Patents

Literature

42results about How to "Strength reached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV-curable composition and adhesive film comprising same, adhesive tape, and adhesive member

ActiveCN110643286ACause corrosionStrength reachedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyPolymer science

The invention relates to a UV-curable composition, and an adhesive film comprising the same, an adhesive tape, and an adhesive member. The UV-curable composition is a photo-base catalyzed UV curable composition. The UV-curable composition comprises: (1) an acrylic polymer and / or an ethylene-vinyl acetate copolymer; (2) a curable component containing a polyfunctional thiol and a polyfunctional epoxy resin; and (3) a photo-alkali generating agent. The composition disclosed by the invention can be coated into an adhesive tape or an adhesive film, and the adhesive tape or the adhesive film has initial viscosity when UV curing is not carried out, and can reach the strength of a semi-structural adhesive or a structural adhesive after UV curing.

Owner:3M INNOVATIVE PROPERTIES CO

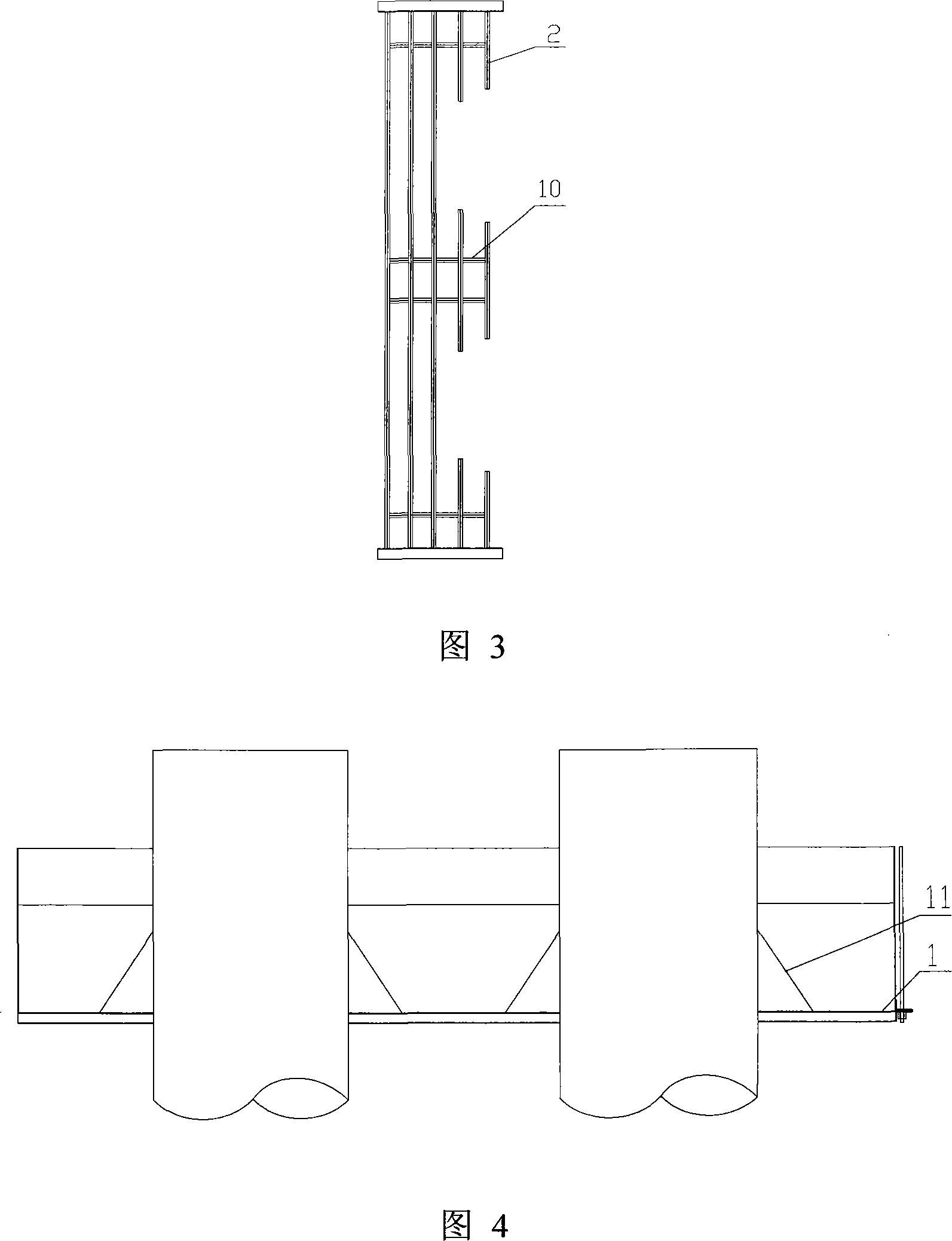

Single-arm steel hanging box and construction method thereof

The invention relates to a single wall steel hanging case, pertaining to a deep water platform and pier column construction enclosure structure. The invention also relates to a construction method for a single wall steel hanging case. The invented single wall steel hanging case mainly comprises a side plate and a bottom plate, wherein the side plate is mainly composed of an upper segment and a lower segment, and the bottom plate comprises a panel, a longitudinal beam and a transverse beam, wherein the panel is paved on the longitudinal beam, the edge of the panel parallel to the longitudinal beam is welded with an equal angle steel, the other two edges are welded with a steel angle flange, and a nut is welded correspondingly at the lower side of the steel angle flange through hole; the longitudinal beam is paved on the transverse beam, each two beams are disposed at the two sides of the hole, each end of the beam is welded with a anchor backing board, and a through hole is disposed at the inner and outer two sides of the anchor backing board corresponding to the side plate. The bottom of the invented single wall hanging case is removable, and the shortcoming of the traditional steel hanging case that the bottom plate is not recoverable is overcome.

Owner:SHANDONG LUQIAO CONSTR

Repair method for improving pumping rod strength

InactiveCN1766335AHigh strengthStrength reachedDrilling rodsPositive displacement pump componentsUltimate tensile strengthQuenching

The invention discloses a restoring method of oil pumping rod rigidity in the oil exploitation technique domain, which is characterized by the following: adapting alternative quenching method to restore the oil pumping rod; improving the rod rigidity; reaching new rod rigidity level; changing the oil pumping rod from grade C to grade D; making the old oil pumping rod of grade D more than 980 MPa.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

