Macropore plugging gelatin

A technology of large pores and gel, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of ineffective development of low-permeability parts of thick oil layers, high cost, low efficiency of injected water, etc., and achieve low cost , Increased crude oil output and small treatment radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

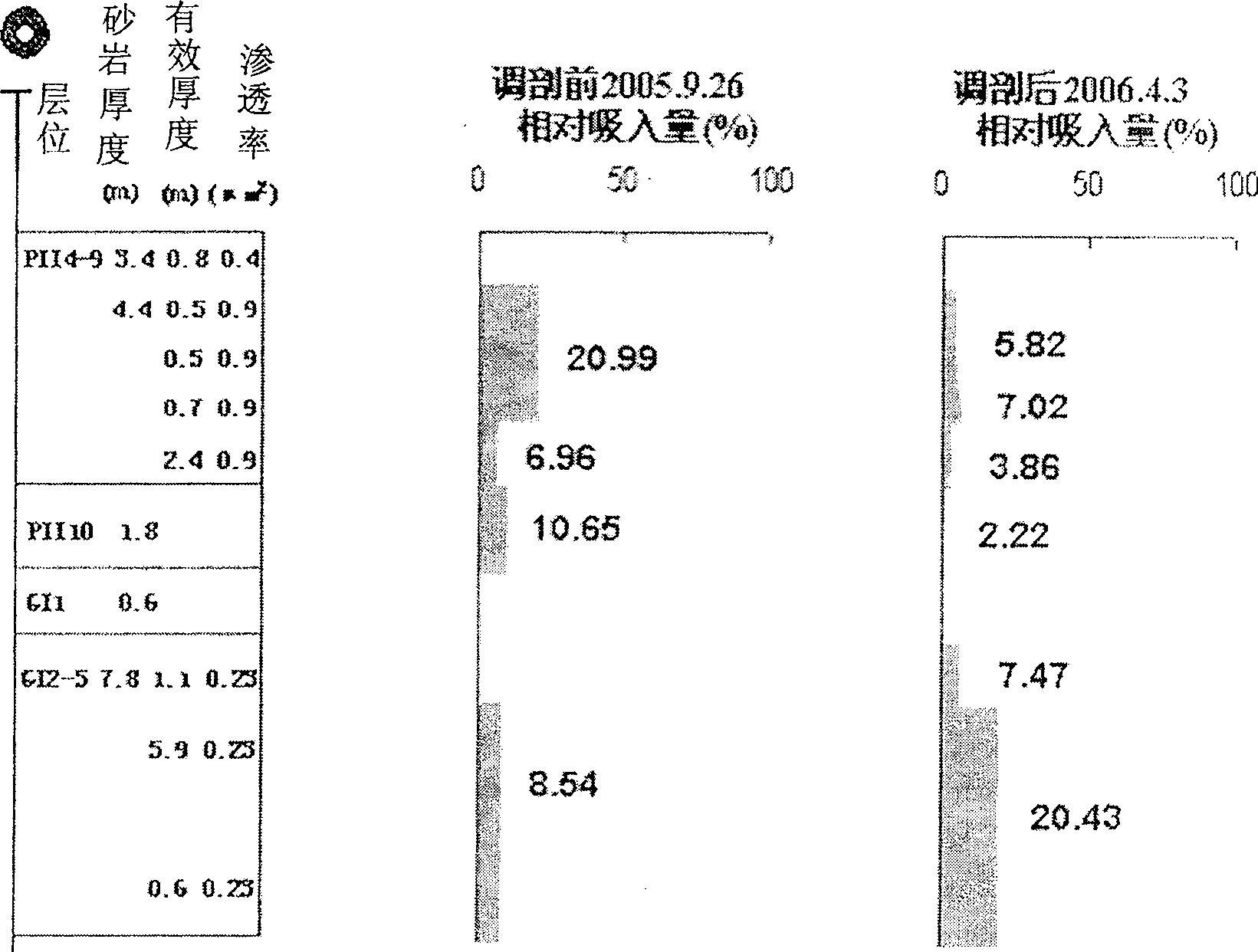

Image

Examples

Embodiment 1

[0010] Embodiment 1, laboratory experiment:

[0011] 1. Foaming volume and half-life:

[0012] Experimental method: Waring Blender method was used to evaluate foam volume and half-life.

[0013] Weigh 100ml of gel foam solution, stir with a high-speed mixer at 3000r / min for 60s, pour the foam into a graduated cylinder, read the foam height, that is, the foam volume. At the same time, the time required to reduce the amount of foam by half and the time for half of the solution to precipitate out, namely the foam half-life and the liquid half-life, were recorded.

