Packing machine for machining strip-shaped timbers

A technology for balers and wood, applied in the field of balers, can solve problems such as baler failures and large-scale baler cost problems, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

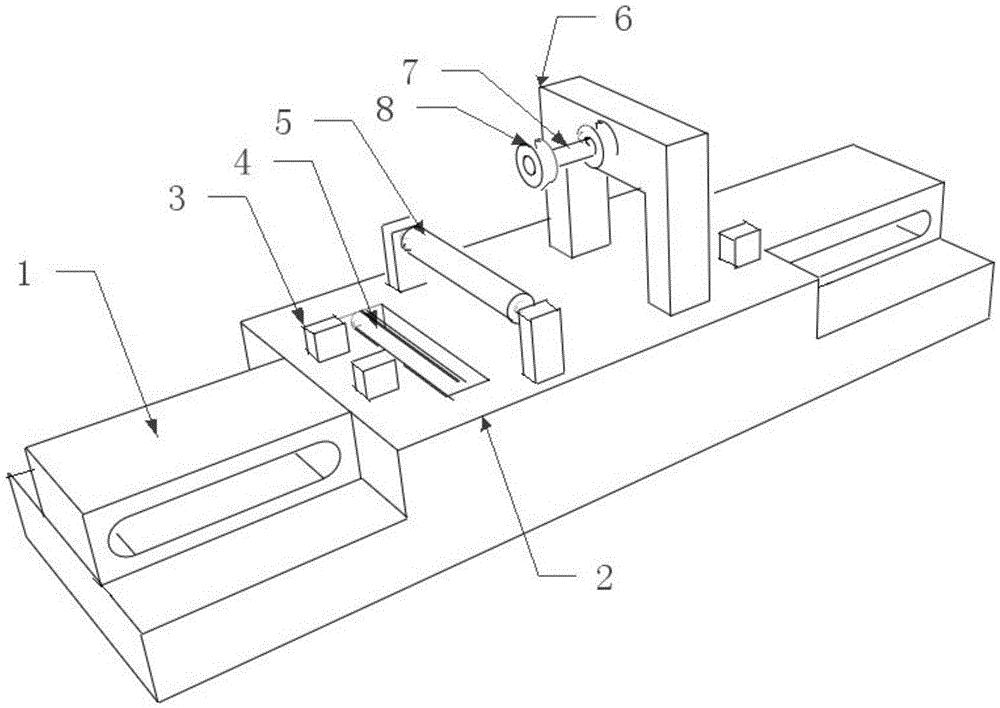

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] see figure 1 A baler for processing strip-shaped timber includes a workbench 2 with a rectangular structure and two transmission devices 1; wherein: the two transmission devices 1 are respectively located at the feeding end and the discharge end of the workbench 2; The junction of the device 1 and the workbench 2 is provided with a limit table 3 to ensure that the wood moves along a straight line; One end is pinned to the top of the bracket 6; the other end of the hanging roller 7 is provided with an external thread, and a nut 8 to prevent the packing material from falling is connected to the external thread; the axis of the hanging roller 7 The direction is the same as the feeding direction of the conveying device 1 ; a limiting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com