Continuously hot-galvanized high-strength steel and production method thereof

A production method, hot-dip galvanizing technology, applied in the field of steel rolling, can solve problems such as poor plasticity, waste of energy and materials, and increase cumbersome procedures, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

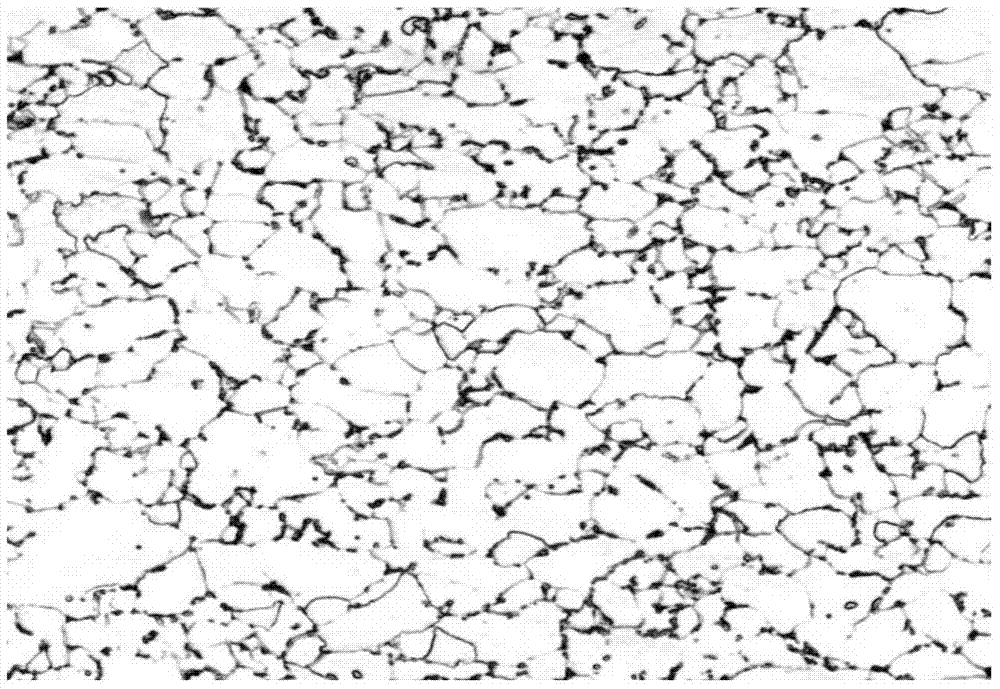

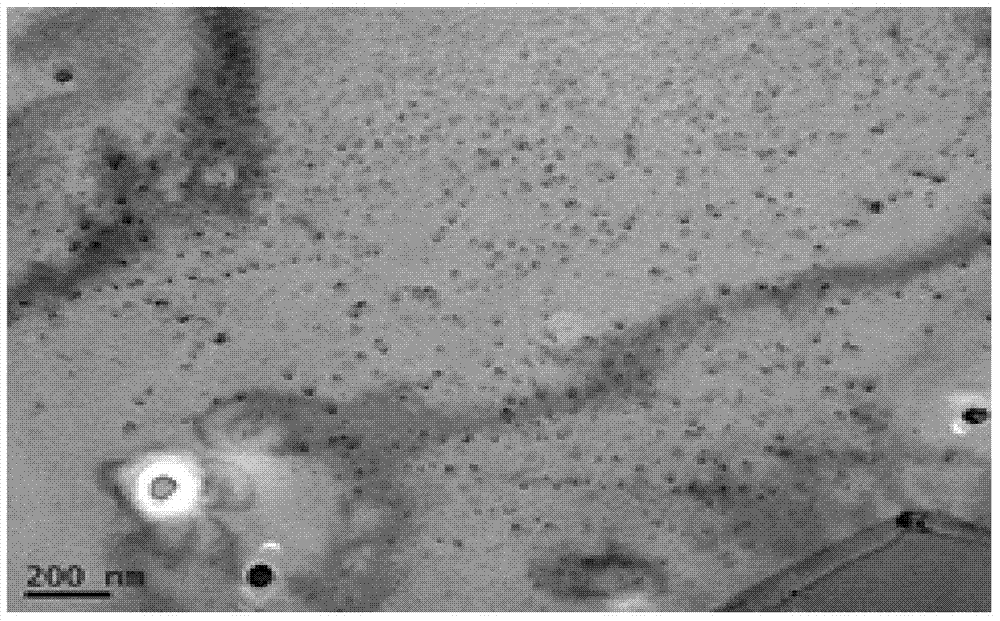

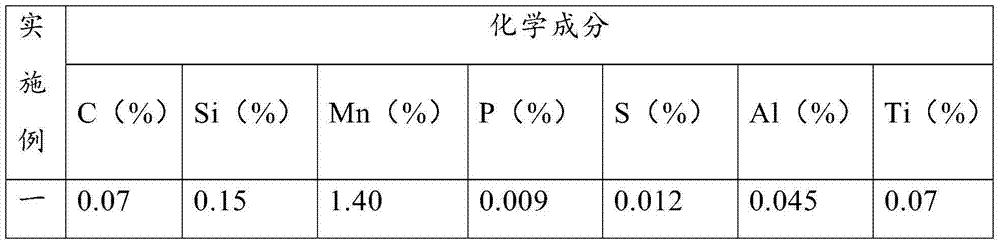

[0020] See Table 1, the chemical composition of steel by mass percentage is: C 0.07%, Mn 1.4%, Si 0.15%, P 0.009%, S 0.012%, Al 0.045%, Ti 0.07%, the balance is Fe and unavoidable impurities .

[0021] See Table 2. In the hot rolling process, the heating temperature is 1250°C, the finish rolling temperature is 850°C, and the coiling temperature is 640°C. In the cold rolling process, the cold rolling reduction is 55%, the annealing temperature is 780°C, and the skin elongation is 0.5%.

[0022] Referring to Table 3, the mechanical properties of the S550GD+Z steel produced by the production method of the hot-dip galvanized high-strength steel S550GD+Z provided by the embodiment of the present invention are as follows: the yield strength is 630MPa, the tensile strength is 760MPa, and the elongation is 16.0%. It has high plasticity and meets industrial requirements.

Embodiment 2

[0024] See Table 1, the chemical composition of steel by mass percentage is: C 0.12%, Mn 0.65%, Si 0.13%, P 0.009%, S 0.012%, Al 0.045%, Ti 0.10%, the balance is Fe and unavoidable impurities .

