Bell-type electric elevator furnace

An electric furnace and bell-type technology, applied in the field of bell-type lifting electric furnace, can solve the problems that it is difficult to meet the needs of electric furnaces entering the laboratory, it is difficult to meet the needs of electric furnace miniaturization, complex structure, etc., and achieve excellent rapid heating performance and excellent furnace temperature uniformity Sexuality, precise effect of heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

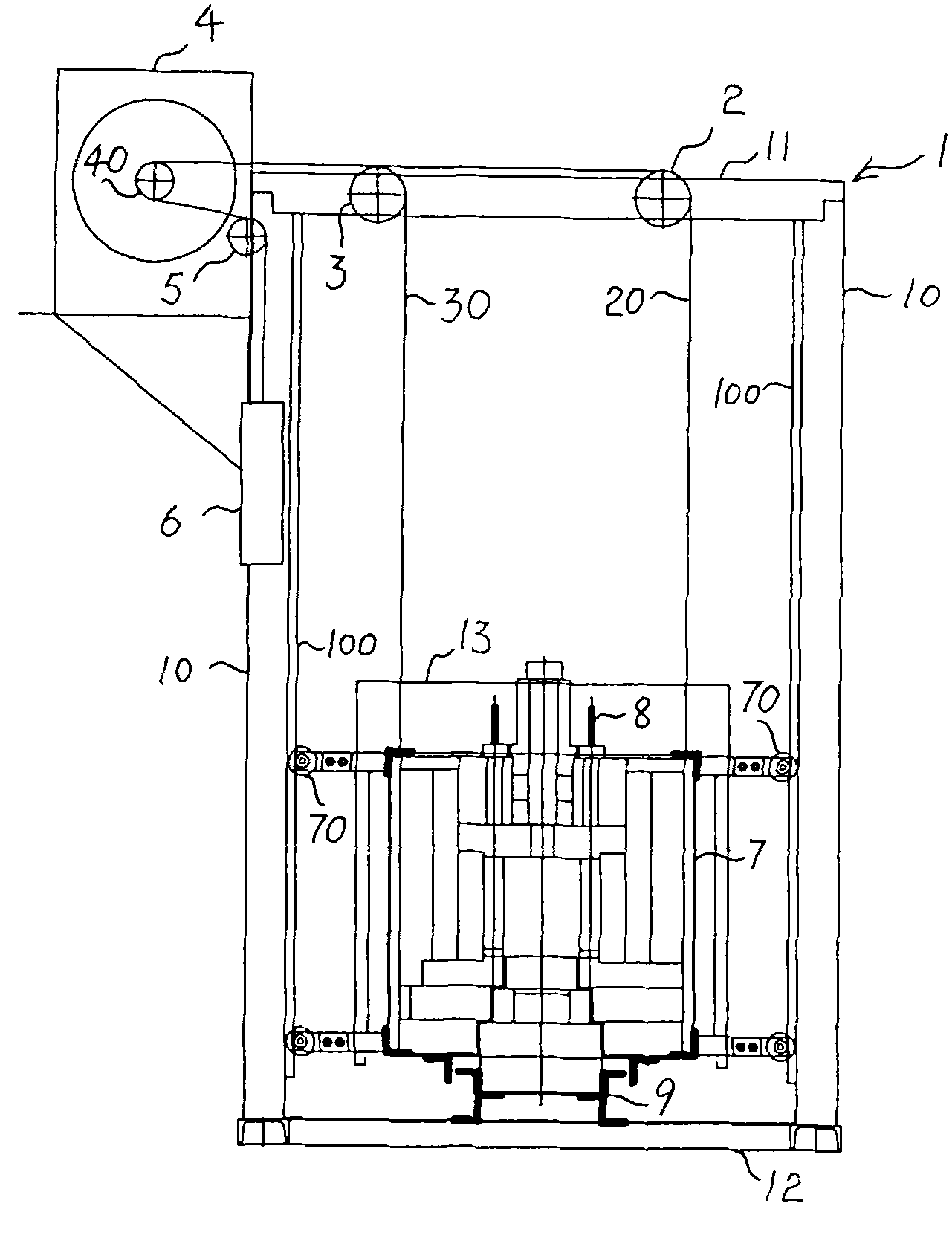

