Foaming agent special for huff and puff of rocket power compound heat carrier

A technology of composite heat carrier and foaming agent, applied in the field of foaming agent, can solve the problems that the temperature resistance and stability cannot meet the requirements of field tests, the degree of longitudinal production is poor, and the production effect is affected, so as to reduce the oil-water interfacial tension and improve Temperature resistance, effect of improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

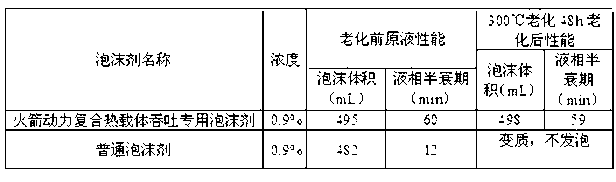

[0016] Embodiment 1, foaming agent temperature resistance performance test:

[0017] Weigh 2 parts each of 0.9g sodium heavy alkylbenzene sulfonate and 0.3g hydroxypropyl modified cellulose with a balance, add them to a 500mL beaker respectively, then add 98.8g water, put a magnetic stirring bar, and stir Stir on the mixer for 30 minutes to prepare a 0.9% rocket-powered composite heat carrier foaming agent solution. Put one part of it into a high-temperature tank and seal it, and age it at 300 ° C for 48 hours. After aging and cooling, take it out and use a high-speed mixer. Stir at a speed of 4000r / min for 60s, then pour into a graduated cylinder to record the volume, and start a stopwatch at the same time, when the eluate reaches 50mL, record the final time as the half-life of the liquid phase. Another copy was sealed and stored at room temperature for 48 hours, and the performance index of the foaming agent was tested by the same method as the aging sample. The experimental...

Embodiment 2

[0021] Embodiment 2, the performance test of foaming agent:

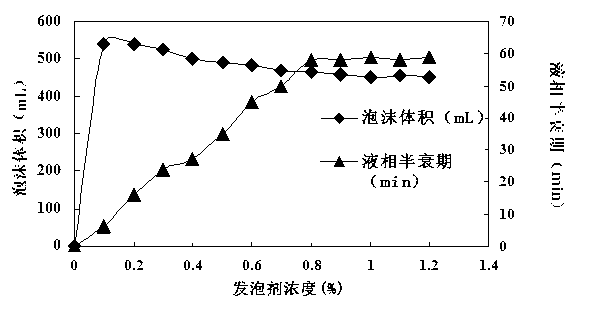

[0022] Weigh 0.5g sodium heavy alkylbenzene sulfonate and 0.1g and 2 parts each of hydroxypropyl modified cellulose with a balance, add them respectively in a 500mL beaker, then add 99.4g water, put into a magnetic stirring bar, and Stir on the stirrer for 30 minutes, and prepare a 0.5% rocket-powered composite heat carrier foaming agent solution. The special foam agent for rocket power composite heat carrier was made into different concentrations, and the foaming volume and half-life were tested by stirring method. The experimental results are shown in the appendix figure 1 .

[0023] Depend on figure 1 It can be seen that the liquid-phase half-life of the foaming agent of the present invention can reach about 60 minutes, the maximum foaming volume can reach 550 mL, and the core resistance factor has reached more than 120 at 300° C. Less than 500 mL, the liquid phase half-life is about 10 minutes. At 300°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com