[0025] See Table 2. In the hot rolling process, the heating temperature is 1280°C, the finish rolling temperature is 840°C, and the coiling temperature is 680°C. In the cold rolling process, the cold rolling reduction is 65%, the annealing temperature is 780°C, and the skin elongation is 0.5%.

[0026] Referring to Table 3, the mechanical properties of the S550GD+Z steel produced by the production method of the hot-dip galvanized high-strength steel S550GD+Z provided by the embodiment of the present invention are as follows: the yield strength is 680MPa, the tensile strength is 790MPa, and the elongation is 15.5%. It has high plasticity and meets industrial requirements.

Embodiment 3

[0028] See Table 1, the chemical composition of steel by mass percentage is: C 0.08%, Mn 0.80%, Si 0.15%, P 0.009%, S 0.012%, Al 0.045%, Ti 0.05%, the balance is Fe and unavoidable impurities .

[0029] See Table 2. In the hot rolling process, the heating temperature is 1230°C, the final rolling temperature is 820°C, and the coiling temperature is 640°C. In the cold rolling process, the cold rolling reduction is 45%, the annealing temperature is 730°C, and the skin elongation is 0.5%.

[0030] Referring to Table 3, the mechanical properties of the S550GD+Z steel produced by the production method of the hot-dip galvanized high-strength steel S550GD+Z provided by the embodiment of the present invention are as follows: the yield strength is 570MPa, the tensile strength is 682MPa, and the elongation is 17.5%. It has high plasticity and meets industrial requirements.

[0031]

[0032]

[0033] Table 1

[0034]

[0035] Table 2

[0036]

[0037] table 3

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com