Composite floating body material structure

A technology of material structure and floating body, which is applied in the fields of agricultural gas emission reduction, soilless cultivation, water/sludge/sewage treatment, etc. It can solve the problems of easy breakage, low strength and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

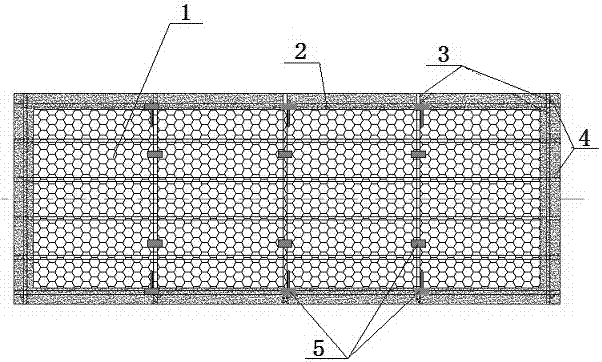

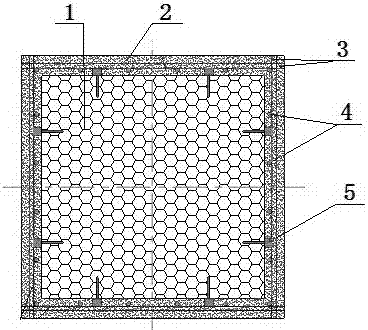

[0010] Referring to the accompanying drawings, a composite floating body material structure includes a polystyrene foam inner core 1, which is characterized in that: a plug-in pad 5 is arranged on the polystyrene foam inner core 1, and a transverse rib 3 is arranged at a position corresponding to the pad 5 The horizontal ribs 3 and the longitudinal ribs 4 are evenly arranged around the polystyrene foam inner core 1, and the transverse ribs 3 and the longitudinal ribs 4 are connected together by binding, and polyurethane foam is arranged on the outer layer of the polystyrene foam inner core 1. The protective layer 2 wraps the transverse ribs 3 and the longitudinal ribs 4 therein to form a composite floating body material structure. The transverse ribs 3, longitudinal ribs 4 and polystyrene foam inner core 1 are separated by a certain distance.

[0011] The manufacture process of the present invention is as follows:

[0012] According to the design size of the floating bed, det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com