Double-screw rotor set and vacuum pump

A rotor group and twin-screw technology, applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve the problems of weakening the working efficiency of vacuum pumps, affecting the life of screw rotors, and large wear of screw rotors , to achieve the effect of satisfying dynamic balance, prolonging life and improving shaft efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

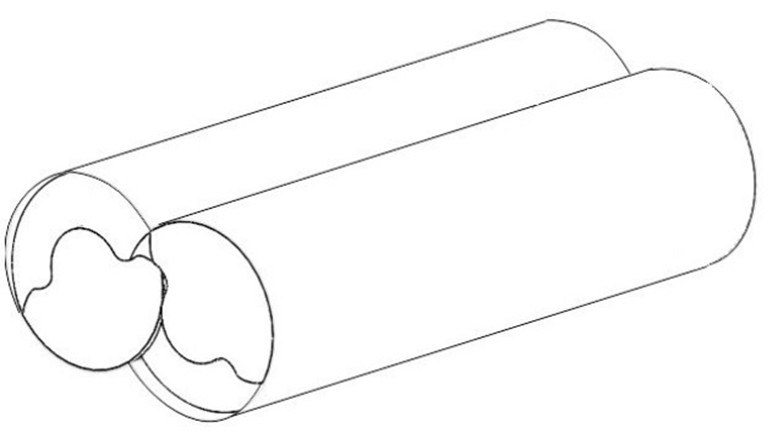

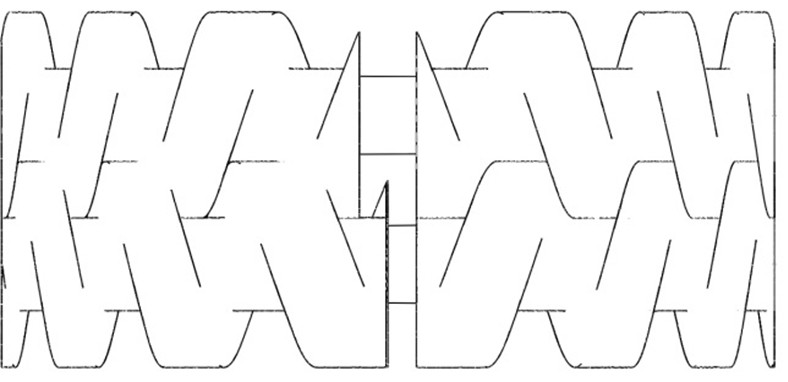

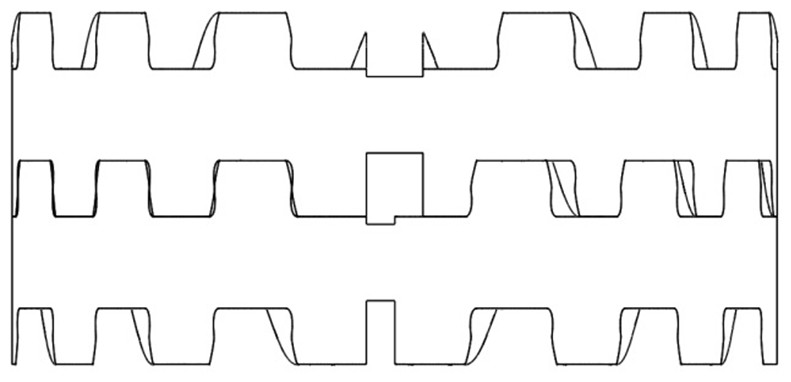

[0022] This embodiment discloses a twin-screw rotor group, including a male rotor and a female rotor. The number of teeth of the male and female rotors is 1, and the tooth shape is trapezoidal. The male rotor and the female rotor mesh with each other. The two-stage screw rotor composed of symmetrically connected variable-pitch screws, the initial pitch of one of the variable-pitch screws in the male rotor ps=70mm , the end pitch of the variable pitch screw pe=30mm, Rotor length L=200mm, Rotor Angle t=20rad, Axial position of variable pitch screw in male rotor z1=-(1000*(p1i- ((7t 2 ) / 100+ p1i 2 ) 0.5 )) / t ,in p1i is the axial position of the variable pitch screw in the male rotor z1 The pitch of the variable-pitch screw at the position; through the symmetrical characteristics of the two-stage screw rotor, the relationship between the pitch of the male rotor and its axial position can be obtained, and the relationship between the pitch of the female rotor and its...

Embodiment 2

[0024] This embodiment discloses a vacuum pump, which includes a "∞"-shaped cylinder intersecting two circles, a motor and a gear transmission system. A male rotor and a female rotor are arranged in the cylinder. The number of teeth of the male and female rotors is 1, and the tooth shape is trapezoidal. , the male rotor and the female rotor are meshed with each other. The male and female rotors are two-stage screw rotors composed of two variable-pitch screws symmetrically connected in opposite directions. The initial pitch of one of the variable-pitch screws in the male rotor is ps=70mm , the end pitch of the variable pitch screw pe=30mm, Rotor length L =200mm, Rotor Angle t=20rad, Axial position of variable pitch screw in male rotor z1=-(1000*(p1i- ((7t 2 ) / 100 +p1i 2 ) 0.5 )) / t ,in p1i is the axial position of the variable pitch screw in the male rotor z1 The pitch of the variable-pitch screw at the position; through the symmetrical characteristics of the ...

Embodiment 3

[0027] This embodiment discloses a vacuum pump, which includes a "∞"-shaped cylinder intersecting two circles, a motor and a gear transmission system. A male rotor and a female rotor are arranged in the cylinder. Both the male and female rotors have two teeth, and the tooth shape is trapezoidal. , the male rotor and the female rotor are meshed with each other. The male and female rotors are two-stage screw rotors composed of two variable-pitch screws symmetrically connected in opposite directions. The initial pitch of one of the variable-pitch screws in the male rotor is ps=70mm , the end pitch of the variable pitch screw pe=30mm, Rotor length L =200mm, Rotor Angle t=20rad, Axial position of variable pitch screw in male rotor z1=-(1000*(p1i- ((7t 2 ) / 100 +p1i 2 ) 0.5 )) / t ,in p1i is the axial position of the variable pitch screw in the male rotor z1 The pitch of the variable-pitch screw at the position; through the symmetrical characteristics of the two-stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com