Manufacturing method of greenhouse thin film

A production method and film technology, which are applied in chemical instruments and methods, botanical equipment and methods, greenhouse cultivation, etc., can solve the problems of not being able to drive plastic films at the same time, difficult to transport or pull, and increase the requirements for setting, so as to simplify production. Operation process, the effect of improving tensile strength and high composite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

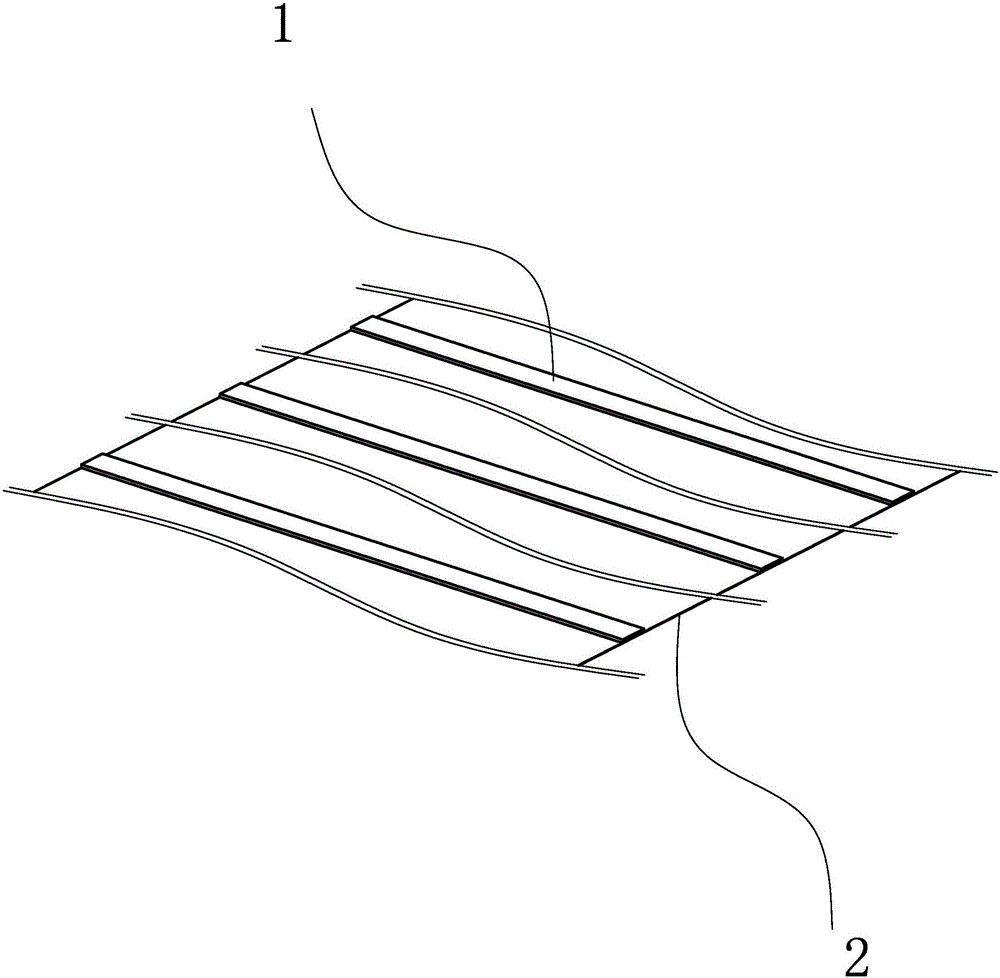

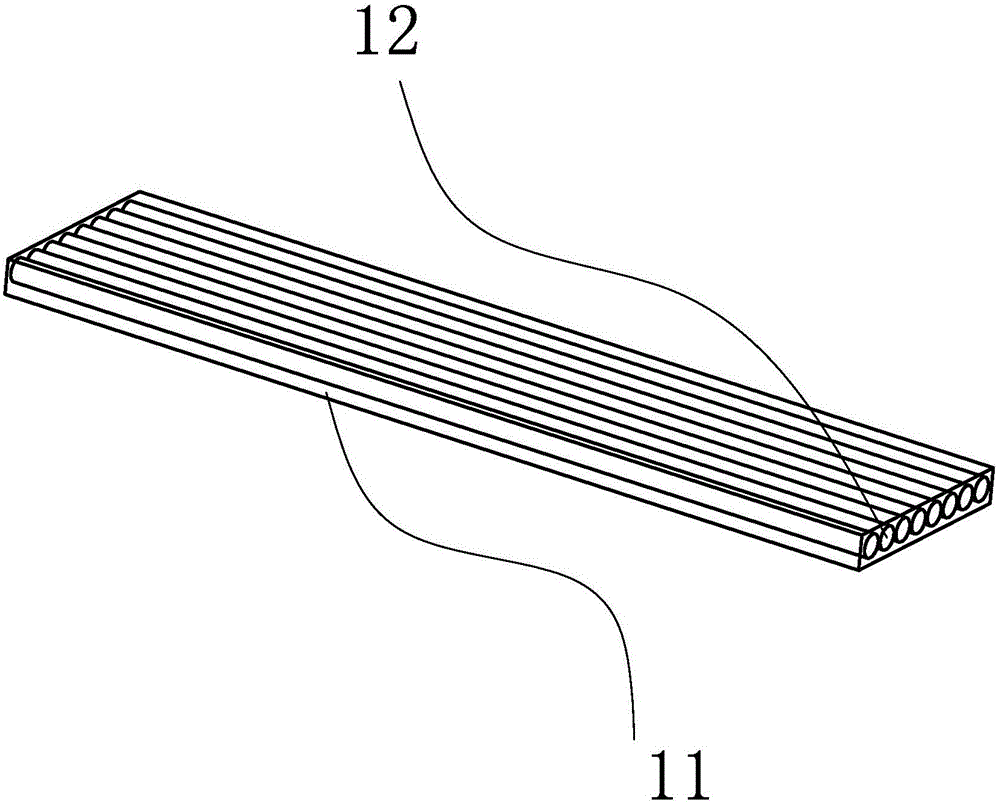

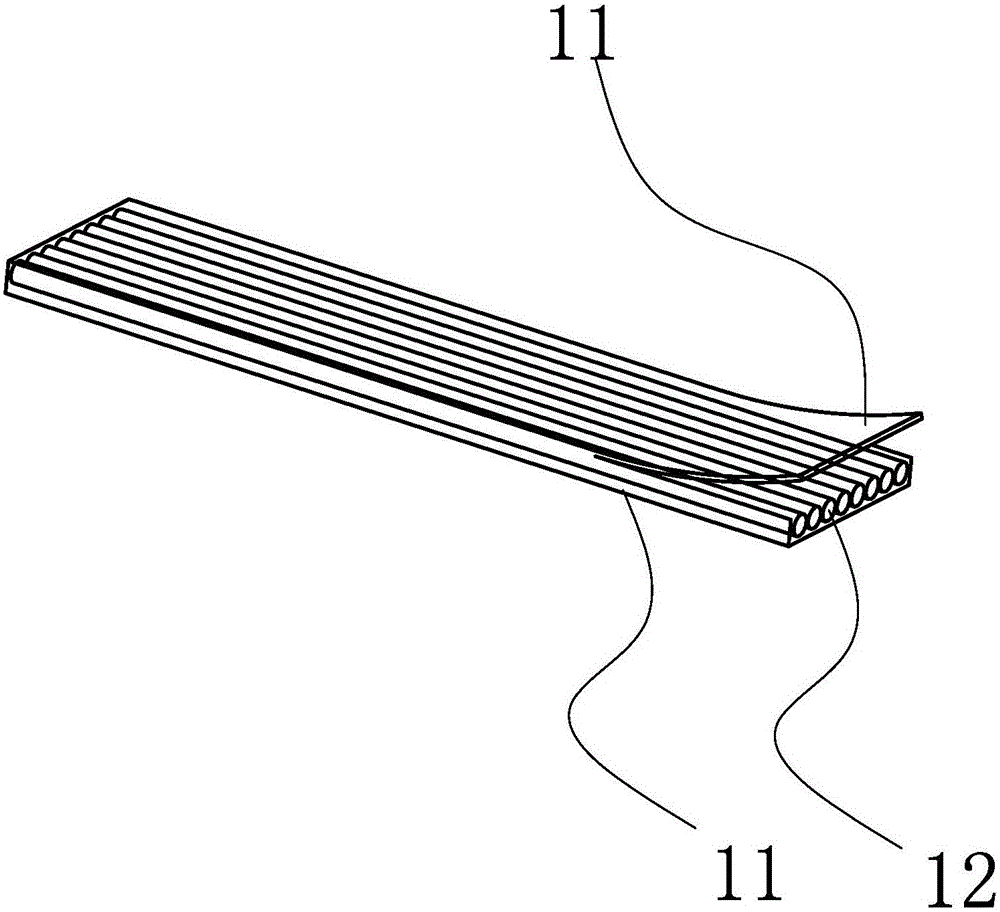

[0034] According to the number of plastic laminated tapes 1 set on the PE plastic film 2, the corresponding plastic laminated tapes 1 of the corresponding number of rolls are selected and placed at the beginning of unwinding for unwinding; similarly, the rewound PE plastic film 2 Correspondingly placed at the beginning of unwinding for unwinding; the plastic lamination belt 1 and PE plastic film 2 are driven to move to the next process in turn by the traction mechanism arranged on the subsequent process, wherein it is best to set the traction mechanism on the hot Between the compounding