Automatic silver point welding equipment for bimetal sheet of thermal protector

An automatic welding and bimetal sheet technology, applied in welding equipment, metal processing equipment, resistance welding equipment, etc., can solve problems such as material jam, low production efficiency, and high failure rate of equipment operation, so as to reduce the rate of consumables and save production costs , the effect of smooth running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

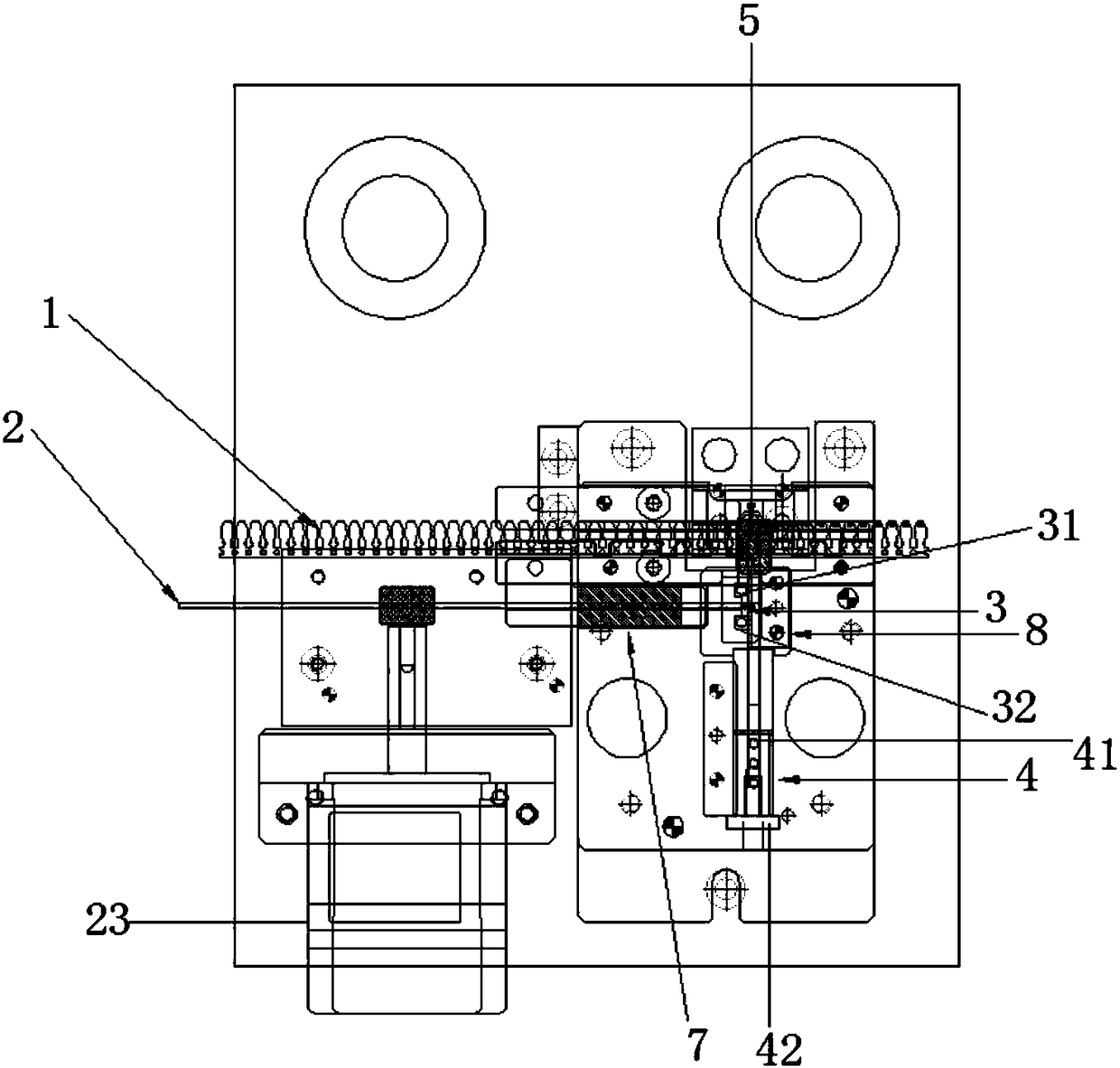

