Non-oxidation well vacuum furnace

A technology of vacuum furnace and oxidation well, which is applied in the field of non-oxidation well-type vacuum furnace to achieve the effects of reasonable design, long service life and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

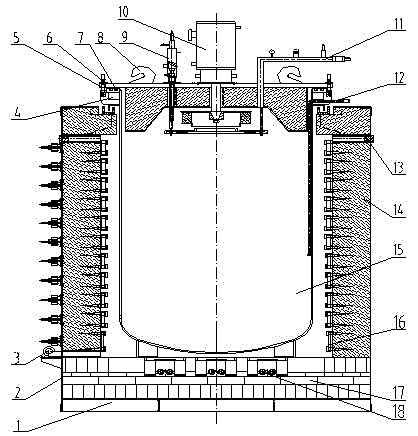

[0011] Referring to the accompanying drawings, the non-oxidation well-type vacuum furnace of the present invention includes a furnace body, an inner container 15 and a cover body, the furnace body includes a furnace frame 1, a furnace shell 2 and a furnace lining 14, and the furnace frame 1 adopts channel steel It is welded with steel plates, fixedly positioned on the ground, and welded steel plates (thickness ≮ 3 mm) furnace shell 2 are attached to the surface of the furnace frame 1. The furnace shell 2 is fixed with a furnace lining 14 by riveting technology. In this embodiment, the total thickness of the furnace lining 14 is ≮300 mm, and a high-alumina fiber (composite) module with a bulk density of 200-250 kg / m3 is used, surrounded by the furnace lining 14. The opening of the furnace is upward, and a layer of high-temperature curing agent is sprayed on the surface of the furnace lining 14 to form a layer of heat insulation wall, which increases the strength and heat radiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com