Novel vacuum pump and novel multi-stage vacuum pump

A vacuum pump, a new type of technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of increased equipment investment and operating costs, high working noise, low vacuum degree, etc., to achieve low noise, low power consumption, The effect of high ultimate vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

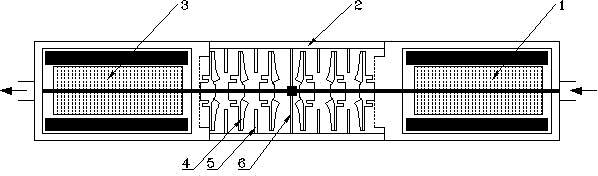

[0013] Such as figure 1 As shown, a novel vacuum pump of the present invention includes a straight cylindrical pump body 2, two ends of the pump body are provided with connecting flanges, and the connecting flanges are fastened by screws. The two ends of the pump body 2 are respectively provided with an air inlet and an air outlet. A forward-rotating high-speed motor 1 and a reverse-rotating high-speed motor 3 are respectively installed at both ends of the pump body 2. The high-speed motor is fixed in the pump body through a bracket. The rotating shafts of the two high-speed motors are opposite to each other, and the rotating directions are opposite. Three impellers 4 are respectively installed on the rotating shafts of the two high-speed motors. The number of the impellers can be adjusted according to the different needs of the pressure. Guide vanes 5 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com