Harmless resourceful treatment method for barium slag and prepared building material

A treatment method and a resource-recycling technology are applied in the field of barium slag harmless and resource-recycling treatment methods and the field of prepared building materials, which can solve the problems of difficult operation of barium slag, inability to effectively connect harmless and resourceful, and the like. rate requirements, meet the sufficiency of material fluidity and contact, and reduce the effect of leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

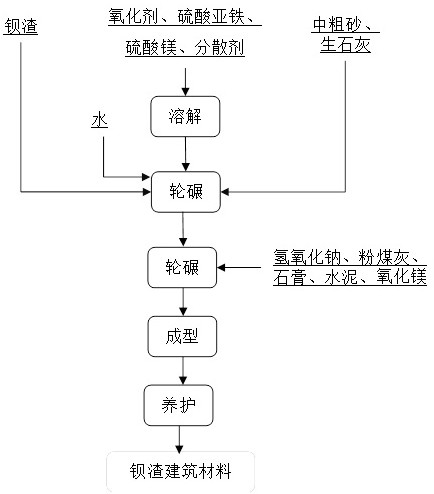

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for harmless and resourceful treatment of barium slag, comprising the following steps:

[0055] (1) Prepare sodium persulfate, ferrous sulfate, magnesium sulfate, and lignosulfonate in a mass ratio of 3:1:6:1 to form a stabilizer solution with a mass concentration of 10%;

[0056] (2) Add 80 kg of barium slag, 20 kg of medium coarse sand, and 15 kg of quicklime into the wheel mill, add 30 kg of the stabilizer solution prepared in step (1) into the wheel mill, and knead in the wheel mill for 20 minutes;

[0057] (3) Add 0.2kg of sodium hydroxide, 50kg of fly ash, 10kg of gypsum, 15kg of cement, and 5.4kg of magnesium oxide into the wheel mill, and continue mixing for 3 minutes;

[0058] (4) The mixture obtained in step (3) is vibrated and molded, and the barium slag building material can be obtained after moisturizing and curing for 28 days.

[0059] The strength performance test and barium ion leaching toxicity test were carried out on...

Embodiment 2

[0062] This embodiment provides a method for harmless and resourceful treatment of barium slag, comprising the following steps:

[0063] (1) Prepare sodium persulfate, ferrous sulfate, magnesium sulfate, and lignosulfonate in a mass ratio of 3:1:6:1 to form a stabilizer solution with a mass concentration of 15%;

[0064] (2) Add 80 kg of barium slag, 20 kg of medium coarse sand, and 15 kg of quicklime into the wheel mill, add 30 kg of the stabilizer solution prepared in step (1) into the wheel mill, and knead in the wheel mill for 20 minutes;

[0065] (3) Add 0.4kg of sodium hydroxide, 50kg of fly ash, 10kg of gypsum, 15kg of cement, and 8.1kg of magnesium oxide into the wheel mill, and continue mixing for 5 minutes;

[0066] (4) The mixture obtained in step (3) is vibrated and molded, and the barium slag building material can be obtained after moisturizing and curing for 28 days.

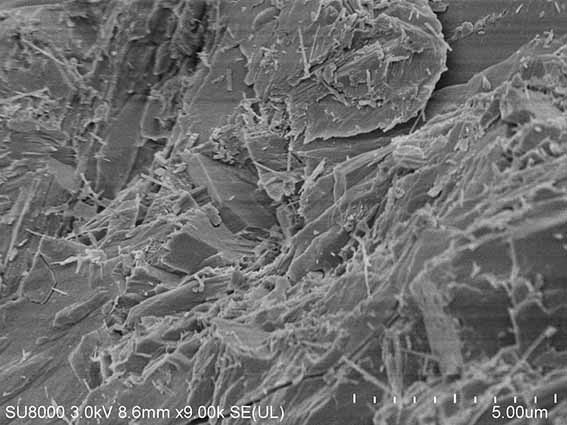

[0067] image 3 It is a microscopic schematic diagram of the barium slag building material pr...

Embodiment 3

[0070] This embodiment provides a method for harmless and resourceful treatment of barium slag, comprising the following steps:

[0071] (1) Prepare sodium persulfate, ferrous sulfate, magnesium sulfate, and lignosulfonate in a mass ratio of 3:1:6:1 to form a stabilizer solution with a mass concentration of 15%;

[0072] (2) Add 75 kg of barium slag, 25 kg of medium coarse sand, and 15 kg of quicklime into the wheel mill, add 25 kg of the stabilizer solution prepared in step (1) into the wheel mill, replenish 3.75 kg of water, and knead in the wheel mill 20 minutes;

[0073] (3) Add 0.4kg of sodium hydroxide, 50kg of fly ash, 10kg of gypsum, 15kg of cement, and 5.6kg of magnesium oxide into the wheel mill, and continue mixing for 5 minutes;

[0074] (4) The mixture obtained in step (3) is vibrated and molded, and the barium slag building material can be obtained after moisturizing and curing for 28 days.

[0075] With reference to the same test method as in Example 1, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com