Numerically controlling vertical-horizontal saw cutting metal belt band saw

A metal strip and sawing technology, which is applied to sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of troublesome workpieces, inability to feed and sawing in a horizontal direction, and achieve the effect of convenient sawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

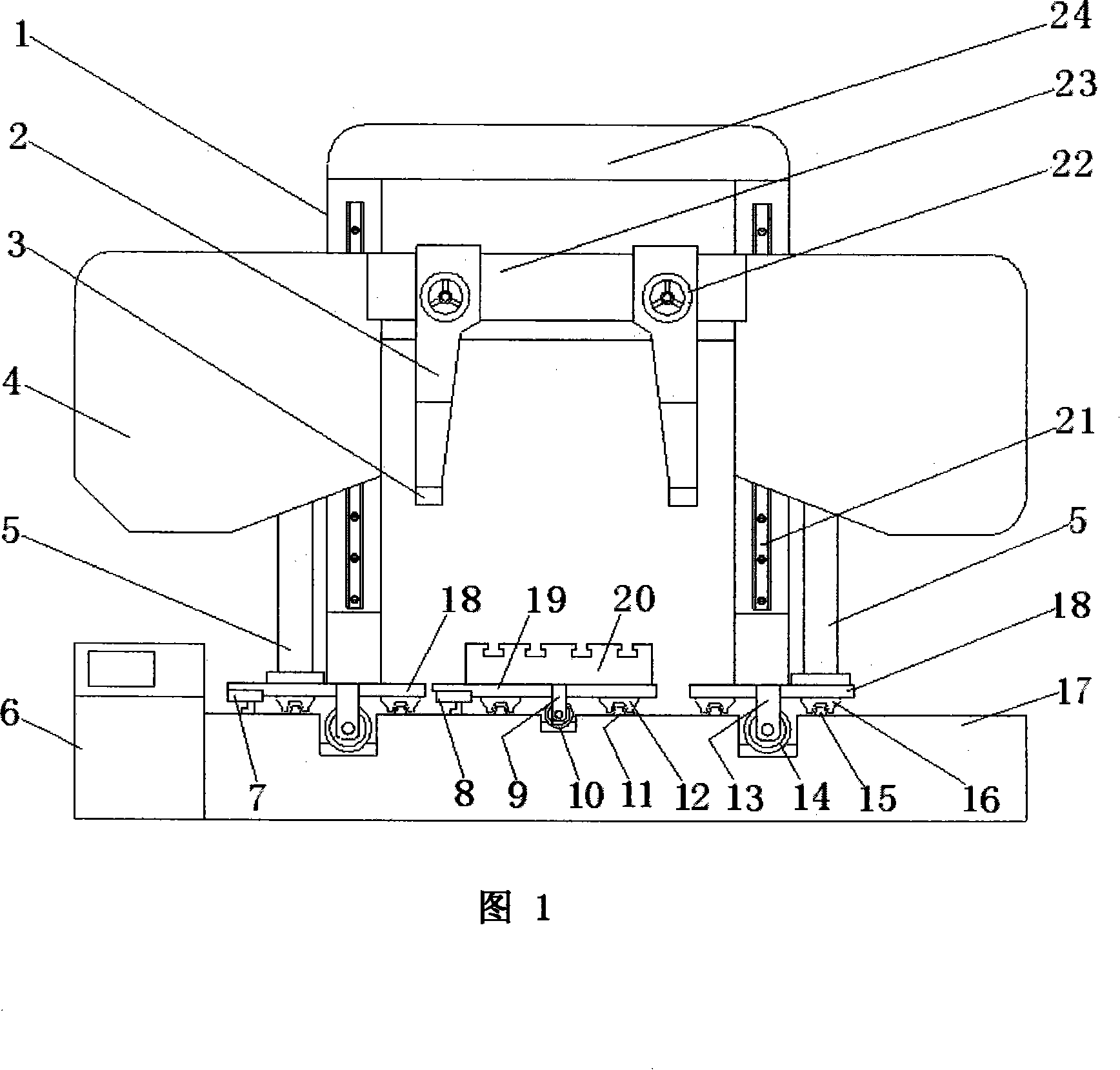

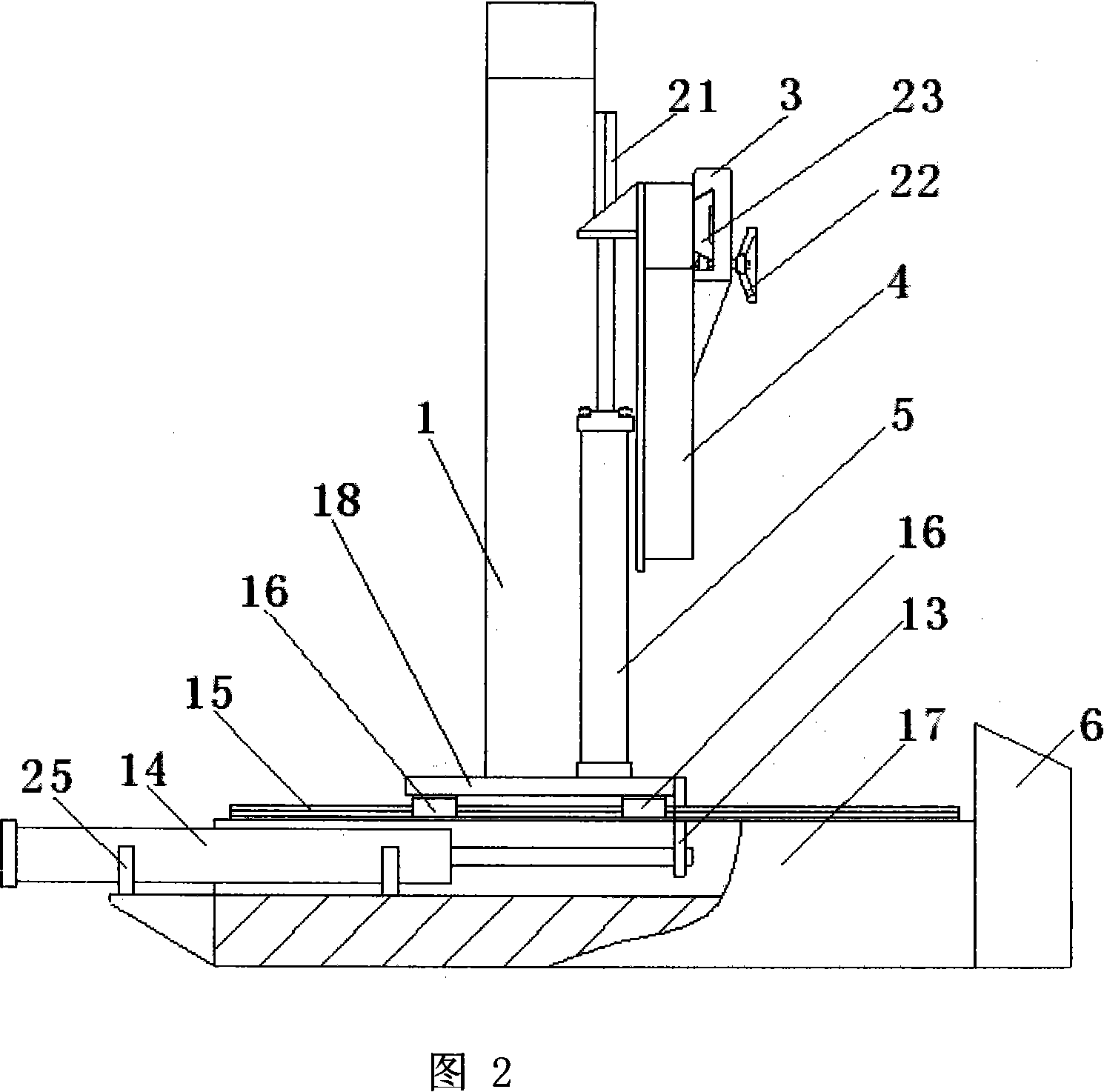

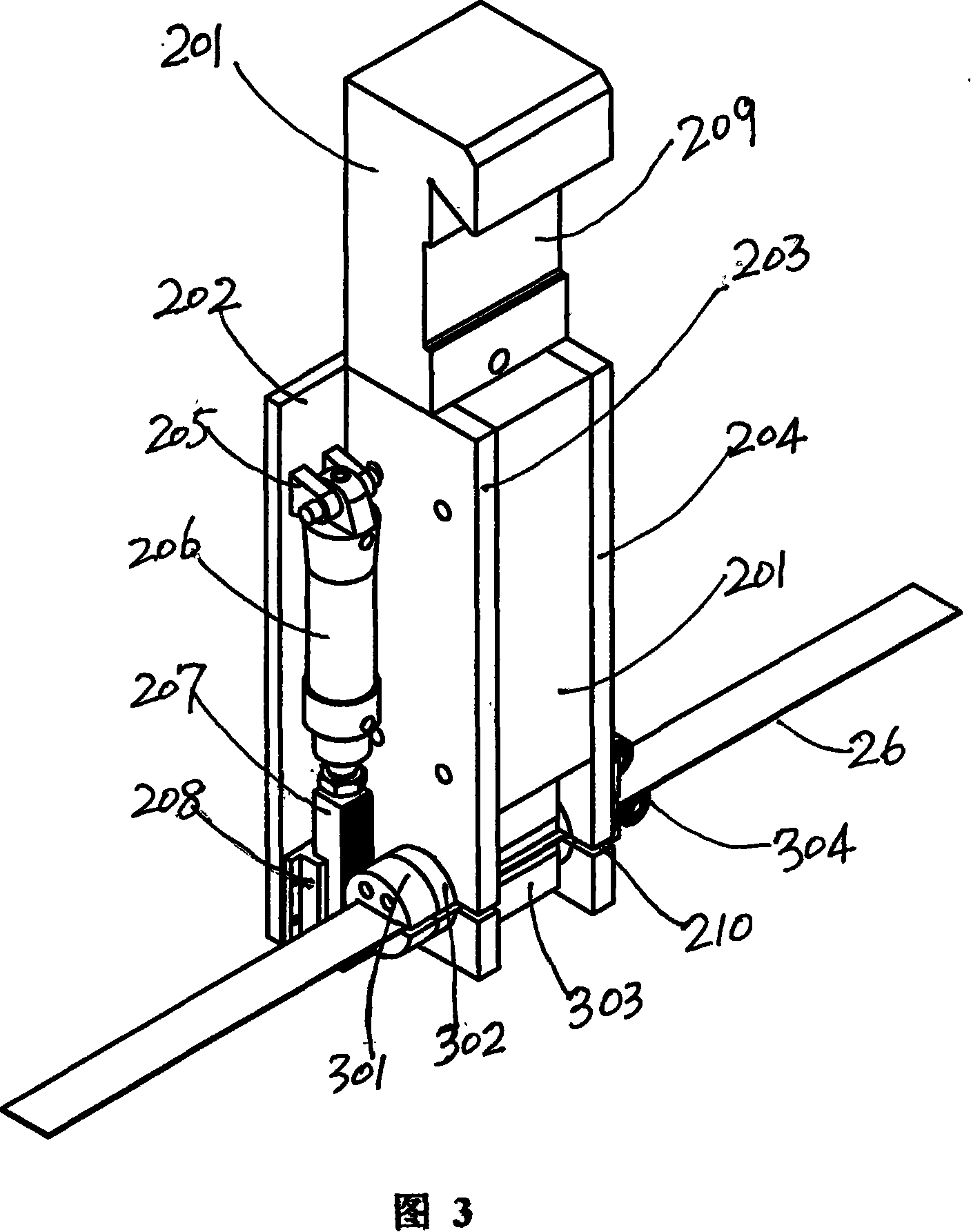

[0020] In the accompanying drawings, 1-column, 2-guiding arm, 3-guiding head, 4-saw frame, 5-saw frame lifting cylinder, 6-electrical control box, (7,8)-displacement limit switch, (9, 13)-vertical plate, 10-table displacement cylinder, 14-column displacement cylinder, (11, 15, 21)-linear guide rail, (12, 16)-slider, 17-bed, 18-column base, 19 -Workbench base, 20-workbench, 22-locking wheel, 23-beam of saw frame, 24-top beam of gantry frame, 25-fixed seat, 26-saw band; and 201-arm body, 202-rear side panel , 203-left side plate, 204-right side plate, 205-oil cylinder base, 206-guided drive cylinder, 207-sliding rack, 208-rack slide seat, 209-connecting neck, 210-front cutout, 211- Support, 212-adjusting screw, 213-fixed rack, 214-rack slide, 301-transmission gear, 302-cylindrical head, 303-guide head body, 304-guide roller, 305-roller seat, 306-guide Block, 307-radial cut, 308-connecting screw hole, 309-ring end, 310-step surface.

[0021] As shown in Figures 1 and 2, a CNC v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com