Double-station type high-frequency vacuum dryer and implementation method thereof

A vacuum dryer and double-station technology, applied in the direction of local agitation dryers, static material dryers, dryers, etc., can solve the problems of poor use effect, low production efficiency, poor drying effect, etc., and achieve circulation system Perfect, wide application range, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

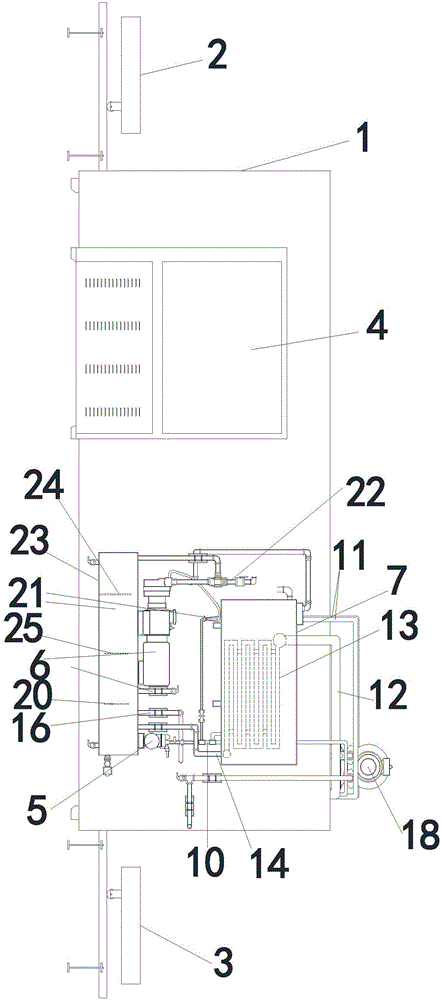

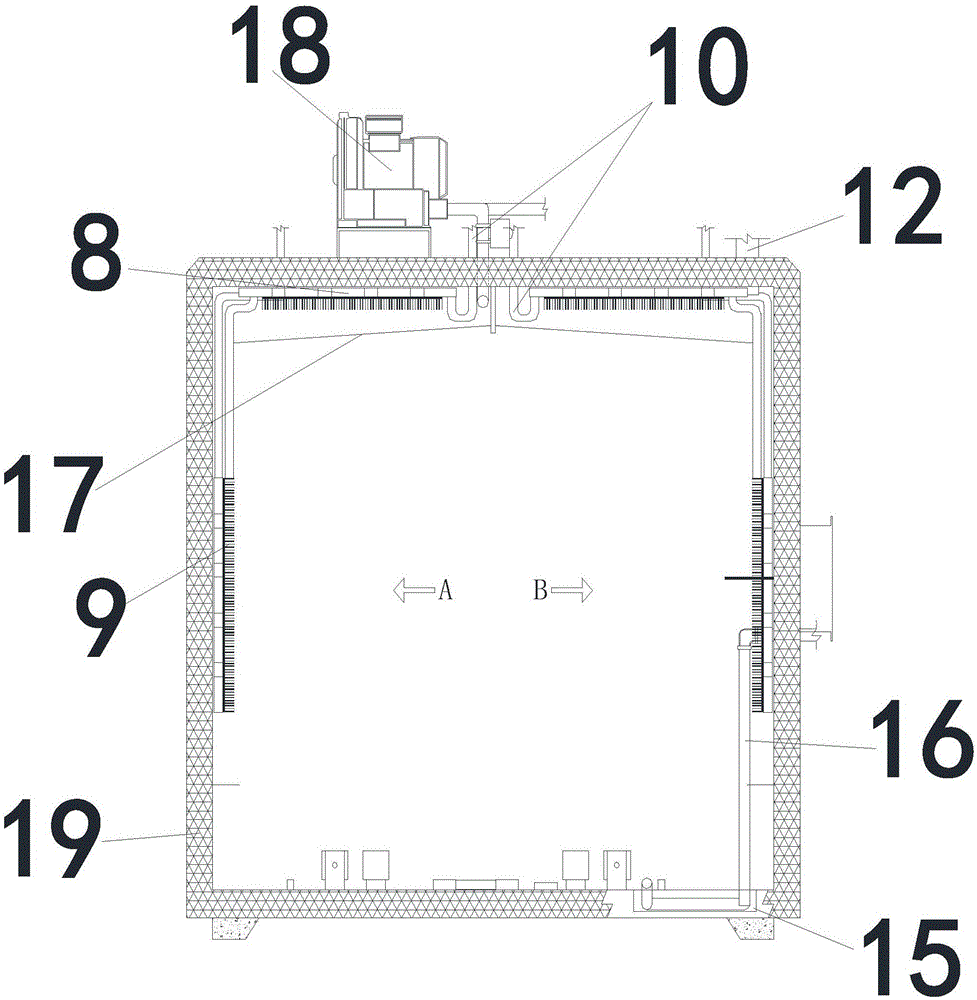

[0049] Such as Figure 1~2As shown, a double-station type high-frequency vacuum dryer includes a box body. The box body adopts a front door and a rear door. There is a high-frequency machine on the side, and a water collection tank system is installed on the side of the high-frequency machine. A water circulation pump is installed on the water collection tank system. The water circulation pump is connected to the cooling end of the vacuum pump through a pipeline, and the vacuum pump is connected to the top of the upper water tank through a pipeline; the water circulation pump is connected to the top of the water tank through a pipeline. It is connected to the first condensation sheet on the top of the box and the second condensation sheet on the side. The pipes of the first condensation sheet and the second condensation sheet in the box are connected in parallel. There is a condensation outlet pipe on the top of the box, and the condensation outlet pipe is connected to The top...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is: the water collection tank in this embodiment is connected to the cooling pump; the second horizontal pipe is in the shape of an "S", and the purpose of the design is to improve the use effect. It has been proved by experiments that the qualified rate is increased by 12%. Above; the present embodiment also includes a controller, the controller is respectively connected with the high-frequency machine, the water circulation pump, the water collection tank system and the gas circulation system, and the controller is also connected with the Internet of Things, and the step (4) vacuum pump starts to work, so that the box The negative pressure in the body is 0.03MPa; after the test in step (6) is normal, let go of the vacuum, and adjust the high-frequency machine to 46 degrees Celsius; in step (7), the temperature rises slowly, not exceeding 3 degrees Celsius per hour, until it rises to 46 degrees Celsius ; In step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com