Ashless high-performance vacuum pump oil

A high-performance, vacuum oil technology, applied in the field of lubricating oil, can solve the problems of high price and late start, achieve long service life, reduce waste oil discharge, and reduce the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

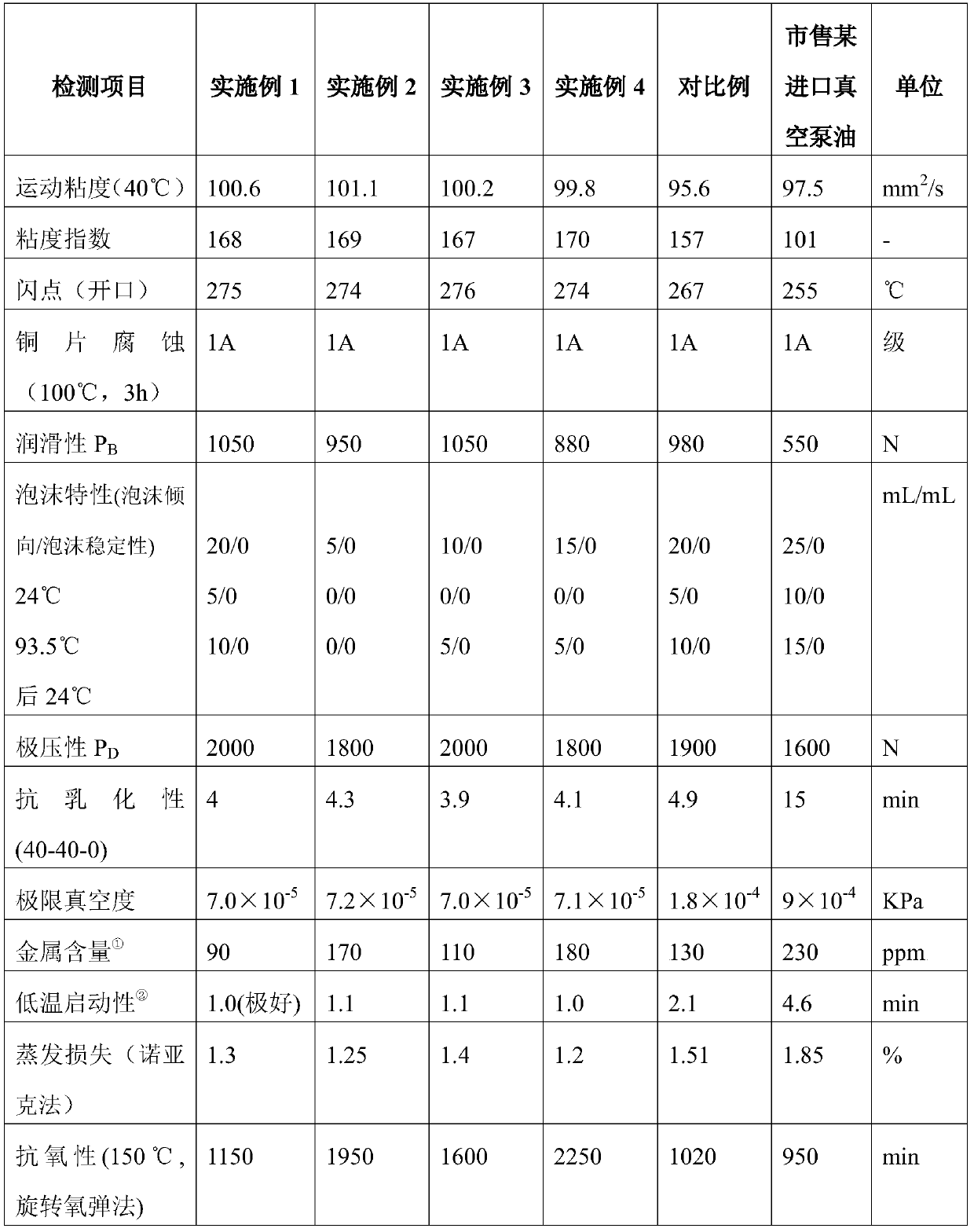

Embodiment 1

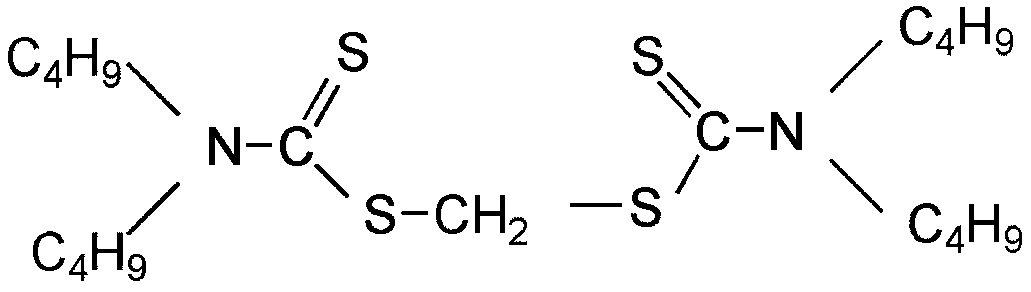

[0027] An ashless high-performance vacuum pump oil, including the following raw materials in weight percentage: dimethylene-dibutylthiocarbamate 2%, N,N-di(2-ethylhexyl)-methyl-1H - Benzotriazole-1-methylamine 0.05%, Triisobutyl Phosphate 0.01%, Sulfurized Alkylphenol 0.4%, Dinonyldiphenylamine amine 0.1%, Tolyltriazolate 0.1%, and base Oil has been replenished to 100%.

Embodiment 2

[0029] An ashless high-performance vacuum pump oil, including the following raw materials in weight percentage: 0.8% of dialkyl dithiophosphate, 0.3% of 2,5-dimercapto-1,3,4 thiadiazole derivatives, phosphoric acid 0.5% triisobutyl ester, 0.8% sulfurized alkylphenol, 0.3% octyl / butyl benzidine, 0.3% methyl benzotriazole ester, and supplemented with base oil to 100%.

Embodiment 3

[0031] An ashless high-performance vacuum pump oil, including the following raw materials in weight percentage: 1.2% of isopropylphenyl phosphate, 0.1% of 2,5-dimercapto-1,3,4 thiadiazole derivatives, triphosphate 0.3% isobutyl ester, 0.5% thioether phenol, 0.2% octyl / butyl benzidine, 0.2% methyl benzotriazole ester, and supplemented with base oil to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com