Multi-stage hot-pressing type vacuum pumping system

A vacuum system, hot press technology, applied in lighting and heating equipment, steam/steam condenser, etc., can solve the problems of water vapor heat, poor recovery and utilization rate, high noise, and reduced suction capacity in low-pressure areas , to achieve a good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

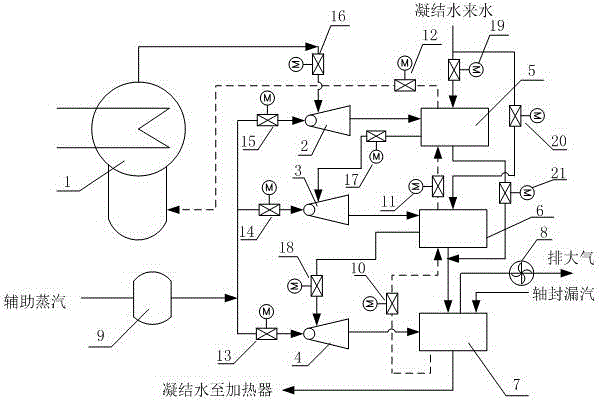

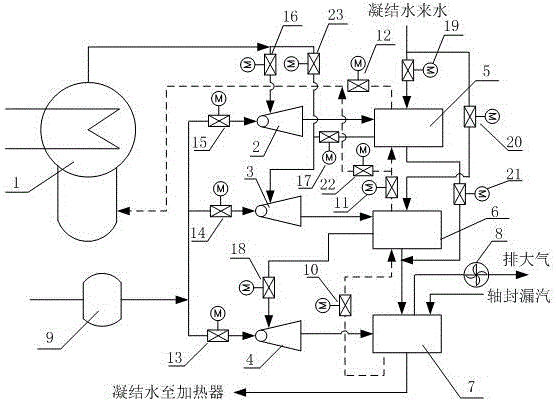

[0048] The invention provides a multi-stage hot-pressing vacuum system, which includes a power steam surge tank, a multi-stage hot press, a steam condensing device matched with the hot press, and valves and pipe fittings connected to related devices. This system uses auxiliary steam as the power source, does not consume power, and is easy to maintain. In addition, the cooling water of the condensing device is condensed water from a large machine, and the drainage is self-flowed to the condenser hot well step by step, so that the waste heat of steam and drainage can be recovered. Utilization improves the energy-saving effect; in addition, the final condenser of this set of devices is replaced by a shaft-sealed heater, which saves the equipment footprint and facilitates the transformation of the power plant.

[0049] The multi-stage hot-press vacuum system provided by the present invention includes a power steam surge tank (9), a multi-stage hot press (2, 3, 4), and a steam conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com