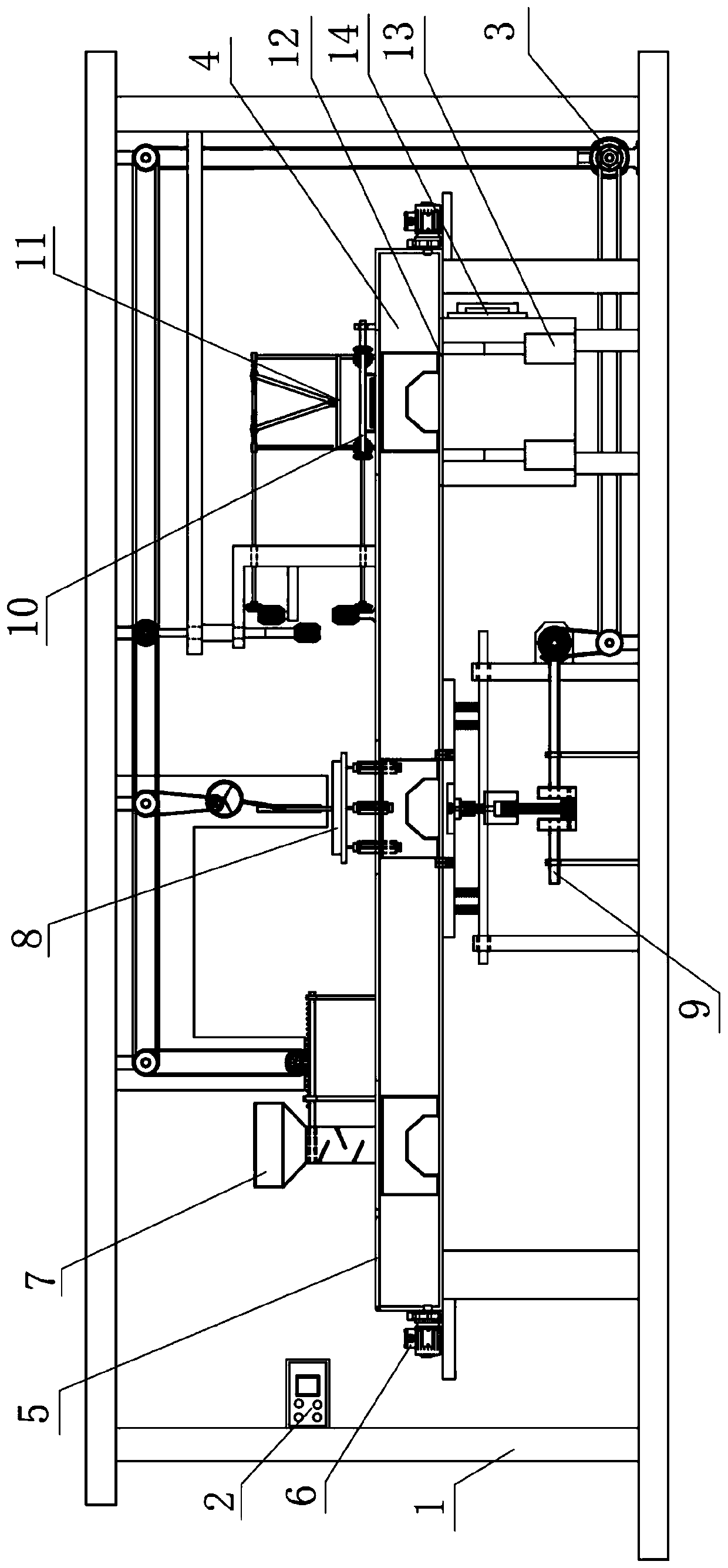

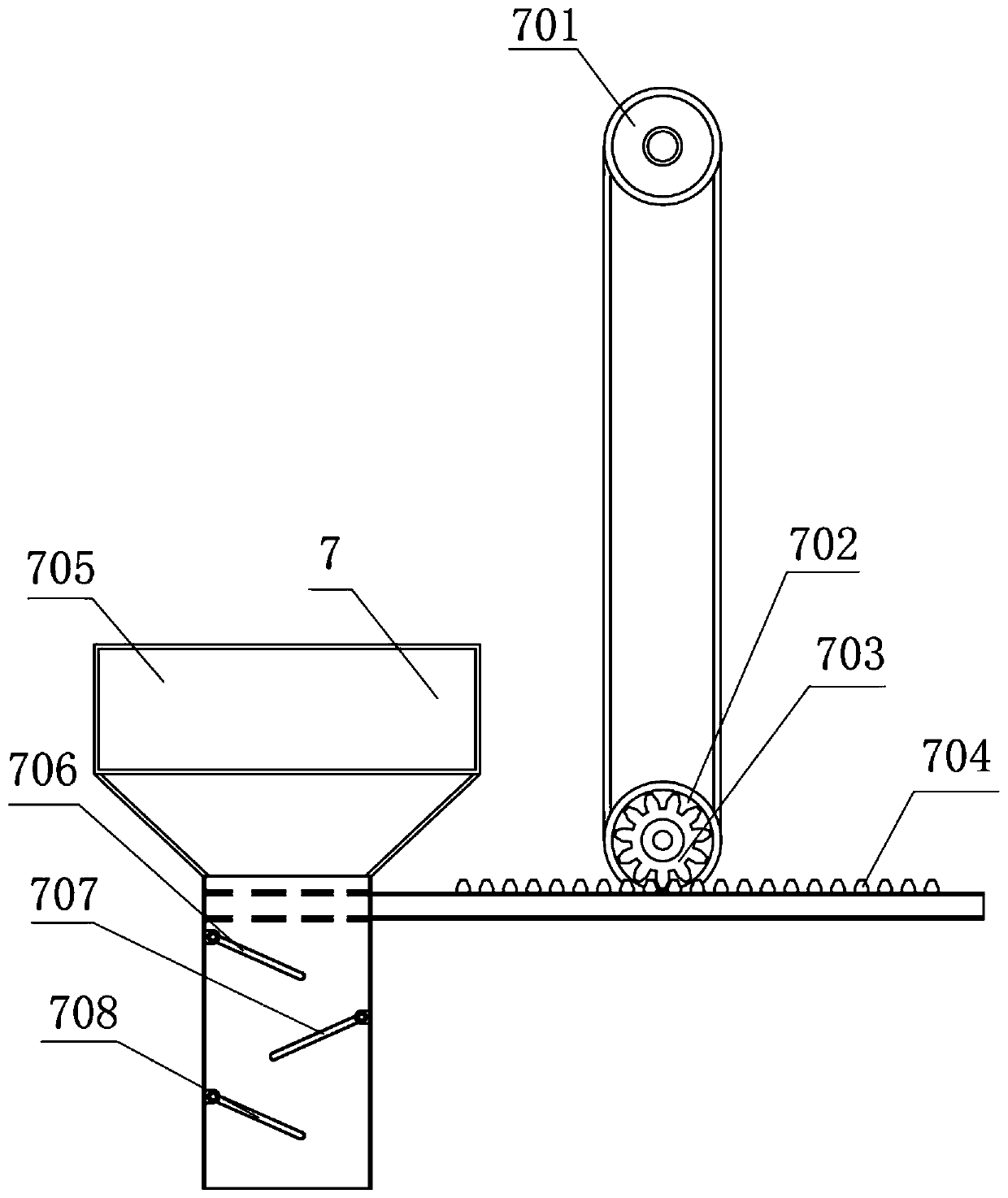

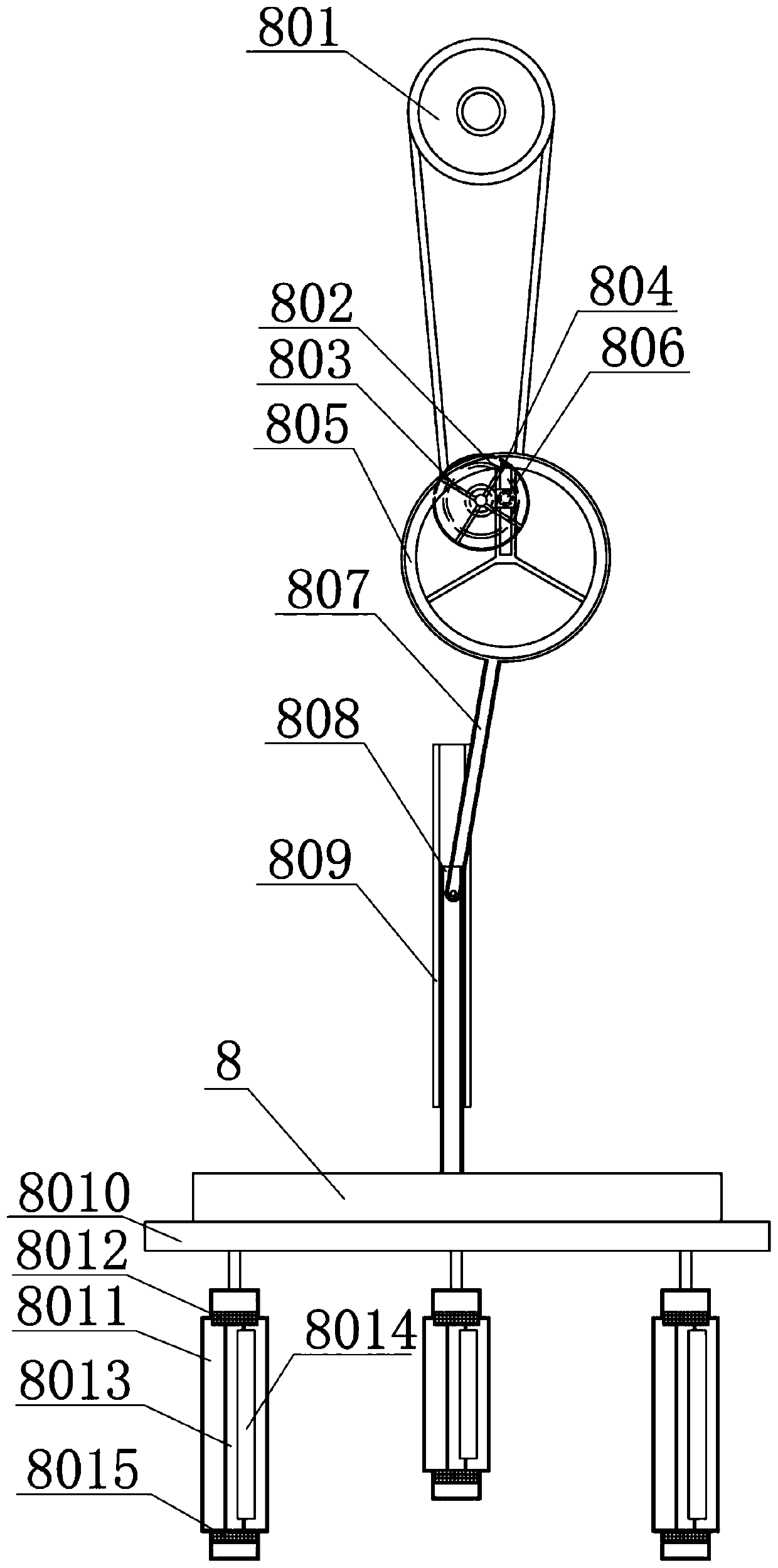

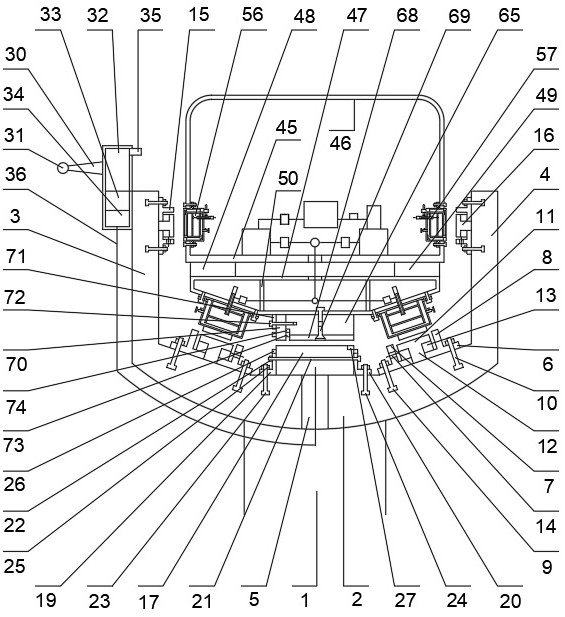

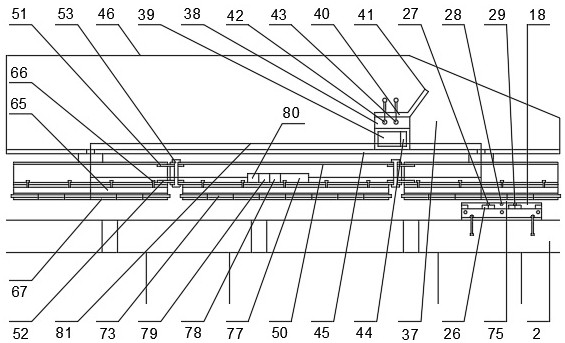

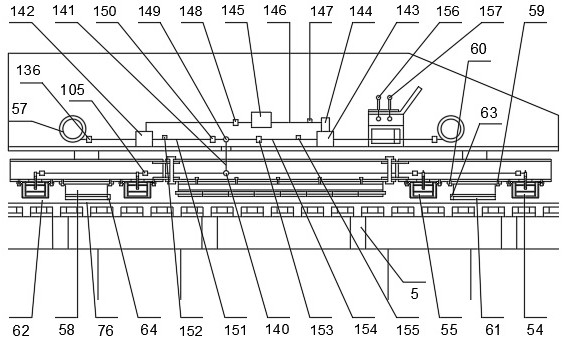

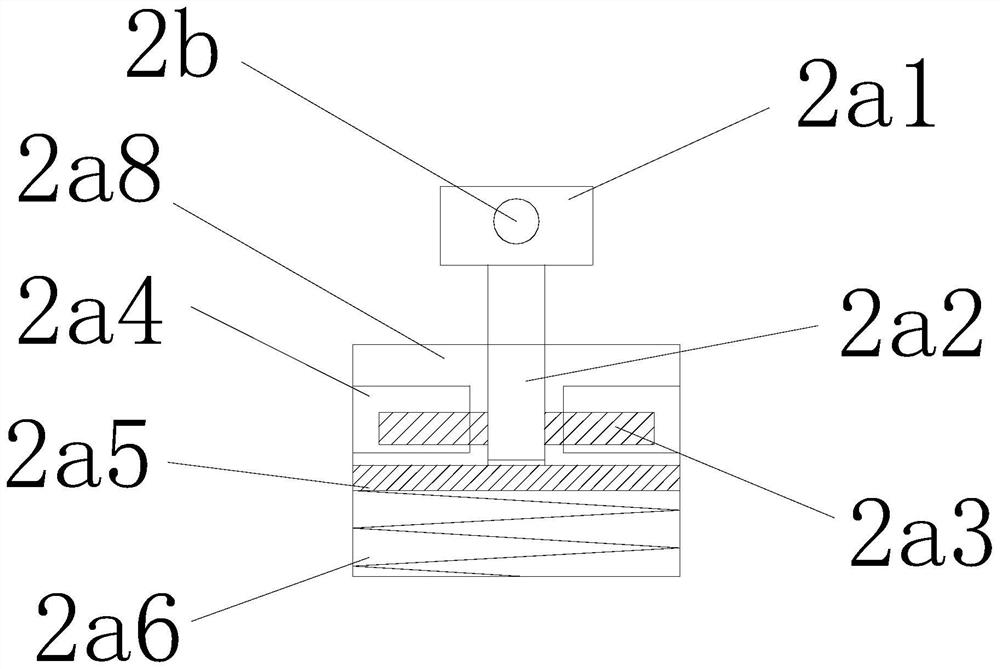

Forming die of prefabricated component

ActiveCN111251438ATightly boundSo as not to damageCeramic shaping plantsFeeding arrangmentsPhysicsElectric machinery

The invention relates to a prefabricated component, in particular to a forming die of a prefabricated component. The invention aims at solving the technical problem to provide the forming die of the prefabricated component. The forming die of the prefabricated component comprises a support frame, a control screen, a motor, a conveying pipe, a cover plate, an air pump, a feeding mechanism, a variable-speed vibrating mechanism, a vibrating table, a flatly spreading mechanism, a compacting mechanism, an ascending and descending plate, a first electric push rod and a discharging opening, wherein the control screen is arranged at the upper side of the middle part of the left end inside the support frame; and the motor is arranged at the right side of the bottom end inside the support frame. Theforming die of the prefabricated part achieves the effects that the mechanical operations of feeding, vibration and press polishing on a die of the prefabricated component is realized; the die is enabled not to be damaged when concrete is added into the die; the overflowing waste cannot be caused; a layering phenomenon is enabled to be avoided during the vibration; the vibration completion degreeis improved; no air bubble and no crack existing on the surface are ensured; the intensity of the prefabricated component is improved; and meanwhile, the mass production can be realized.

Owner:中山市粤华混凝土有限公司

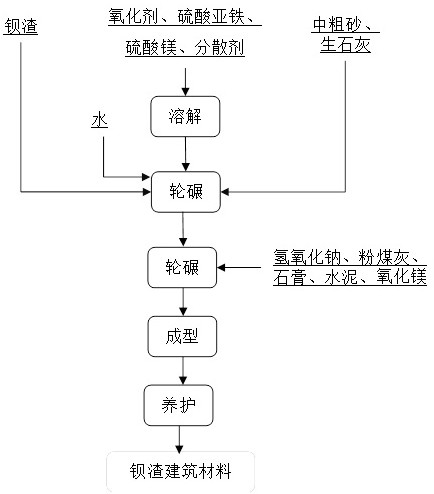

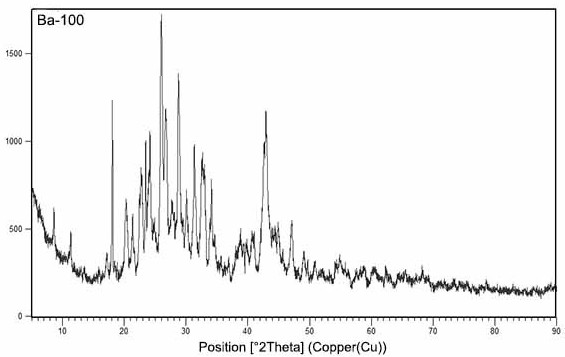

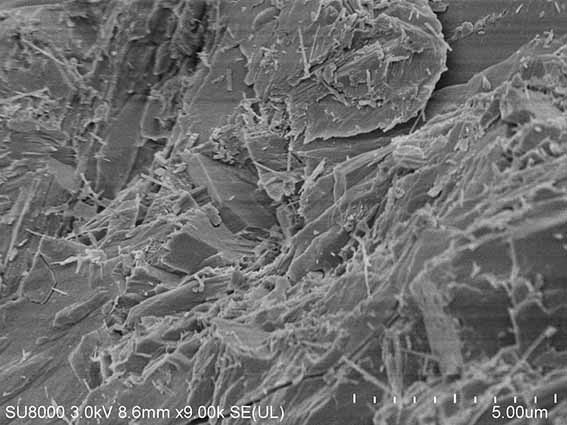

Harmless resourceful treatment method for barium slag and prepared building material

The invention relates to a barium slag harmless resourceful treatment method and a prepared building material.The method comprises the steps that a proper amount of oxidizing agent, ferrous sulfate, magnesium sulfate and dispersing agent are dissolved with water, and a stabilizer solution is obtained; adding a proper amount of barium slag, medium-coarse sand and quick lime into an edge runner mill, adding the stabilizer solution into the edge runner mill, supplementing a proper amount of water, and uniformly mixing to obtain a first mixture; adding a proper amount of sodium hydroxide, fly ash, gypsum, cement and magnesium oxide into the first mixture, and continuing mixing to obtain a second mixture; and carrying out vibration compression molding on the second mixture, and preserving moisture and curing to obtain the barium residue building material. According to the method, wheel rolling equipment is utilized, harmlessness and recycling of the barium slag are carried out in the same equipment step by step, excessive soluble sulfate is utilized step by step to fix barium, meanwhile, magnesium oxide is added later to eliminate the influence of soluble magnesium sulfate on the performance of the building material, and the barium ion leaching toxicity of the obtained barium slag building material is low and is as low as about 0.3 mg / L.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Clinker preparation method of sintering method aluminium oxide production technology

A proces for preparing the grog used for producing aluminium oxide by sinter method includes pulverizing bauxite, proportionally mixing it with concentrated carbon liquid, lime, sodium carbonate and other circulating materials, ball grinding to obtain raw slurry, drying, shaping, stacking in kiln and calcining. Its advantages are less environmental pollution, low energy consumption and high productivity.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

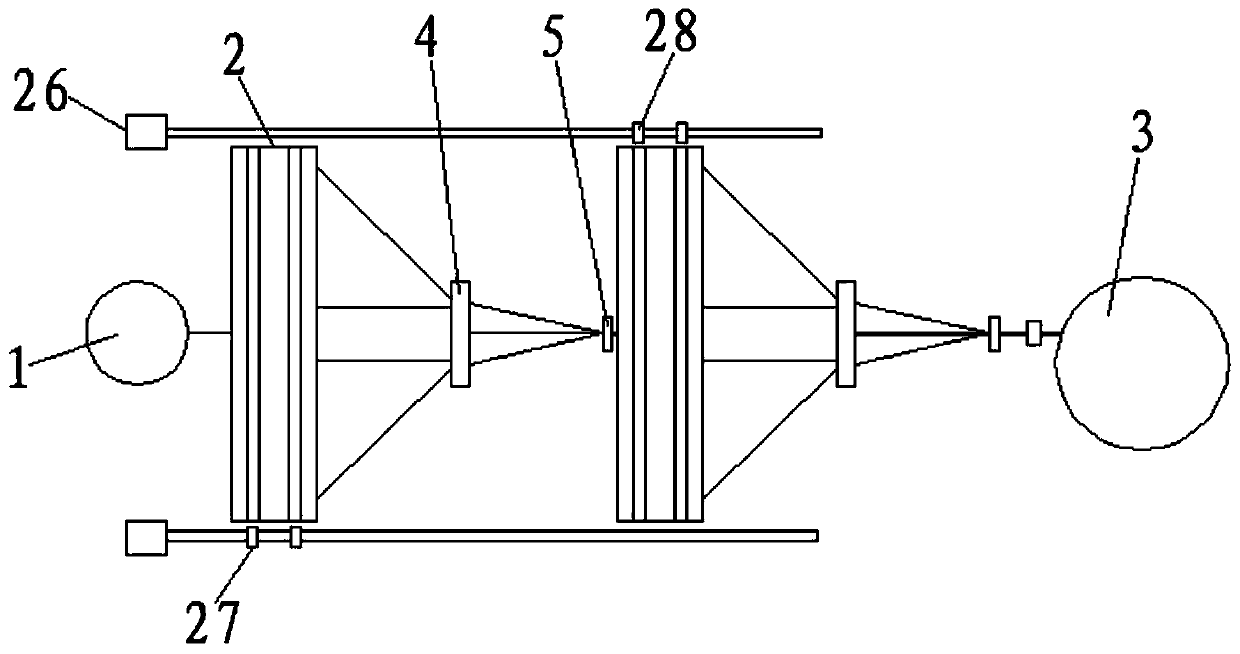

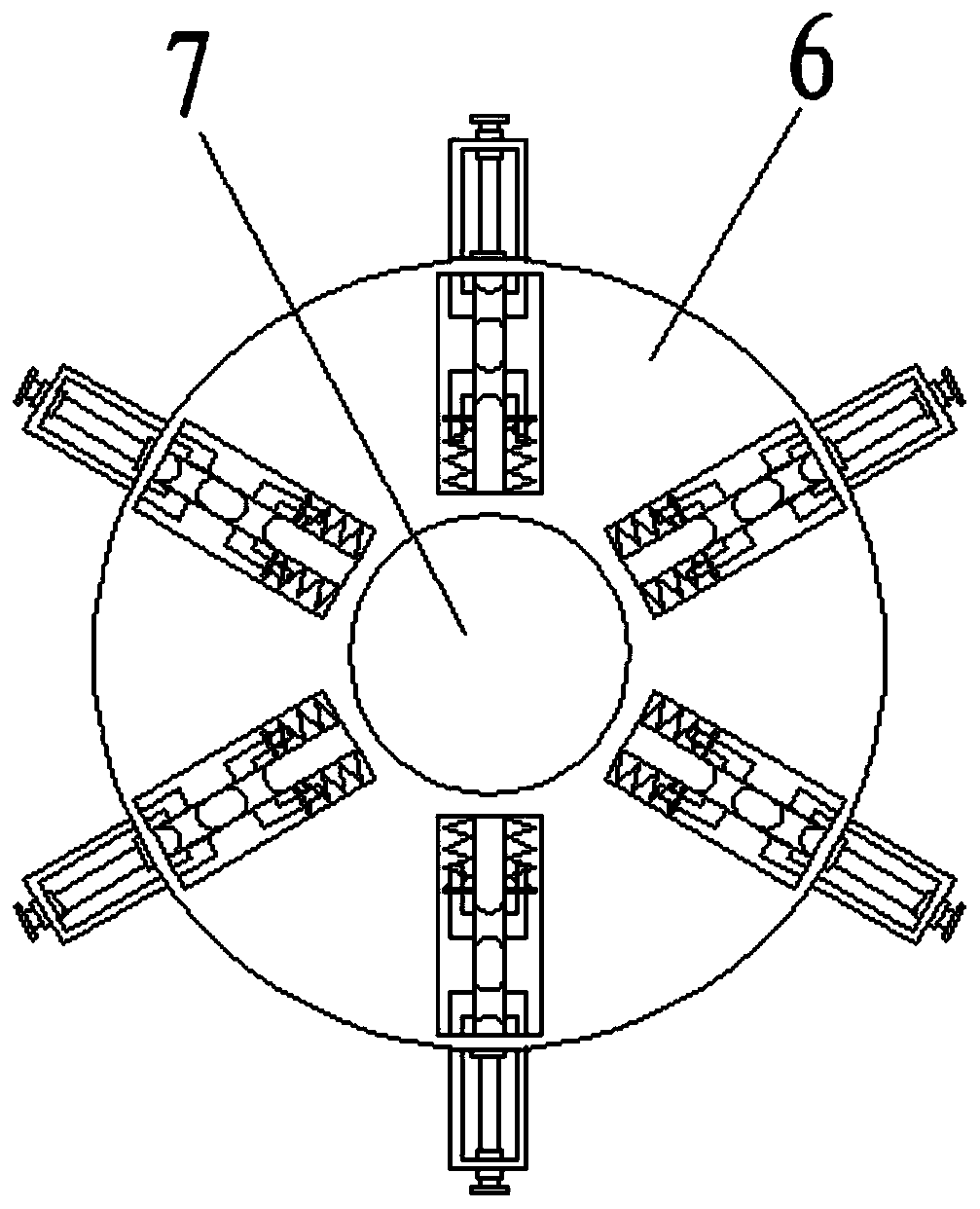

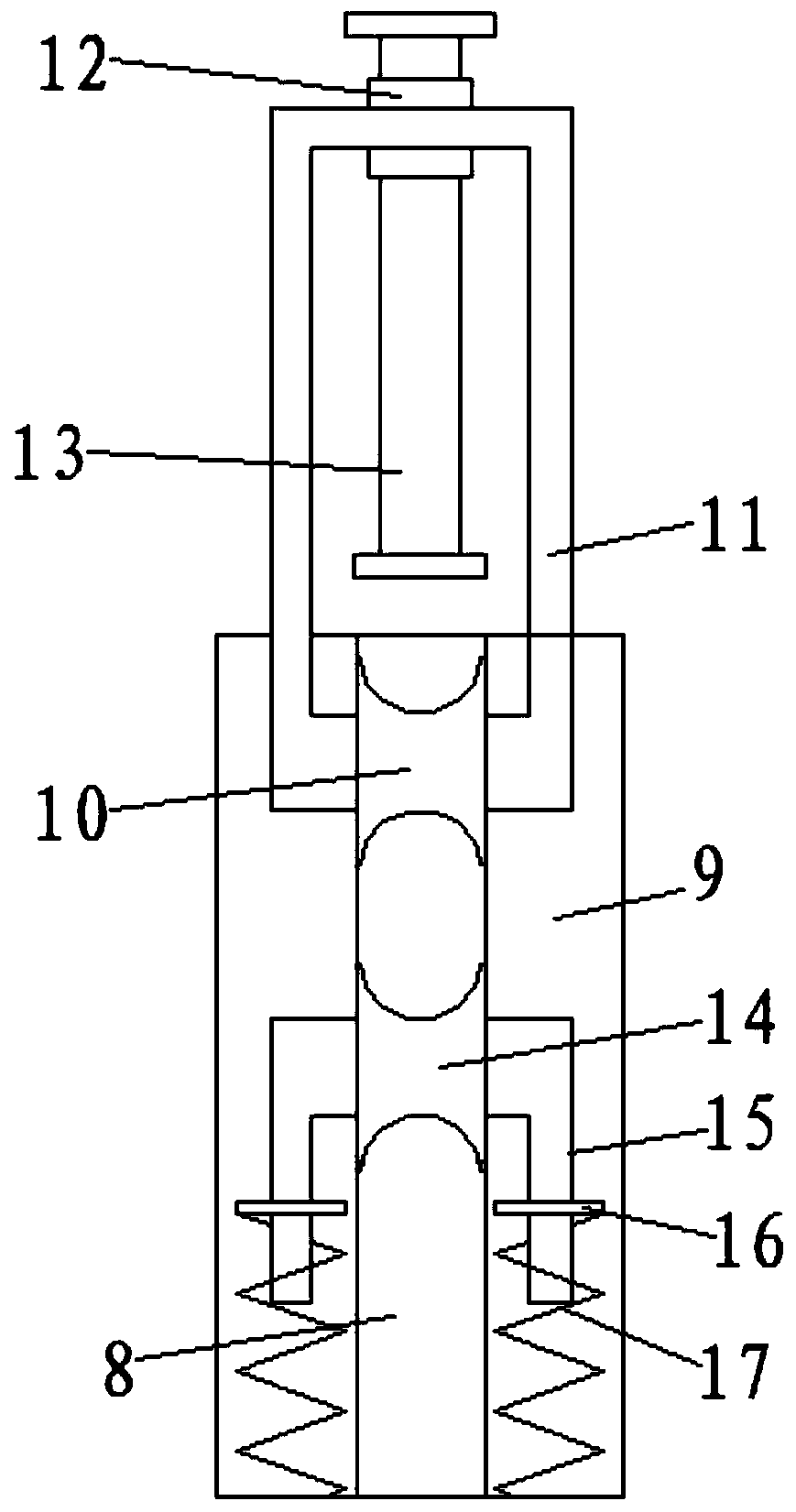

Resistance heating system for ultra-high strength steel

ActiveCN106211389BImprove efficiencySmall footprintHot plates heating arrangementsOhmic-resistance heating detailsSheet steelWelding power supply

