Crawler chassis testing system and testing method

A technology of crawler chassis and testing system, applied in the field of agricultural machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

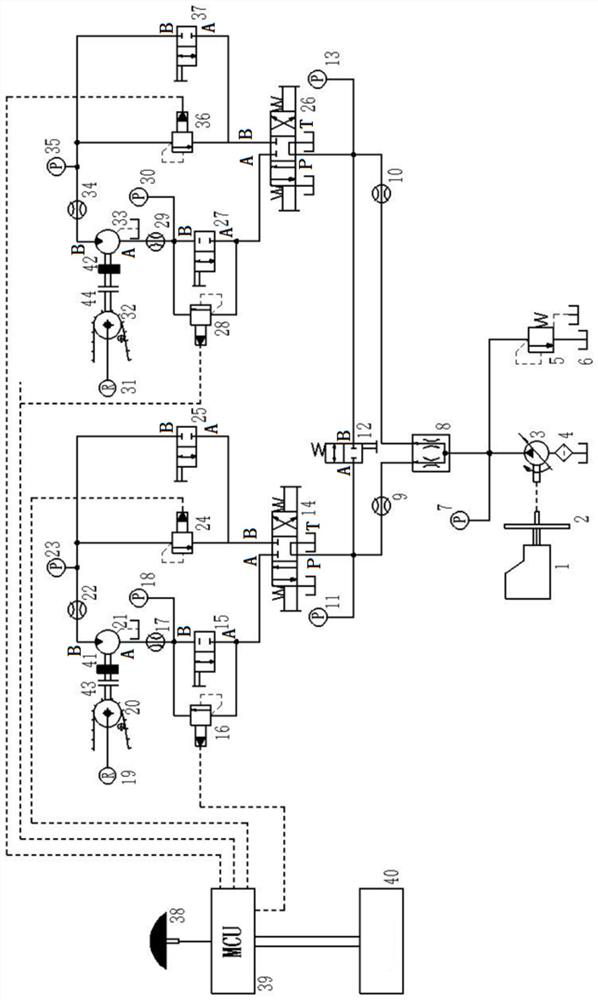

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] Such as figure 1 As shown, the present invention provides a crawler chassis testing system, including an engine 1, a connecting device 2, a variable pump 3, an oil tank 6, a flow control valve 12, a pressure sensor A7, a pressure sensor B11, a pressure sensor C13, a pressure sensor D18, a pressure sensor Sensor E23, pressure sensor F30, pressure sensor G35, torque sensor A41, torque sensor B42, encoder A19, encoder B31, microcontroller 39, speed measurement module 38 and host computer 40;

[0041] The engine 1 is connected with the variable pump 3 through the connecting device 2; the oil inlet of the variable pump 3 is connected with the oil tank 6, and the oil outlet of the variable pump 3 is connected with the oil inlet of the relief valve 5 and the oil inlet of the diverter valve 8 respectively. The oil outlet of the relief valve 5 is connected to the oil tank 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com