Melting iron and steel slag heat energy recovery method and device

A heat recovery and iron and steel slag technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problem of no reliable method, achieve the effect of simple structure, less equipment investment, and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method and device of the present invention will be described in detail below through specific embodiments.

[0019] A method for recovering heat from molten steel slag, the method is to put blast furnace or converter molten steel slag and a small amount of cold steel slag into an insulating slag tank, mix them evenly, and form a slag pool in the slag tank; The granulation of molten iron and steel slag increases the heat exchange area and effectively recovers the heat energy of the molten slag; the process of heat energy recovery is realized by blowing in cold air, which is heated by the cold air and then directed into the waste heat boiler. The added amount of cold slag is 30-50% of the weight of molten hot steel slag.

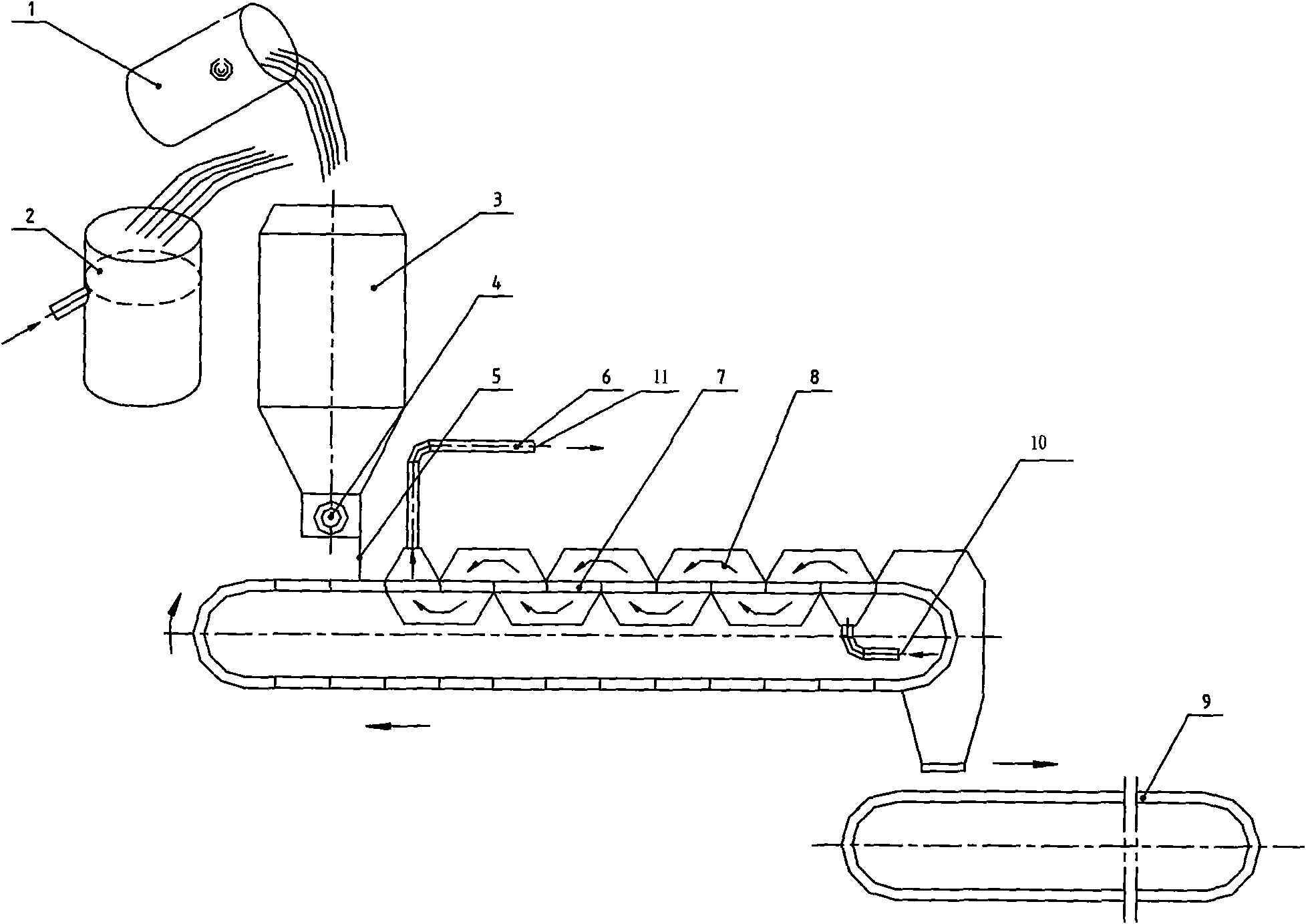

[0020] See figure 1 , a device for recovering heat energy from molten steel slag, including molten slag tank 1, cold slag injector 2, mixed slag tank 3, secondary granulation device 4, distributor 5, hot air recovery pipe 6, trolley 7, wind cover 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com