High-plasticity and easy-to-be-eliminated extrusion molding agent

A molding agent, high plasticity technology, applied in the field of high plasticity, easy to exclude extrusion molding agent, can solve the problems of rough cracking products, low qualification rate, long production cycle of extrusion products, etc., to avoid adverse effects, ash content Low, shortened production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiment of the present invention.

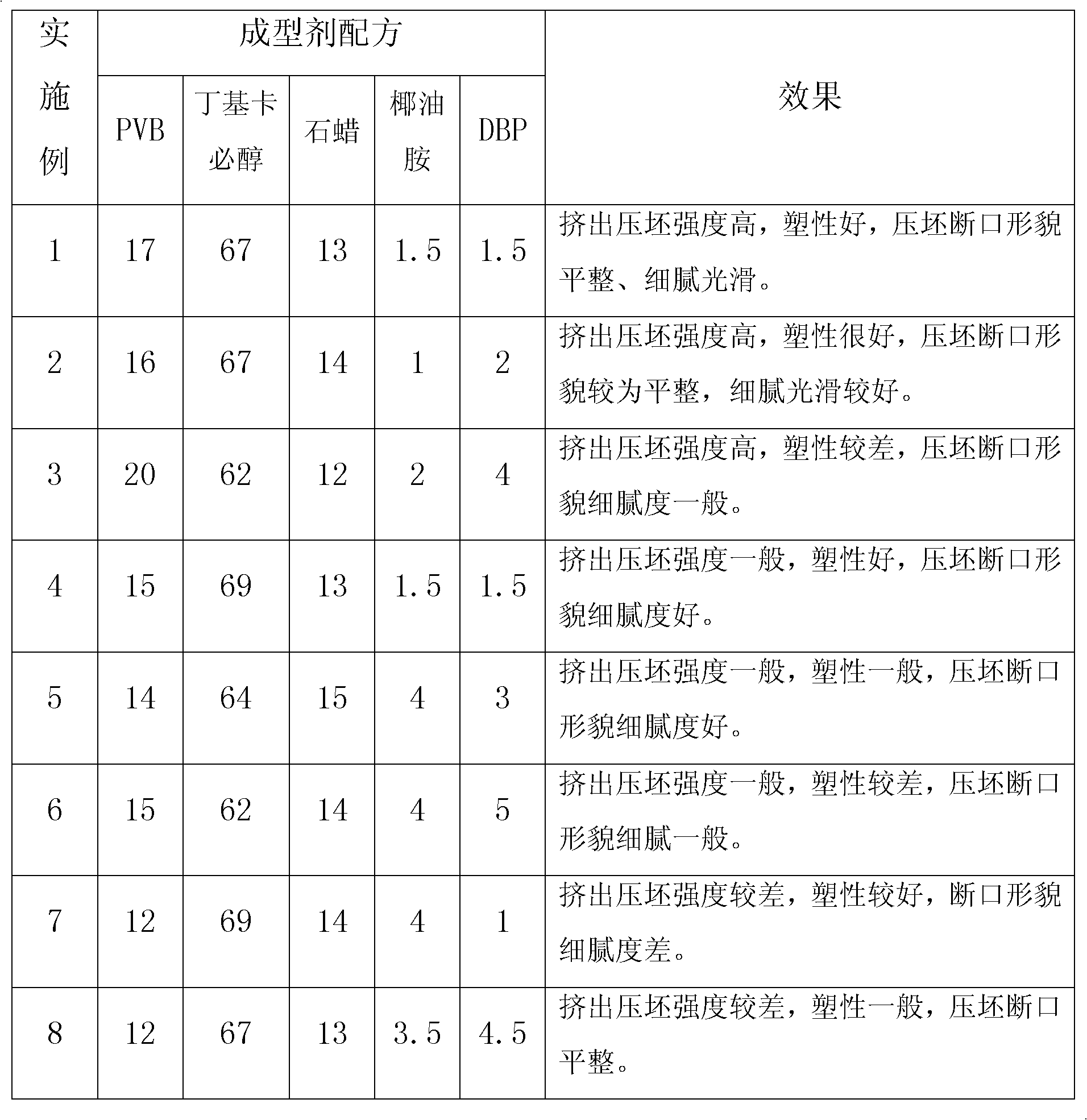

[0019] The molding agents of different proportions of the present invention are listed below, as well as the implementation effect of using the molding agent for cemented carbide extrusion production.