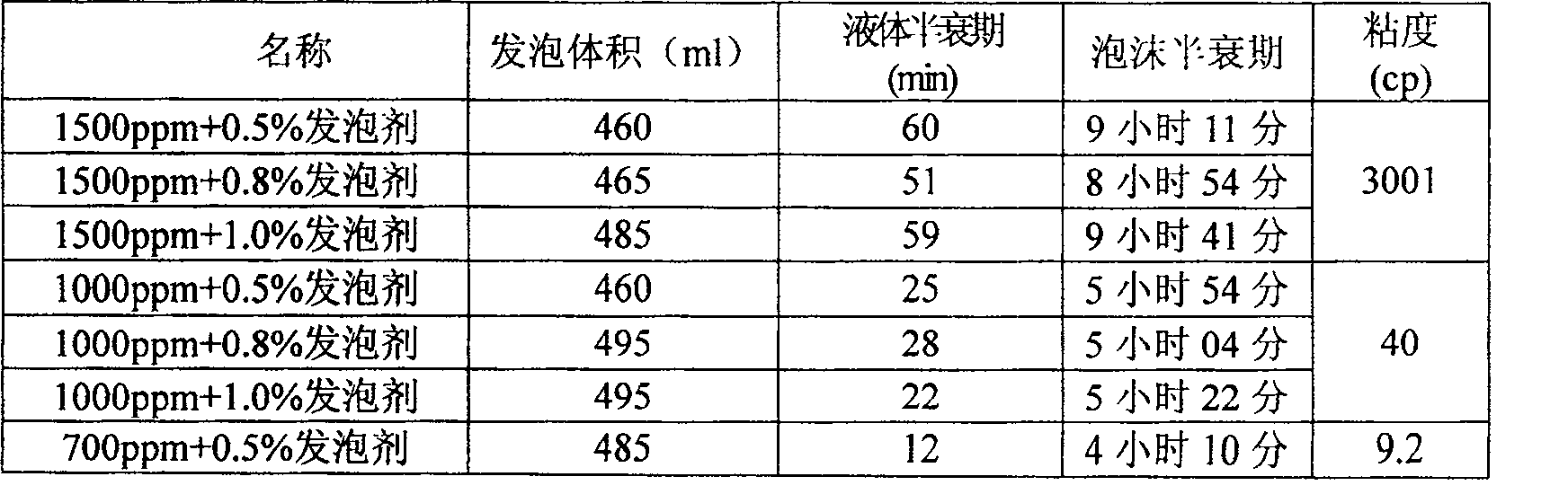

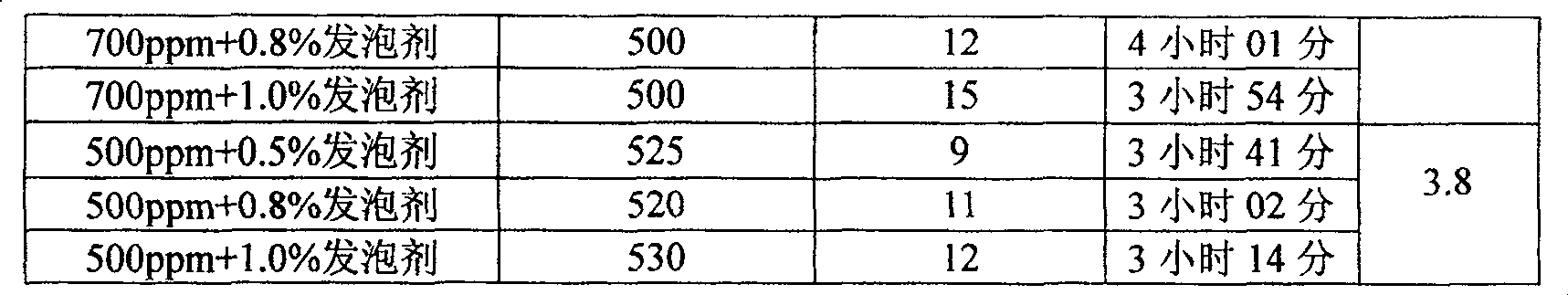

[0014] Gel foam foam volume and half-life table Table 1

[0015]

Solution concentration volume before foaming

(ml) Volume after foaming

(ml) liquid half-life

(min) foam half-life

(min) 1500ppmN+0.8%F 100 510 24 238

[0016] 2. Screening of the concentration of gel system and the concentration of foaming agent sodium dodecylbenzenesulfonate:

[0017] In the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com