Single-arm steel hanging box and construction method thereof

A technology of steel hanging box and angle steel, which is applied in the direction of caisson, infrastructure engineering, construction, etc., can solve the problems of non-recyclable, large amount of pouring concrete for the bottom cover, waste, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

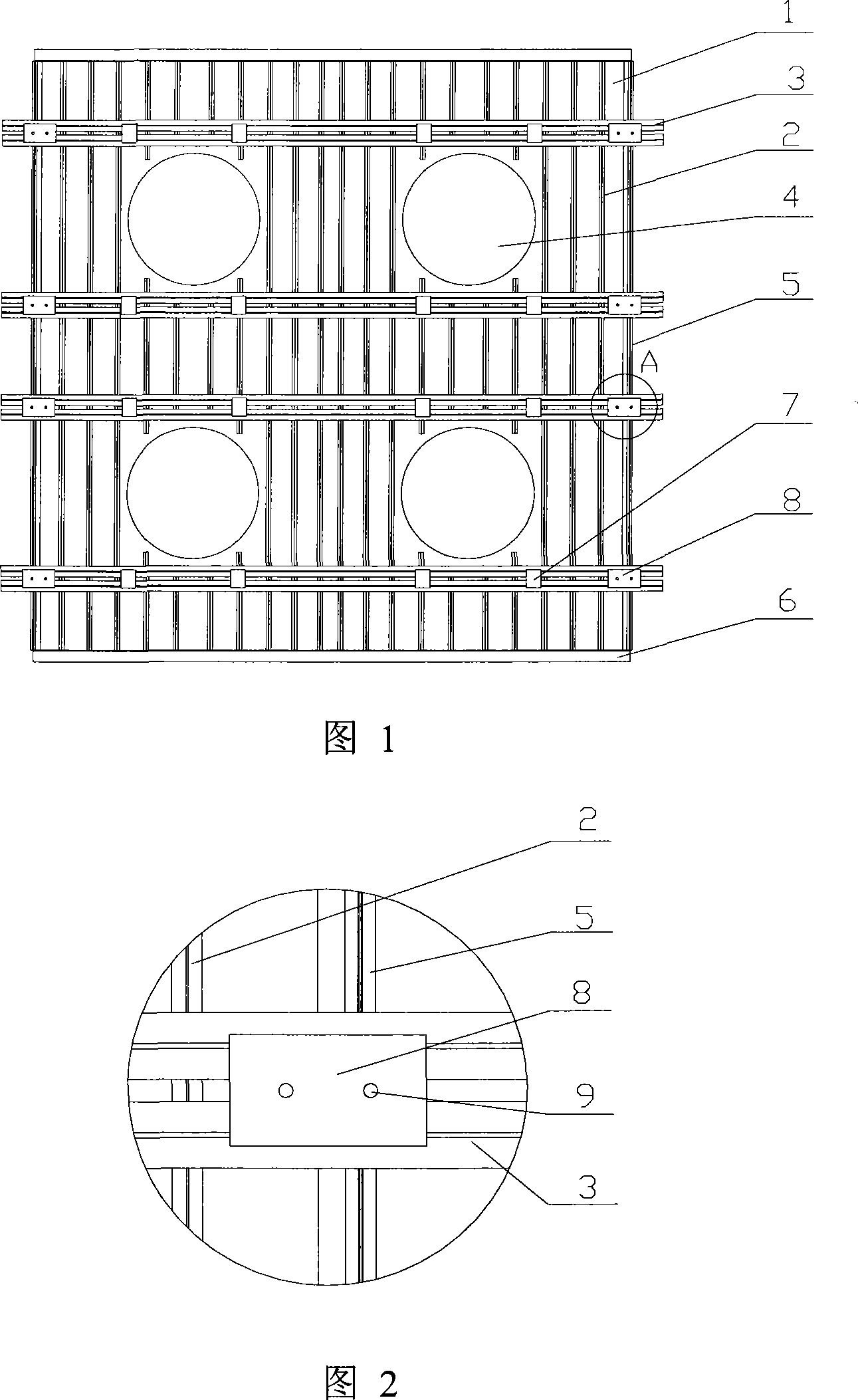

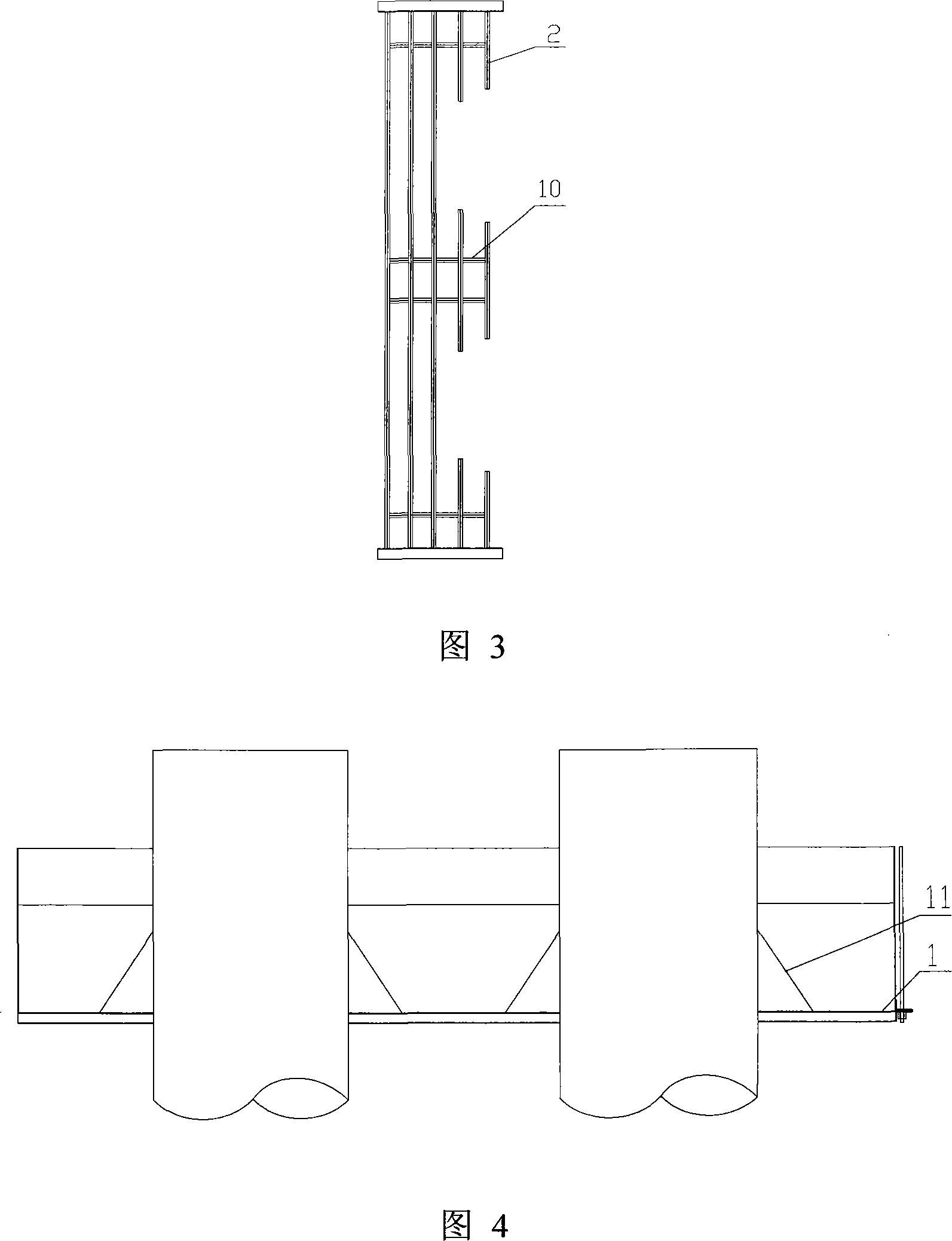

[0041] With reference to accompanying drawings 1, 2 and 3 of the description, the single-wall steel hanging box of the present invention mainly includes side plates and bottom plates, wherein the side plates are mainly composed of upper joints and lower joints. The bottom plate includes a panel 1, a longitudinal beam 2 and a crossbeam 3, wherein the panel 1 is laid on the longitudinal beam 2, and its side parallel to the longitudinal beam 2 is welded with an equilateral angle steel 5, which is used as the side of the boom, and it is connected to the side of the longitudinal beam 2. The following section is directly buckled, and the seal is sealed with a rubber plate. The other two sides of the panel 1 are welded with an angle steel flange 6, and the lower side of the angle steel flange through hole is welded with a nut correspondingly, and this side is connected with the lower panel by using an angle steel flange to clamp a rubber plate. The panel 1 is limited and fixed by usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com