High concentration paper pulp grinding method and device

A high-concentration pulp technology, applied in the field of pulp and papermaking, can solve the problems of unfavorable further improvement of product quality, low fiber separation rate, high pulp swelling degree, etc., to achieve normal and reliable operation of equipment and high refining quality Reliable, highly breathable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below we will further illustrate the present invention in conjunction with accompanying drawing:

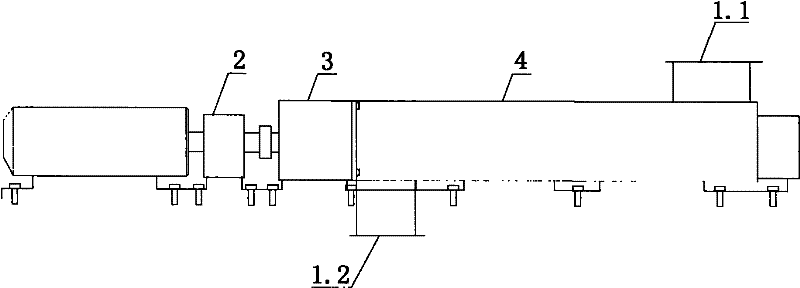

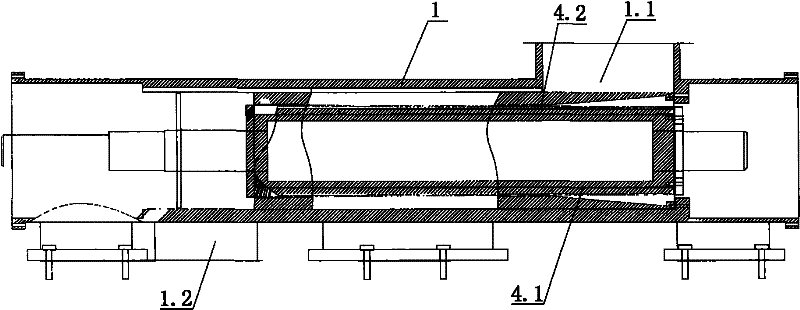

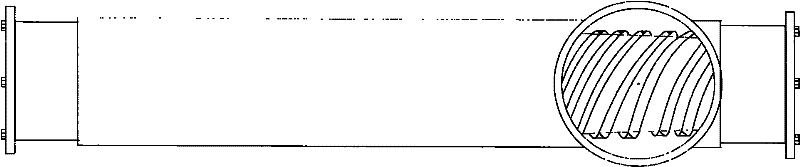

[0024] Such as Figure 1-Figure 7 As shown, the equipment for realizing the refining method of high-concentration pulp includes a casing 1, and a power system 2, a knife adding device 3 and a refining mechanism 4 connected in sequence, and the refining mechanism 4 includes a conical roller 4.1 and a conical roller 4.1. The matched grinding sleeve 4.2 is installed on the inner wall of the casing 1. One end of the casing 1 is provided with a feeding port 1.1, and the other end is provided with a discharging port 1.2. The grinding sleeve 4.2 is provided with a The feed port and the grinding sleeve 4.2 are also provided with a discharge port that matches the discharge port 1.2; the cone surface of the cone roller 4.1 is covered with multi-thread threads, and along the thin end of the cone roller 4.1 to the thick end of the cone roller 4.1, the thread groove It gradually becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com