Owner:HERON INTELLIGENT EQUIP CO LTD

Continuously hot-galvanized high-strength steel and production method thereof

InactiveCN104726772AHigh strengthPrecipitation strengthening effect is remarkableHot-dipping/immersion processesSteelmakingUltimate tensile strength

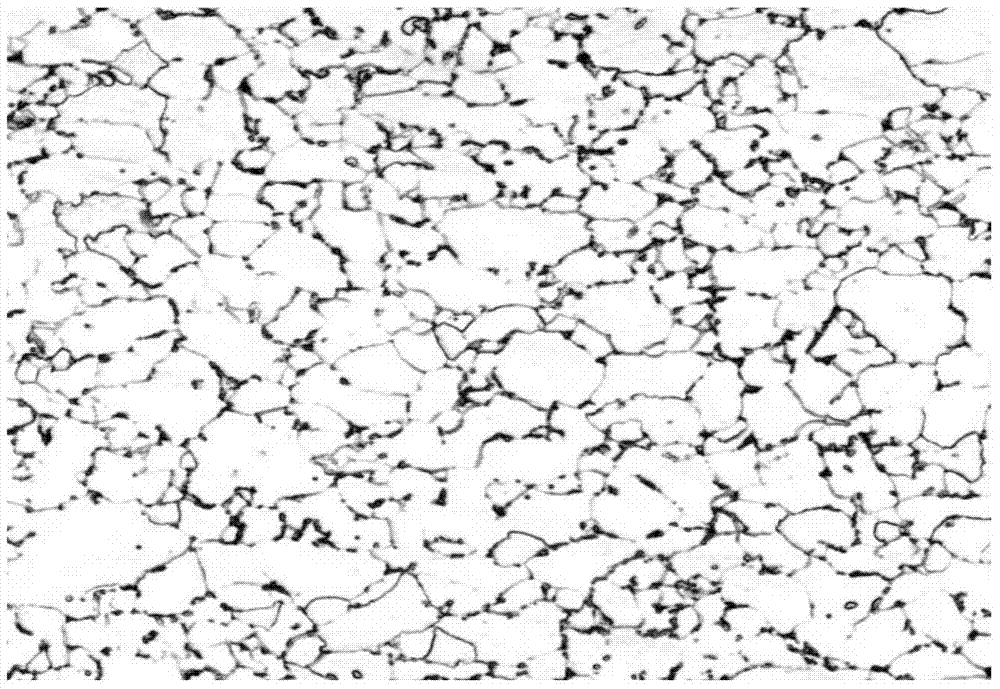

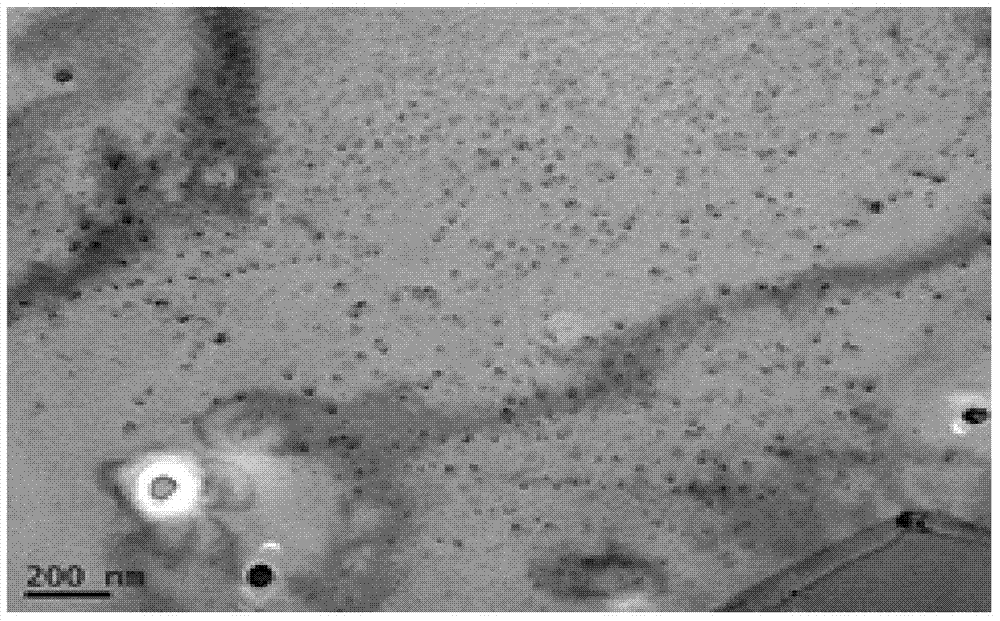

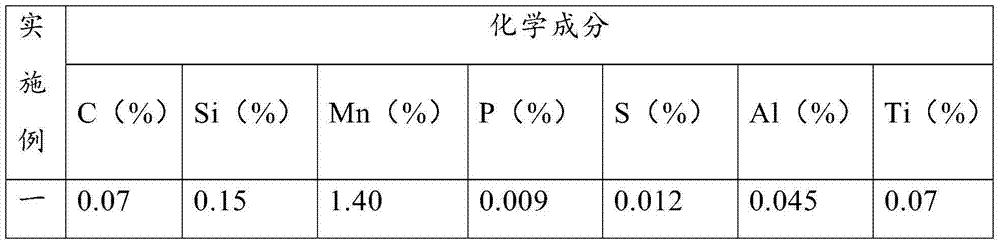

The invention relates to the technical field of steel rolling, and particularly relates to continuously hot-galvanized high-strength steel and a production method thereof. The high-strength steel comprises the following chemical components in percentage by mass: 0.05-0.15% of C, 0.6-1.5% of Mn, 0.10-0.50% of Si, less than or equal to 0.015% of P, less than or equal to 0.018% of S, 0.03-0.07% of Als, 0.05-0.10% of Ti, and the balance of Fe and unavoidable impurities. The invention also provides the production method of the hot-galvanized high-strength steel S550GD + Z. The production method comprises the steps of steelmaking, hot rolling, cold rolling, continuous hot galvanizing, and finishing. According to the production method of the continuously hot-galvanized high-strength steel provided by the invention, a required strength is achieved through controlling the components, the coiling temperature, the soaking temperature of continuous hot galvanizing, and the ductility of a finishing machine. The method greatly increases the plasticity of finished products, and avoids resource wasting caused by temperature transition arising from low-temperature annealing in a conventional continuous hot galvanizing production method.

Owner:SHOUGANG CORPORATION

Multifunctional nylon bobbin

InactiveCN102850778AImprove water absorptionGood dimensional stabilityRigid pipesGlass fiberWeather resistance

The invention discloses a multifunctional nylon bobbin. The multifunctional nylon bobbin is composed of materials including, by weight, 2-10 parts of glass fibers, 1-5 parts of flame retardant, 1-3 parts of weather resistance agent and the balance nylon. The multifunctional nylon bobbin is fine in flame-retardant and heat-resistance performance, high in mechanical strength and resistant to wear, and the service life thereof is greatly prolonged.

Owner:霍中南

Quick-setting and rapid-hardening road pavement repair concrete with super-early strength and preparation method thereof

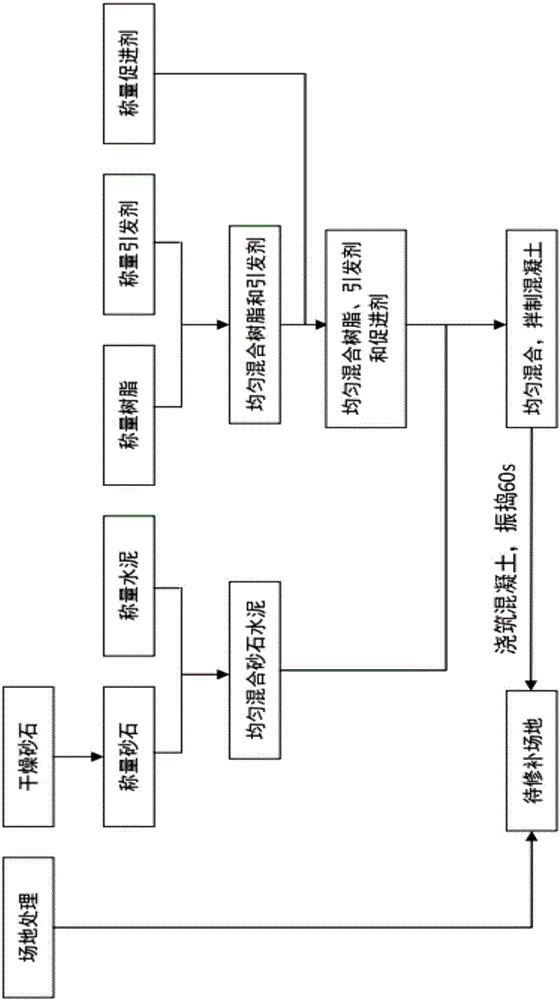

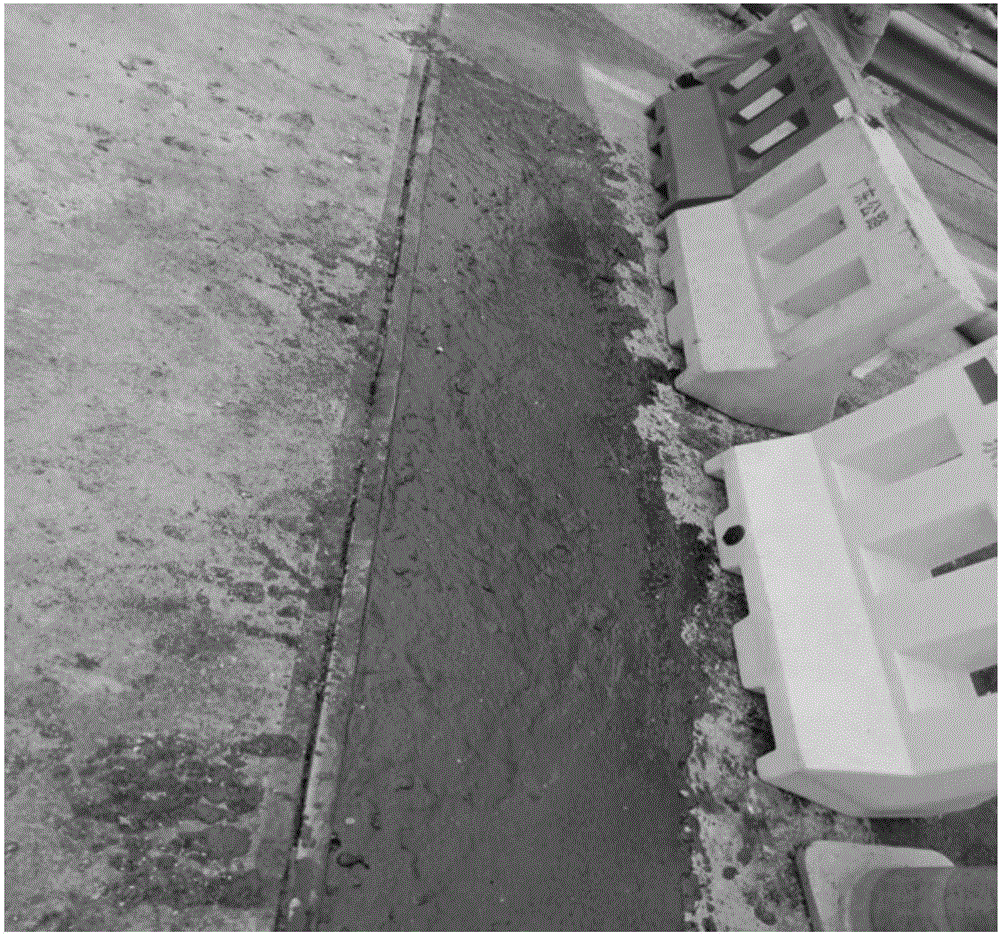

The invention relates to a quick-setting and rapid-hardening road pavement repair concrete with super-early strength and a preparation method thereof. The quick-setting and rapid-hardening road pavement repair concrete is prepared from the following raw materials in unit usage amount (kg / m<3>): 320 to 350 parts of gel material, 730 to 790 parts of river sand, 920 to 960 parts of crushed stone, 250 to 350 parts of cement, 3 to 4 parts of initiator, and 1.5 to 2 parts of accelerant. The quick-setting and rapid-hardening road pavement repair concrete with super-early strength has the advantages that the content of gel material is 320 to 350kg / m<3>; the content of gel material is low, the cost is low, the mechanical property is better, the shrinkage rate is little, the 6h compressive strength is no lower than 30MPa, the total shrinkage rate is 0.03 to 0.05%, the 7d compressive strength is higher than 60MPa, the 28d compressive strength is higher than 72.6MPa, and the requirement on road curing conditions is low.

Owner:GUANGDONG UNIV OF TECH +1

Elevated half-tube intelligent five-rail high-temperature superconducting maglev train system

InactiveCN113829888AImprove efficiencyReduce copper lossRailway tracksElectric energy managementConvertersRotor (electric)

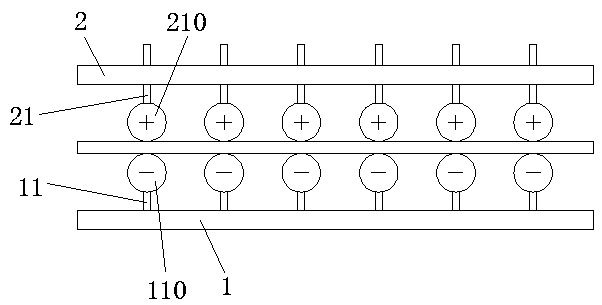

According to an elevated half-tube intelligent five-rail high-temperature superconducting maglev train system, a plurality of magnetic circuits of four electromagnetic rails of an elevated half-tube intelligent five-rail subsystem are linearly arranged and connected with a plurality of single coils in series in the same direction, and the four electromagnetic rails generate a continuous and uniform magnetic field in the rail direction; pinning magnetic fluxes generated by high-temperature superconducting blocks in 12 monitoring type intelligent Dewar are correspondingly arranged on the four electromagnetic rails in the half tubes respectively, the four electromagnetic rails are surrounded, and the acting force of automatic suspension, automatic stabilization and automatic guiding of the maglev train is enhanced; a plurality of section converters supply power under the control of a photoelectric proximity switch and a wireless remote control receiving module, the electromagnetic field intensity of the electromagnetic rails and the middle electromagnetic rail in the four sections can be controlled, the electromagnetic field can be turned off, and the four electromagnetic rails and the middle electromagnetic rail outside the sections are all in a power-off state; the electromagnetic rails in the interval generate a moving magnetic field to drive a linear direct-current permanent magnet motor rotor; and a linear alternating current generator rotor synchronously induces alternating current output.

