Carbon-adding hard alloy material and preparation method thereof

A cemented carbide and mixed material technology, applied in the field of friction pairs for mechanical seals, can solve the problems of poor dry friction performance and high cost, and achieve the effects of enhanced dry friction performance, easy operation and reduced friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

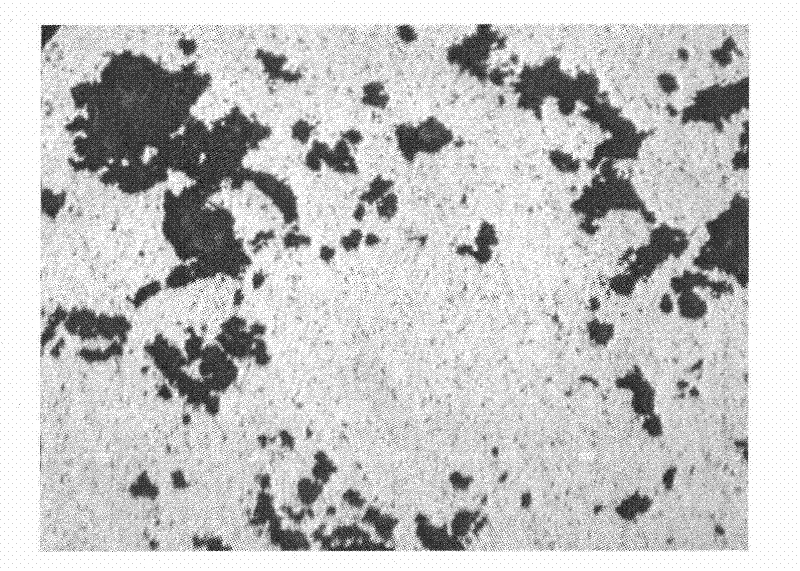

[0044] Weigh the raw materials of the following formula ratio: 90 parts by weight of tungsten carbide (WC), 4.2 parts by weight of nickel (Ni), 0.4 parts by weight of chromium (Cr), 0.4 parts by weight of cobalt (Co), 2 parts by weight of paraffin wax (as plasticizer) Parts, graphite (C) 3 parts by weight.

[0045] Produced according to the following process:

[0046] (1) Mixing: WC, Ni, Cr, Co are mixed evenly by the above weight parts;

[0047] (2) ball milling: in the mixture that step (1) obtains, add the aviation gasoline as grinding medium, every kilogram of mixture adds 0.3 liters of aviation gasoline, then carries out 48 hours of ball milling to the mixture that has added aviation gasoline with ball mill change;

[0048] (3) add paraffin wax as plasticizer by above-mentioned weight component, then ball mill homogenization 6 hours, make each material mix evenly;

[0049] (4) drying: vacuum drying the mixed material after step (3) ball milling and homogenization, so t...

Embodiment 2

[0063] Weigh the raw materials of the following formula ratio: 90 parts by weight of tungsten carbide (WC), 4.2 parts by weight of nickel (Ni), 0.4 parts by weight of chromium (Cr), 0.4 parts by weight of cobalt (Co), and 2 parts by weight of plasticizer (paraffin wax) , 5 parts by weight of graphite (C).

[0064] The preparation process is the same as in Example 1, wherein the density of the molded green body obtained after step (7) compression molding is 7.482g / cm 3 ; Its density of cemented carbide material obtained after step (9) sintering is 12.107g / cm 3 .

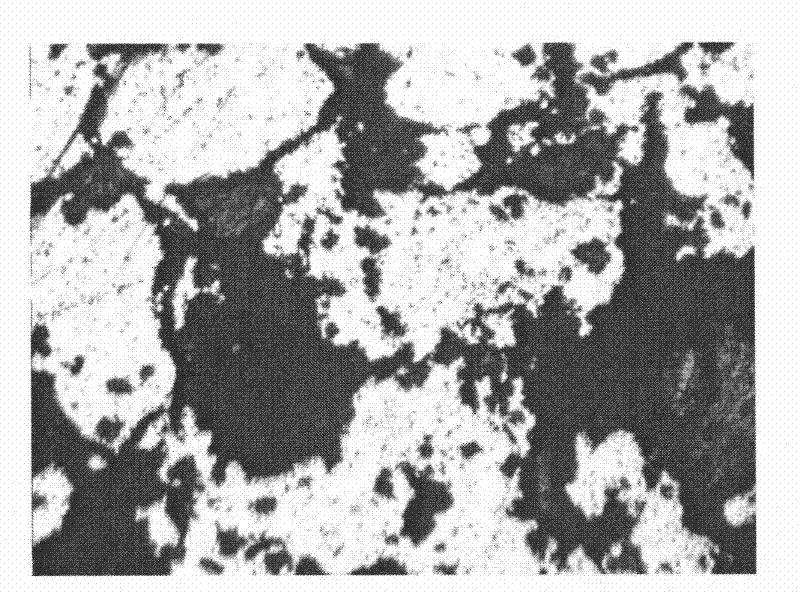

[0065] Compared with Example 1, Example 2, except that the carbon component has been increased, the density decreases, and the carbon particles in the obvious tissue increase significantly in addition (see figure 2 ).

[0066] After being processed into parts, it has passed the 1.6MPa static pressure test without leakage.

Embodiment 3

[0068] Weigh the raw materials of the following formula ratio: 90 parts by weight of tungsten carbide (WC), 4.2 parts by weight of nickel (Ni), 0.4 parts by weight of chromium (Cr), 0.4 parts by weight of cobalt (Co), and 2 parts by weight of plasticizer (paraffin wax) , graphite (C) 2 parts by weight.

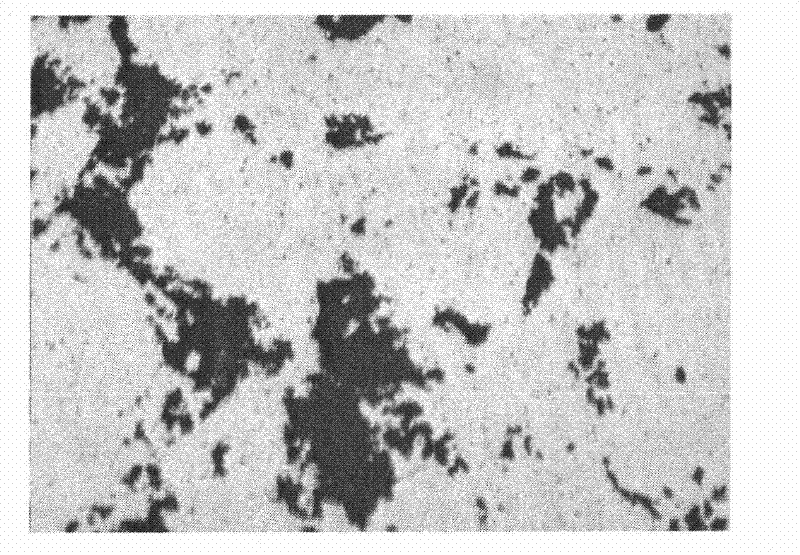

[0069] The preparation process is the same as that in Example 1, wherein the green body density of 7.521g / cm is obtained after step (7) compression molding 3 ; Its density of cemented carbide material obtained after step (9) sintering is 12.752g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com