Chain clamping mechanism for dish washing machine

A washing machine and chain clip technology, which is applied in the washing machine/rinsing machine of tableware, the parts and applications of washing machine/rinsing washing machine of tableware, etc., can solve the problems of shedding, overlapping, displacement, etc., and achieve thorough cleaning and stable operation , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

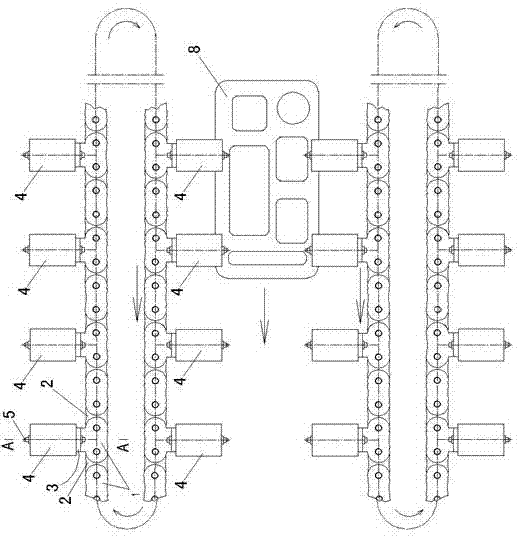

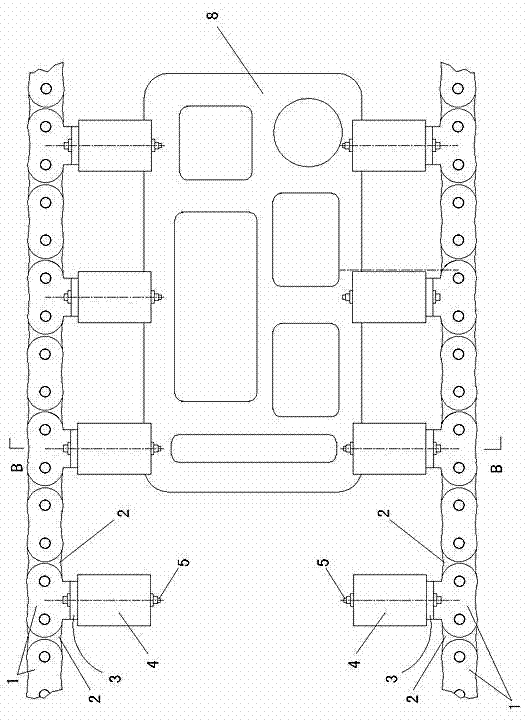

[0010] Such as figure 1 , 2 , shown in 3: there are two groups of chain mechanisms connected with the driving device in the present embodiment, each chain mechanism has a driving sprocket and a driven sprocket, the wheel shaft of the driving sprocket is connected to the driving device, and the driving device drives the chain mechanism run.

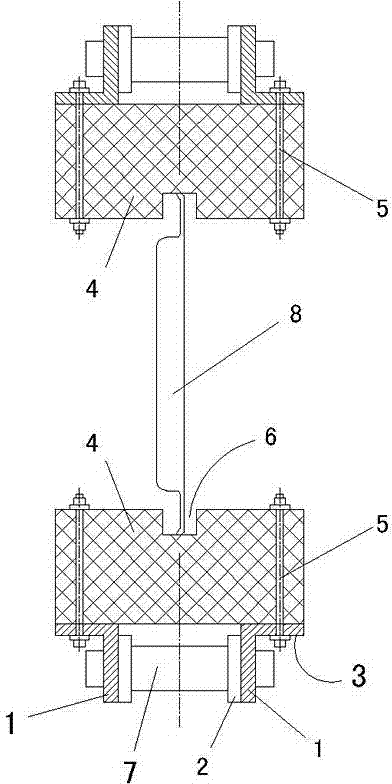

[0011] Elastic clamping blocks 4 are connected at intervals at the outer chain piece 1 on each chain, and the connection mode is that there are flanges 3 bent outward on the outer side of the outer chain piece 1, and the flanges 3 on both sides form A plane on which the bottom surface of the elastic clamping block 4 sits and is fixedly connected by clamping block bolts 5 . A groove 6 is provided in the middle part of the outer surface of the elastic clamping block 4 . The inner chain piece 2 on the chain and the sleeve 7 fitted outside the chain shaft are not connected with the elastic clamping block.

[0012] When utilizing this trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com