Owner:朱幕松

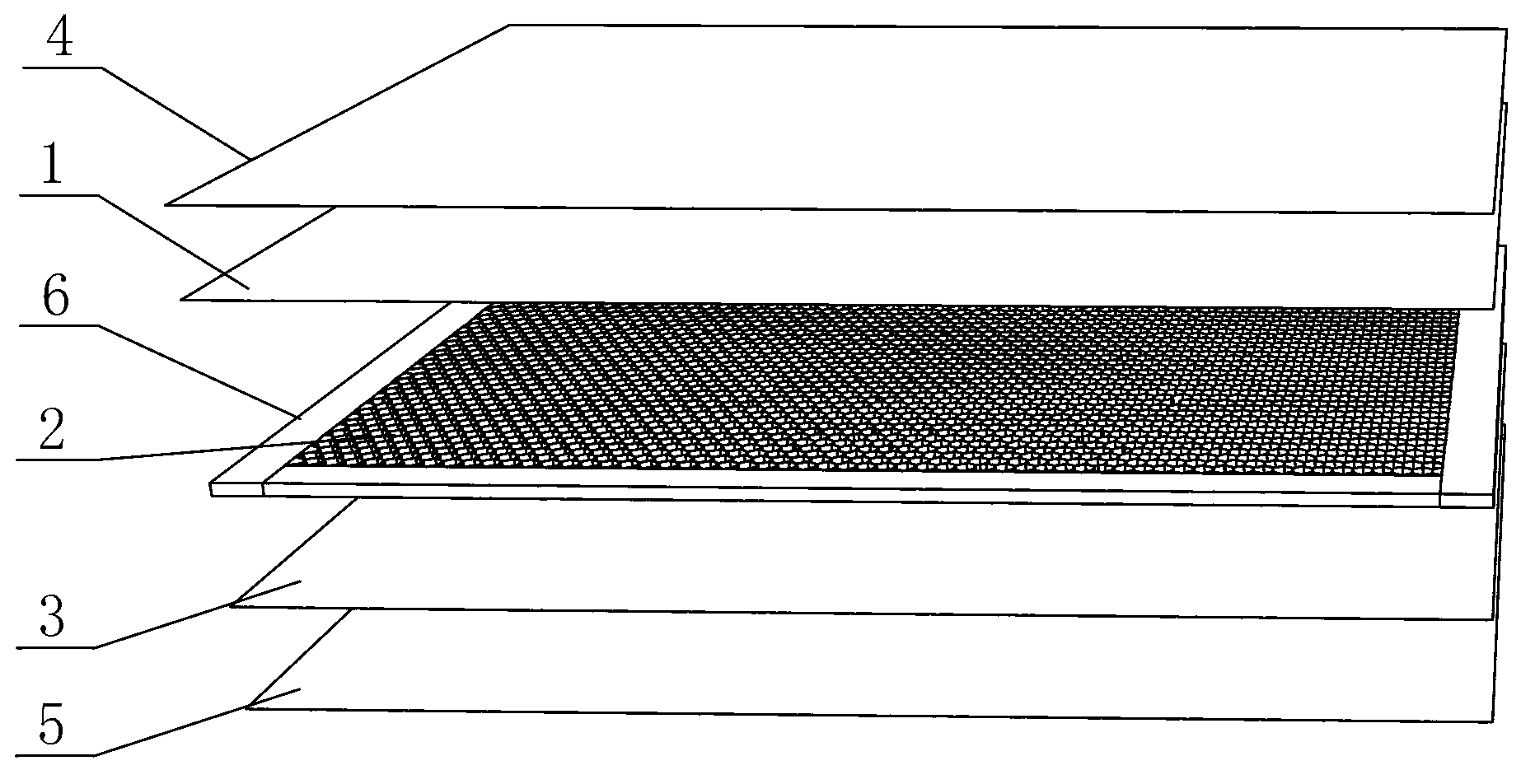

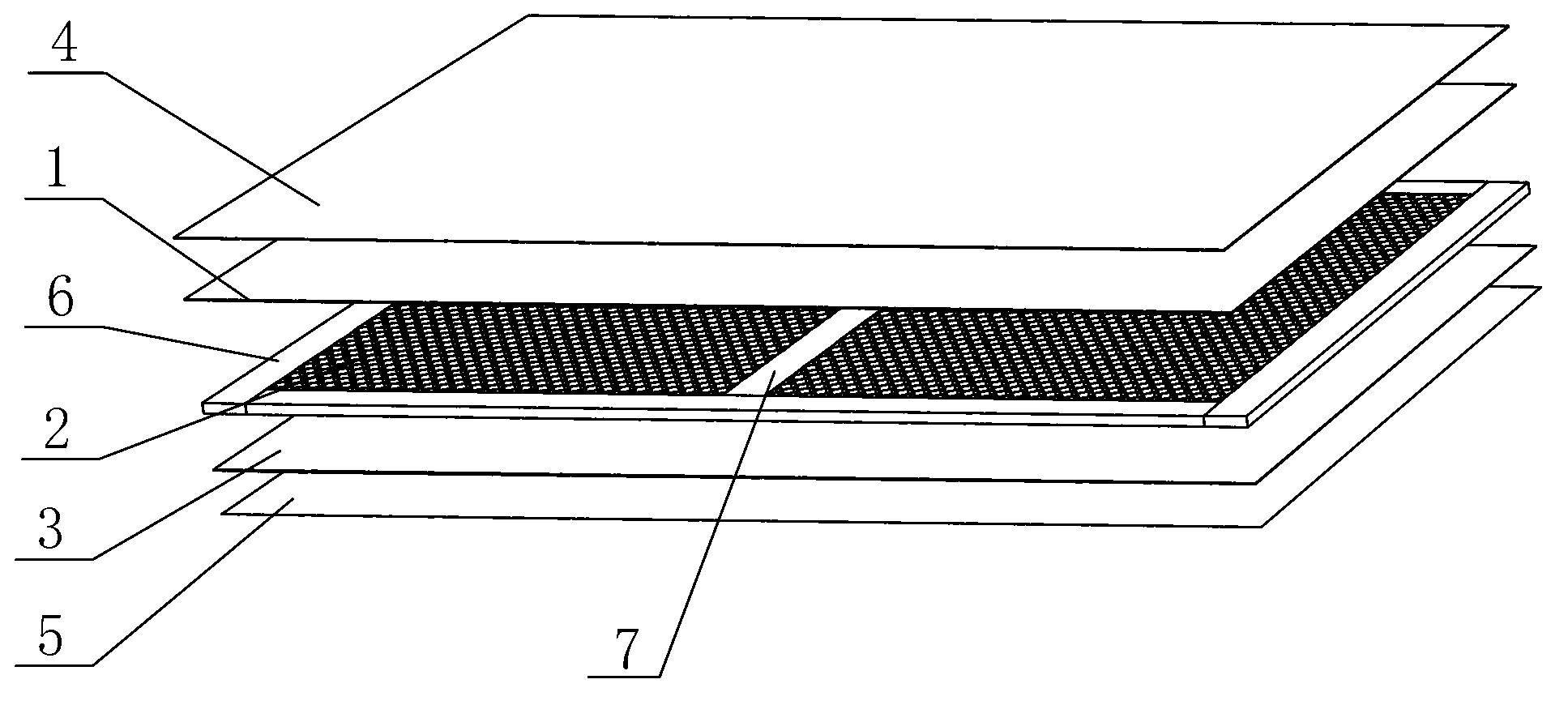

Environment-friendly rectangular composite plate

ActiveCN103231550AImprove protectionStrength reachedPaper/cardboard layered productsCardboardHoneycomb

The invention discloses an environment-friendly rectangular composite plate comprising a surface plate, a bottom plate, and a central layer arranged between the surface plate and the bottom plate. The central layer is a honeycomb paper core. The surface plate and the bottom plate are respectively adhered with the central layer by using glue. The surface plate and the bottom plate both comprise at least one layer of paperboard or paper skin. The central layer also comprises a rectangular frame arranged on the periphery of the honeycomb paper core and glued with the honeycomb paper core. The thickness of the frame is same as that of the honeycomb paper core. According to the invention, the central layer is the honeycomb paper core, and the surface plate and the bottom plate are paper skin or paperboard. The three are all sourced from paper products, such that advantages of light weight and low cost are provided. Wood is not directly used, such that forest resource protection is promoted. The strength of the composite plate reaches that of a wood composite plate or even higher.

Owner:东莞市迅虹纸业有限公司

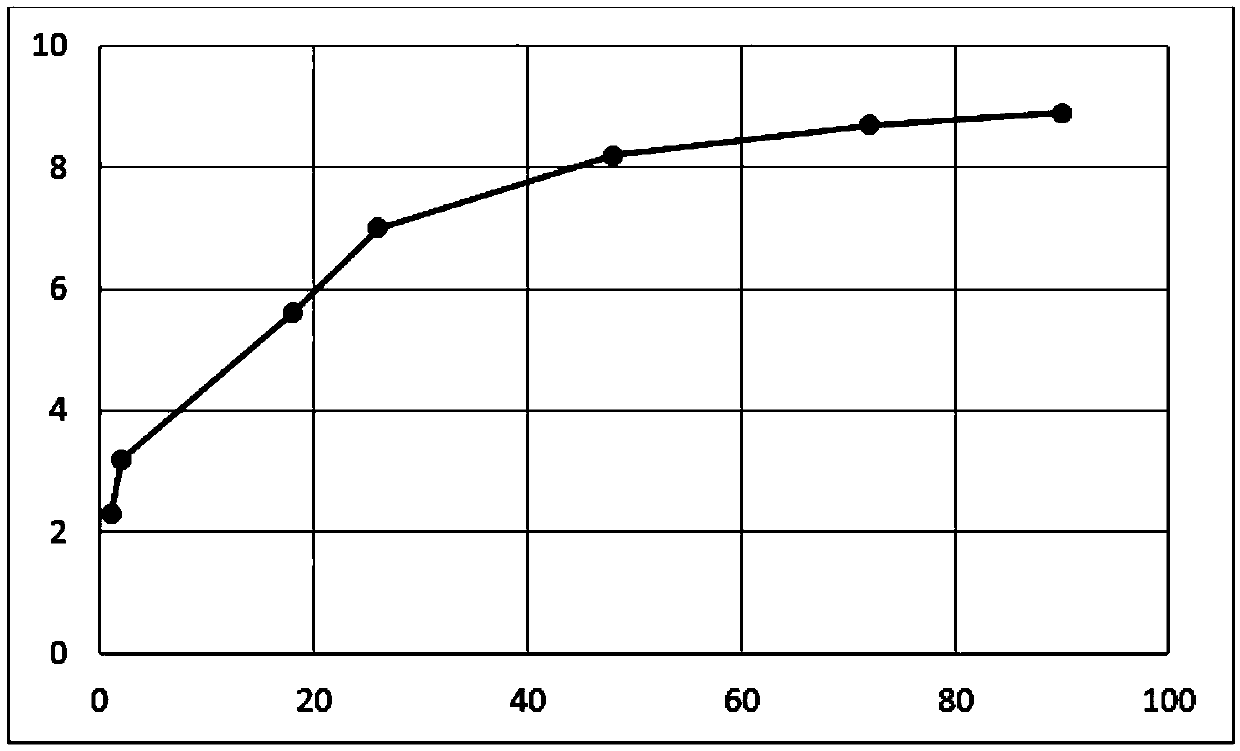

A granulating method for a round-particle potassium fertilizer

InactiveCN106242646AHigh strengthStrength reachedPotassium fertilisersAgricultural engineeringBiology

The invention relates to the technical field of agricultural fertilizers and particularly relates to a granulating method for a straight round-particle potassium fertilizer. The method includes crushing the potassium fertilizer with a ball mill into particles the granularity of which is 80 meshes, wetting the potassium fertilizer with water the weight of which is 5-7% of the weight of the potassium fertilizer, fully mixing, adding the potassium fertilizer into a screw extruder, extruding to obtain cylindric small segments the diameter of which is 3-4 mm and the length of which is 2-4 mm to preform the potassium fertilizer, rounding the potassium fertilizer small segments and improving strength in a revolving drum with the time being 10 min or above to achieve certain strength, drying the potassium fertilizer in a mesh-belt type drying machine with the drying temperature being controlled to be 120-200 DEG C, drying time being 40-60 min, and moisture removing temperature being 70-80 DEG C, and cooling the dried material in a revolving drum cooler until the temperature is 60 DEG C or below to obtain the round-particle potassium fertilizer. The degree of particle circularity of a prepared product is 95%, a product yield is 90% or above and strength is 30-40 N.

Owner:SUIFENHE QUARTZ ECONOMIC TRADE

Novel frost-resistant concrete

The invention discloses novel frost-resistant concrete. Raw materials comprise cement, stones, yellow sands, melon seed-shaped drug slices, coal gangue, phosphorus slag powder, zeolite powder, rubber powder, a carboxylated butadiene-styrene rubber emulsion, cellulose, a water reducer, an accelerator, a compound pumping aid, an alkaline-aggregate reaction inhibitor, sodium thiosulfate, sodium acetate and water. The compound pumping aid is obtained by mixing, grinding, crushing and screening calcium lignosulphonate, a polycarboxylate efficient water reducer, anhydrous sodium sulfate, sodium abietate, hydroxyethylmethylcellulose and coal ash. The novel frost-resistant concrete is high in strength and good in frost-resistance.

