Method for preparing large-size sheet by using small-diameter wood

A large-format, small-diameter wood technology, which is applied to the jointing of wooden veneers, manufacturing tools, sawing equipment, etc., can solve the problems of low utilization rate of small-diameter wood, improve use value, reduce processing loss, and small thickness error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below figure 1 To attach Figure 13 , to further describe the specific embodiments of the present invention.

[0036] Using small-diameter wood with a diameter of 60mm to 110mm to prepare a large-format sheet with a thickness of 5mm to 20mm includes the following steps:

[0037] Step 1: wood section preparation: first cut the small-diameter wood with a diameter of 60mm to 110mm into a length specification of 1000mm, and then cut the wood section according to the small head diameter of 60mm to 69mm, 70mm to 79mm, 80mm to 89mm, and 90mm to 99mm , The size grade of 100mm~110mm is divided into five diameter specifications, and then the wood section is dried to a moisture content of 12%.

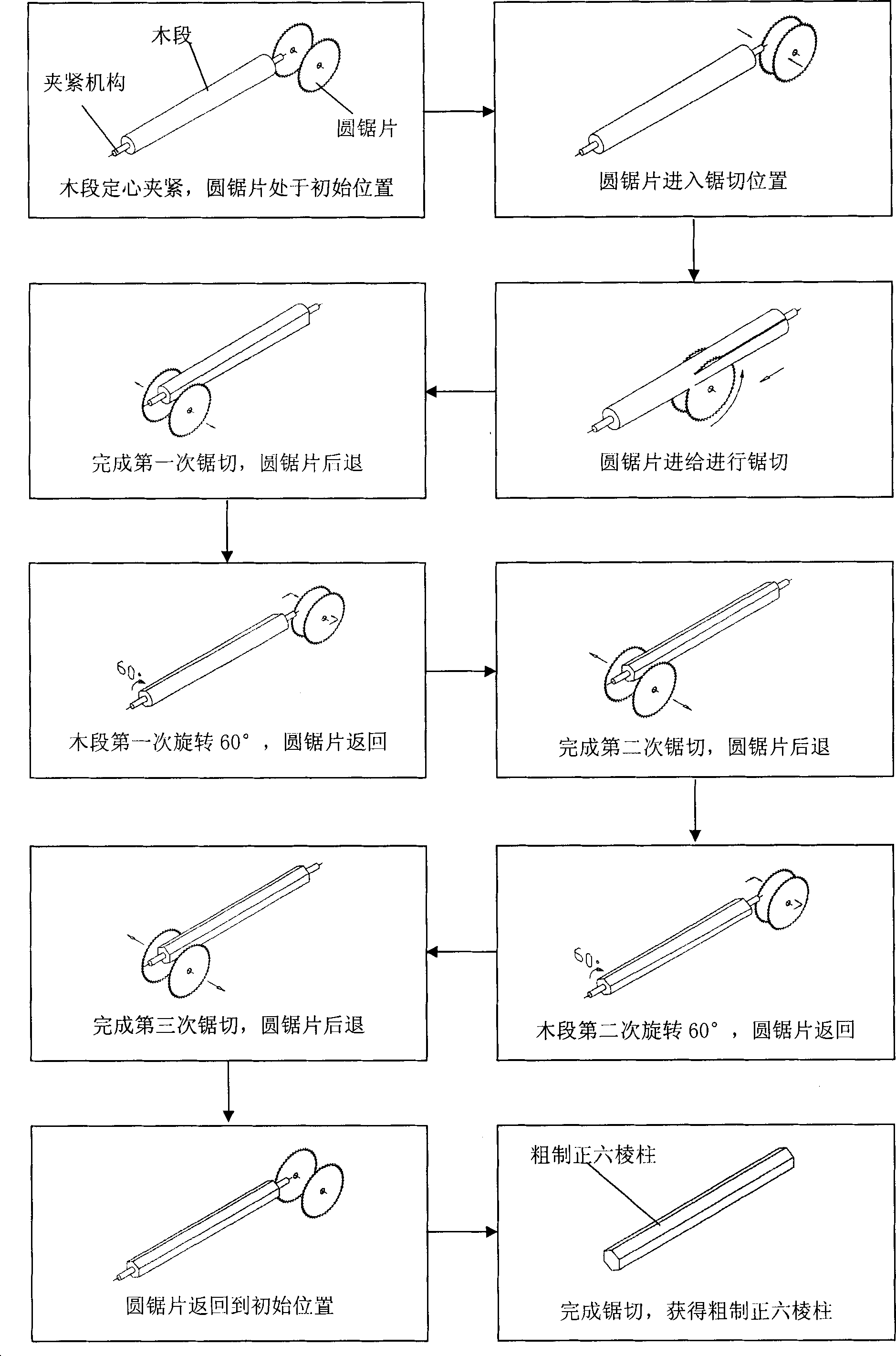

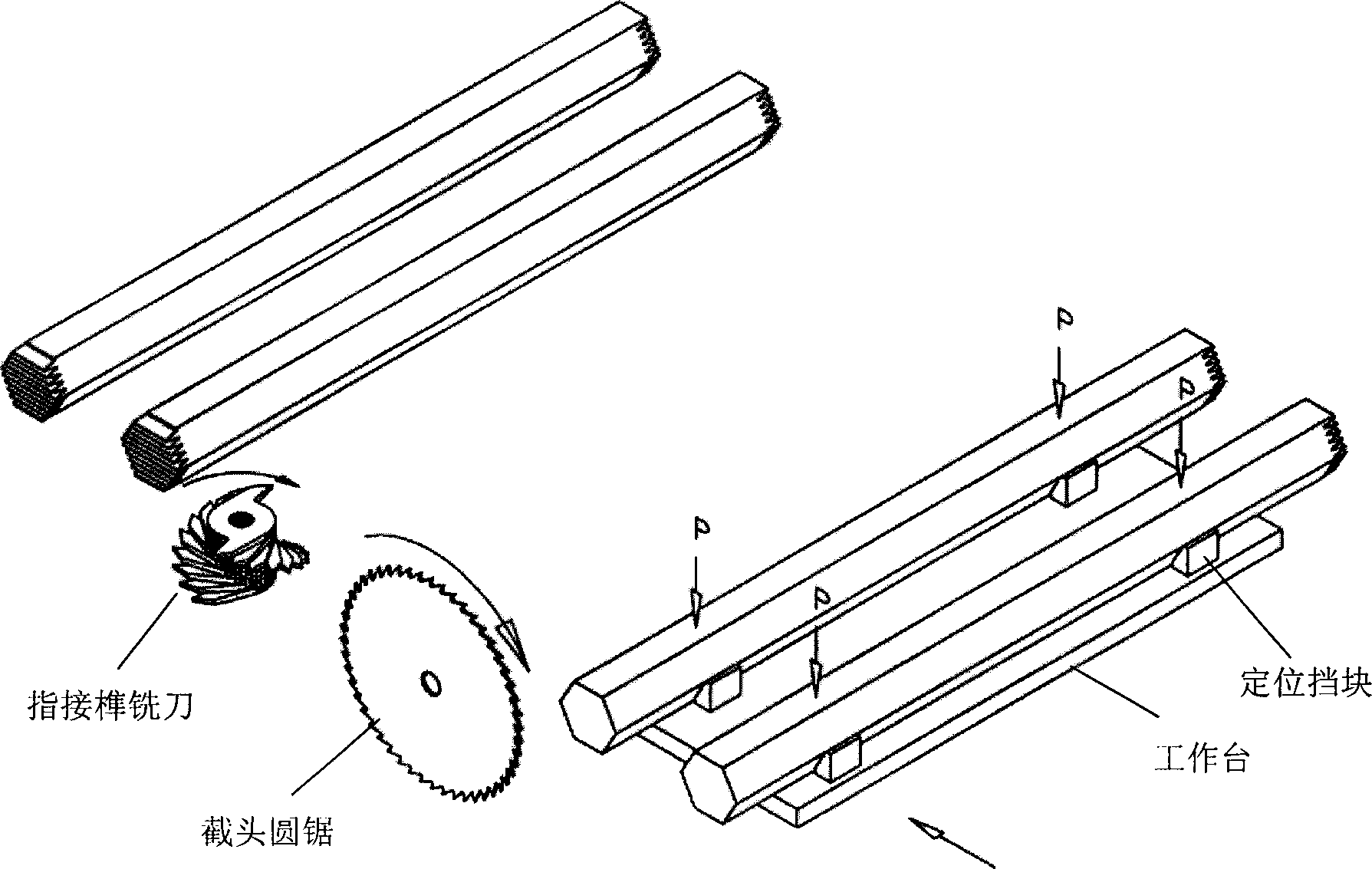

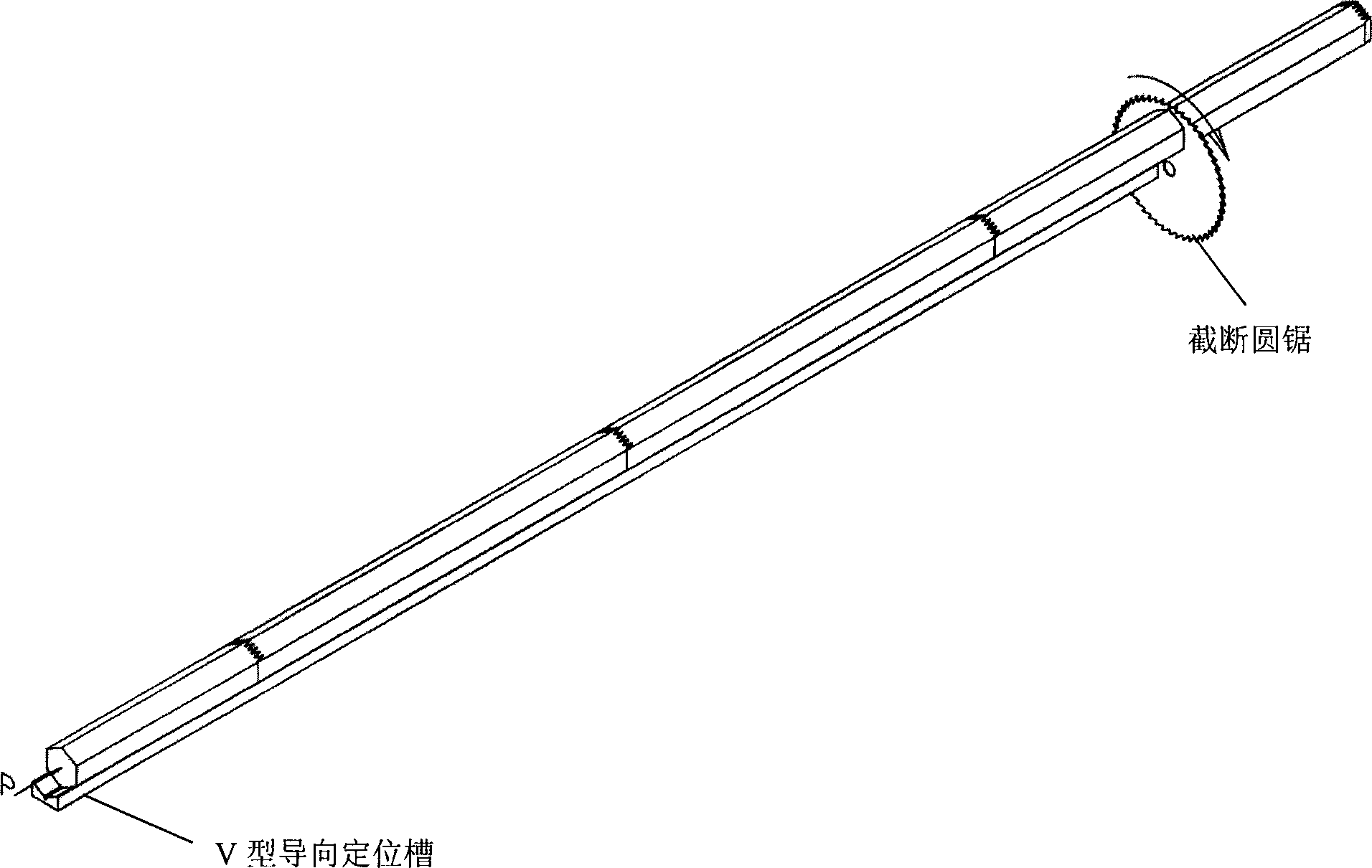

[0038] Step 2: Processing rough regular hexagonal prism: as attached figure 1 As shown, the wood sections of the five kinds of diameters are respectively cut into rough regular hexagonal prisms by using a CNC indexing double-saw circular saw machine with automatic centering fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com