[0020]

[0021] Among them: polyvinyl butyral (PVB) is the bonding component, which acts as a skeleton support, and its content plays a major role in the strength of the compact. Butyl carbitol (diethylene glycol butyl ether) is the solvent, the higher the content, the better the plasticity of the billet. Both cocoic acid and dibutyl phthalate are surfactants, which can effectively promote the wetting of the forming agent on the particle surface and promote the uniform mixing of materials. Paraffin wax can maintain shape and plasticize, but too high content is unfavorable for the removal of forming agent.

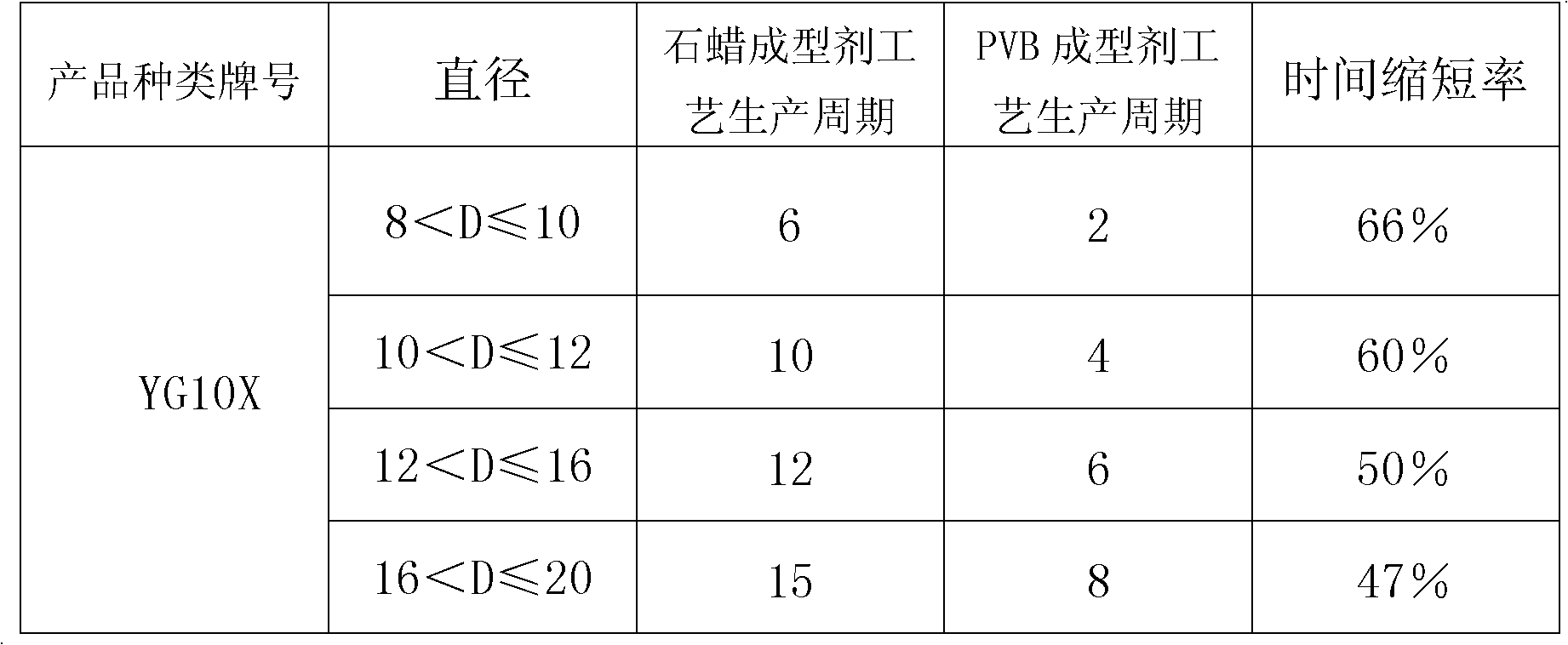

[0022] Compared with the rods extruded by PVB molding agent, the drying time in the shade is shortened by 56% on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com