Owner:安徽省无为市泉塘预制厂

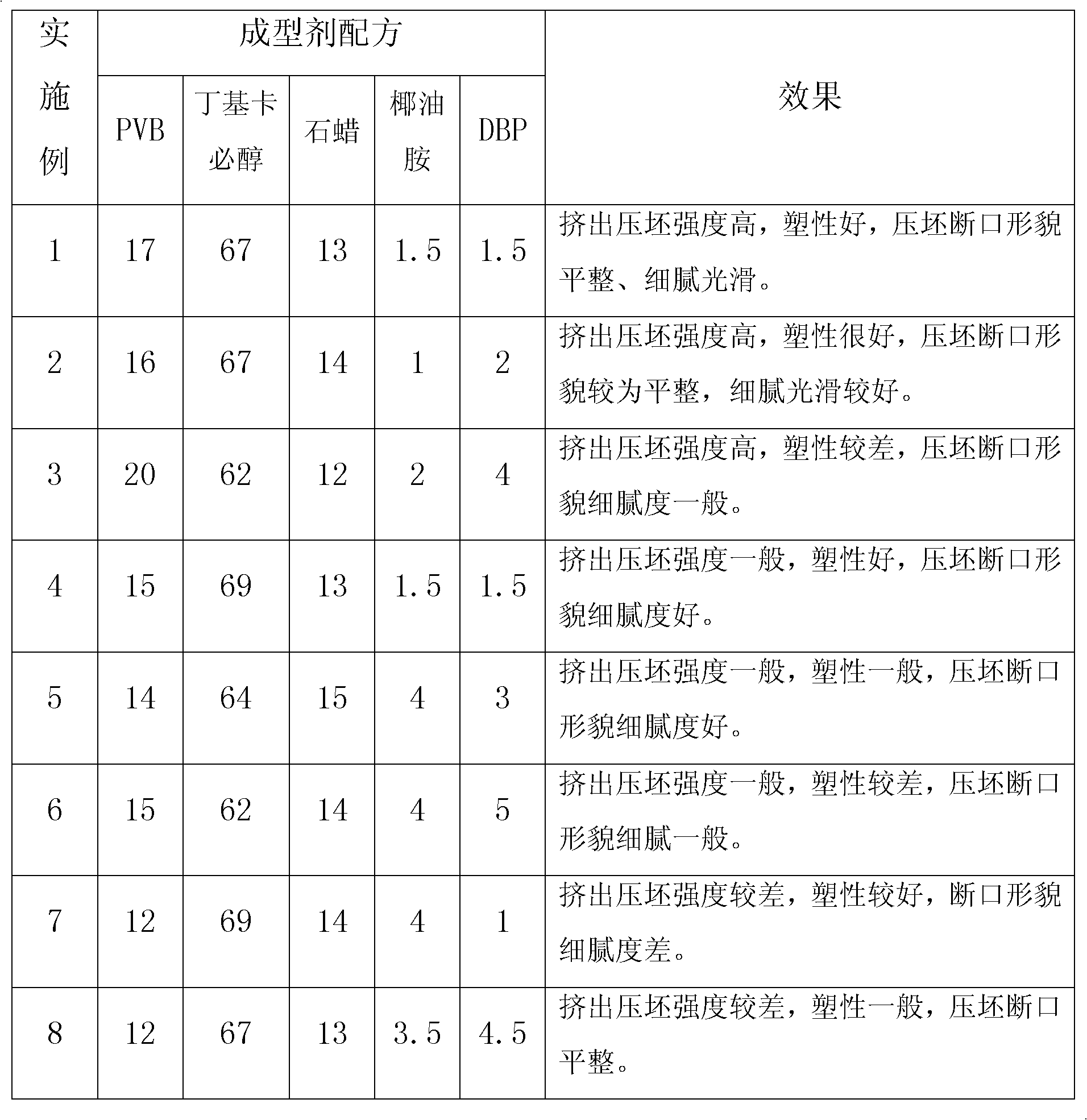

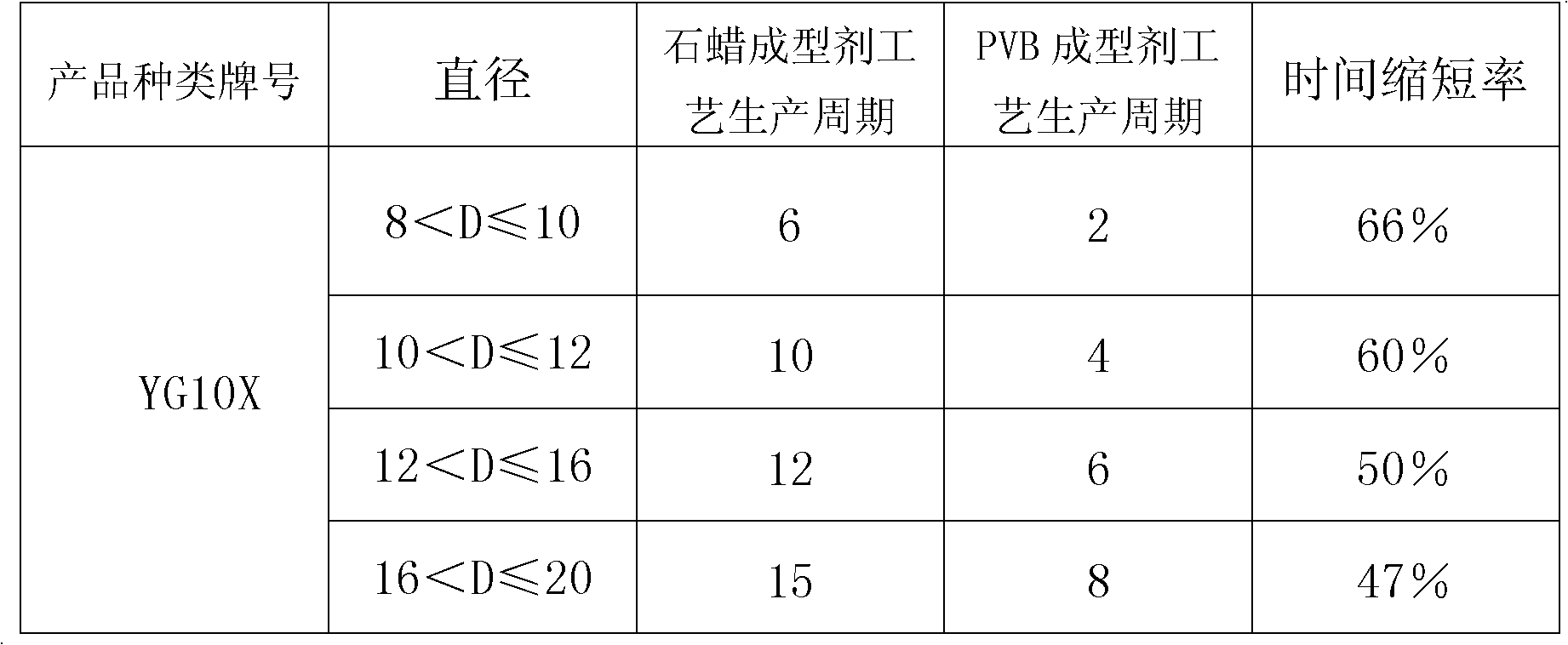

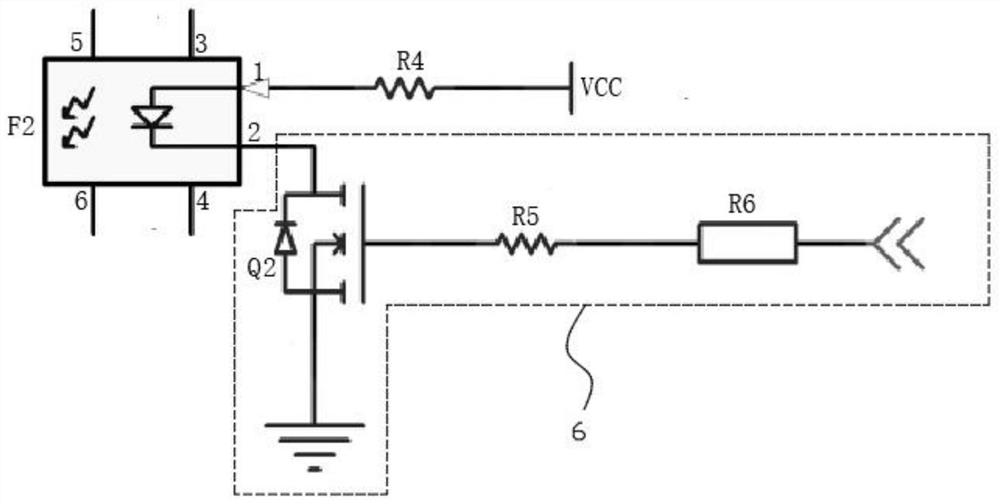

High-plasticity and easy-to-be-eliminated extrusion molding agent

The invention discloses a high-plasticity and easy-to-be-eliminated extrusion molding agent. The extrusion molding agent is prepared by the following raw materials, by weight: polyvinyl butyral 10-20%, butylcarbitol (diethylene glycol monobutyl ether) 60-70%, cocinic acid (yituomin) 1-5%, DBP (dibutyl phthalate) 1-5% and paraffin 10-15%. The extrusion molding agent provided in the invention provides a pressed shape with a fairly good strength and plasticity. With the extrusion molding agent provided in the invention, qualified rate of products is improved and production period of the extrusion products is shortened.

Owner:XIAMEN TUNGSTEN

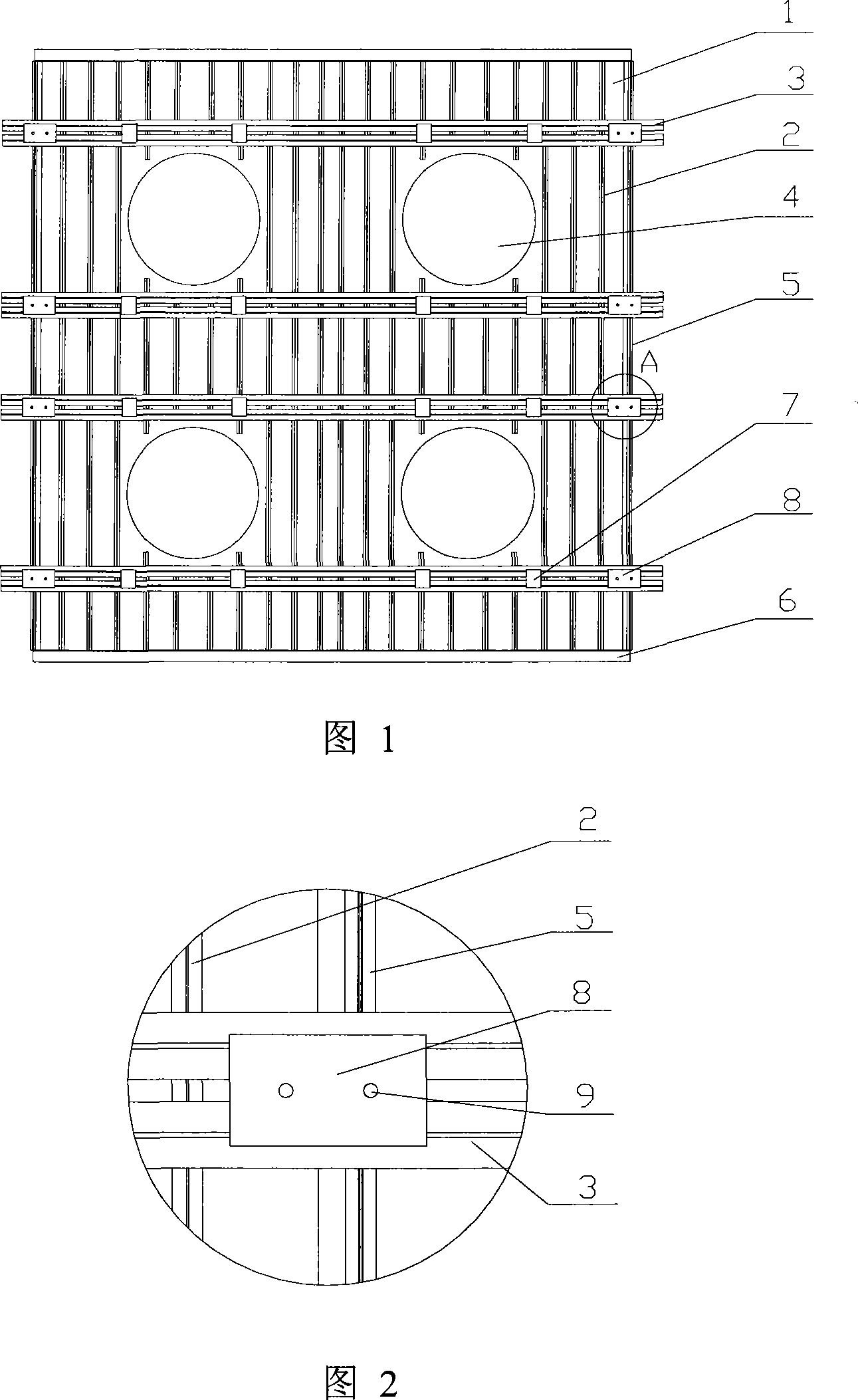

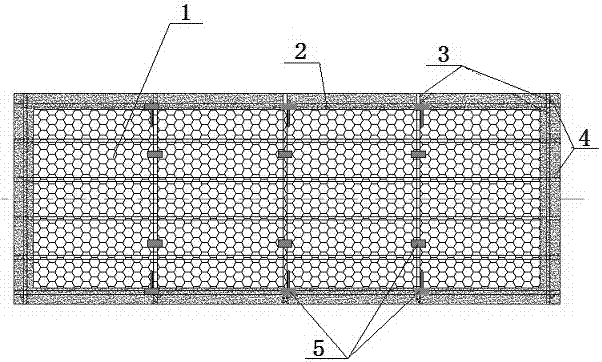

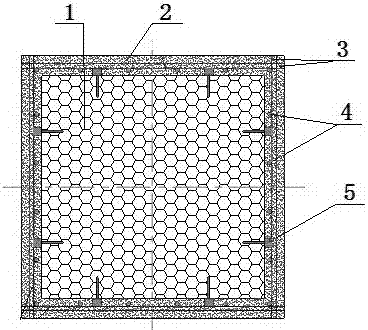

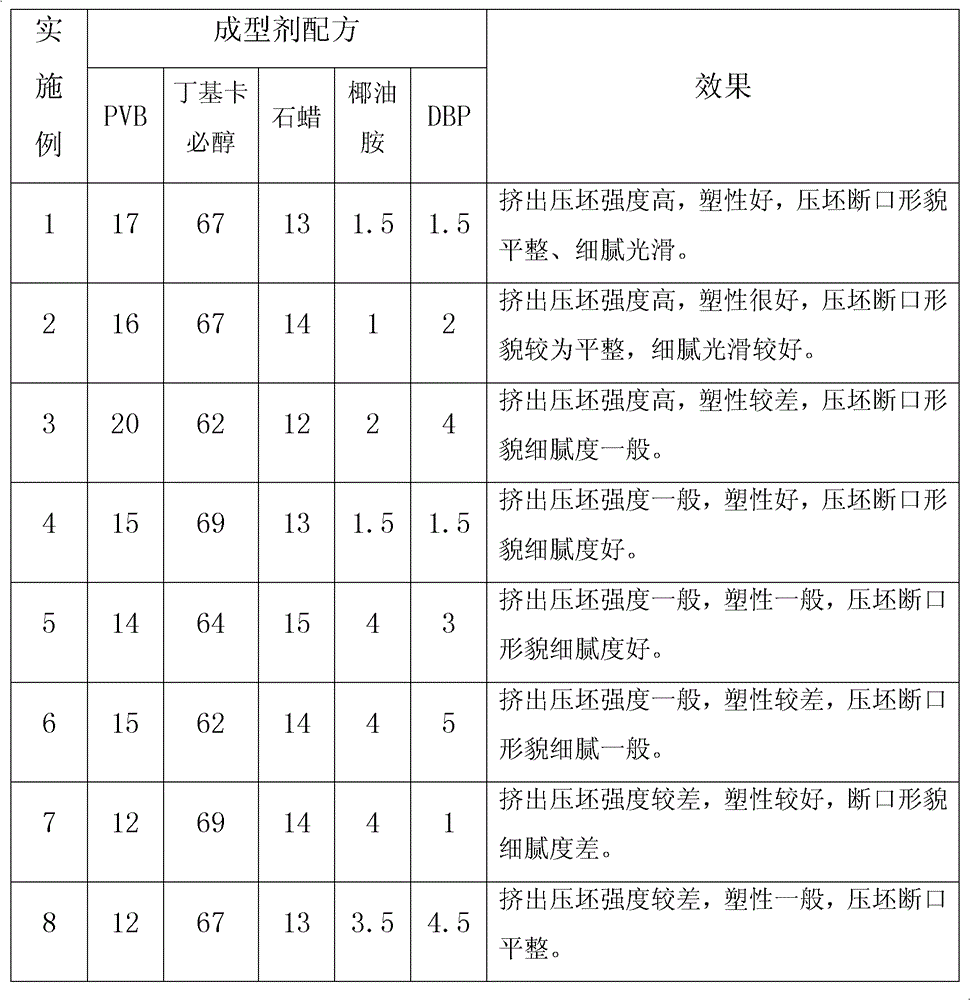

Composite floating body material structure

InactiveCN107018813ALow priceIncrease buoyancyAgriculture gas emission reductionCultivating equipmentsFoaming agentPolystyrene

The invention relates to a composite floating body material structure which comprises a polystyrene foam inner core (1). The composite floating body material structure is characterized in that inserting type cushion blocks (5) are distributed on the polystyrene foam inner core (1); transverse ribs (3) are arranged in positions corresponding to the cushion blocks (5); the transverse ribs (3) and longitudinal ribs (4) are uniformly distributed around the polystyrene foam inner core (1); the transverse ribs (3) and the longitudinal ribs (4) are connected together in a bundling mode; a polyurethane foamed protection layer (2) is arranged on the outer layer of the polystyrene foam inner core (1); the transverse rib (3) and the longitudinal ribs (4) are wrapped with the polyurethane foamed protection layer (2), therefore, a composite floating body material structure is formed. The transverse ribs (3) and the longitudinal ribs (4) are partitioned for certain distances by the polystyrene foam inner core (1). Reinforcing steel ribs are added to the surface of a polystyrene foam material, and a polyurethane foaming agent is injected, so that the strength, the toughness and the buoyancy are improved.

Owner:杨承峰

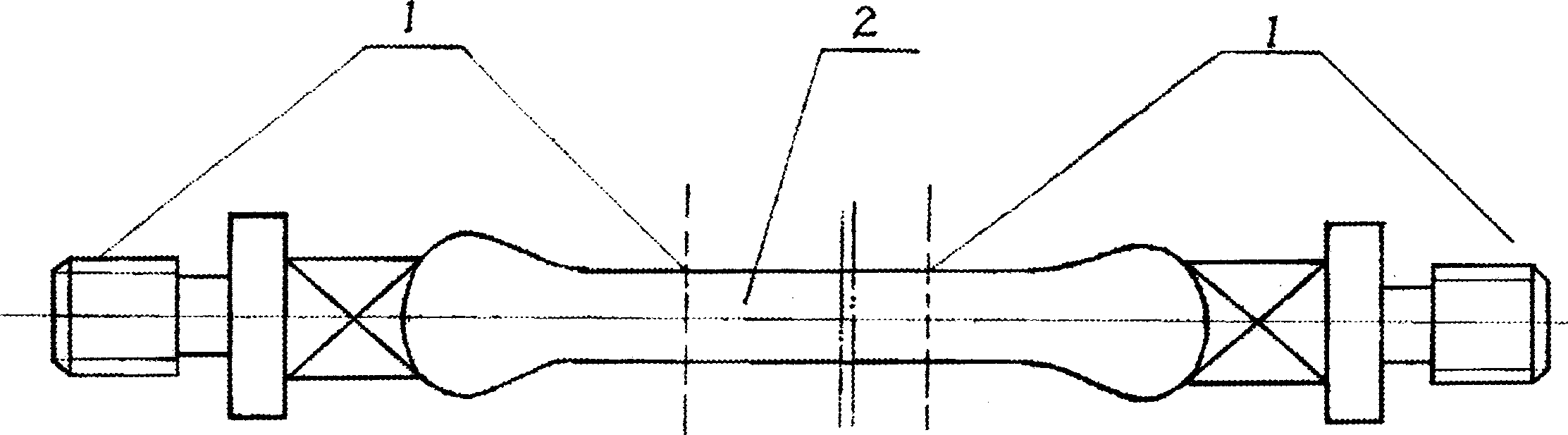

Twisting adjusting device for rope twisting machine and adjusting method of twisting adjusting device

InactiveCN111021119AIncrease the closeness of contactHigh tensile strengthRope making machinesWinding machineCircular disc

The invention discloses a twisting adjusting device for a rope twisting machine and an adjusting method of the twisting adjusting device. The device comprises a center line rope winding barrel, wherein a center line winds around the center line rope winding barrel, one side of the center line rope winding barrel is connected with a rope winding machine through a plurality of twisting machines, anadjusting mechanism is arranged on one side of each twisting machine, a circular ring is arranged on one side of each adjusting mechanism, each adjusting mechanism comprises a disc, a first center line through hole is formed in the middle of the disc, a plurality of rope twisting openings are uniformly formed in the disc, cavities are formed in two sides of each rope twisting opening, a notch is formed between each cavity and the corresponding rope twisting opening, a first pulley is arranged in each rope twisting opening, and a first middle rod penetrates through the middle of each pulley andpenetrates through the corresponding notch. The device has the beneficial effects as follows: the closeness degree of contact between twisted lines and the center line can be increased by means of the adjusting mechanisms, the tensile strength of steel wire ropes can be further improved, and the design strength of the steel wire ropes can be guaranteed.

