures. The seed crystal fixing device is a graphite sleeve 22, and the graphite sleeve 22 is provided with a plurality of stations where the seed crystal 4 can be installed; a rod-shaped masterbatch 3 is placed in the furnace body 21 . In the silicon core furnace 2 of this embodiment, the semiconductor preheating device 10 is located between the graphite sleeve 22 and the master material 3 , and the three are on the same vertical line. The masterbatch 3 is placed upright or fixed in the furnace body 21 , and is located directly below the graphite preheating sheet 12 .

[0043] As mentioned above, the seed crystal 4 is a fine silicon rod used to make the melted master material 3 grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com