Aluminum alloy heating furnace and heat treatment furnace

A technology for heating furnaces and aluminum alloys, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of wasting floor space and investment costs, and achieve floor space saving, investment cost reduction, and wide temperature working range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The aluminum alloy heating furnace and heat treatment furnace provided by the invention can realize the heating, quenching, annealing and aging treatment of aluminum alloy blanks and products. Combining these four functions, it achieves the multi-purpose effect of one furnace.

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] The aluminum alloy heating furnace provided by the embodiment of the present invention is first introduced below.

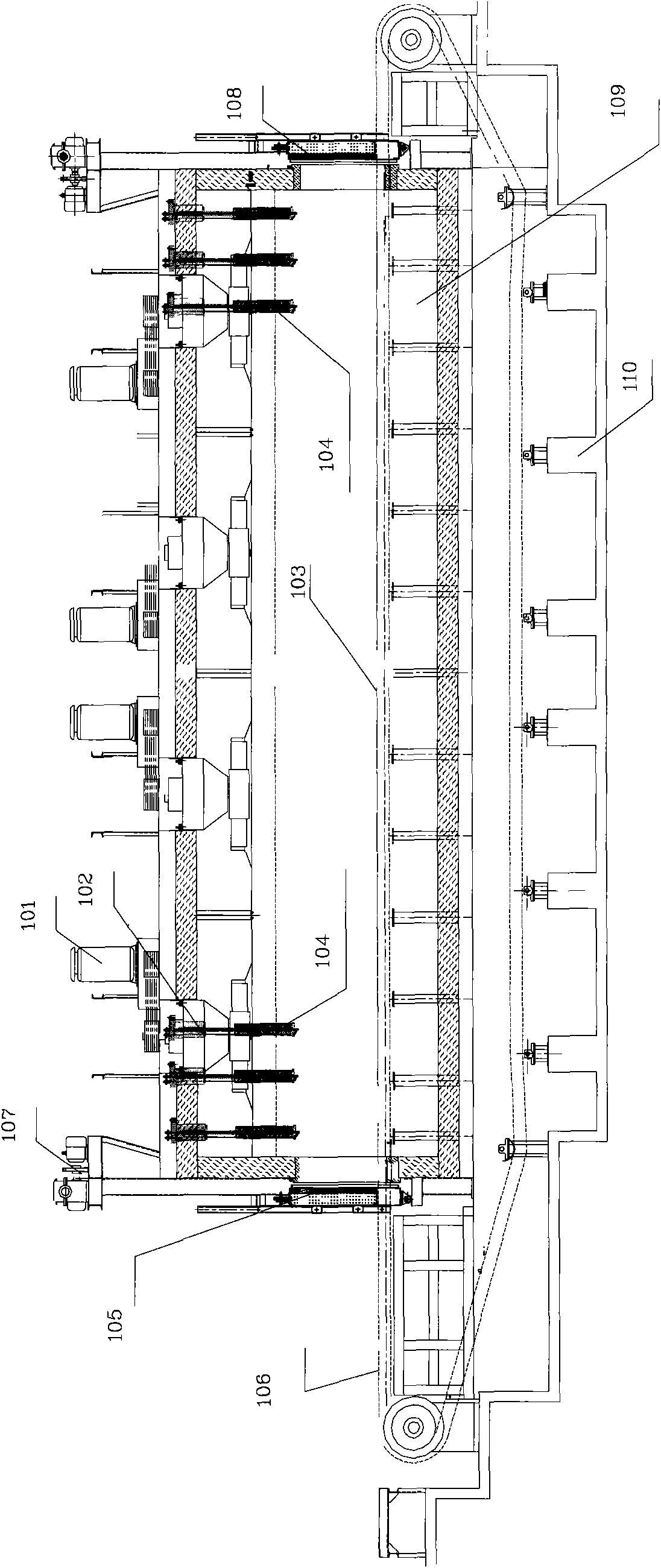

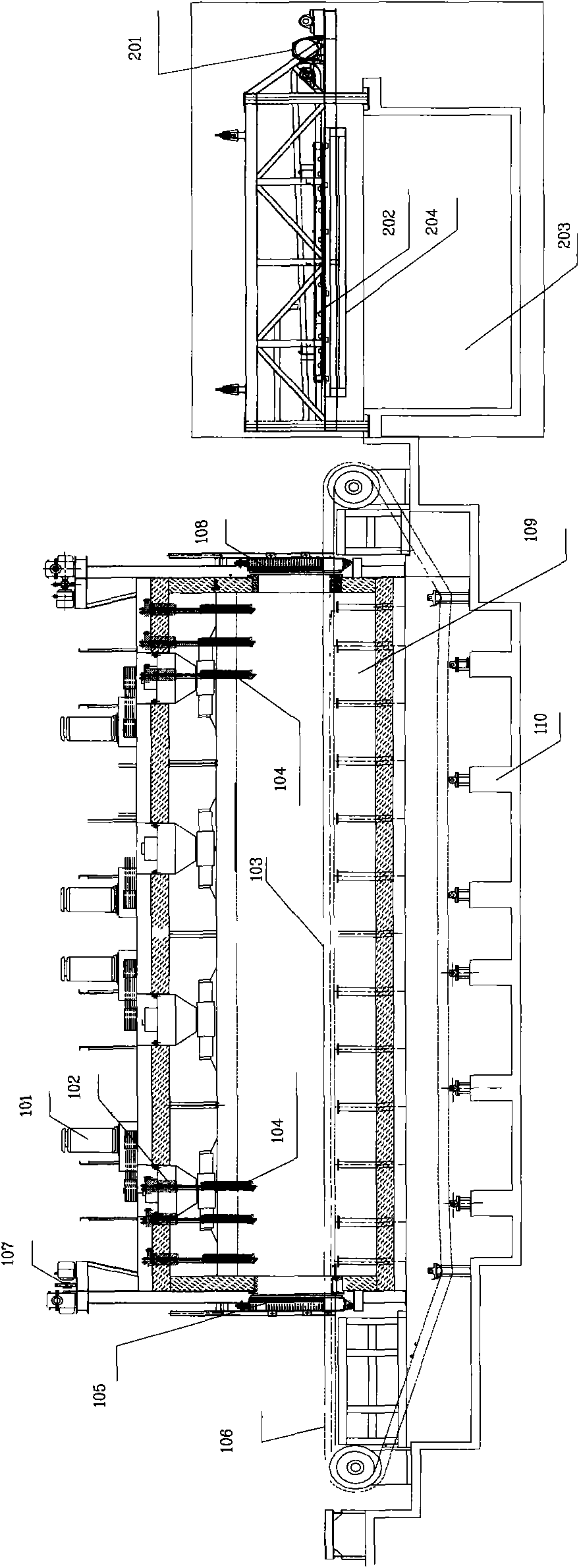

[0047] see figure 1 , which is a structural diagram of the first embodiment of the aluminum alloy heating furnace of the present invention.

[0048] The heating furnace includes a heater 104 , a circulation fan 102 and a fan motor 101 .

[0049] The heaters 104 are distributed on both sides of the roof of the heating furnace, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com