Owner:嘉善精田精密机械股份有限公司

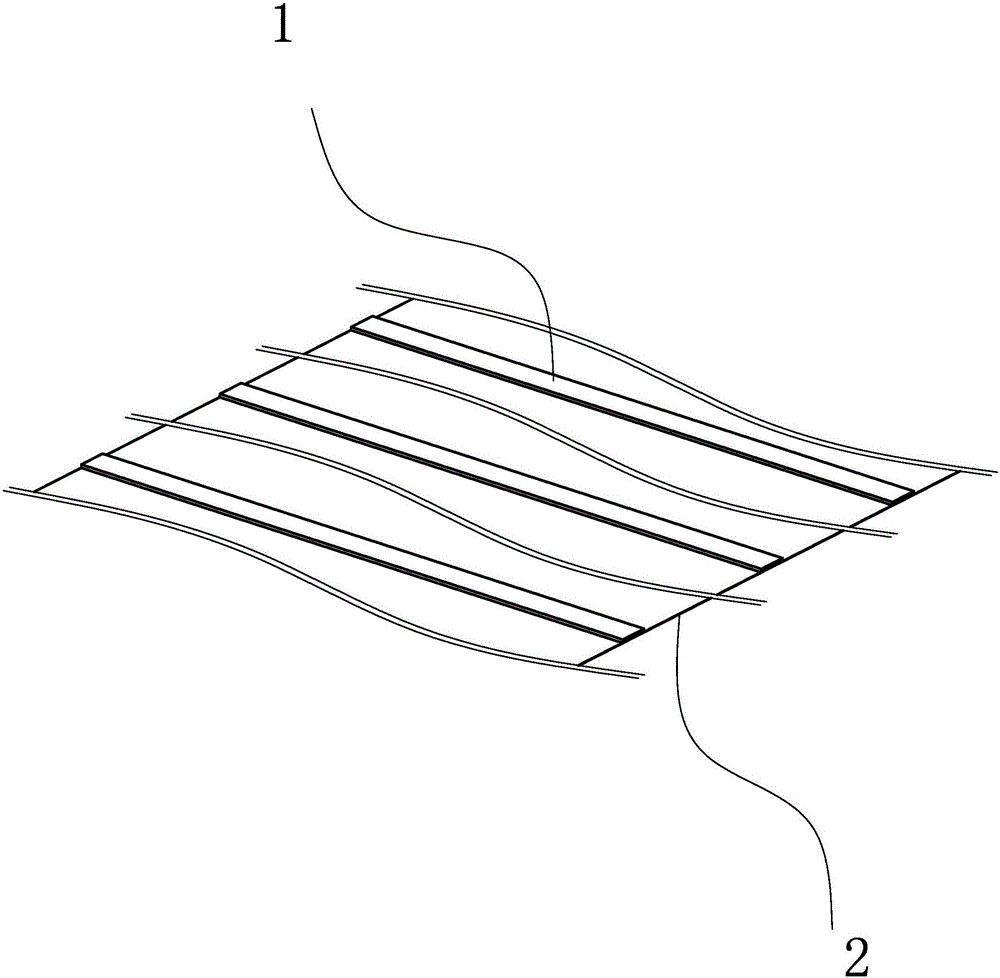

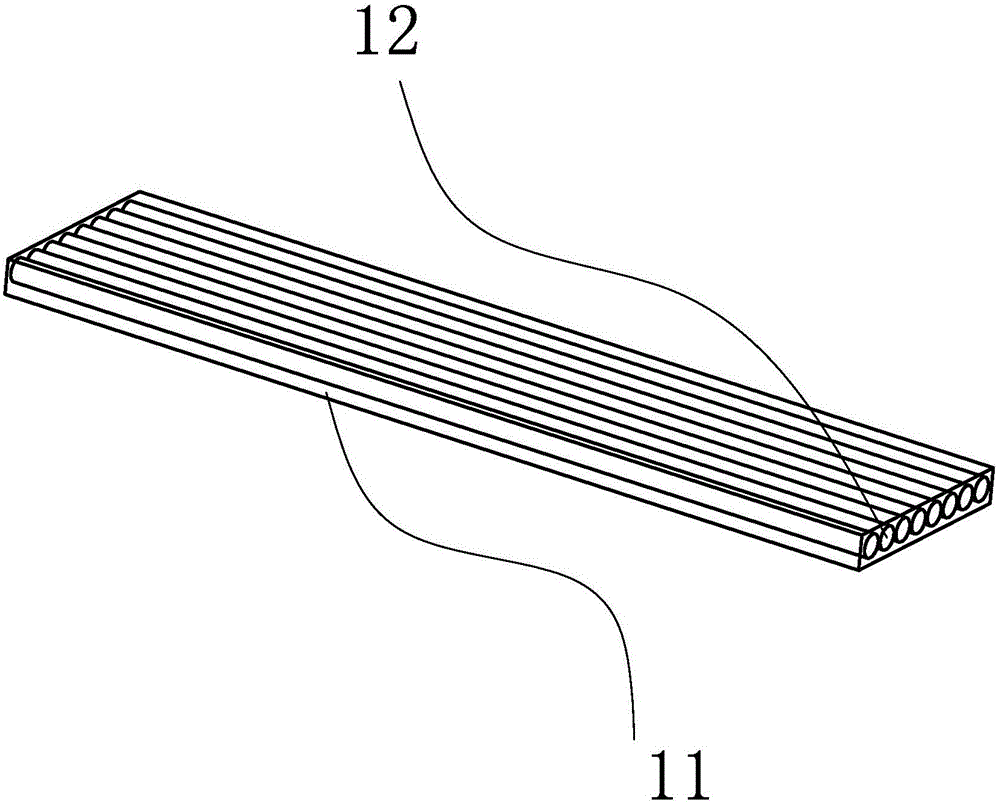

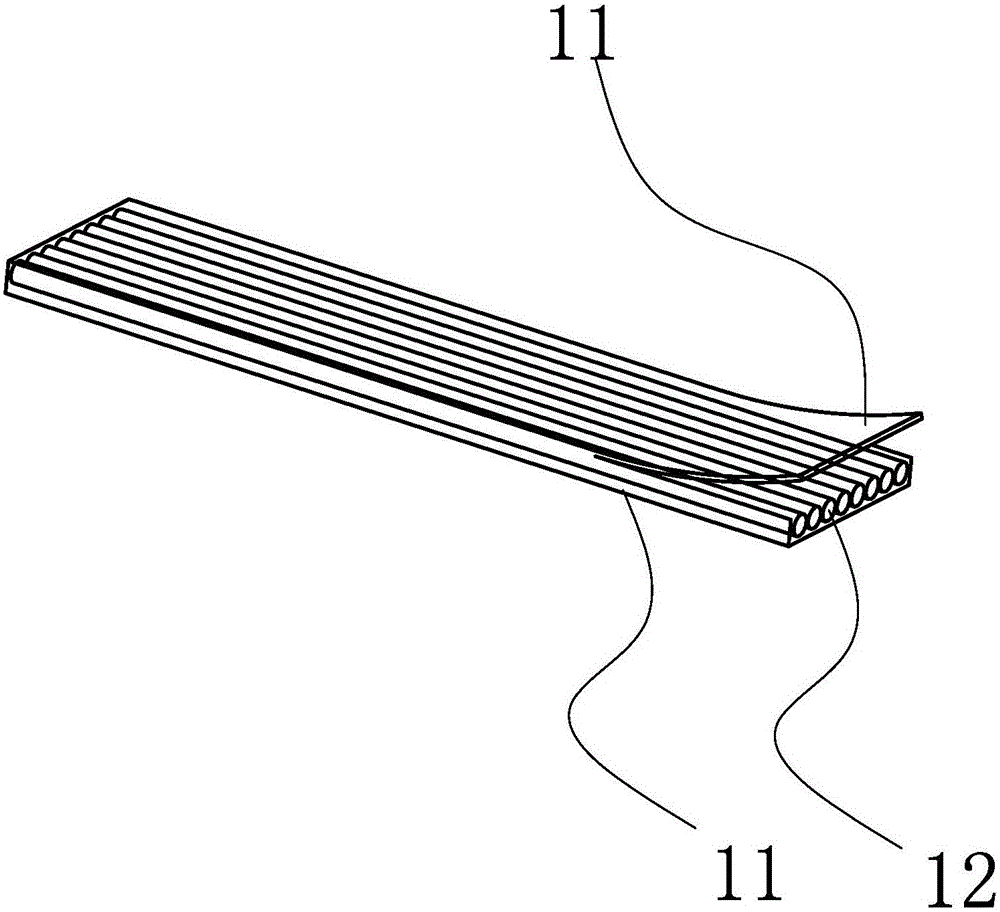

Manufacturing method of greenhouse thin film

ActiveCN106142535AHigh tensile strengthStrength reachedClimate change adaptationLaminationGreenhouseEngineering

The invention relates to a manufacturing method of a greenhouse thin film, belongs to the technical field of agricultural materials, aims to solve the problem that an existing greenhouse thin film is poor in pulling resistance, and provides the manufacturing method of the greenhouse thin film. The method comprises the following steps: enabling a plurality of plastic film pressing belts and plastic thin films to synchronously move towards different procedures under the effect of a traction force, wherein the plastic film pressing belts are parallel to one another, and the plastic film pressing belts are flat; enabling each plastic film pressing belt and the corresponding plastic thin film to be subjected to thermal combination treatment by a thermal combination procedure; enabling the heating temperature of a side of each plastic film pressing belt to be 220-240 DEG C; enabling the heating temperature of a side of each plastic thin film to be 160-190 DEG C; and cooling every plastic film pressing belt and the corresponding plastic thin film after every plastic film pressing belt and the corresponding plastic thin film are subjected to thermal combination integrally so as to obtain the corresponding greenhouse thin film. The binding fastness of every plastic film pressing belt and the corresponding plastic thin film is improved integrally, and therefore, the pulling resistance is improved.

Owner:BOEN SOLAR TECH

Environment-friendly Chinese-character-'ri'-shaped composite flat plate

InactiveCN103213331AImprove protectionStrength reachedSynthetic resin layered productsPaper/cardboard layered productsCardboardChinese characters

The invention discloses an environment-friendly Chinese-character-'ri'-shaped composite flat plate. The composite flat plate comprises a face plate, a bottom plate and a center layer arranged between the face plate and the bottom plate, wherein the face plate and the bottom plate are respectively adhered to the center layer through glue, the center layer is of a honeycombed paper core and comprises a frame which is arranged at the periphery of the honeycombed paper core and is glued to the periphery of the honeycombed paper core, the periphery of the frame is square, a reinforcing strip which connects two opposite sides of the frame is arranged in the frame, and the thickness of the frame and the thickness of the reinforcing strip are equal to that of the honeycombed paper core; and each of the face and bottom plates comprises at least one layer of paper board or paper skin. According to the environment-friendly Chinese-character-'ri'-shaped composite flat plate, the center layer is of the honeycombed paper core, the face plate and the bottom plate are paper boards or paper skins, and sources of raw materials of the center layer, the face plate and the bottom plate are paper products, so that the weight is light, the cost is low, and timber is not directly used so as to benefit for the protection on forest resources; and the strength of the composite flat plate reaches and is even higher than that of a timber composite plate.

Owner:GUANGXI JIN HONG GREEN PACKAGING TECH

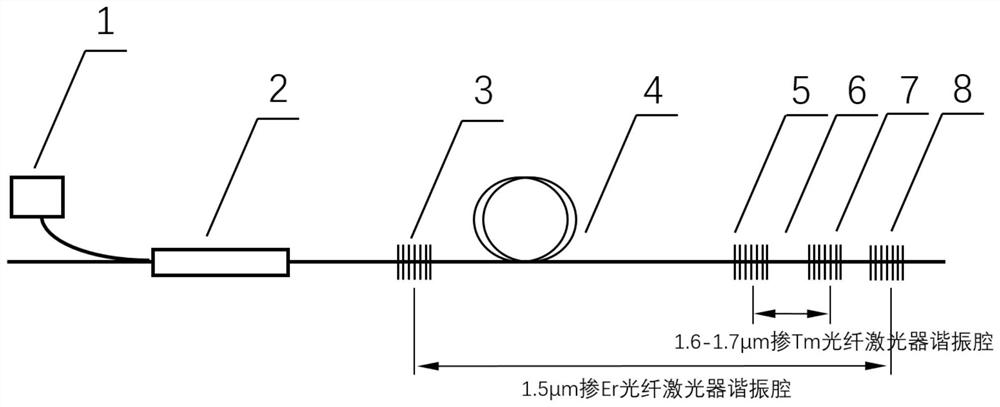

Short-wavelength Tm-doped fiber laser with wave band of 1.6-1.7 microns

ActiveCN112886375AHigh strengthStrength reachedOptical resonator shape and constructionActive medium shape and constructionResonant cavityErbium lasers

The invention discloses a short-wavelength Tm-doped fiber laser with a wave band of 1.6-1.7 microns. The laser is characterized in that a pumping source emits pumping light in an Er-doped active fiber absorption band, and the Er-doped active fiber absorbs the pumping light; when the laser gain exceeds the loss of an Er-doped fiber laser resonant cavity formed by a first Er-doped fiber laser fiber grating and a second Er-doped fiber laser fiber grating which highly reflect a certain wavelength in the L-band, L-band laser near 1570nm is formed to oscillate in the resonant cavity; the Tm-doped active optical fiber absorbs 1570-nm laser and generates laser gain, short-wavelength laser with the wave band of 1.6-1.7 microns is formed under the action of a Tm-doped optical fiber laser resonant cavity formed by the Tm-doped optical fiber laser high-reflection optical fiber grating and the Tm-doped optical fiber laser output optical fiber grating, oscillates in the resonant cavity and is output through the Tm-doped optical fiber laser output optical fiber grating; and the Tm-doped active optical fiber is arranged in a resonant cavity of the Er-doped optical fiber laser.

