Vacuum brazing furnace heating chamber

A technology of vacuum brazing furnace and heating chamber, which is applied in the field of heating chamber, can solve the problems of large heat loss and poor uniformity of furnace temperature in the heating chamber, and achieve uniform heating, small heat loss and good uniformity of furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

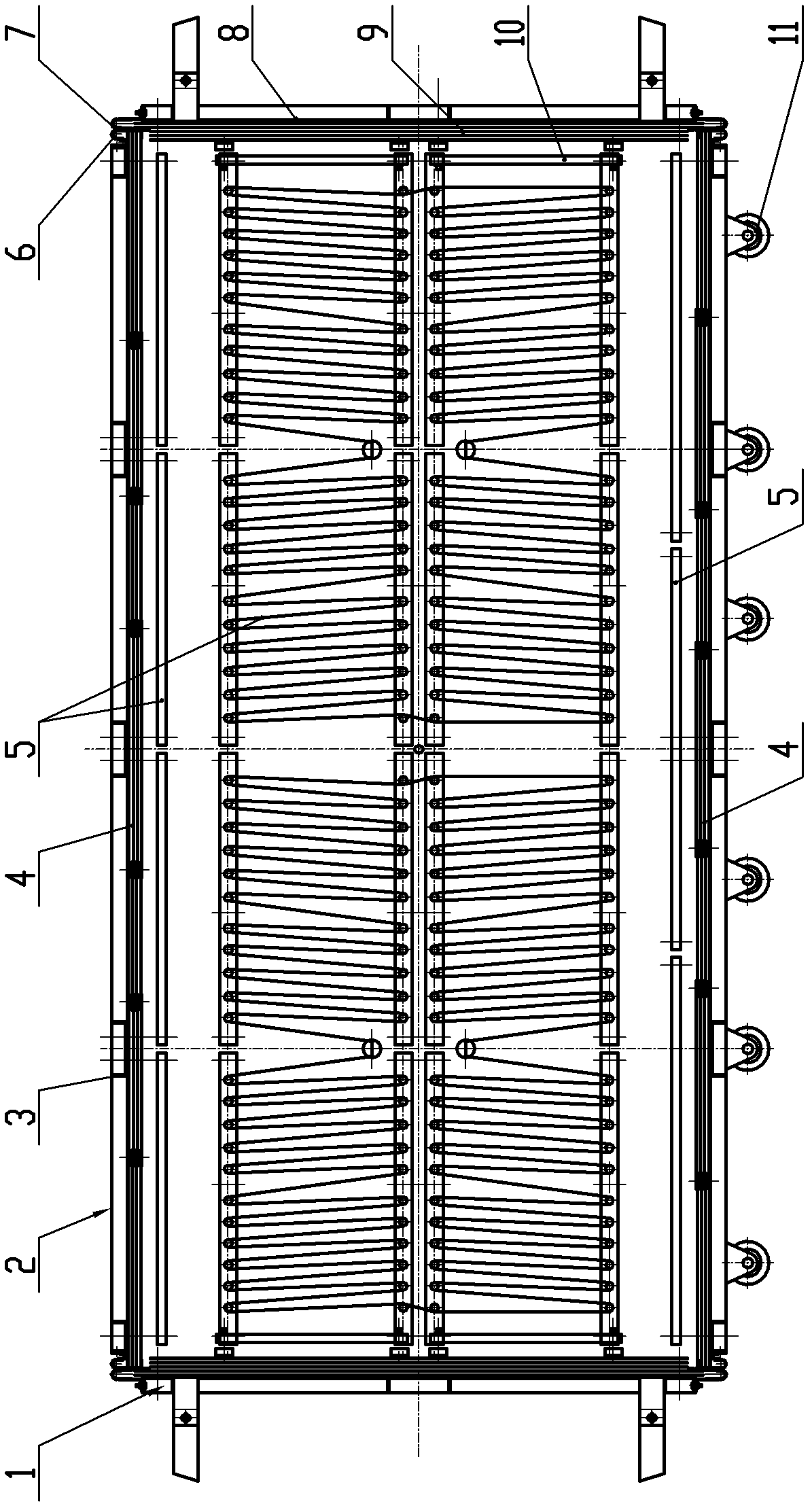

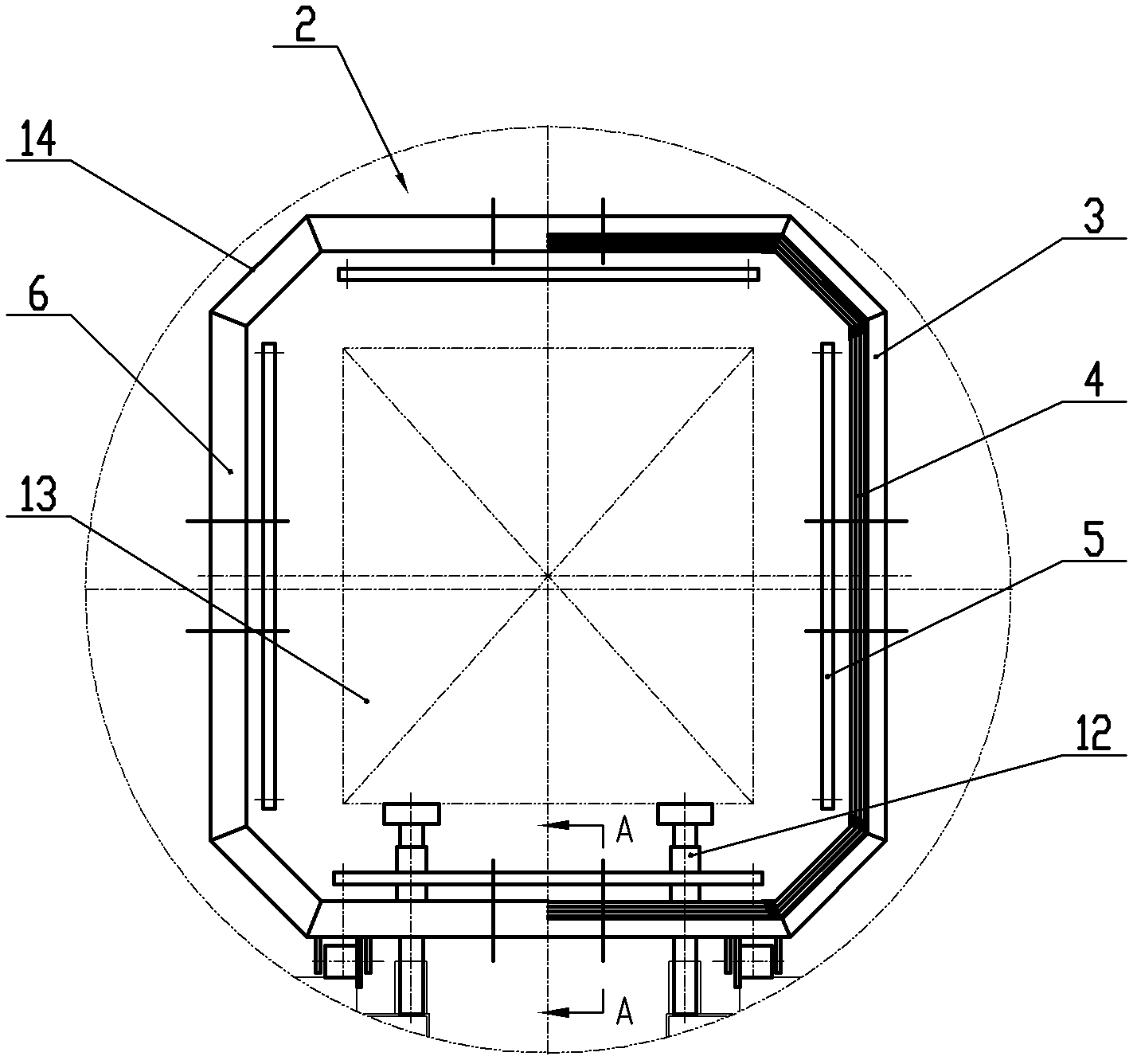

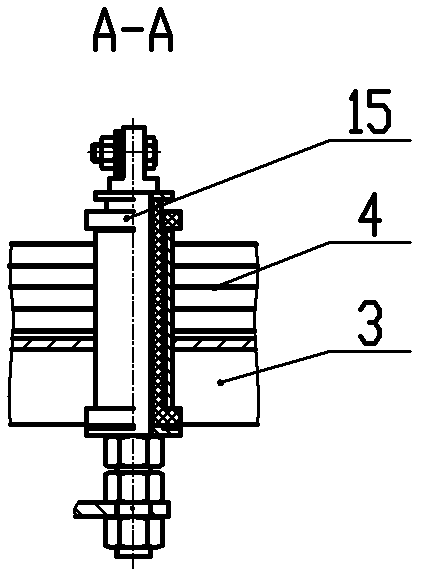

[0015] Figure 1~Figure 5 Including end cover 1, cylinder body 2, cylinder frame 3, cylinder reflection screen 4, cylinder heating assembly 5, cylinder sealing tape 6, end cap sealing tape 7, end cap frame 8, end cap reflection Screen 9, end cover heating assembly 10, wheel 11, hearth assembly 12, working area 13, chamfer 14, cylinder conductive rod 15, end cover conductive rod 16, etc.

[0016] Such as figure 1 As shown, the present invention is a heating chamber of a vacuum brazing furnace, which includes a hollow horizontal cylinder 2 and end caps 1 fixed at both ends of the cylinder 2 .

[0017] Such as Figure 1~Figure 3 As shown, the cylinder 2 includes a stainless steel cylinder frame 3 with a rectangular cross section. A circle of cylinder reflection screens 4 is fixed inside the cylinder frame 3 . The cylinder heating components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com