Acid resistant foamed plugging agent

A technology of plugging agent and foam, which is applied in the field of foam plugging agent, can solve the problems of reduced swept volume, low viscosity, and affecting the development effect of gas injection, and achieve the effects of increasing stability, low cost, and increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

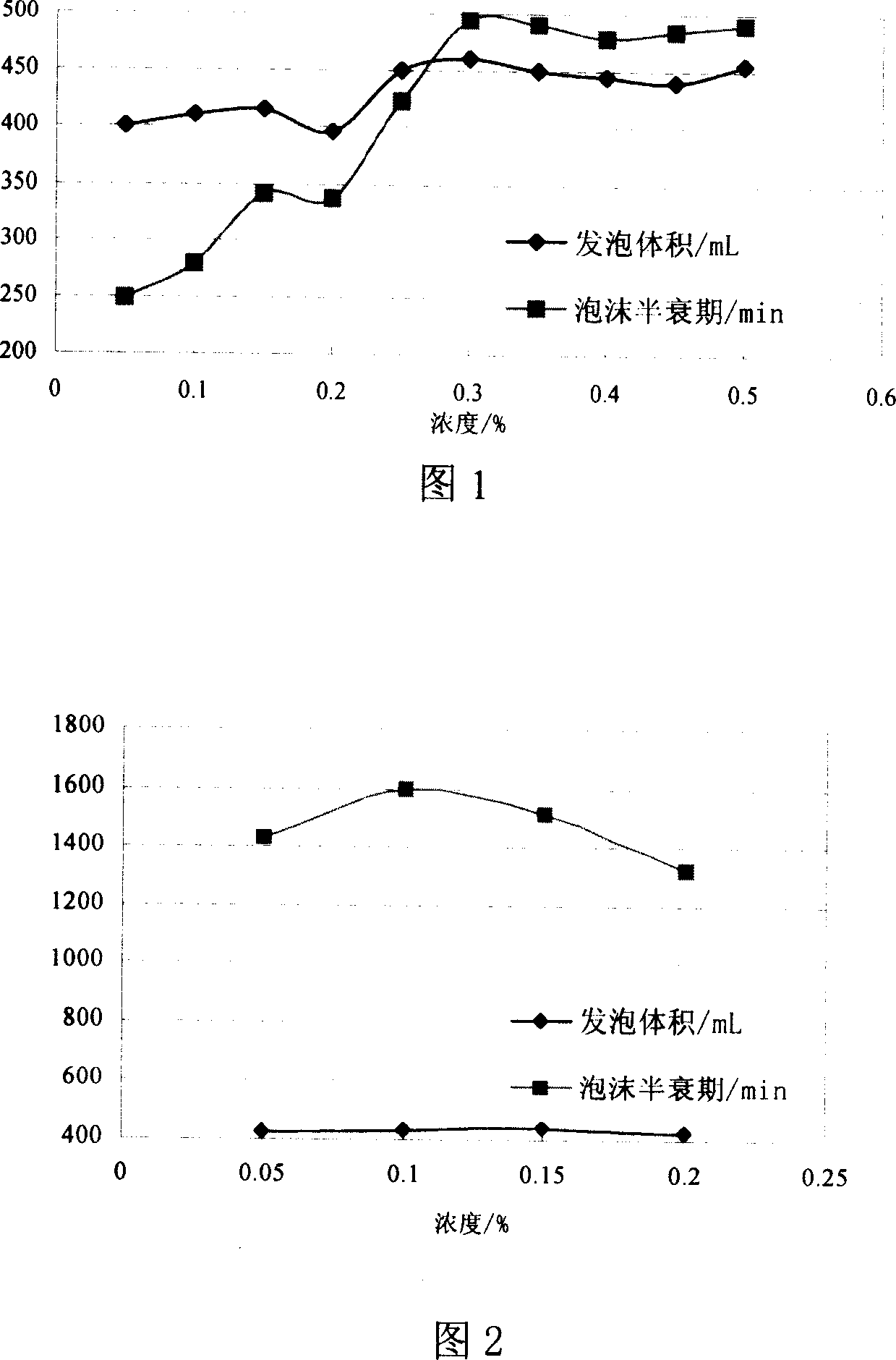

Embodiment 1

[0012] Embodiment 1, stirring method is measured whipping agent: during measurement, 100ml whipping agent solution is poured in the transparent measuring cup that agitator band scale is arranged, stir 60s under high speed (3000 revs), record foam volume and separate from foam The time to half the liquid volume and the time to reduce the foam to half, the former indicates foaming capacity (foaming volume), and the latter two indicate foam stability (half-life). The experimental results are shown in Table 1.

[0013] Foaming volume and half-life of foaming agent Table 1

[0014] Foaming agent

[0015] The results show that: the foaming volumes of these six foaming agents are not much different, but the half-life of sodium dodecylbenzenesulfonate SD-5 is longer, reaching 8.2h; the interfacial tension is lower, reaching 0.56-1.61mN / m.

Embodiment 2

[0016] Embodiment 2, liquid-carrying method to measure foaming agent: Carry out liquid-carrying ability evaluation experiment to 6 kinds of foaming agents with PDP-1 foam dynamic performance tester, carry out foam discharge agent quality inspection operating procedure, concrete experimental method is as follows: 6 kinds of foaming agents A foaming agent is made into 1000ml of 0.3% solution, and the air intake valve is opened to adjust the air volume to 3.42m 3 / h (57mL / min), start to pump the blowing agent after the air flow is stable, the pump speed is 80mL / min, and collect data, stop data collection after 10min, measure the liquid volume after the foam burst in the foam collection cylinder, test The results are shown in Table 2.

[0017] Comparison of foam liquid carrying capacity Table 2

[0018] sample

[0019] Experiments show that: SD-5 (sodium dodecylbenzene sulfonate) and 3#A blowing agent have very high foam liquid carrying capacity, reaching more than 1600...

Embodiment 3

[0020] Example 3. Determination of foaming agents by pouring method (Ross-Miles method): Evaluation experiments were carried out on 6 kinds of foaming agents with a Roche-Miles foam tester. The specific method is as follows: mix 6 kinds of foaming agents into 0.3%, 0.5% concentration 300ml, fill the Roche Mill foam tester with 50ml liquid, measure 200ml solution with a pipette, open the dropper cock, and make the solution vertical Flow down, when the solution in the dropper has flowed out, start the stopwatch immediately and read the initial foam height, read the second height after 5min, the experimental results are shown in Table 3.

[0021] Comparison of foaming height of pouring blowing agent Table 3

[0022]

[0023] Experiments show that the foam height of SD-5 (sodium dodecylbenzenesulfonate) reaches 185mm, and the foam height remains basically unchanged after 5 minutes, followed by 3#A and SD-2, whose foam height reaches more than 150mm. The comprehensive co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com