Strong convection structure box type furnace

A box-type furnace and strong convection technology, applied in the field of kilns, can solve the problems of furnace temperature uniformity, different temperature heat transfer, etc., and achieve the effect of improving furnace temperature uniformity, small size and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

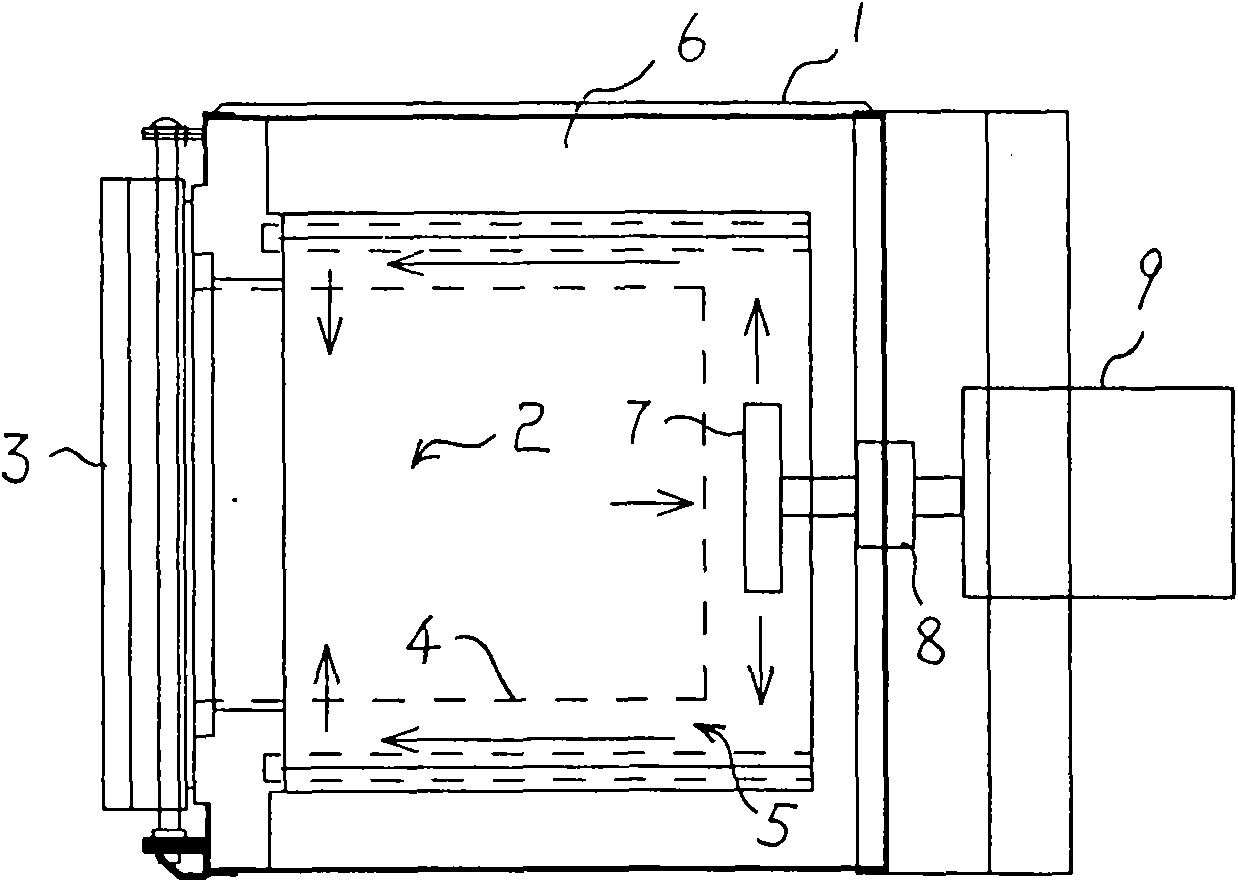

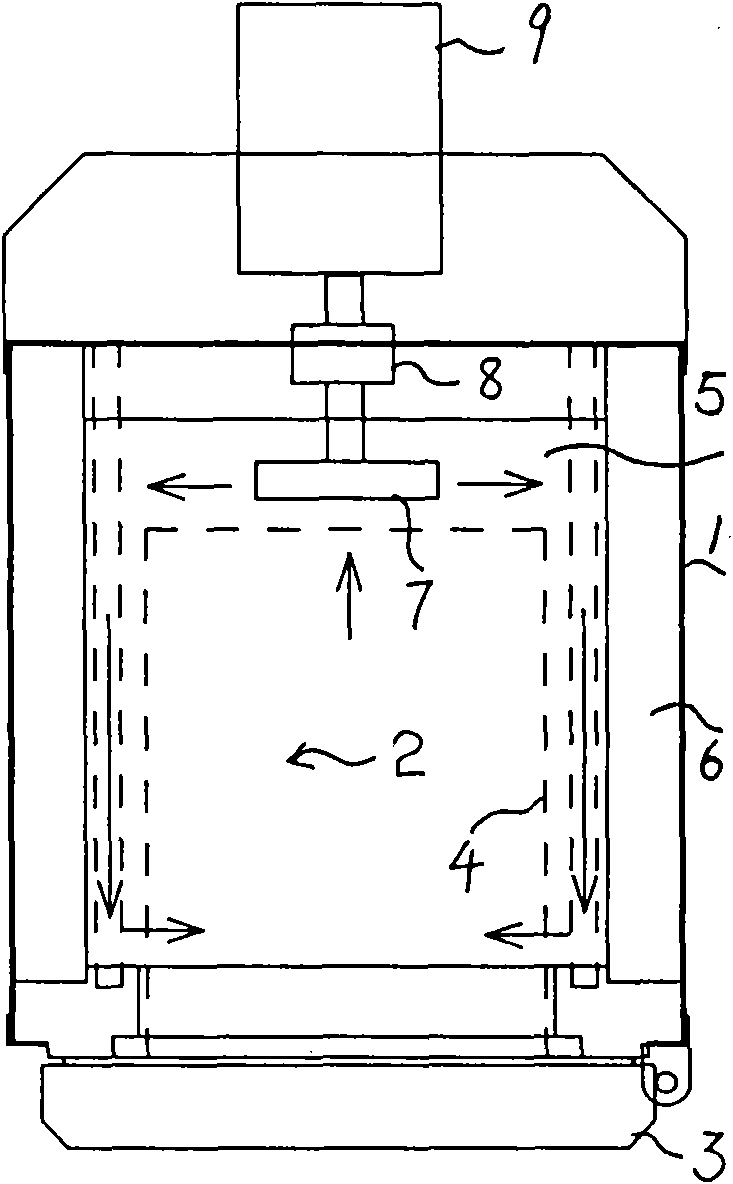

[0019] The present invention will be further described below in conjunction with accompanying drawing:

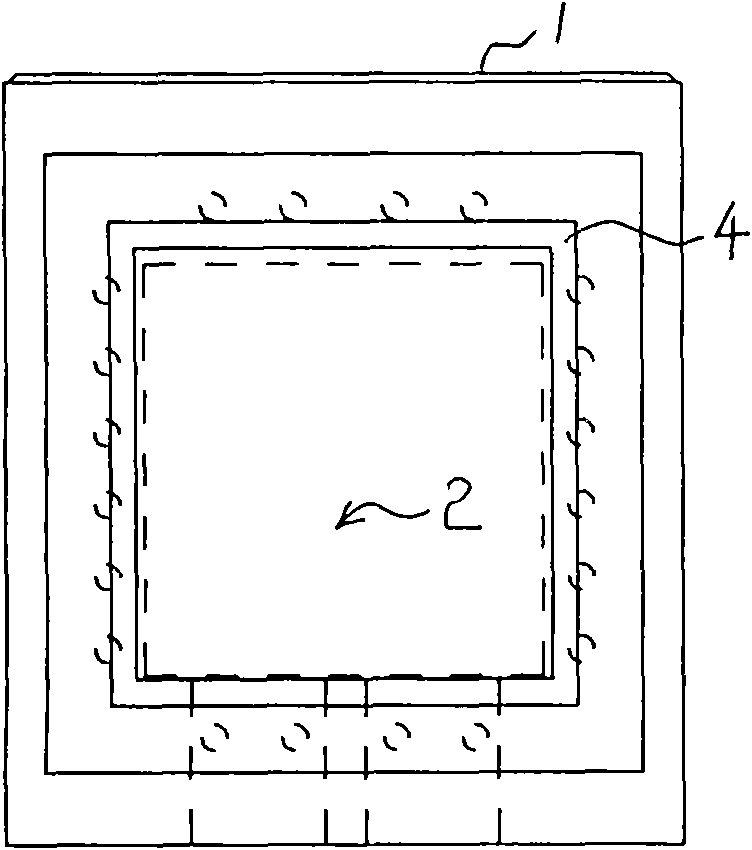

[0020] A box-type furnace with a strong convection structure, comprising a box-shaped furnace body 1 and a furnace door 3 arranged on the box-shaped furnace body 1, the inside of the box-shaped furnace body 1 is an internal heating chamber 2, and the box-shaped furnace body 1 is equipped with a guide The flow liner 4, the flow liner 4 is a barrel-shaped structure, and the edge of the barrel-shaped opening is provided with a sealing baffle 42, and the space between the outer wall of the flow liner 4 and the box-shaped furnace body 1 is the flow liner cavity 5; the flow liner 4 Air suction port 40 is arranged on it, and air suction port 40 is provided with the fan 7 that connects blower fan 9, and fan 9 is located on the box-shaped furnace body 1, and the backflow air inlet hole 41 is provided on the diversion liner 4 outer wall.

[0021] The box-shaped furnace body 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com