Quick-setting and rapid-hardening road pavement repair concrete with super-early strength and preparation method thereof

A road surface repair and concrete technology, applied in the field of building materials, can solve the problems of high content of gelling components, high cost, shrinkage rate, and mechanical properties that cannot meet the ideal requirements, and achieve low cost, good mechanical properties, and reduced maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A quick-setting, fast-hardening and ultra-early-strength pavement patching concrete, which is composed of cementitious material, river sand, crushed stone, cement, initiator and accelerator;

[0047] According to the unilateral dosage kg / m 3 In standard terms, the dosage of each component is as follows: 320-350 cementitious material, 730-790 river sand, 920-960 crushed stone, 250-350 cement, 3-4 initiator, 1.5-2 accelerator.

[0048] Among them, the gelling material is 191C unsaturated polyester resin, the solid content is 63-69%, and the liquid viscosity is 400-600MPa·s. The unsaturated polyester resin used in the quick-setting, fast-hardening, super-early-strength pavement repair concrete of the present invention is formed by polycondensation of unsaturated dibasic acid diol or saturated dibasic acid unsaturated diol with ester bonds and A linear polymer compound with unsaturated double bonds is a thermosetting resin that can be cured at room temperature and molded und...

Embodiment 2

[0070] A quick-setting, fast-hardening, super-early-strength pavement repair concrete, other features are the same as in Example 1, the difference is that the following equipment is used, according to the unilateral dosage kg / m 3 According to the standard, the dosage of each component is as follows: cementitious material 330-350, river sand 730-760, gravel 920-960, cement 250-330, initiator 3.3-3.5, accelerator 1.7-1.8.

[0071] The cementitious material content of the fast-setting, fast-hardening, super-early-strength pavement repair concrete is 330-350 kg / m 3 , low cementitious material content, low cost, good mechanical properties and small shrinkage. By checking its performance, the 6-hour compressive strength is not less than 30MPa, the total shrinkage rate is 0.3-0.5‰, the 7d compressive strength is higher than 60MPa, and the 28d compressive strength is higher than 72.6MPa. The concrete of the present invention has low requirements on road maintenance conditions, and so...

Embodiment 3

[0073] A quick-setting, fast-hardening, super-early-strength pavement patching concrete, single square (m 3 ) Concrete components are as follows: 330kg of unsaturated polyester resin, 920kg of 5-10 crushed stone, 750kg of river sand, 300kg of cement, 3.3kg of initiator, and 1.7kg of accelerator.

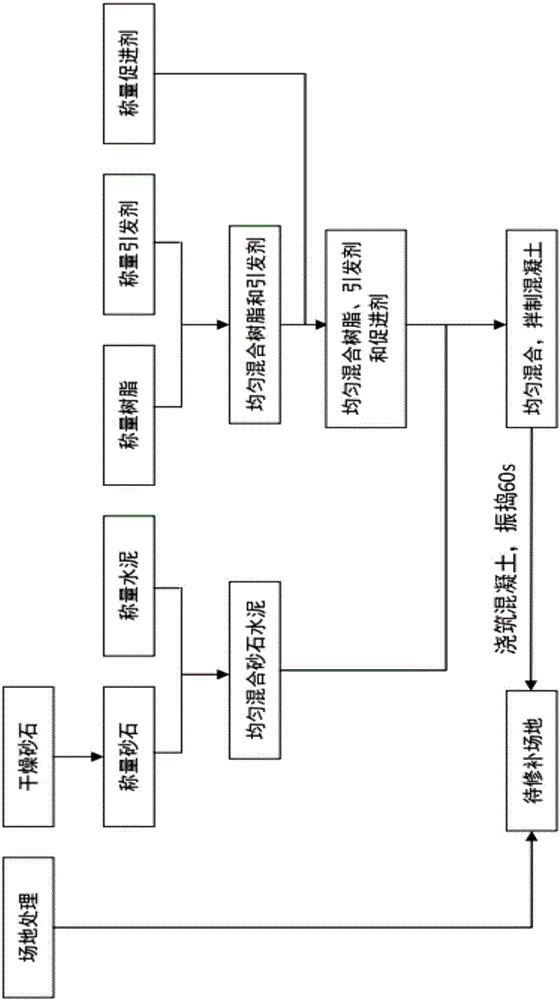

[0074] After the materials are ready, follow the steps below:

[0075] The first step: dry the gravel, sieve the gravel, and treat the road surface to be repaired at the same time;

[0076] Step 2: Mix concrete 100L (0.1m 3 ), calculate and weigh the mass of each component, unsaturated polyester resin 33kg, river sand 75kg, gravel 92kg, cement 30kg, initiator 300ml, accelerator 150ml.

[0077] The quality of each component of crushed stone is shown in Table 1:

[0078] Table 1

[0079] Particle size (mm) The mass of each component of single concrete crushed stone (㎏) 31.5-26.5 11.5 26.5-19 20 19-16 9.5 16-9.5 25 9.5-4.75 26

[0080] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com