Repair method for improving pumping rod strength

A repair method and a sucker rod technology, which are applied to drill pipes, earthwork drilling, pumps with flexible working elements, etc., can solve the problems of inability to improve the life cycle of sucker rods, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

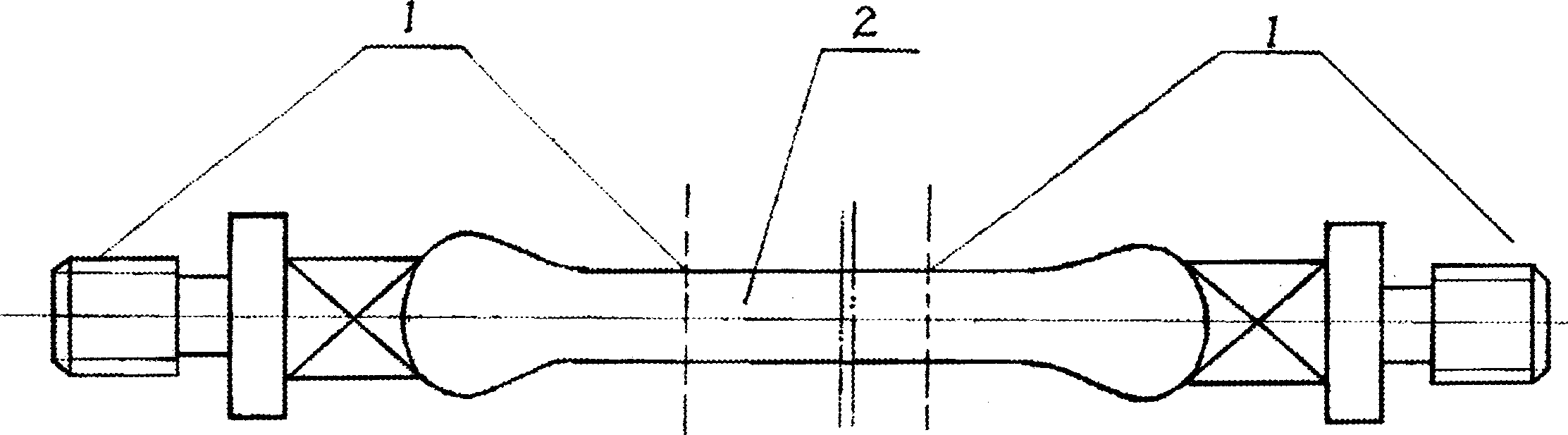

Image

Examples

Embodiment Construction

[0007] The technical characteristics of the present invention will be described in detail below in conjunction with practical embodiments.

[0008] In actual operation and technical implementation, the technological requirement is to first select the decommissioned low-strength sucker rods, that is, to remove the broken, excessively bent or severely corroded sucker rods; The sucker rod is degreased, that is, the oil stain on the surface of the rod body is removed with diesel oil or cleaning agent; the rod head and the rod body are inspected on the sucker rod after oil removal, that is, the rod head is inspected with magnetic particle flaw detection to check whether there is any defect on the rod head, The rod body is inspected by eddy current to check whether there is any fatigue damage on the rod body and whether there is any defect on the surface of the rod body; after the inspection, the sucker rod is repaired with a pin, that is, the screw on the rod head is repaired with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com