Environment-friendly rectangular composite plate

An environmentally friendly, square-shaped technology, applied in chemical instruments and methods, paper/cardboard layered products, layered products, etc., can solve problems affecting service life, affecting use safety, weakening strength, etc., to prolong service life and avoid Potential safety hazards, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

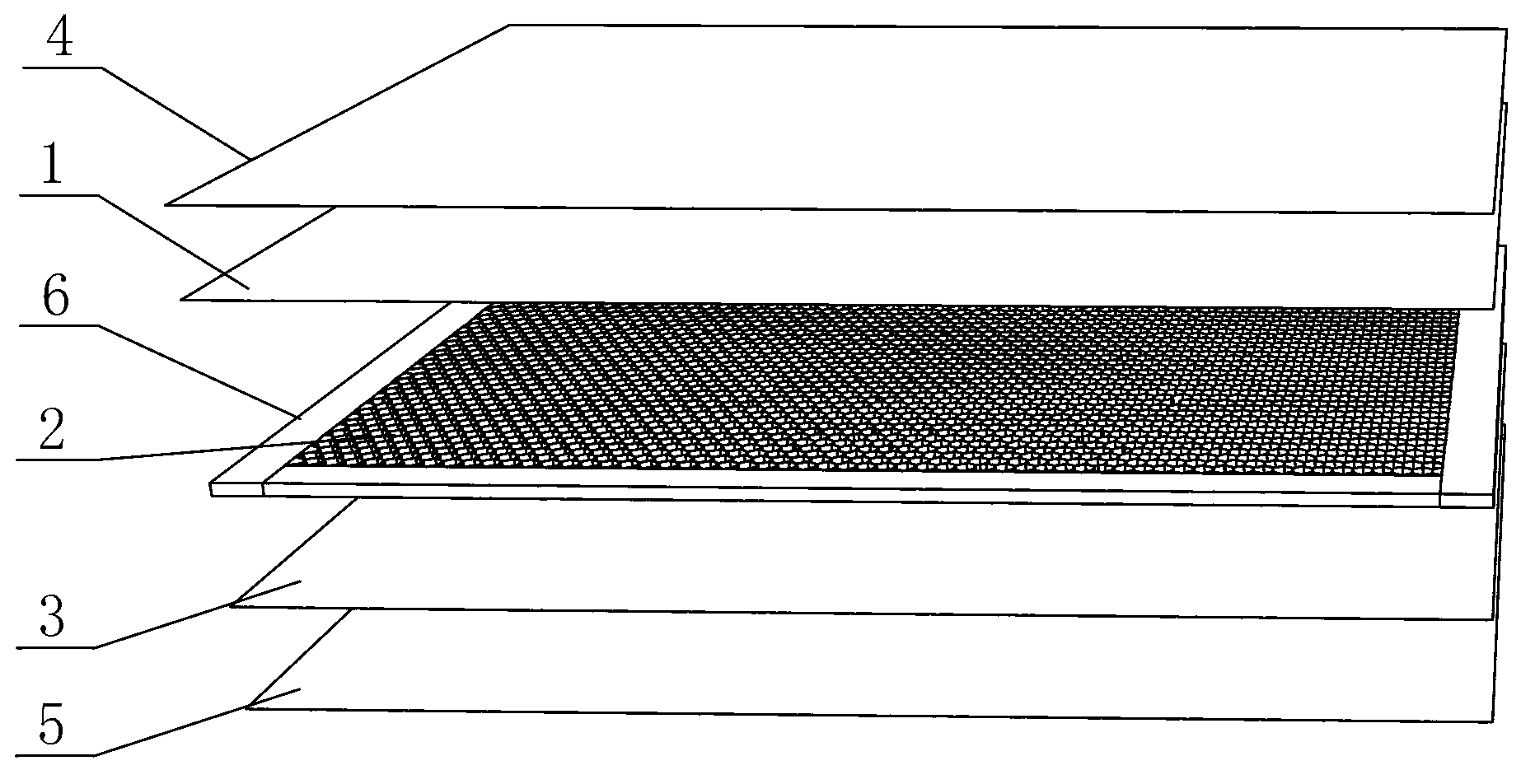

[0020] An environment-friendly square composite flat panel of the present invention, such as figure 1 Shown is a schematic diagram of its layered structure. In the solid figure, all layers are bonded. The environmentally friendly square composite flat panel includes a panel 1, a bottom panel 3 and a central layer 2 arranged between the panel 1 and the bottom panel 3. The central layer 2 is a honeycomb paper core, and the panel 1 and the bottom panel 3 are respectively glued to the central layer 2 by glue. Together, the panel 1 and the bottom plate 3 both include at least one layer of cardboard or paper skin, and the central layer 2 also includes a square frame 6 arranged around the periphery of the honeycomb paper core and glued to the periphery of the honeycomb paper core. The thickness of the frame 6 is the same as The thickness of the honeycomb paper core is equal. The face plate 1 and bottom plate 3 have the same shape and size as the central layer 2, and the entire compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com