Packing machine of novel structure

A new type of structure and baler technology, which is applied in the field of balers, can solve problems such as baler failures, large-scale baler costs, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

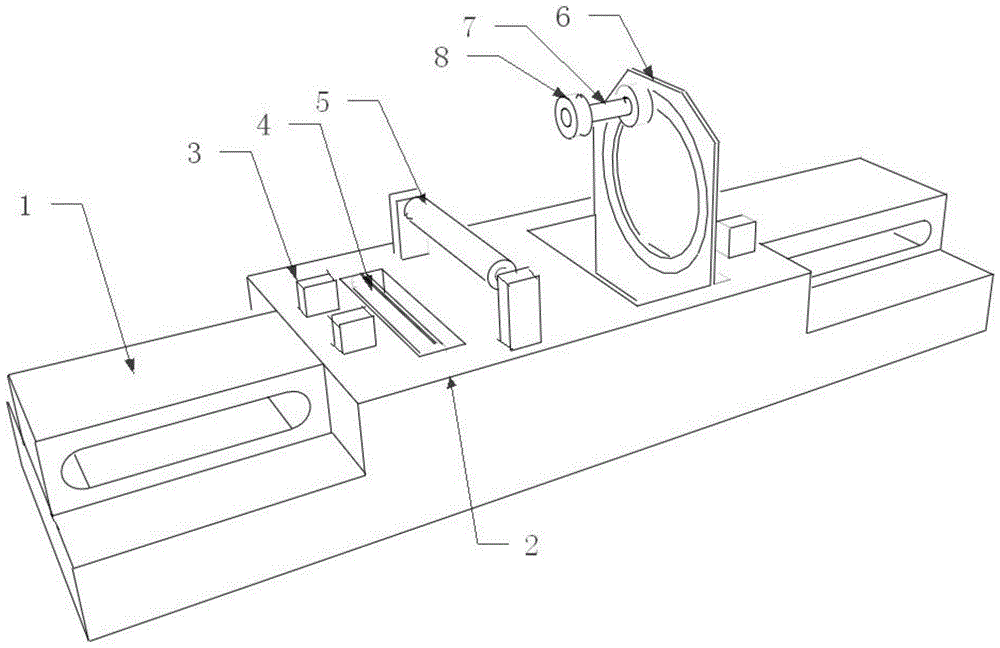

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] see figure 1 , a new structure of the baler includes a workbench 2 of rectangular structure and two transfer devices 1; wherein: the two transfer devices 1 are respectively located at the feeding end and the discharge end of the workbench 2; between the two transfer devices 1 and The joints of the workbench 2 are all provided with a limit table 3 to ensure that the wood moves along a straight line; The circular through hole that guarantees that timber passes through, and track is installed around described circular through hole, and one end pin of described hanging material roller 7 is connected on a fixed base, and described fixed base is installed with the track that is connected with. Roller; the other end of the hanging roller 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com