Owner:TIANJIN UNIV

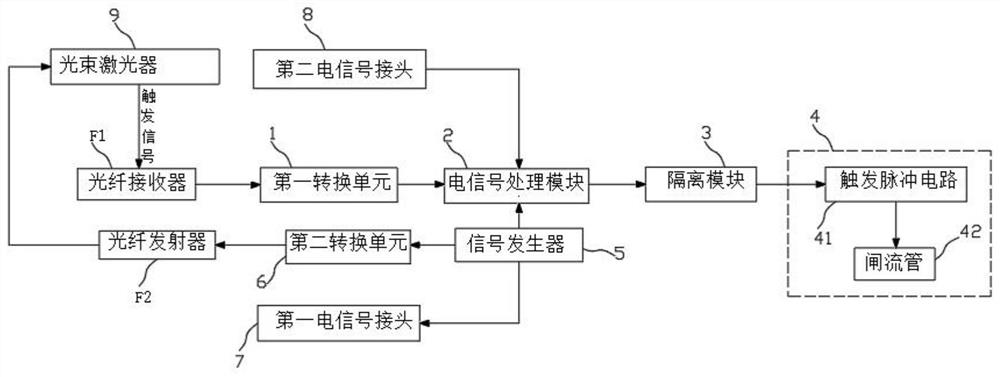

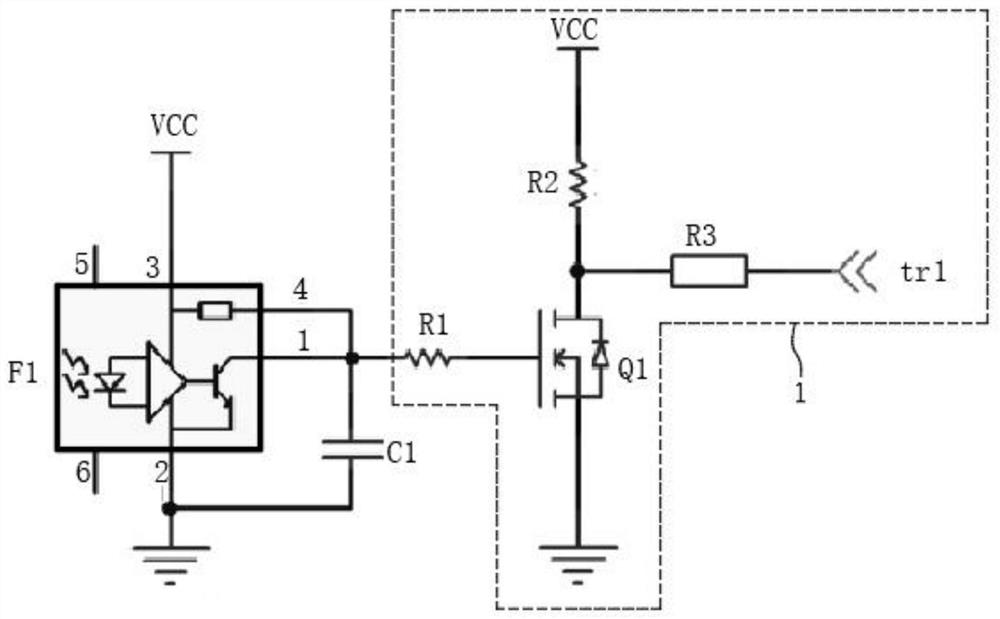

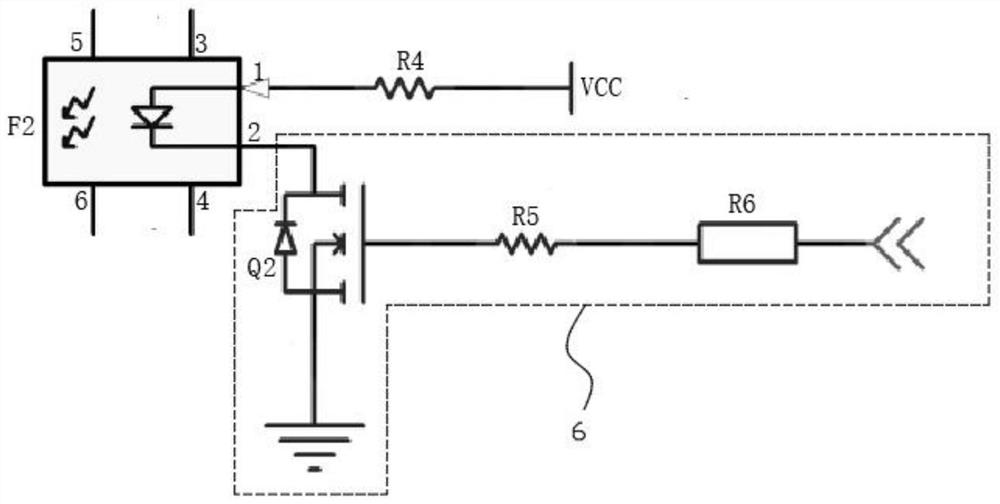

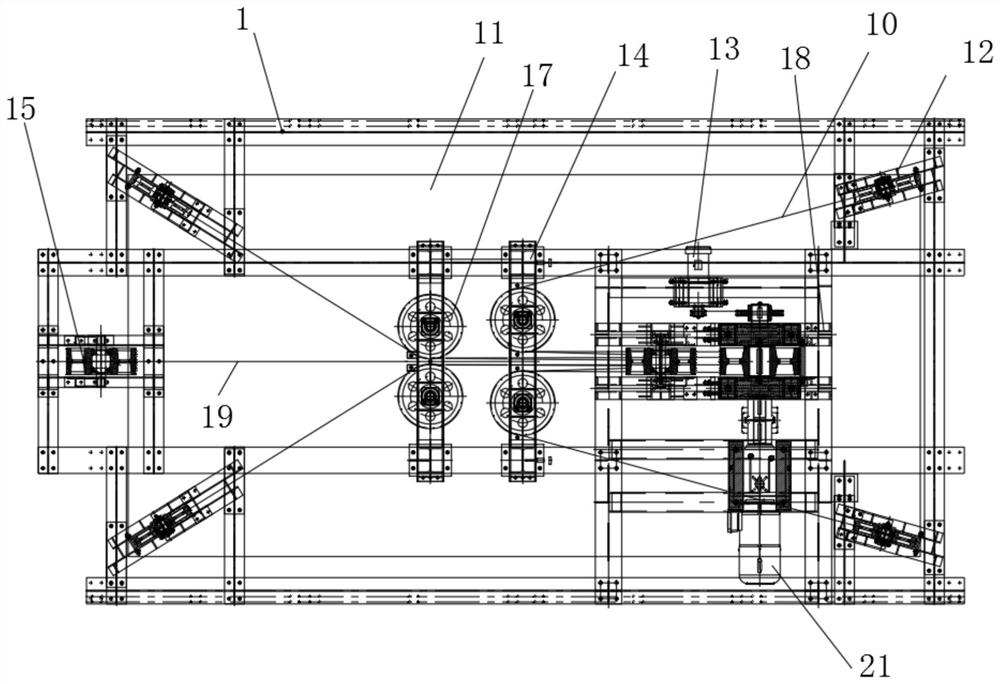

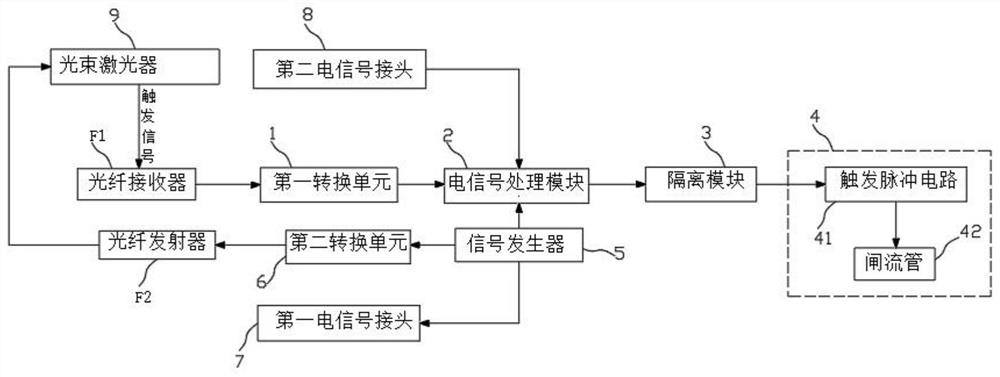

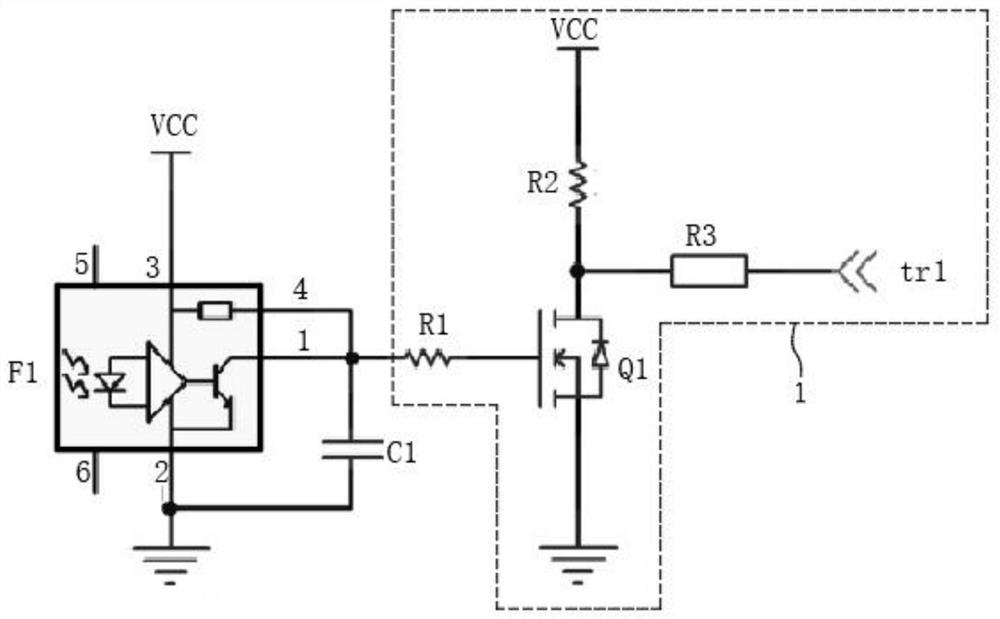

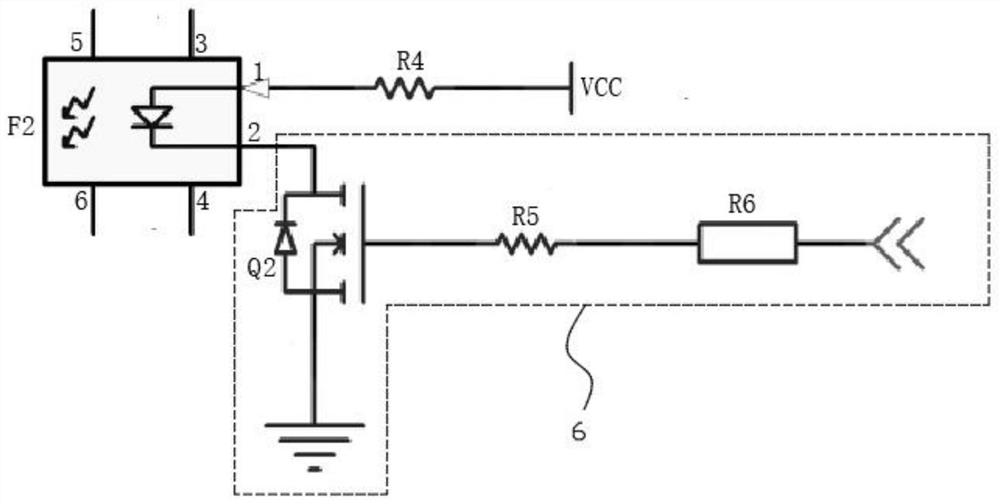

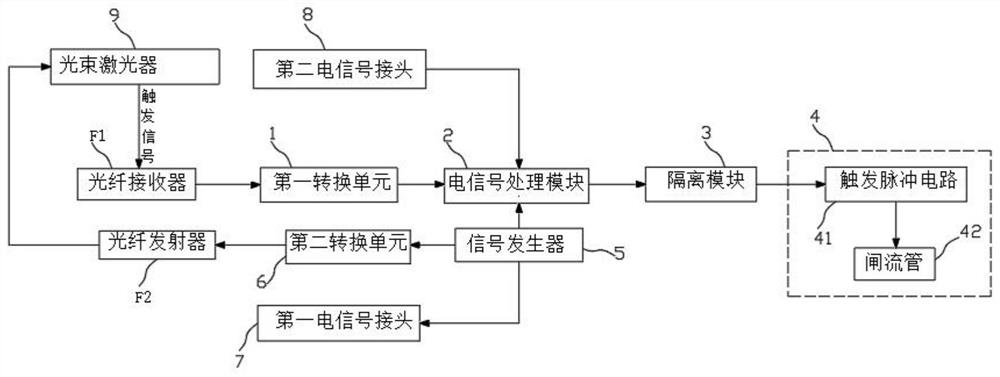

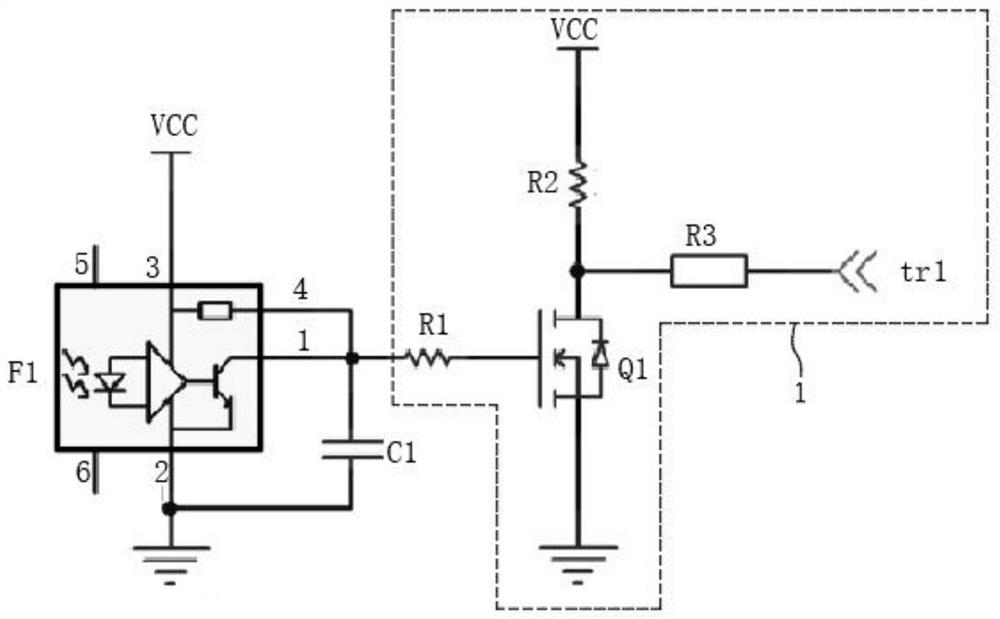

Circuit for triggering excimer laser to generate plasma

ActiveCN112787209ATime synchronizationDischarge synchronizationLaser detailsCapacitanceVoltage pulse

The invention relates to the field of excimer lasers, in particular to a circuit for triggering an excimer laser to generate plasma. The circuit comprises a device for triggering the excimer laser and a pulse circuit for driving the excimer laser. The device for triggering the excimer laser comprises a signal acquisition module and an electric signal processing module. The pulse circuit for driving the excimer laser comprises a trigger pulse circuit, and the trigger pulse circuit comprises a first power supply unit used for supplying power to the trigger end of the gas laser. The first power supply unit comprises a tenth capacitor and a charging power supply used for charging the tenth capacitor. Therefore, the time that the seed light reaches the excimer laser can be ensured to be synchronous with the discharge of the excimer laser. Therefore, under the mutual matching action of the transistor and the tenth capacitor, a high-voltage pulse signal with a fast front edge and low jitter can be generated and sent to the excimer laser, so that the working performance of the excimer laser is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

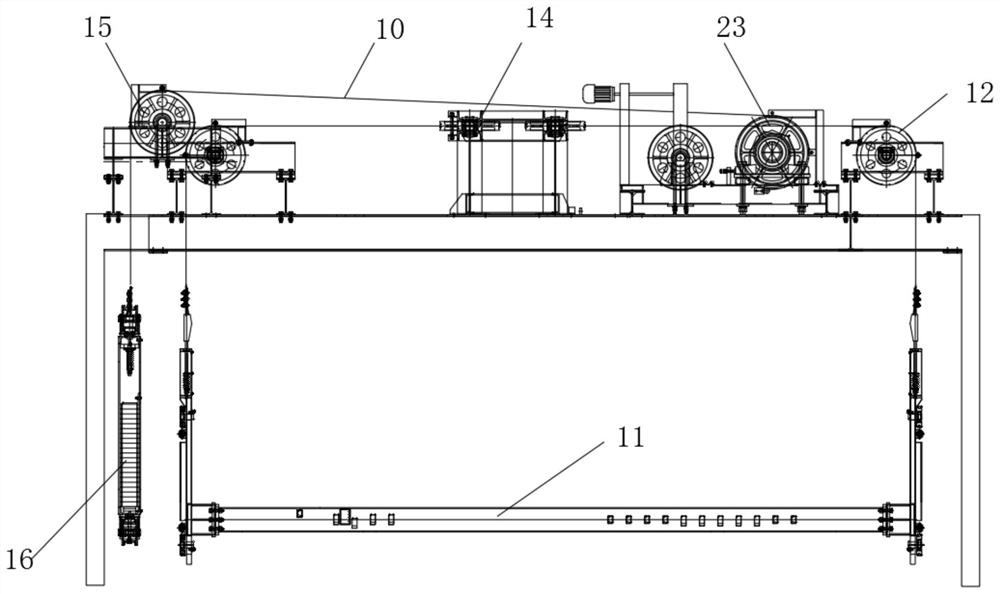

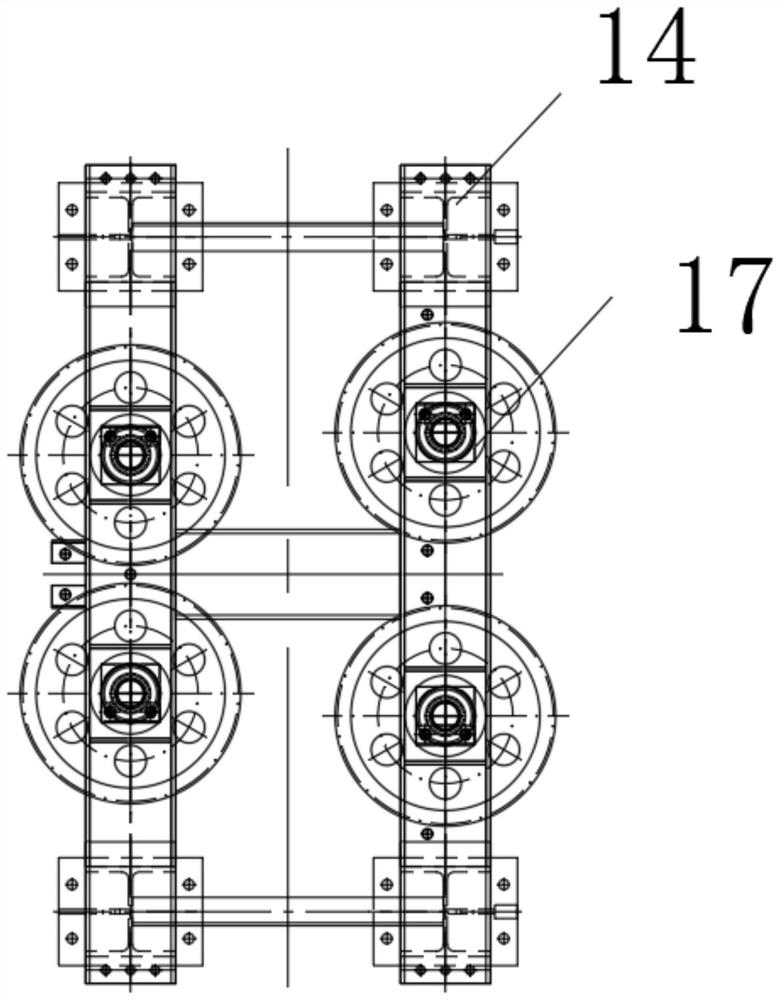

Improved traction lifting system for intelligent parking garage

The invention relates to the field of stereo garages, and particularly discloses an improved traction lifting system for an intelligent parking garage. The improved traction lifting system comprises a support, wherein first pulleys are rotatably connected to the four corners of the top of the support correspondingly, steel wire ropes are slidably connected to the first pulleys, and a lift car is fixedly connected to the steel wire ropes; one ends of the four steel wire ropes are fixedly connected to the four corners of the lift car correspondingly, the ends, away from the lift car, of the steel wire ropes are fixedly connected with a traction assembly arranged on the support, and four I-shaped rotating wheels are rotatably connected to the four steel wire ropes; and the rotating wheels are rotatably connected with a fixing frame fixedly connected to the center of the top of the support. According to the improved traction lifting system for the intelligent parking garage, the defect that the service life of a transmission traction steel wire rope is short is effectively overcome, the transmission efficiency of the steel wire ropes is optimized, meanwhile, noise generated during operation of the improved traction lifting system is reduced, and thus a traction transmission system is safer, more stable, more efficient and longer in service life.

