A flue gas desulphurization denitration method adopting two adsorption columns in series connection and a device therefor

A technology of desulfurization, denitrification, and adsorption tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as increasing operating costs and increasing the amount of ammonia gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0139] The mixing device (M) used in the following examples includes an air pipeline (602), an ammonia pipeline (606), an air helical section (609), an ammonia helical section (610), a mixing section (612) and a mixing Gas outlet (616), wherein the ammonia pipe (606) is inserted (or extended into) the air pipe from one side of the larger diameter air pipe (602), then bent and along the axis of the air pipe (602) along the The air flow direction extends a certain distance L (it is for example 20-80%, more preferably 35-65% of the total length of the mixing device, such as L=0.2-2 meters, preferably 0.3-1.5 meters), the end of the ammonia pipeline (606) The section is an ammonia gas spiral segment (610), and the ammonia gas spiral segment (610) includes m helical ammonia passages separated by m longitudinally extending spiral plates (608) in the ammonia pipeline (606), in addition , the air spiral section (609) corresponding to the ammonia gas spiral section (610) comprises a sp...

Embodiment approach 1

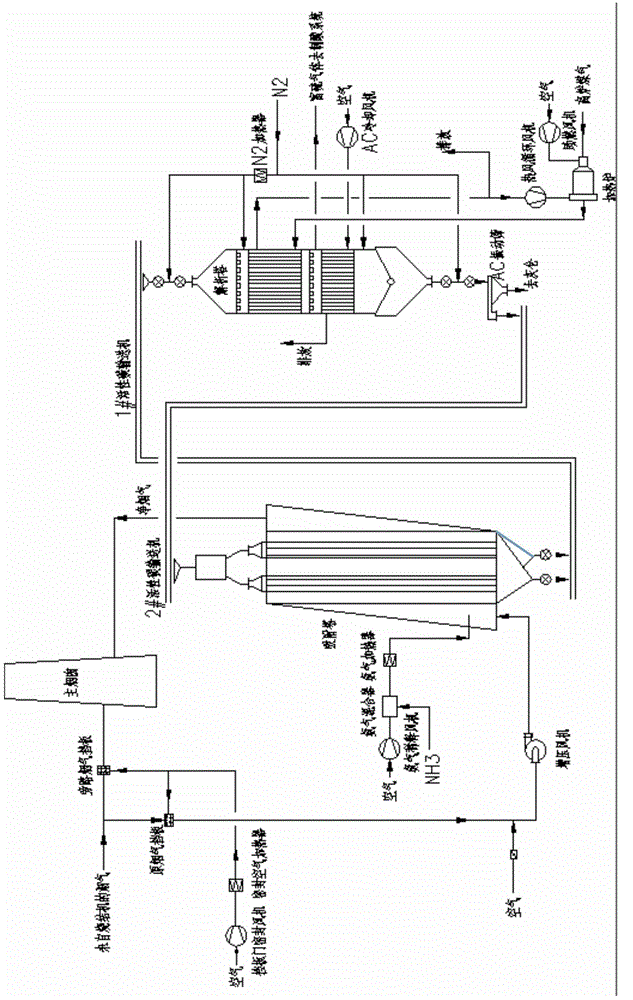

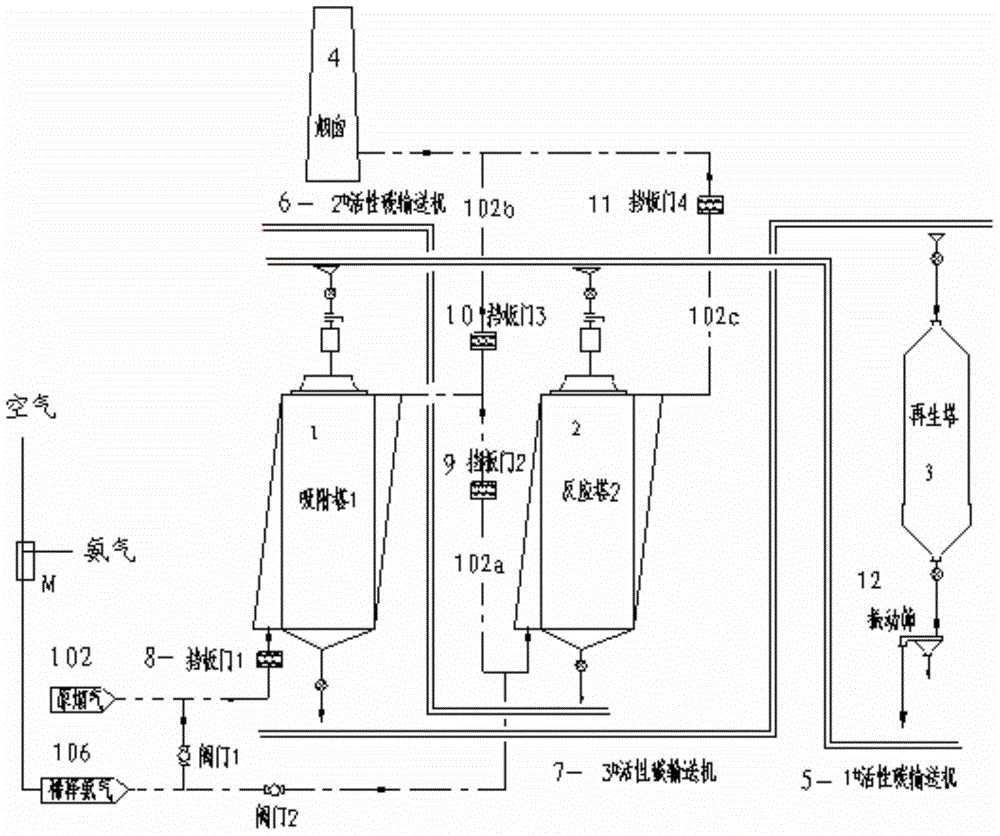

[0150] use figure 1 and the flow shown in Figure 2. Wherein the adsorption tower (1) and the adsorption tower (2) are shown in Figure 2, that is, a single-tower single-bed adsorption tower.

[0151] A desulfurization and denitrification device comprising double adsorption towers in series, comprising