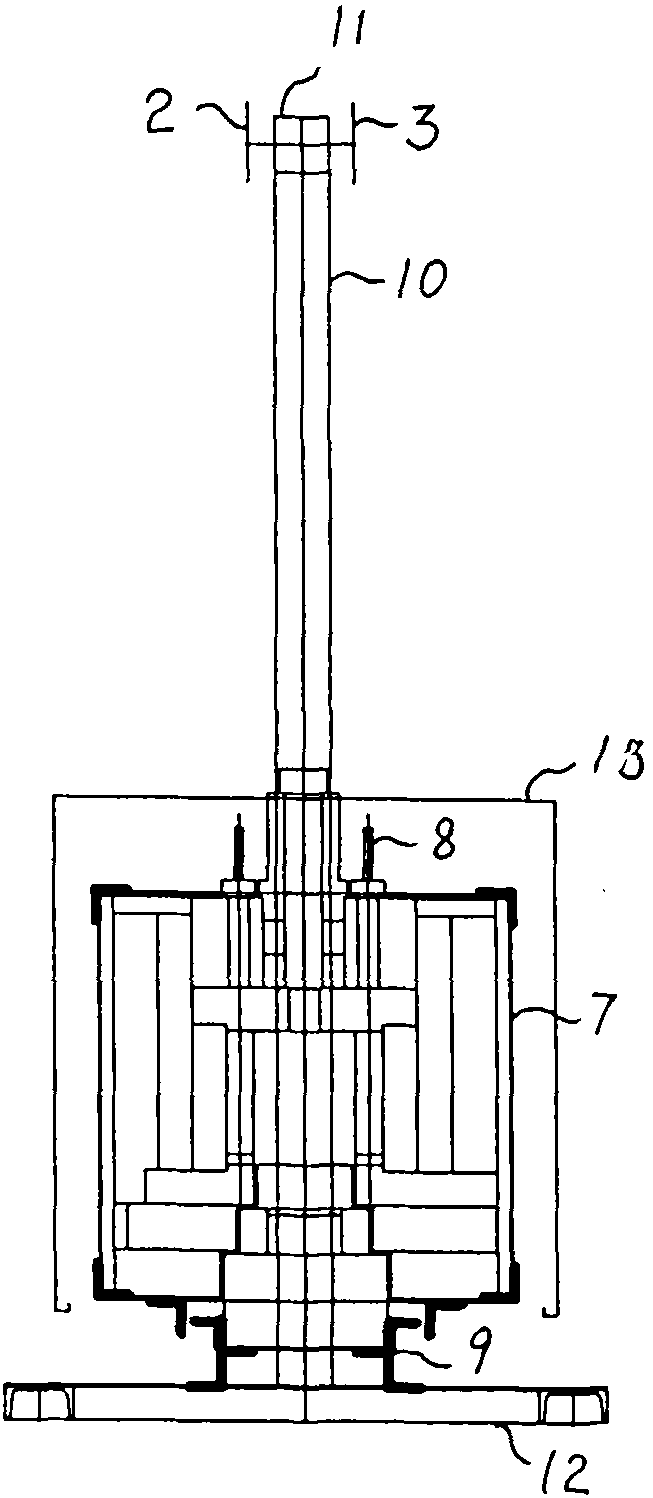

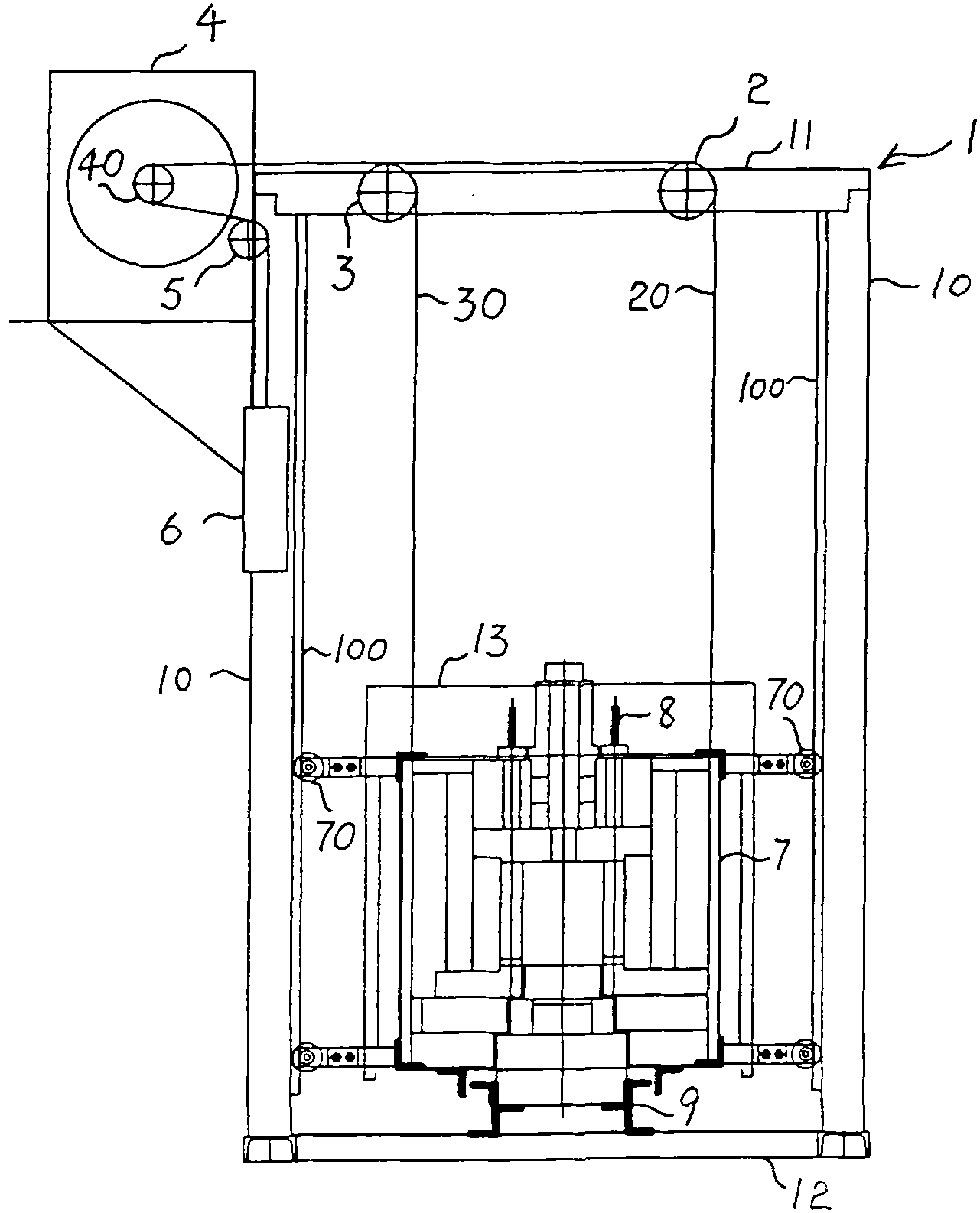

[0015] The present invention will be further described below in conjunction with the drawings:

[0016] A bell-jar type lifting electric furnace includes a heating furnace body 7, and a heating body 8 is arranged in the heating furnace body 7, which is characterized in that a door frame 1 is arranged above the heating furnace body 7, and the upper part of the door frame 1 is a beam 11, and the beam 11 Both ends are provided with a longitudinal support 10, each longitudinal support 10 is provided with a guide rail 100 on the inner side, the heating furnace body 7 is provided with a guide wheel 70 connected to the guide rail 100; a reducer 4 is provided on one side of the door frame 1 , Reducer 4 has two output shaft heads, the two output shaft heads are symmetrically arranged, the two output shaft heads can be the two shaft ends of an output shaft, and each output shaft head is equipped with a reducer lifting drive A first hoisting sprocket 2 and a second hoisting sprocket 3 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com