Ceramic aluminum-coated plate for IGBT (Insulated Gate Bipolar Translator) packaging and preparation method thereof

A technology of aluminum clad plate and ceramic bottom plate, which is applied in the field of ceramic metallization, can solve the problems of inability to adapt to various environments, single performance of ceramic bottom plate, and single performance of single aluminum, so as to improve furnace temperature uniformity, good toughness, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

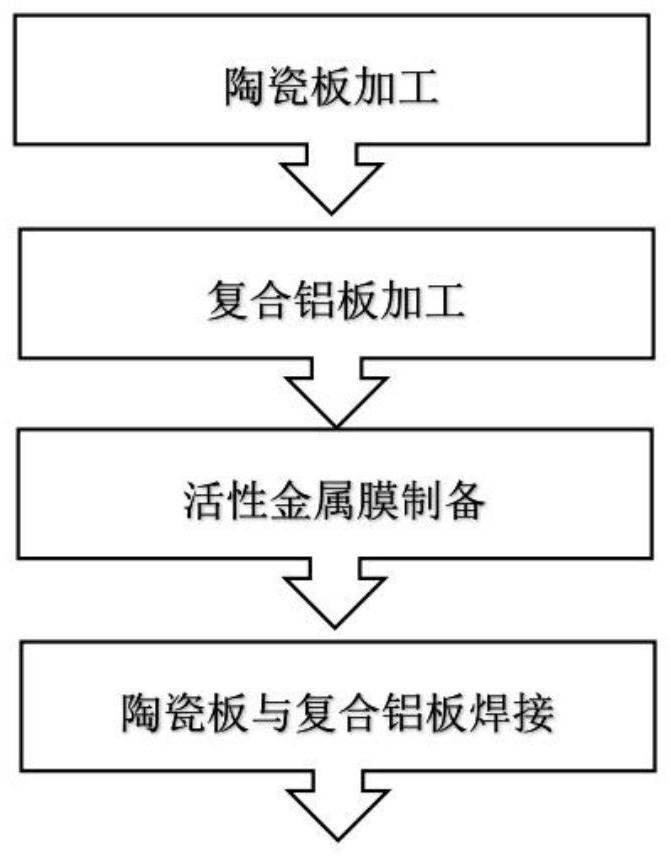

Method used

Image

Examples

Embodiment 1

[0027] Weigh 200g of clay, 100g of quartz, 20g of feldspar, and 10g of silicon carbide, mix them evenly by wet ball milling, and then dry them. Then use molding to weigh 0.8mm squares, remove the glue, sinter at 1350°C for 3 hours, and cool with the furnace to obtain ceramic blanks. Then the ceramic blank was ground and cut into 50×50mm ceramic square pieces for use. 0.2mm thick pure aluminum, 0.02mm thick aluminum-magnesium alloy and 0.01mm aluminum-copper alloy are hot-pressed by vacuum hot-pressing process, the hot-pressing temperature is 620°C, and the pressure is 50MPa to obtain a composite aluminum plate for use. Au-25.5Ag-25.2Ge alloy active solder with a thickness of 20um was printed on a 50×50mm ceramic square by screen printing technology, and then put into an oven at 105°C for 24h to dry. Then heat up to 505°C under 4N argon atmosphere and weld for 10 minutes, then cool down to 300°C at 1°C / min and then cool in the furnace to obtain the aluminum-clad board. The test...

Embodiment 2

[0029] Weigh 200g of clay, 100g of quartz, 20g of feldspar, and 10g of silicon carbide, mix them evenly by wet ball milling, and then dry them. Then use molding to weigh 0.8mm squares, remove the glue, sinter at 1350°C for 3 hours, and cool with the furnace to obtain ceramic blanks. Then the ceramic blank was ground and cut into 50×50mm ceramic square pieces for use. 0.2mm thick pure aluminum, 0.02mm thick aluminum-magnesium alloy and 0.01mm aluminum-copper alloy are hot-pressed by vacuum hot-pressing process, the hot-pressing temperature is 620°C, and the pressure is 50MPa to obtain a composite aluminum plate for use. Au-25.5Ag-25.2Ge alloy active solder with a thickness of 5um was printed on a 50×50mm ceramic square using a screen printing process, and then put into an oven at 105°C for 24h to dry. Then raise the temperature to 505°C under 4N argon atmosphere and weld for 10 minutes, then cool down to 300°C at 1°C / min and then cool in the furnace to obtain the aluminum-clad ...

Embodiment 3

[0031] Weigh 200g of clay, 100g of quartz, 20g of feldspar, and 10g of silicon carbide, mix them evenly by wet ball milling, and then dry them. Then use molding to weigh 0.8mm squares, remove the glue, sinter at 1350°C for 3 hours, and cool with the furnace to obtain ceramic blanks. Then the ceramic blank was ground and cut into 50×50mm ceramic square pieces for use. 0.2mm thick pure aluminum, 0.02mm thick aluminum-magnesium alloy and 0.01mm aluminum-copper alloy are hot-pressed by vacuum hot-pressing process, the hot-pressing temperature is 620°C, and the pressure is 50MPa to obtain a composite aluminum plate for use. Au-25.5Ag-25.2Ge alloy active solder with a thickness of 20um was printed on a 50×50mm ceramic square by screen printing technology, and then put into an oven at 105°C for 24h to dry. Then heat up to 505°C under 6N argon atmosphere and weld for 10 minutes, then cool down to 300°C at 1°C / min and then cool down with the furnace to obtain the aluminum-clad board. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com