Composite multifunctional intelligent fire-fighting robot

A fire-fighting robot, multi-functional technology, applied in dryers, lighting and heating equipment, drying, etc., can solve the problems of hindering the normal progress of the device, reducing the service life of the battery, increasing the battery load, etc., to increase the smoke exhaust time, Effect of increasing service life and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

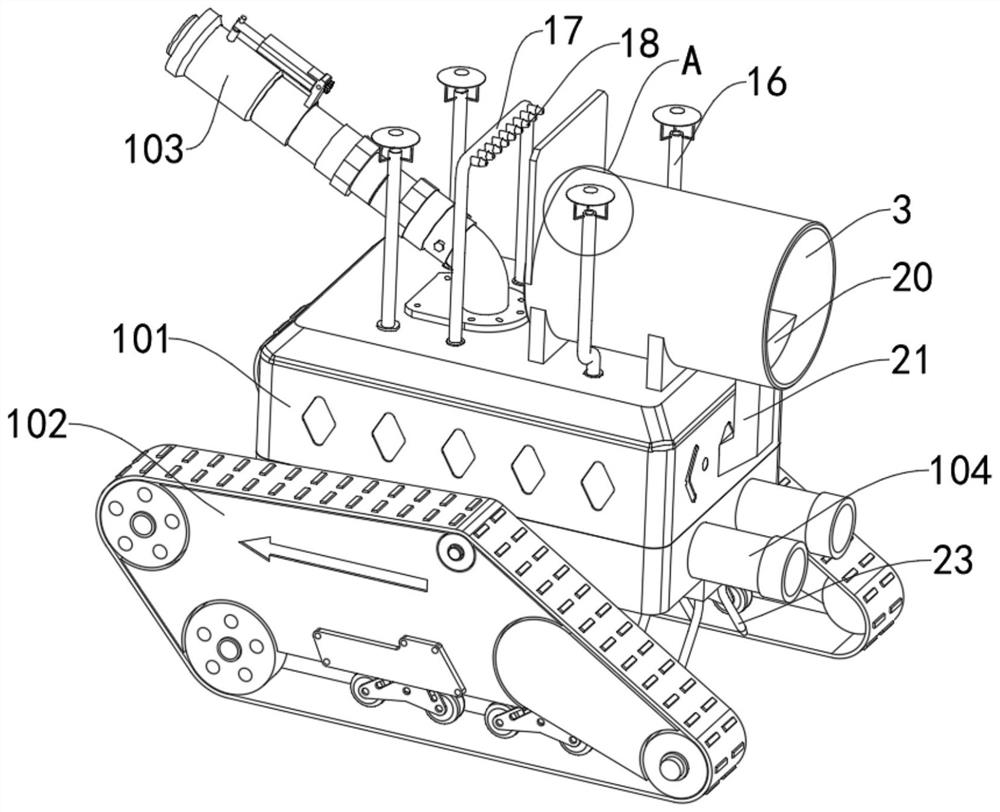

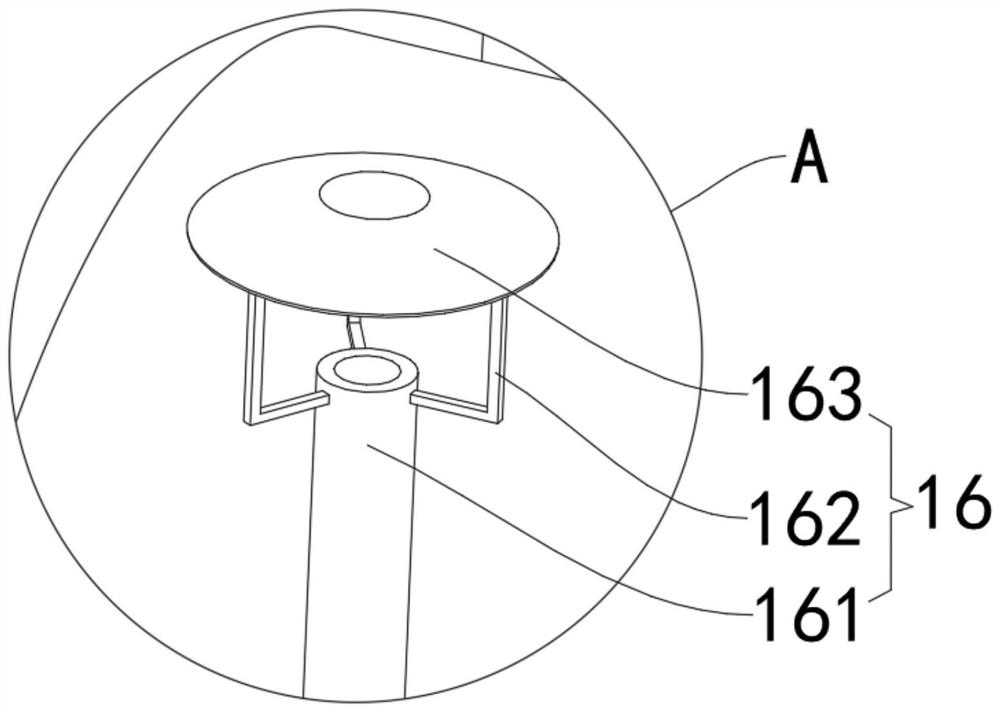

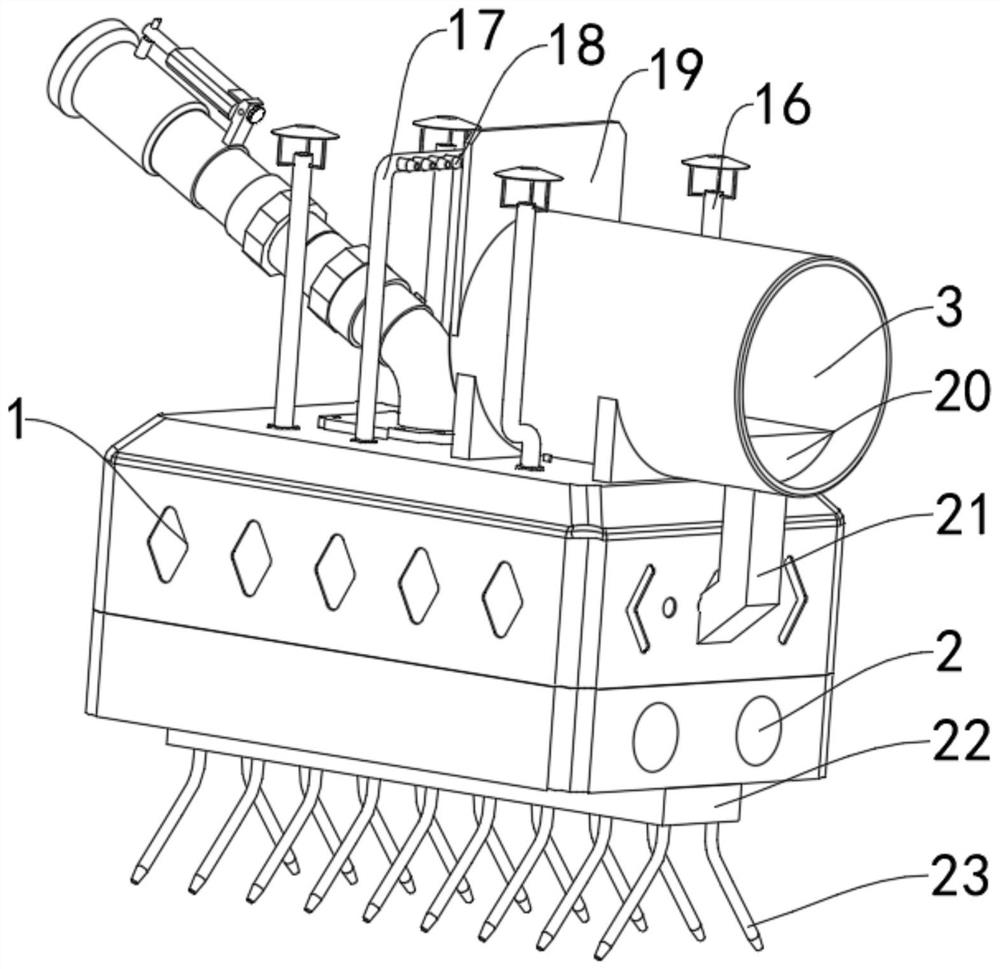

[0050] see Figure 1-10 , the present invention provides a technical solution: a composite multi-functional intelligent fire-fighting robot, comprising a fire-fighting robot body 1, a running water chamber 2 is provided in the middle of the fire-fighting robot body 1, and an air duct 3 is fixedly installed on the top of the fire-fighting robot body 1, The inner cavity of the air duct 3 is fixedly equipped with a fixed frame-4, the middle part of the fixed frame-4 is movably connected with a connecting shaft 5, the middle part of the connecting shaft 5 is fixedly equipped with a fan blade 6, and the left end of the connecting shaft 5 is provided with a transmission device 7, The middle part of the fire-fighting robot body 1 is movably connected with a transmission shaft 8, and the left end of the water flow chamber 2 is provided with a driving water tank 9, and the inner cavity of the driving water tank 9 is fixedly equipped with a fixed frame two 10, and the middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com