Large-scale average-temperature table type low-temperature annealing furnace

An annealing furnace and low temperature technology, which is applied in the field of large-scale uniform temperature desktop low-temperature annealing furnaces, can solve the problems of easy noise, low work efficiency, and hidden safety hazards, and achieve the effects of blast furnace temperature uniformity, high work efficiency, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

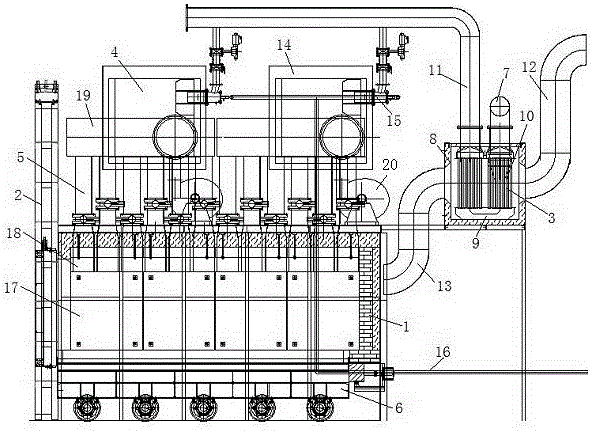

[0008] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. Large-scale uniform temperature desktop low-temperature annealing furnace, including furnace body 1, furnace door 2, air preheating device 3, gas heating device 4, temperature uniform device 5 and hot air circulation device, the lower part of furnace body 1 is equipped with a platform that moves along the track Car device 6, the rear side of the furnace body 1 is provided with a lifting furnace door 2 for sealing the furnace body 1, the inside of the furnace body 1 is provided with a furnace lining, and the insulation fiber cotton is filled between the furnace lining and the inner wall of the furnace body 1. The air preheating device 3 is composed of an air intake pipe 7, a preheating chamber 8, a U-shaped connecting pipe 9, a heat exchange pipe 10 and an air supply pipe 11. The air intake pipe 7 and the air supply pipe 11 are respectively fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com