Bulk particle conveying device

A technology for conveying devices and particles, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., and can solve problems such as inability to bend and turn, and conveying routes that can only be straight lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

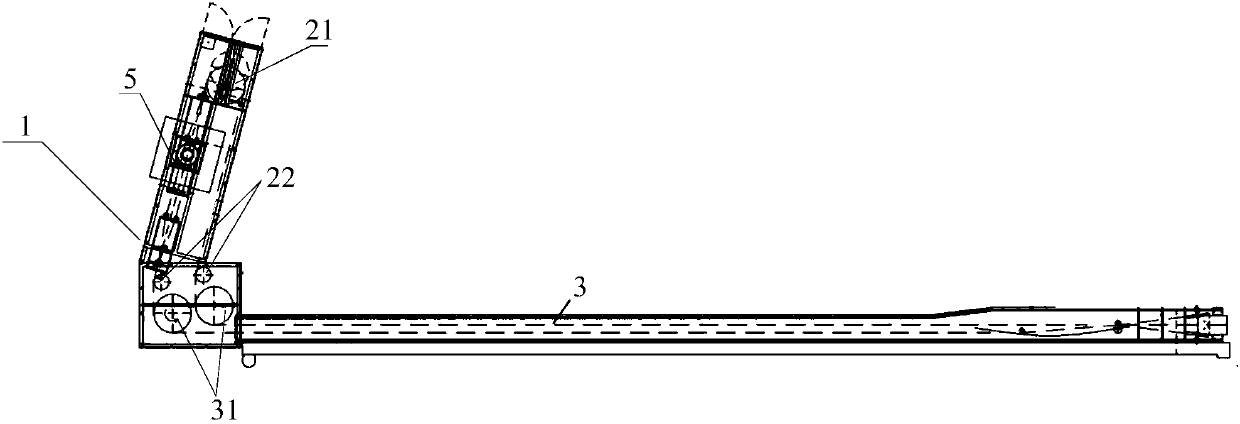

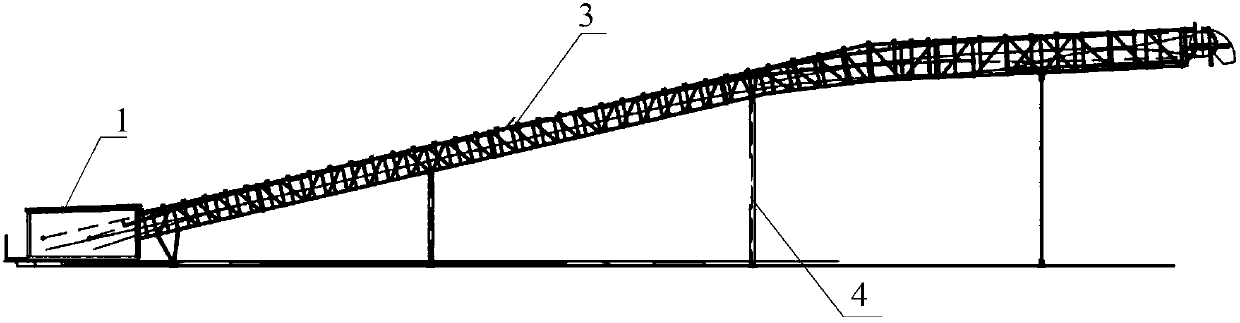

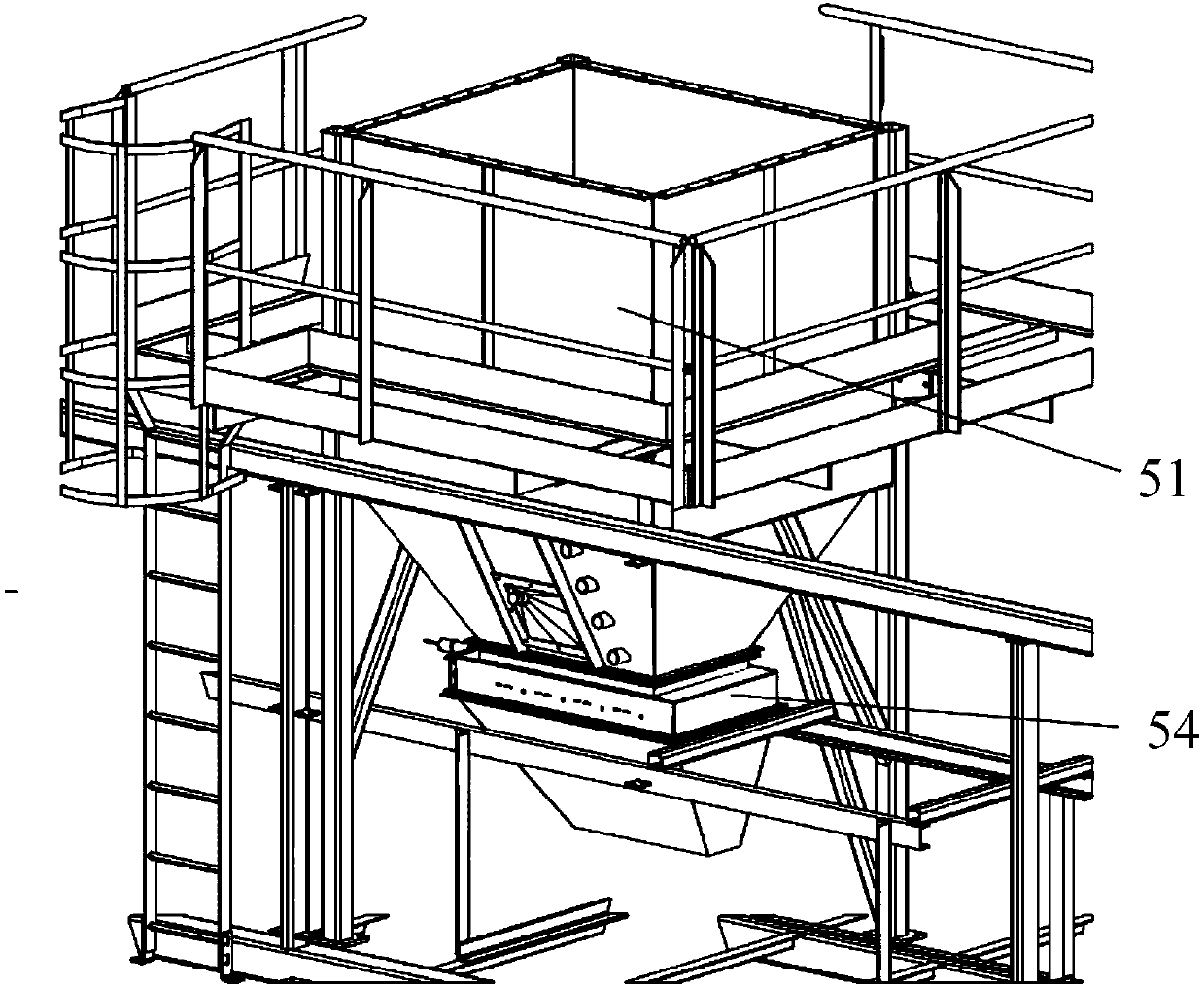

[0045] This embodiment provides a bulk particle conveying device, and the bulk particle may include: ore particles, food particles, metallurgical particles and feed particles, etc.; figure 1 As shown, the device includes: filling platform 1, steering mechanism 2, transmission mechanism 3; wherein,

[0046] The filling platform 1 is provided with a steering mechanism 2, and the filling platform 1 is used for filling the bulk particles; specifically, see figure 1 , the device also includes a housing, the housing includes: a truss and a thin plate; the filling platform 1, the steering mechanism 2 and the transmission mechanism 3 are installed on the truss; the thin plate is installed on the The outside of the above-mentioned truss forms a closed space to avoid environmental pollution during the process of conveying materials, and in this way can also convey items that have requirements for the environment.

[0047] Here, both the filling platform 1 and the transmission mechanism...

Embodiment 2

[0066] In practical application, when utilizing the delivery device provided by Embodiment 1 to deliver fish feed, the details are as follows:

[0067] Such as figure 1 As shown, the device includes: filling platform 1, steering mechanism 2, transmission mechanism 3; wherein,

[0068] The filling platform 1 is provided with a steering mechanism 2, and the filling platform 1 is used for filling the bulk particles; specifically, see figure 1 , the device also includes a housing, the housing includes: a truss and a thin plate; the filling platform 1, the steering mechanism 2 and the transmission mechanism 3 are installed on the truss; the thin plate is installed on the The outside of the above-mentioned truss forms a closed space to avoid environmental pollution during the process of conveying materials, and in this way can also convey items that have requirements for the environment.

[0069] Here, both the filling platform 1 and the transmission mechanism 3 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com