[0152] 1) the first adsorption tower (1) and the second adsorption tower (2) connected in series;

[0153] 2) activated carbon regeneration tower (3) (or analysis tower);

[0154] 3) The raw flue gas conveying flue (102) upstream of the flue gas input port of the adsorption tower (1), on which a cold air inlet (P1) and a process water nozzle (P2) are arranged,

[0155] 4) The primary flue gas pipeline (102a), its front end is connected to the flue gas outlet of the first adsorption tower (1) and its rear end is connected to the second adsorption tower (2) via the second baffle door (9) the intake chamber,

[0156] 5) the secondary clean flue gas pipeline (102b), its front e...

Embodiment approach 2

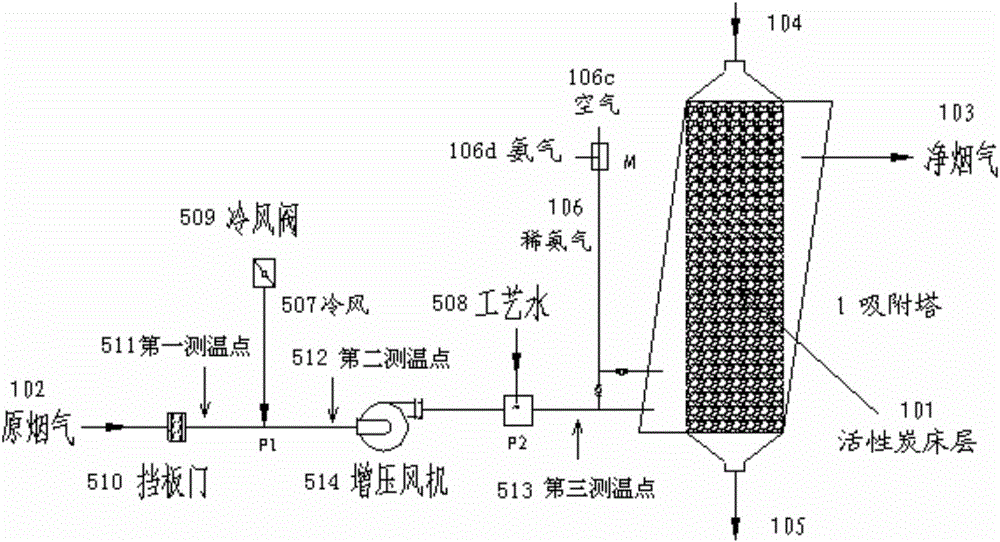

[0181] use figure 1 And the flow process shown in Fig. 2, but adsorption tower (1) and adsorption tower (2) are as image 3 As shown, that is, a single-tower three-bed adsorption tower.

[0182] A desulfurization and denitrification device comprising double adsorption towers in series, comprising

[0183] 1) the first adsorption tower (1) and the second adsorption tower (2) connected in series;

[0184] 2) activated carbon regeneration tower (3) (or analysis tower);

[0185] 3) the original flue gas delivery flue (102) upstream of the flue gas input port of the first adsorption tower (1), on which a cold air inlet (P1) and a process water nozzle (P2) are provided,

[0186] 4) The primary flue gas pipeline (102a), its front end is connected to the flue gas outlet of the first adsorption tower (1) and its rear end is connected to the second adsorption tower (2) via the second baffle door (9) the intake chamber,

[0187] 5) the secondary clean flue gas pipeline (102b), its f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com