Owner:ANHUI HONGJIEWEIER PARKING EQUIP CO LTD

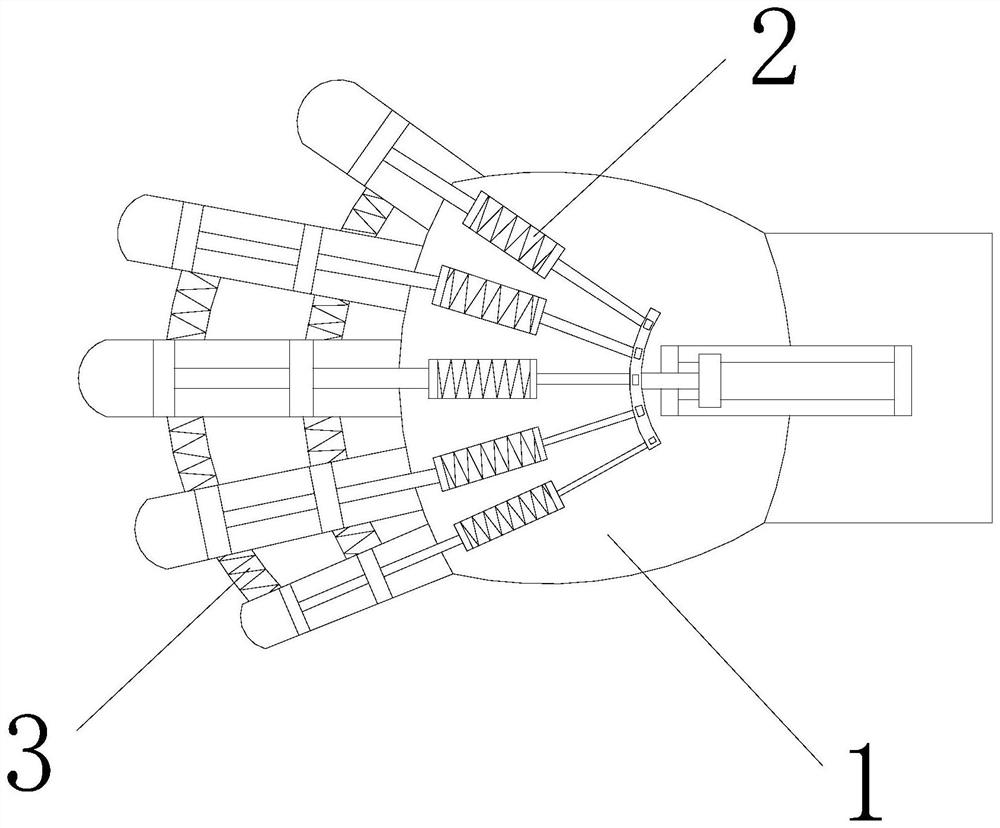

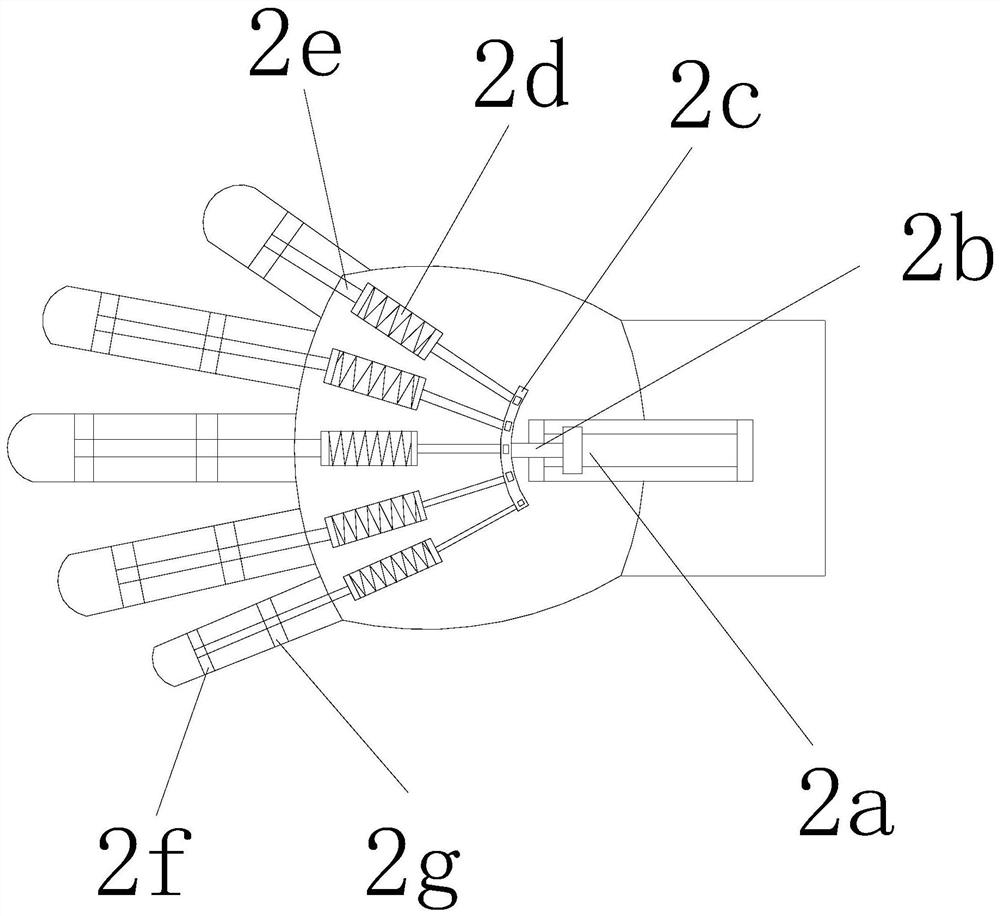

Finger separating plate for training joints

InactiveCN113509700AControl powerStrength reachedGymnastic exercisingClassical mechanicsStructural engineering

The invention discloses a finger separating plate for training joints. The finger separating plate structurally comprises a glove, a transverse training mechanism and a longitudinal training mechanism. A fixed clamping strip is clamped by a connecting buckle on a traction mechanism, so that the traction mechanism is connected with a second training rope, and the training of one or more hand joints is solved; and the length of a transverse training spring is adjusted through an adjusting handle, and the strength during training is controlled by matching a clamping block with a fixing block. The two ends of a longitudinal training spring are fixed through a U-shaped barb and a longitudinal limiting ring, and the position of the longitudinal training spring is limited through a limiting block, so that the problem of hand tension training is solved.

Owner:陈勇彪

Carbon-adding hard alloy material and preparation method thereof

ActiveCN101851718BImproved ability to withstand dry frictionReduce coefficient of frictionGasolineParaffin oils

The invention discloses a carbon-adding hard alloy material and a preparation method thereof. The alloy comprises the following raw materials in parts by weight: 89-91 parts of tungsten carbide, 3.7-4.7 parts of nickel, 0.35-0.45 part of chromium, 0.35-0.45 part of cobalt, 1.0-2.0 parts of paraffin, 2.0-5.0 parts of graphite and the balance aviation gasoline, wherein 0.2-0.35 liter of aviation gasoline is added in per kilogram of the above materials. The hard alloy of the invention has better dry friction property compared with the traditional hard alloy; and the hard alloy has lower production cost, also has good wear resistance, high strength and other properties of the traditional hard alloy, and has the advantages of simple preparation technology, easy operation and the like.

Owner:NINGBO VULCAN TECH CO LTD

Device for triggering excimer laser

ActiveCN112864786ATime synchronizationFacilitates intuitive discharge controlExcitation process/apparatusGas laser constructional detailsPhysical chemistryLight beam

The invention relates to the field of excimer lasers, in particular to a device for triggering an excimer laser. The device comprises the following components: a signal collection module is used for acquiring a trigger signal of a light beam laser which sends seed light to a gas laser; an electric signal processing module is used for receiving and processing the trigger signal, collected by the signal collection module, of the light beam laser, and inputting the processed trigger signal to the enabling end of the gas laser, so that the time when the seed light reaches the gas laser is synchronous with the discharge time of the gas laser; and the discharge time of the gas laser is controlled by the enabling end of the gas laser. Therefore, the time that the seed light reaches the excimer laser can be ensured to be synchronous with the discharge of the excimer laser, so that the excimer laser can be used as a laser amplifier.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A circuit for triggering an excimer laser to generate plasma

ActiveCN112787209BTime synchronizationDischarge synchronizationLaser detailsCapacitanceVoltage pulse

The invention relates to the field of excimer lasers, in particular to a circuit for triggering excimer lasers to generate plasma. It includes a device for triggering the excimer laser and a pulse circuit for driving the excimer laser; the device for triggering the excimer laser includes a signal acquisition module and an electrical signal processing module; the pulse circuit for driving the excimer laser includes a trigger pulse The circuit, the trigger pulse circuit includes a first power supply unit for supplying power to the trigger terminal of the gas laser; the first power supply unit includes a tenth capacitor, a charging power source for charging the tenth capacitor. Therefore, the present invention can ensure that the time when the seed light reaches the excimer laser is synchronized with the discharge of the excimer laser. Therefore, under the interaction of the transistor and the tenth capacitor, the present invention can generate a high-voltage pulse signal with fast leading edge and low jitter for the excimer laser, so as to ensure the working performance of the excimer laser.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Drilling hole sealing material

InactiveCN100535076CHigh strengthStrength reachedDrilling compositionSodium bicarbonateSodium Bentonite

Owner:CHINA UNIV OF MINING & TECH

High-plasticity and easy-to-be-eliminated extrusion molding agent

The invention discloses a high-plasticity and easy-to-be-eliminated extrusion molding agent. The extrusion molding agent is prepared by the following raw materials, by weight: polyvinyl butyral 10-20%, butylcarbitol (diethylene glycol monobutyl ether) 60-70%, cocinic acid (yituomin) 1-5%, DBP (dibutyl phthalate) 1-5% and paraffin 10-15%. The extrusion molding agent provided in the invention provides a pressed shape with a fairly good strength and plasticity. With the extrusion molding agent provided in the invention, qualified rate of products is improved and production period of the extrusion products is shortened.

Owner:XIAMEN TUNGSTEN

Environmentally friendly square composite flat panel

ActiveCN103231550BImprove protectionStrength reachedPaper/cardboard layered productsPaperboardHoneycomb

The invention discloses an environment-friendly rectangular composite plate comprising a surface plate, a bottom plate, and a central layer arranged between the surface plate and the bottom plate. The central layer is a honeycomb paper core. The surface plate and the bottom plate are respectively adhered with the central layer by using glue. The surface plate and the bottom plate both comprise at least one layer of paperboard or paper skin. The central layer also comprises a rectangular frame arranged on the periphery of the honeycomb paper core and glued with the honeycomb paper core. The thickness of the frame is same as that of the honeycomb paper core. According to the invention, the central layer is the honeycomb paper core, and the surface plate and the bottom plate are paper skin or paperboard. The three are all sourced from paper products, such that advantages of light weight and low cost are provided. Wood is not directly used, such that forest resource protection is promoted. The strength of the composite plate reaches that of a wood composite plate or even higher.

Owner:东莞市迅虹纸业有限公司

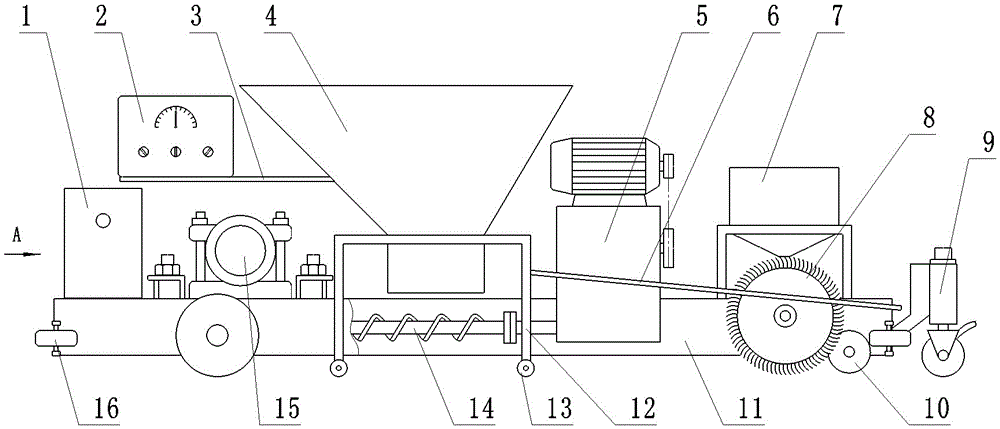

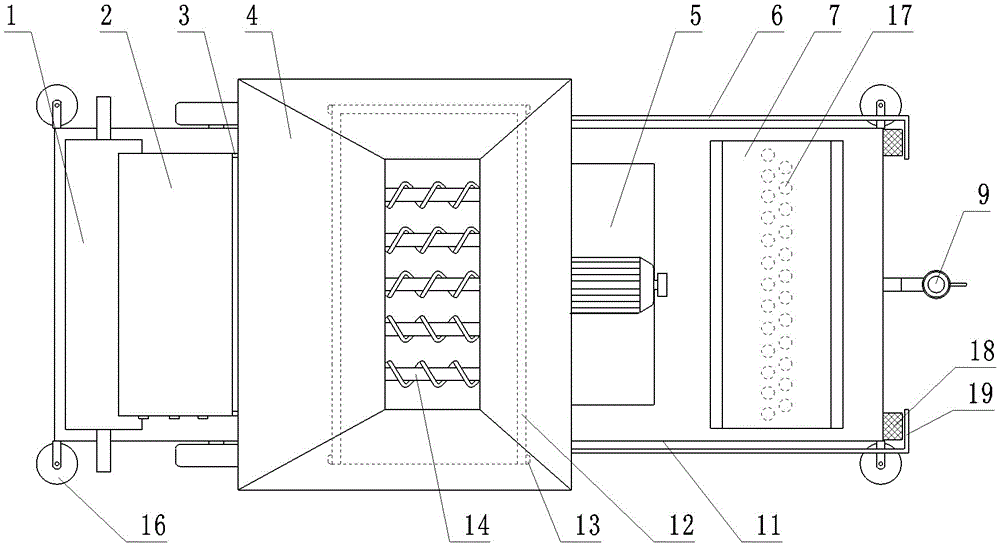

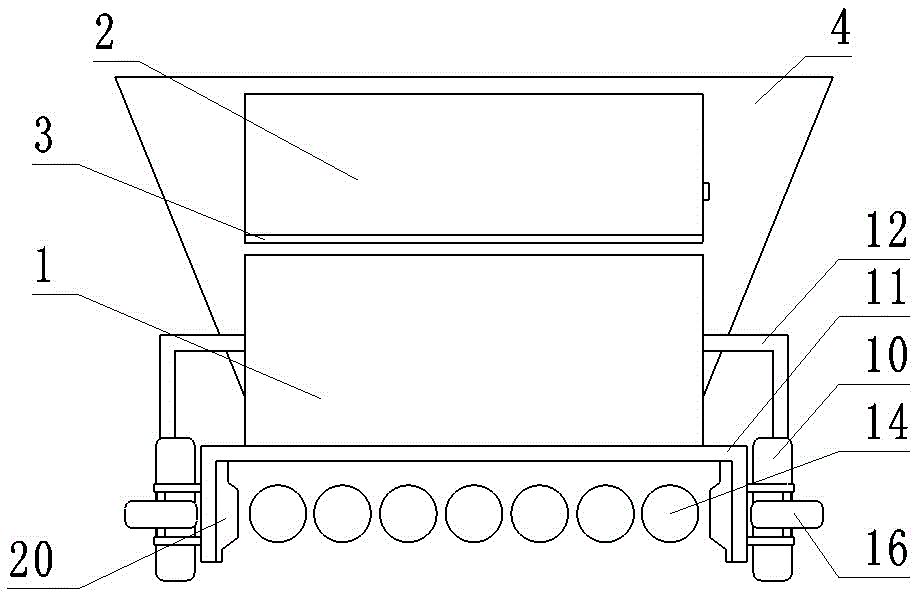

Lightweight partition wall block forming machine, partition wall block and connection method of the partition wall block

InactiveCN103802195BDoes not affect cuttingAvoid cloggingConstruction materialWallsBrickMolding machine

The invention discloses a lightweight partition wall block forming machine, a partition wall block and a connection method of the partition wall block. By separating the hopper from the unit, the vibration of the unit does not affect the feeding of the hopper when producing the partition wall block. , can prevent the material in the hopper from being vibrated and cause blockage, so it can be vibrated for a long time to produce thicker outer wall blocks, which are denser and stronger, and do not need to be placed inside the wall blocks The required strength can also be achieved by setting the steel bars. There are track positioning wheels on both sides of the front and rear ends of the frame, which can walk in the track. The partition wall blocks produced are straighter. There is a spacer box at the front end of the frame. The bottom of the release agent box is also provided with a brush roller, which can automatically smear the release agent on the ground when the partition wall block is produced to prevent the partition wall block from sticking to the ground. Compared with the prior art, the present invention not only It saves resources, saves time and labor, and can also be used as exterior wall bricks.

Owner:汤凯全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com