Multistage circulating flow moving bed bio-membrane reactor and application thereof

A technology of moving bed biofilm and circulating flow, which is applied in the field of multi-stage circulating flow moving bed biofilm reactor, can solve the problems of effluent water quality decline, filler fluidization insufficient, and sewage treatment efficiency low, so as to improve the flow state and extend the Residence time, the effect of improving the efficiency of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

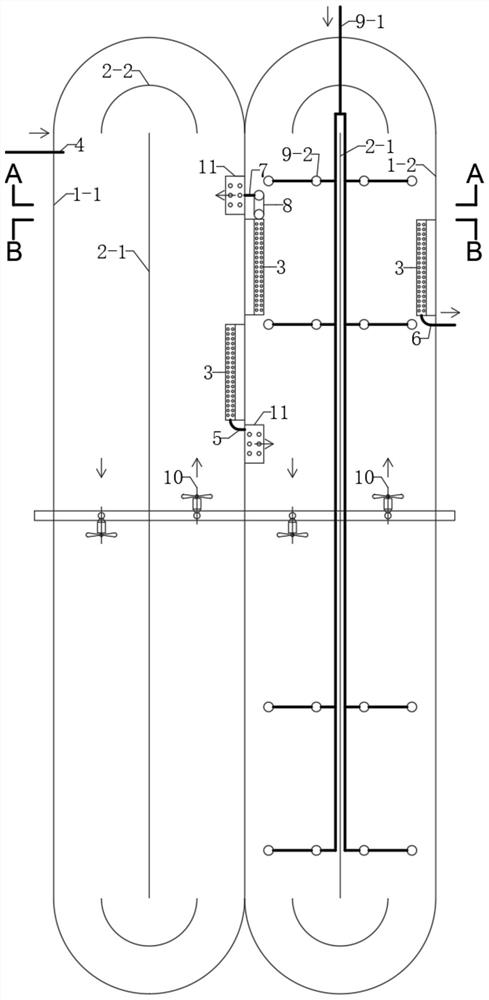

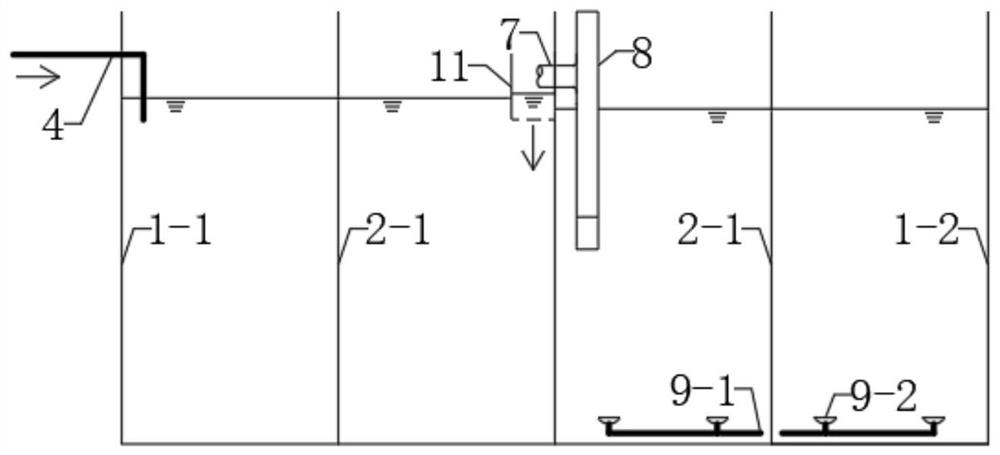

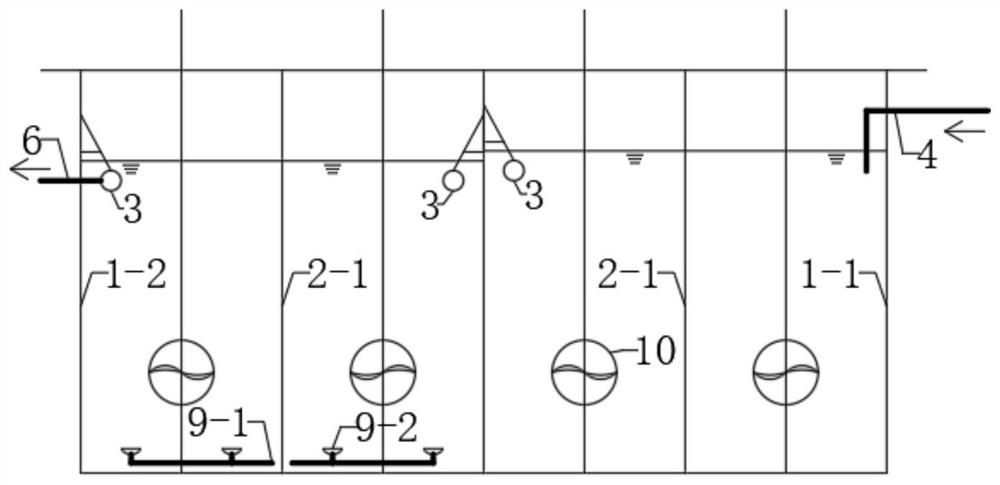

[0038] A multi-stage circulating flow moving bed biofilm reactor, such as figure 1 , figure 2 and image 3 As shown, it includes a first reaction tank 1-1, a second reaction tank 1-2, a first deflector 2-1, a second deflector 2-2, a perforated screen 3, an inlet pipe 4, a first outlet Water pipe 5, the second outlet pipe 6, return pipe 7 and internal return device 8, wherein said first reaction tank 1-1 is anoxic reaction tank or anaerobic reaction tank, and said first reaction tank 1-2 is preferably Oxygen tank.

[0039] The first deflector 2-1 is vertically arranged in the first reaction poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com