Rocket power composite heat carrier throughput fluid diversion technique

A composite heat carrier and liquid flow diversion technology, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of enlarged swept volume, intensified interlayer plane contradiction, and low viscosity, and achieves multi-economy. Benefit, enlargement of sweep volume, effect of changing the direction of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1. Liquid flow diversion process before huff and puff in well B2-D4-P29:

[0019] Due to the severe heterogeneity of the oil layer after polymer flooding and the development of high-permeability strips, in order to prevent the injection of composite heat carriers from ineffective and inefficient circulation along the high-permeability zones, prevent gas channeling, expand the swept volume, and improve oil displacement efficiency, the compounding Before the heat carrier huff and puff, it is necessary to carry out liquid flow diversion process construction on the test well group.

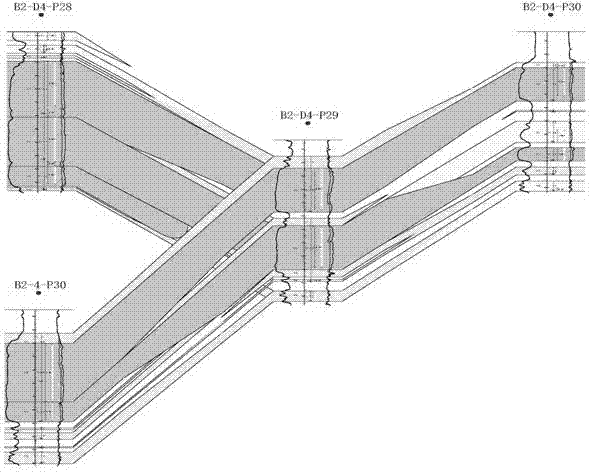

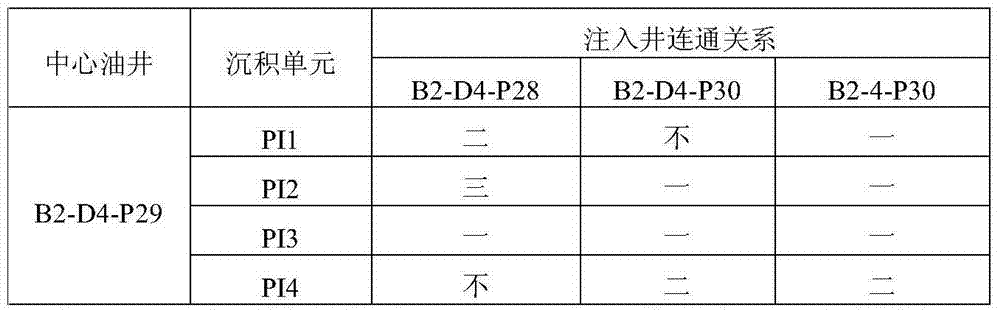

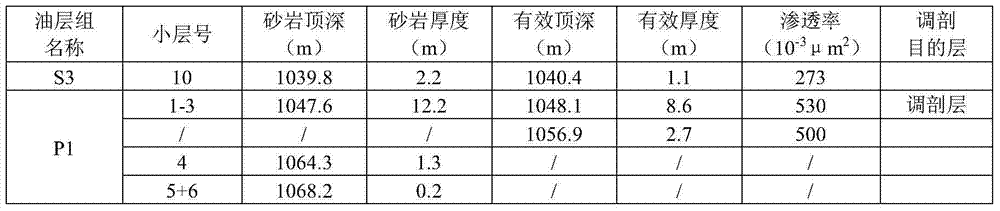

[0020] The three injection wells connected to B2-D4-P29 are B2-D4-P30, B2-D4-P28 and B2-4-P30 respectively. The connection status of the well group is as follows: figure 1 shown by figure 1 , Table 1 shows that B2-D4-P29 and B2-D4-P28 have a high connectivity rate and a large connectivity thickness, followed by well B2-4-P30 with better connectivity, and poorer connectivity with B2-D4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com