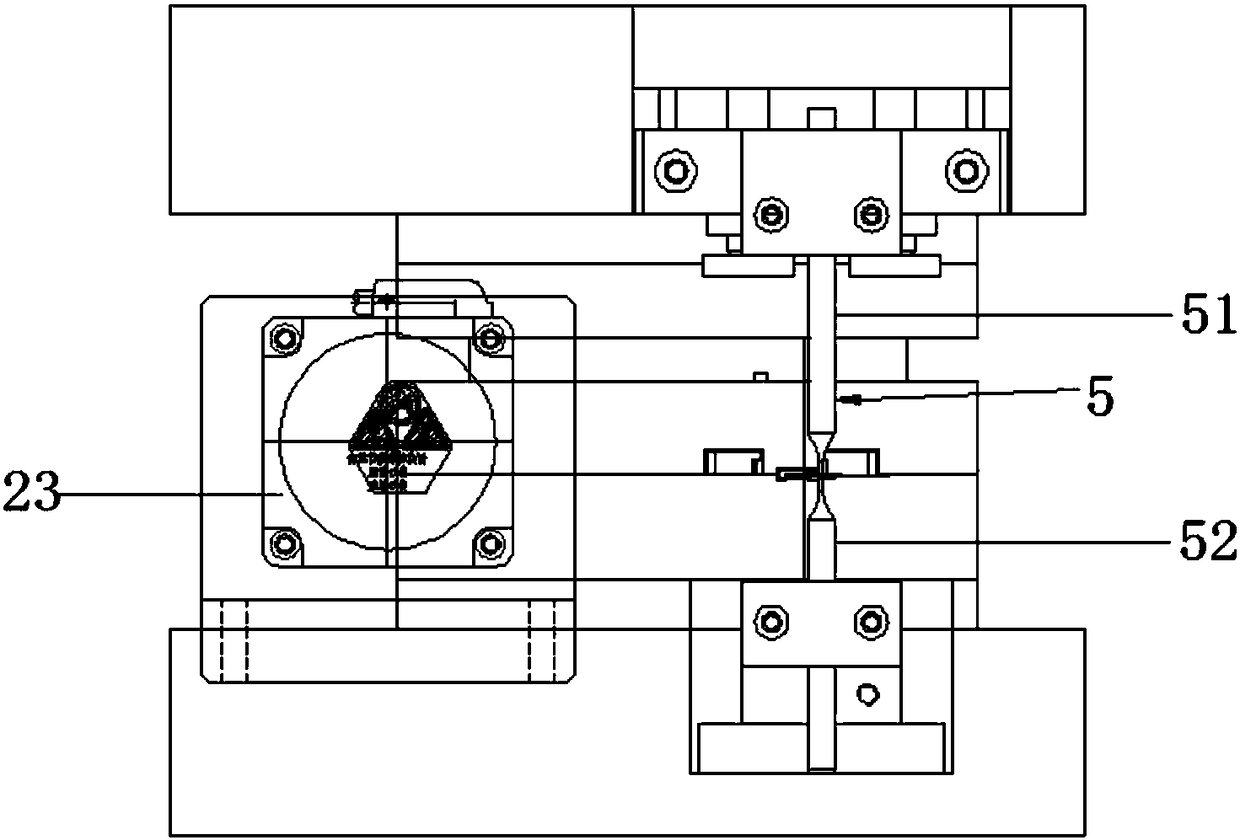

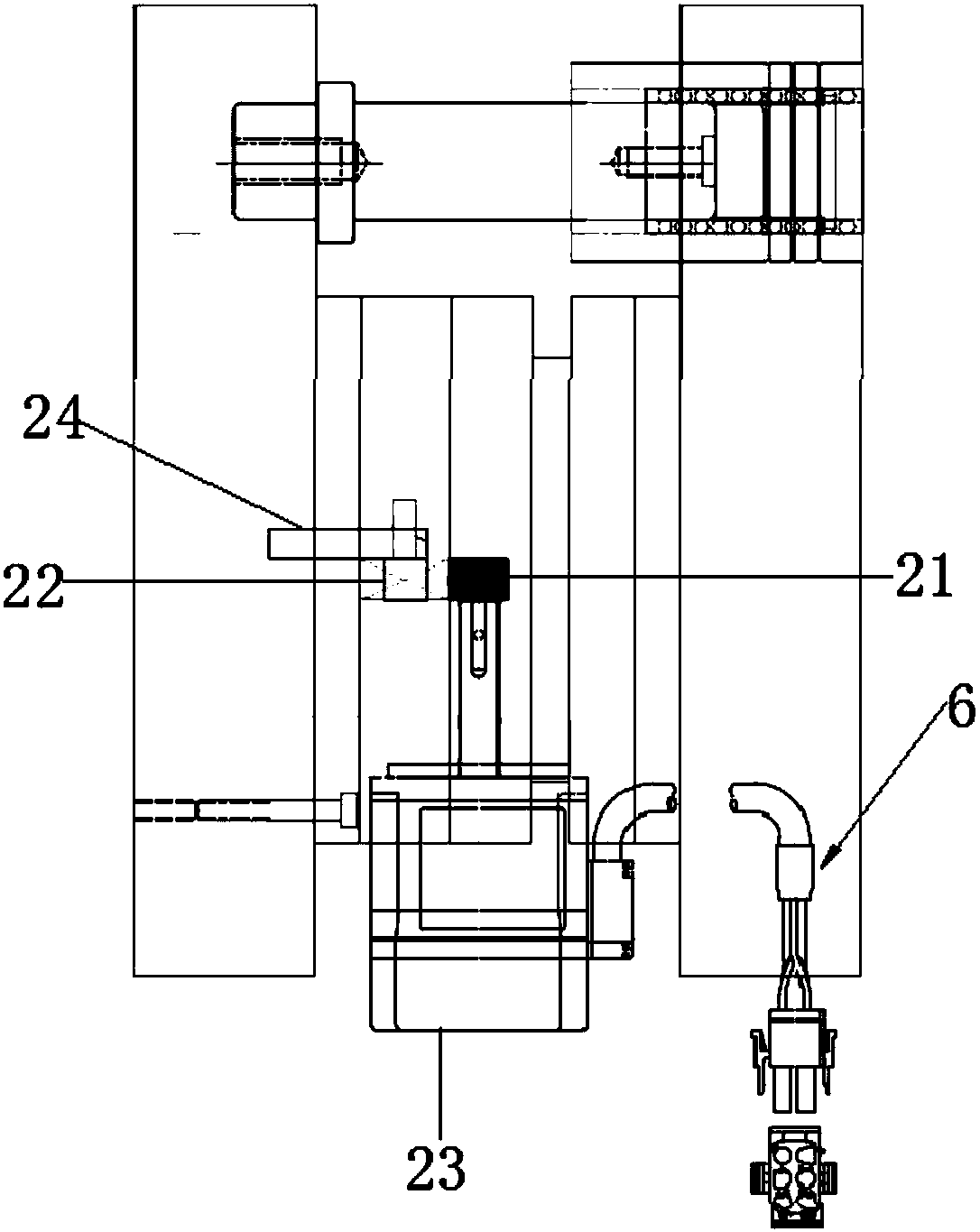

[0037] Embodiment: a kind of automatic welding equipment of bimetal sheet silver point of thermal protector, as Figure 1-Figure 4 Shown, comprise bimetal feed mechanism 1, silver tape feed mechanism 2, material cutting mechanism 3, pushing material mechanism 4 and welding mechanism 5, described bimetal sheet feeding mechanism, silver belt feeding mechanism, cutting mechanism, pushing material The mechanism and the welding mechanism are respectively fixed on the workbench;

[0038] Described silver belt feeding mechanism 2 comprises conveying belt, driving wheel 21, driven wheel 22 and the first motor 23 that drives described driving wheel to rotate, and described conveying belt is positioned between driving wheel and driven wheel and conveying belt is at the center of driving wheel. Rolling down drives the silver belt to move forward, the first motor 23 is fixed on the workbench, the driving wheel 21 is sleeved on the output shaft of the first motor 23, the driven wheel 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com