process (plastic lamination tape 1 and PE plastic film 2 thermal lamination process) and the cooling process; no matter how many plastic lamination tapes are thermally compounded on the PE plastic film 2, each can be processed sequentially during the entire production line. Root carries out complete operation process and then carries out next processing; Also can make a plurality of plastic lami...

Embodiment 2

[0037] According to the number of plastic laminated tapes 1 set on the PE plastic film 2, the corresponding plastic laminated tapes 1 of the corresponding number of rolls are selected and placed at the beginning of unwinding for unwinding; similarly, the rewound PE plastic film 2 Correspondingly placed at the beginning of unwinding for unwinding; drive each plastic lamination belt 1 and PE plastic film 2 to move to each process in turn through the traction mechanism arranged on the subsequent process, wherein it is best to set the traction mechanism Between the thermal lamination process (every plastic lamination belt 1 and PE plastic film 2 thermal lamination process) and the cooling process; , and the width of the plastic film 2 is 6 meters, and the length can be adjusted as required, so that the plastic lamination tape 1 is compounded with five plastic lamination tapes 1 along the width direction of the plastic film 2 with equal insulation, wherein the plastic film 2 width ...

Embodiment 3

[0040] According to the number of plastic laminated tapes 1 set on the PE plastic film 2, the corresponding plastic laminated tapes 1 of the corresponding number of rolls are selected and placed at the beginning of unwinding for unwinding; similarly, the rewound PE plastic film 2 Correspondingly placed at the beginning of unwinding for unwinding; drive each plastic lamination belt 1 and PE plastic film 2 to move to each process in turn through the traction mechanism arranged on the subsequent process, wherein it is best to set the traction mechanism Between the thermal lamination process (every plastic lamination belt 1 and PE plastic film 2 thermal lamination process) and the cooling process; , and the width of the plastic film 2 is 6 meters, and the length can be adjusted according to needs, so that the plastic lamination tape 1 is compounded with 8 plastic lamination tapes 1 along the width direction of the plastic film 2 with equal insulation, wherein the plastic film 2 wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com