Three-cavity sliding vane vacuum pump cylinder and type line design method thereof

A technology of vacuum pumps and sliding vanes, which is applied in the direction of pumps, calculations, pump components, etc., can solve the problems of low compression efficiency, small internal volume ratio, large exhaust volume, etc., and achieve rich cylinder shape types and maximum ultimate vacuum degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

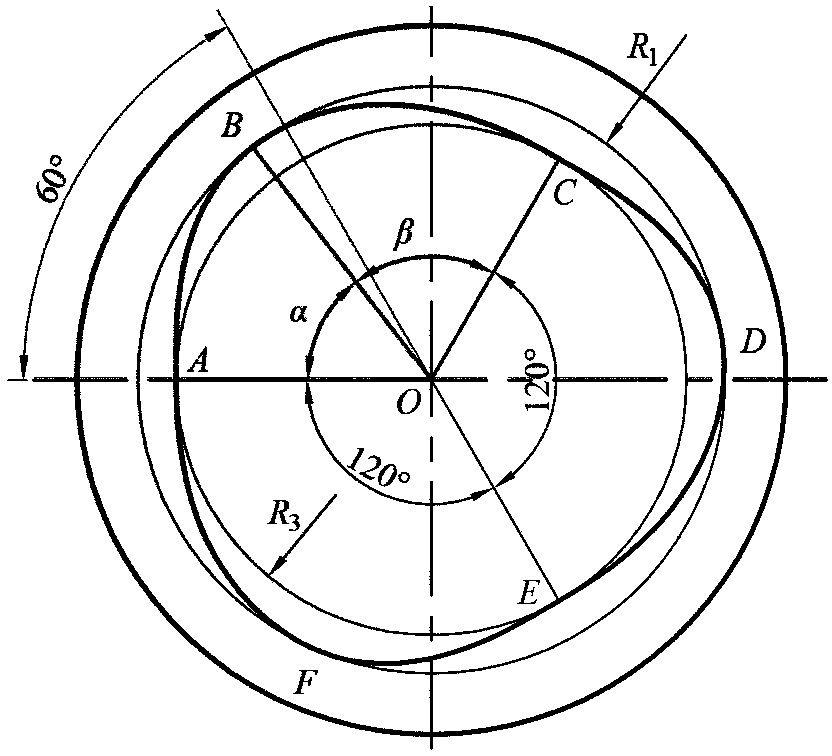

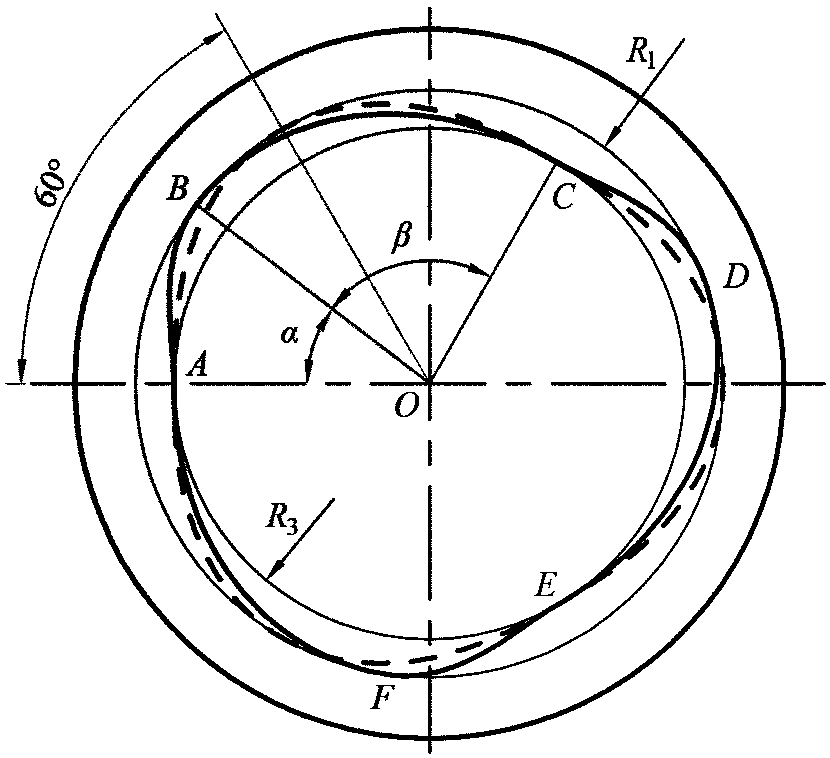

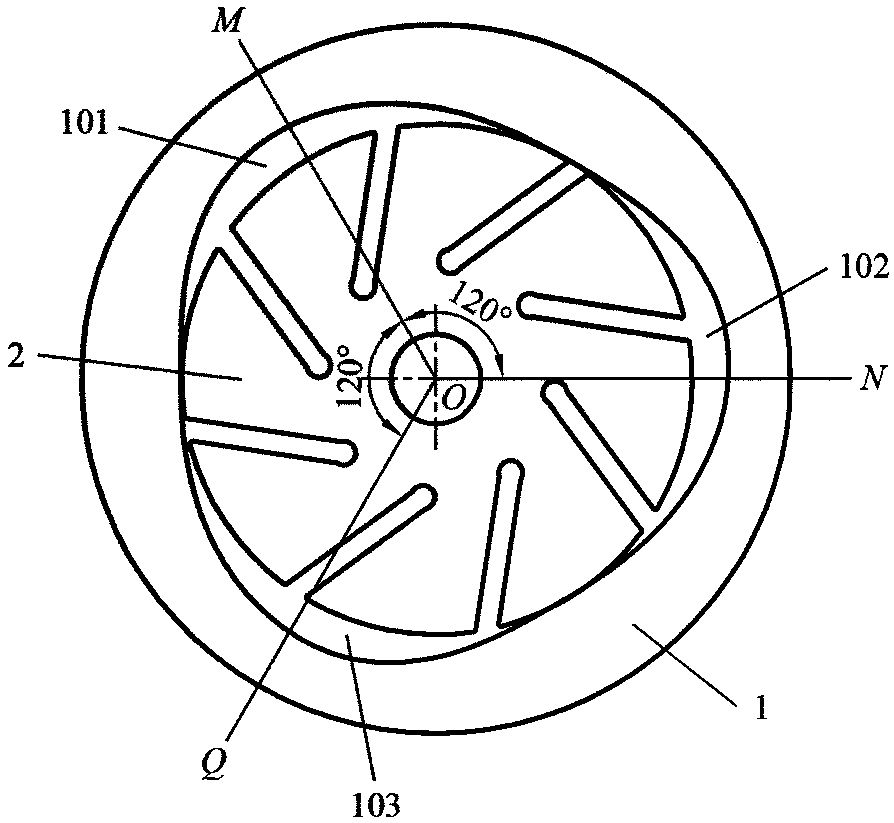

[0037] like figure 1 As shown, the profile lines in the cylinder (1) are distributed in the clockwise direction as follows: the first suction section curve AB, the first discharge section curve BC, the second suction section curve CD, the second discharge section curve DE, the third The suction section curve EF and the third discharge section curve FA are completely smooth connections between the composition curves and the second derivative is continuous; point A, point C and point E are the lowest points that the slide can reach, located at the origin O as the center of the circle, the radius is the bottom circle radius R 3 On the circle; Points B, D and F are the highest points that the slider can reach, located at the origin O as the center of the circle, and the radius is the top circle radius R 1 On the circle; the size of the central angle ∠AOB corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com